Analytical Solutions for the Construction of Deeply Buried

advertisement

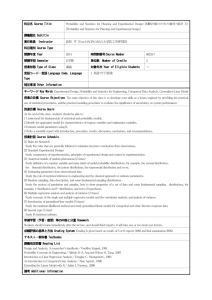

Rock Mech Rock Eng (2013) 46:1481–1498 DOI 10.1007/s00603-012-0362-7 ORIGINAL PAPER Analytical Solutions for the Construction of Deeply Buried Circular Tunnels with Two Liners in Rheological Rock H. N. Wang • Y. Li • Q. Ni • S. Utili M. J. Jiang • F. Liu • Received: 19 October 2012 / Accepted: 27 December 2012 / Published online: 21 February 2013 Springer-Verlag Wien 2013 Abstract The construction of underground tunnels is a time-dependent process. The states of stress and strain in the ground vary with time due to the construction process. Stress and strain variations are heavily dependent on the rheological behavior of the hosting rock mass. In this paper, analytical closed-form solutions are developed for the excavation of a circular tunnel supported by the construction of two elastic liners in a viscoelastic surrounding rock under a hydrostatic stress field. In the solutions, the stiffness and installation times of the liners are accounted for. To simulate realistically the process of tunnel excavation, a time-dependent excavation process is considered in the development of the solutions, assuming that the radius of the tunnel grows from zero until its final value according to a time-dependent function to be specified by the designers. The integral equations for the supporting pressures between rock and first liner are derived according to the boundary conditions for linear viscoelastic rocks (unified model). Then, explicit analytical expressions are obtained by considering either the Maxwell or the Boltzmann viscoelastic model for the rheology of the rock mass. Applications of the obtained solutions are illustrated using two examples, where the response in terms of H. N. Wang (&) Y. Li School of Aerospace Engineering and Applied Mechanics, Tongji University, Shanghai 200092, People’s Republic of China e-mail: wanghn@tongji.edu.cn Q. Ni S. Utili School of Engineering, University of Warwick, Coventry CV4 7AL, UK M. J. Jiang F. Liu Department of Geotechnical Engineering, College of Civil Engineering, Tongji University, Shanghai 200092, People’s Republic of China displacements and stresses caused by various combinations of excavation rate, first and second liner installation times, and the rheological properties of the rock is illustrated. Keywords Tunnels Rheological rock Liner Analytical research List of Symbols A, B a D1, D2 … D12 EL1 (EL2 ) Ei ðGi Þ fB1 ðfB2 Þ fM1 ðfM2 Þ GB1 GB GL1 ðGL2 Þ GM GK G H Laplace transform functions of s Function of the excavation process Constant coefficients Young’s modulus of the first (second) liner The ith Young’s (shear) modulus in the general viscoelastic model Free term of integral equation Free term of integral equation Shear elastic modulus of the Hookean element in the Boltzmann model Shear elastic modulus of the Kelvin element in the Boltzmann model Shear elastic modulus of the first (second) liner Shear elastic modulus of the Hookean element in the Maxwell model Shear elastic modulus of the Kelvin element in the Burgers model Relaxation shear modulus in the rock viscoelastic model Function defined in Eq. (13) 123 1482 H. N. Wang et al. I kM ðkM Þ kB ðkB Þ kMi (i ¼ 1; 2; . . .; n) KL1 ðKL2 Þ KðtÞ pðtÞ p0 p1 ðp2 Þ q q1 R R0 R1 R2 (R3 ) r; h; z s sij ðeij Þ t t0 t1 (t2 ) u0r u1r u2r 8 < u0r ur ¼ u1r : 2 ur urL1 ðurL2 Þ 0 t\t1 t1 t\t2 t t2 v WM and WB Greek Symbols mL1 ðmL2 Þ dij dðtÞ Du1 ¼ u0r u1r 123 Function defined in Eq. (13) Kernel of the integral equation Kernel of the integral equation Iterated kernel Bulk elastic modulus of the first (second) liner Relaxation bulk modulus in the rock viscoelastic model Supporting pressure between first liner and surrounding rock Compressive stress at infinity Supporting pressure pðtÞ during the first (second) liner stage Supporting pressure between first and second liner Supporting pressure qðtÞ during the second liner stage Tunnel radius Initial radius of tunnel Final radius of tunnel Inner radius of the first (second) liner Cylindrical coordinates Variable in the Laplace transform Deviator tensor of stress (strain) tensors Time End time of excavation Installation time of the first (second) liner Radial displacement in the absence of liners (any t) Radial displacement in the presence of the first liner (t [ t1) Radial displacement in the presence of the second liner (t [ t2) Radial displacement of the rock Radial displacement of the first (second) liner Excavation rate Kernel function of Eq. (35) and Eq. (69) Poisson’s ratio of the first (second) liner Unit tensor Delta function Reduction of radial displacement in the rock due Du2 ¼ u1r u2r Du1þ ¼ ur ðr; tÞ ur ðr; t1 Þ Du2þ ¼ ur ðr; tÞ ur ðr; t2 Þ Du1tot ¼ ur ðr; t2 Þ ur ðr; t1 Þ Du2tot ¼ ur ðr; 1Þ ur ðr; t2 Þ k1 to k4 gM gB gi rr ðrh Þ rz rrL1 ðrrL2 Þ rhL1 ðrhL2 Þ rij ðeij Þ rmm ðemm Þ to the presence of the first liner (t [ t1) Reduction of radial displacement in the rock due to the presence of the second liner (t [ t2) Incremental radial displacement occurring since the installation of the first liner (t [ t1) Incremental radial displacement occurring since the installation of the second liner (t [ t2) Total additional displacement occurring between the installation of the two liners Total additional displacement occurring after the installation of the second liner Constant coefficients Viscosity coefficient of the dashpot element in the Maxwell model Viscosity coefficient of the dashpot element in the Boltzmann model The ith viscosity coefficient in the general viscoelastic model Radial (hoop) stress in the rock z-Direction stress in the rock Radial stress of the first (second) liner Hoop stress of the first (second) liner Stress (strain) tensor Mean stress (strain) 1 Introduction Most types of rocks exhibit time-dependent behavior. During the excavation of a tunnel, the surrounding rock deforms gradually due to the natural rock rheology. After the excavation is complete, supports typically in the form of concrete or shotcrete liners are put in place to seal the rock and to reduce radial deformations. Displacements of the surrounding rock and pressure between liner and rock are critical parameters to be determined for tunnel design. Therefore, proper simulation of the sequence of actions involved in tunneling, including the whole process of Analytical Solutions for the Construction of Deeply Buried Circular Tunnels excavation and support construction, is of great importance to obtain a reliable tool for the determination of optimal values of tunneling parameters to achieve optimal design. This problem can be tackled either numerically or analytically. Numerical methods are widely used in many complex underground projects (Chehade and Shahrour 2008; Prazeres et al. 2012). Although numerical methods such as finite element, finite difference, discrete element, and boundary element can provide useful answers, the insight into the nature of the problem that can be gained from analytical solutions is an important aspect that cannot be overlooked (Carranza-Tores and Fairhurst 1999). In fact, analytical solutions in closed form can be used to obtain a first estimation of the design parameters, providing guidance in the conceptual stage of the design process. They make it possible to run parametric analyses for a wide range of values of the problem parameters so that a better understanding of the physics of the problem can be gained by investigating the sensitivity of the solution to the input parameters. In addition, closed-form solutions provide a benchmark against which the overall correctness of numerical analyses can be assessed. Tunnel excavation is a long-term process which takes place over a significant time, during which the tunnel face advances at variable speed. If a cross-section of the tunnel is considered, its radius grows over time according to the excavation process employed. However, in the closed-form analytical solutions presented in the literature to date, the excavation process is assumed to be instantaneous. In this paper, instead, the excavation time is accounted for so that the influence of the excavation process on the final tunnel convergence and pressure acting on the liners can be investigated by a parametric analysis. This allows optimization of the excavation time, which thus becomes a design parameter. Analytical solutions for stresses within a wedge-shaped body subject to gravity were presented by Rashba (1953), who carried out the earliest analytical studies on problems with time-dependent geometry. The first analytical research in civil engineering considering construction processes considered stress analysis of filled culverts (Brown et al. 1968; Christiaon and Chuntranuluk 1974). Analytical solutions for some problems with changing geometry were also provided by Namov (1994). More recently, research has been carried out to seek analytical solutions for viscoelastic problems involving time-dependent boundary regions using the principle of correspondence (Cao 2000; Wang and Nie 2010; Wang and Cao 2006). In tunnel construction, unlike the aforementioned research, the domain of the problem decreases during the excavation stage, and increases subsequently during the construction of the liners. Furthermore, the surrounding ground material is rheological; i.e., its mechanical properties are time dependent. These factors add to the complexity of the problem, making it difficult to achieve analytical solutions in closed form. 1483 Unlike the case of linear elastic materials with constitutive equations in the form of algebraic equations, linear viscoelastic materials have their constitutive relations expressed by a set of operator equations. In general, it is very difficult to obtain analytical solutions for most viscoelastic problems, especially in case of time-dependent boundaries, although some closed-form or theoretical solutions have been developed for excavations in rheological rock (Gnirk and Johnson 1964; Ladanyi and Gill 1984; Brady and Brown 1985). However, in all these works, excavation is assumed to take place instantaneously. Concerning the geomaterial–liner interaction, several studies (Savin 1961; Peck et al. 1972; Einstein and Schwartz 1979) have been carried out for excavations in elastic or viscoelastic rock. Sulem et al. (1987) presented an analytical solution to determine the radial displacements and the pressure applied on tunnel linings having assumed a Kelvin–Voigt model to describe the time-dependent behavior of the surrounding rock. Using the complex variable method and assuming the rock to be elastic, Wang and Li (2009) achieved analytical solutions for the fields of stress and displacement around a lined circular tunnel, accounting for both misfit and the interaction between liner and the surrounding geomaterial. In previous research (Sulem et al. 1987; Ahmad et al. 2010), the effect of the progressive advancement of the tunnel face along the longitudinal direction was accounted for. Assuming an isotropic stress state and a viscoelastic Burgers model for the rock, Nomikos et al. (2011) derived analytical solutions in closed form and performed a parametric study on the effect of the liner parameters. Different supports such as sprayed liners, twoliner systems, and anchor-grouting support were analyzed by Mason and Stacey (2008) and Mason and Abelman (2009). Liners were assumed to be instantaneously applied at the end of the excavation. In tunnel practice, however, liners may be installed at any time after excavation, which is the case considered in this paper. In summary, in the current literature on the construction of lined tunnels in viscoelastic rock, the process of excavation is ignored and only the longitudinal advancement of the tunnel face is considered by introducing a fictitious lining pressure so that the problem can be mathematically cast as a fixed boundary problem. Many problems of linear viscoelasticity can be solved using the principle of correspondence (Lee 1955; Christensen 1982; Gurtin and Sternberg 1962). However, the cross-section of a tunnel is excavated in stages, which implies a time-dependent geometrical domain, so the principle of correspondence cannot be employed. In this paper, an axisymmetric tunnel excavated in rheological rock supported first by a primary liner, then by a secondary one is analyzed. The rheological properties of the rock mass are accounted for within a unified viscoelastic model. Also a time-dependent excavation process is 123 1484 H. N. Wang et al. considered in the development of the solutions, assuming that the radius of the tunnel grows from zero until its final value according to a time-dependent function to be specified by designers. Although the obtained analytical solutions are rigorously applicable only to the axisymmetric case, i.e., a single deeply buried tunnel, Schuerch and Anagnostou (2012) demonstrated that solutions achieved for axisymmetric conditions are still valid for a wide range of different ground conditions and for several cases of noncircular tunnels with small error. In case of twin tunnels, the solution is applicable only if the distance between the tunnels is such that the influence of the presence of one tunnel on the stress state of the rock around the other is negligible. In this paper, first the proposed analytical solutions are derived, then two examples are considered to illustrate the influence of the excavation process and the installation times of the liners on the obtained time-dependent stresses and displacements. 2 Definition of the Problem Excavation of an axisymmetric circular tunnel in a rheological rock mass is considered. The following assumptions are made: 1. 2. 3. The rock mass is homogeneous, isotropic, and linearly viscoelastic. The tunnel is first excavated and then supported by the construction of two liners at different times. First the radius of the tunnel grows from zero to R1, at the end of the excavation; secondly support is provided by a temporary concrete liner; third, after some time, a second, permanent liner is installed. The problem is cast as a two-dimensional (2D) infinite viscoelastic plane subject to a hydrostatic uniform stress with a circular opening whose radius varies with time. The rate of excavation is small, so that it can be assumed that it does not induce any dynamic stress. In the analysis, the effect of the advancement of the tunnel along the longitudinal direction is not accounted for. This means that the cross-section considered in this analysis is at a sufficient distance from the tunnel face that stresses and strains are unaffected by three-dimensional effects. The tunneling process can be divided into three stages. During the first stage (excavation stage) spanning from time t ¼ 0 to t ¼ t1 , with t1 being the installation time of the first liner, the radius of the tunnel varies as follows: R0 þ aðtÞ 0 t t0 RðtÞ ¼ ð1Þ R1 t [ t0 with RðtÞ being the time-dependent radius of the tunnel, R1 the final tunnel radius at the end of the excavation process, R0 the initial radius ð0 R0 R1 Þ, and a ¼ aðtÞ being a 123 function accounting for the actual excavation process as prescribed by the designers. t0 is the end time of the excavation. From t0 to t1, the rock is free to expand since no liners are present. In this stage, no supporting pressure is present. In order to release part of the pressure, the first liner is often put in place after some time elapses from the end of excavation. Hence, in this derivation, the first liner is built at time t ¼ t1 , with p1 ðtÞ being the contact pressure between rock and the first liner. The second stage (first liner stage) spans from the installation of the first liner at t ¼ t1 to the installation of the second liner at t ¼ t2 . The third stage (second liner stage) spans from the installation of the second liner, at time t ¼ t2 , onwards. For t [ t2 , the contact pressure between rock and the first liner is p2 ðtÞ with q1 ðtÞ being the pressure between the first and the second liner. 3 Mechanical Analysis During the Construction Process 3.1 Analysis of the Rock Mass Cylindrical coordinates (r, h, z) are employed in the derivation of the analytical solution. As shown in Fig. 1, p0 is the hydrostatic in situ stress. The boundary condition for the rock mass is rr ðRðtÞ; tÞ ¼ pðtÞ; rr ð1; tÞ ¼ p0 ðtÞ; ð2Þ 8 0 t\t1 < 0 where pðtÞ ¼ p1 ðtÞ t1 t\t2 is an undetermined : p2 ðtÞ t t2 function. In rock mechanics, Hookean elastic springs and Newtonian viscous dashpots are used to model a variety of rheological characteristics of the rock mass. Figure 2 provides a one-dimensional (1D) illustration of the general Kelvin and Maxwell viscoelastic models with parameters Ei and gi , to be experimentally determined (Flügge 1975). To simulate more complex rock rheologies, additional elastic springs or dashpots can be connected in parallel or in series in the general Kelvin and Maxwell models. The constitutive equations of a general viscoelastic model can be expressed in the form of convolution integrals as sij ðr; tÞ ¼ 2GðtÞ deij ðr; tÞ; ð3aÞ rmm ðr; tÞ ¼ 3KðtÞ demm ðr; tÞ ð3bÞ with sij and eij the deviator tensors of the stress and strain tensors, rij and eij , respectively. By definition, 1 sij ¼ rij dij rmm ; 3 1 eij ¼ eij dij emm : 3 ð4aÞ ð4bÞ Analytical Solutions for the Construction of Deeply Buried Circular Tunnels 1485 Fig. 1 Boundary conditions for rock and liners r R (t ) p0 (t ) θ q(t) R1 R2 p1 (t ) p(t) p0 (t ) first liner ( t > t1 ) rock R3 R2 q(t) second liner (t > t 2 ) Fig. 2 General viscoelastic physical models E1 En η1 ηn f1 ðtÞ df2 ðtÞ ¼ f1 ðtÞ f2 ð0Þ þ η1 ηn (b) General Maxwell viscoelastic physical model model df2 ðsÞ ds: f1 ðt sÞ ds ð5Þ For the case of axisymmetric deformations under planestrain conditions, the general solution for the radial displacement and the three stress components of a rock mass in the Laplace space can be written as (Wang and Nie 2010) AðsÞ þ rBðsÞ; r ð6Þ and 1 1 rr ¼ 2GðtÞ s 2 AðsÞ þ BðsÞ þ 2KðtÞ sBðsÞ; r 3 1 1 rh ¼ 2GðtÞ s 2 AðsÞ þ BðsÞ þ 2KðtÞ sBðsÞ; r 3 2 rz ¼ 2 KðtÞ GðtÞ sBðsÞ: 3 f ðsÞ ¼ Z1 est f ðtÞdt; 0 the inverse transform of which is 1 L ½f ðsÞ ¼ f ðtÞ ¼ 2pi 1 0 ur ¼ En (a) General Kelvin viscoelastic physical G(t) and K(t) are the so-called relaxation moduli, which can be expressed by Ei (or Gi ) and gi in the viscoelastic model. The asterisk (*) in Eq. (3) indicates the convolution integral, the definition of which is Zt E1 ð7Þ AðsÞ and BðsÞ are two undetermined functions of the transform parameter s defined in the Laplace transform of a time function, f ðtÞ, as bþi1 Z f ðsÞest dt: bi1 The inverse transform of Eq. (7) is 2 1 1 1 rr ¼ 2 L ½GðtÞ sAðsÞ þ 2L GðtÞ þ KðtÞ BðsÞs r 3 2 1 1 1 rh ¼ 2 L ½GðtÞ sAðsÞ þ 2L GðtÞ þ KðtÞ BðsÞs r 3 h i 4 h i rz ¼ 2L1 KðtÞ sBðsÞ L1 GðtÞ sBðsÞ : 3 ð8Þ According to the boundary condition of Eq. (2), the functions A(s) and B(s) can be determined as i 1 h AðsÞ ¼ p0 R2 ðtÞ pðtÞR2 ðtÞ ; ð9Þ 2sGðtÞ BðsÞ ¼ h 3p0 2s GðtÞ þ 3KðtÞ i: ð10Þ 123 1486 H. N. Wang et al. Substituting Eqs. (9) and (10) into Eq. (8) provides the explicit form for the radial and hoop stresses in the rock as R2 ðtÞ pðtÞR2 ðtÞ rr ¼ p0 ðtÞ 1 2 ; r r2 ð11Þ R2 ðtÞ pðtÞR2 ðtÞ : rh ¼ p0 ðtÞ 1 þ 2 þ r r2 and 8 < Zt 1 1 p0 ðsÞR2 ðsÞHðt sÞds ur ðr; tÞ ¼ 2r : 0 9 Zt = for t1 \t t2 ; ð16bÞ þR21 p1 ðsÞHðt sÞds ; t1 The radial displacement in the time domain is 1 ur ¼ L1 ½AðsÞ þ rL1 ½BðsÞ: r Assuming " HðtÞ L # 1 1 ð12Þ " 1 sGðtÞ IðtÞ L # 1 1 ; s GðtÞ þ 3KðtÞ and 8 < Zt 1 2 p0 ðsÞR2 ðsÞHðt sÞds ur ðr; tÞ ¼ 2r : 0 ð13Þ þR21 then according to the properties of the convolution integral of the Laplace transform, Eqs. (9) and (10) can be simplified to 1 L ½AðsÞ ¼ HðtÞ ½p0 R2 ðtÞ pðtÞR2 ðtÞ 2 Zt 1 ¼ p0 R2 ðsÞHðt sÞds 2 1 Zt2 t1 p1 ðsÞHðt sÞ ds þ R21 Zt p2 ðsÞHðt sÞds t2 for t [ t2 : 9 = ; ð16cÞ Displacements in the rock mass at a generic time t [ t1 can be calculated as long as the supporting pressures p1 ðtÞ and p2 ðtÞ are known. 3.2 Mechanical Analysis of the Liners 0 1 þ 2 Zt Liners are made of concrete. Here, the Young’s moduli EL1 and EL2 , and the Poisson’s ratios mL1 and mL2 are considered for the first and second liner, respectively. According to elasticity theory, the radial displacement of the first liner subject to the stress boundary conditions outlined in Fig. 1 is 2 pðsÞR ðsÞHðt sÞds 0 3 3 L ½BðsÞ ¼ IðtÞ p0 ðtÞ ¼ 2 2 1 Zt p0 ðsÞIðt sÞds: 0 ð14Þ Substituting Eq. (14) into Eq. (12) yields 8 Zt 1< p0 ðsÞR2 ðsÞHðt sÞds ur ¼ 2r : 0 9 Zt = 3 Zt 2 þ pðsÞR ðsÞHðt sÞds r p0 ðsÞIðt sÞds: ; 2 0 0 ð15Þ Equation (15) provides the general expression for the radial displacements. If the rock mass is incompressible, that is, KðtÞ ¼ 1, no displacements occur before excavation. Considering now the installation of the first liner at time t1 and the second liner at time t2, the expression becomes u0r ðr; tÞ ¼ 1 2r Zt with ð17Þ where R2 is the inner radius of the first liner, qðtÞ ¼ 0 t1 t\t2 is the pressure between the liners, and q1 ðtÞ t t2 EL1 EL1 and KL1 ¼ 12m are the shear and bulk GL1 ¼ 2ð1þm L1 Þ L1 elastic moduli of the first liner, respectively. The expression for the radial displacement undergone by the second liner is p0 ðsÞR2 ðsÞHðt sÞds for 0 t t1 ; ð16aÞ 1 R 2 R2 1 þ mL2 R22 q1 ðtÞ 2 2 3 2 q1 ðtÞ 2 r 2GL2 r R2 R3 KL2 R2 R23 t t2 ; urL2 ðr; tÞ ¼ with 0 123 1 R 2 R2 1 þ mL1 2 1 2 2 ½pðtÞ qðtÞ 2GL1 r R1 R2 KL1 R21 pðtÞ R22 qðtÞ r R21 R22 t t1 ; urL1 ðr; tÞ ¼ ð18Þ where R3 is the inner radius of the second liner, and GL2 and KL2 are the shear and bulk elastic moduli of the Analytical Solutions for the Construction of Deeply Buried Circular Tunnels second liner, respectively. The stresses acting on the first liner are R2 R22 R22 R21 rrL1 ¼ 1 21 qðtÞ 1 pðtÞ; 2 2 2 2 r R1 R2 r R1 R22 R21 R22 R22 R21 rhL1 ¼ 1 þ 2 qðtÞ 1 þ 2 pðtÞ; 2 2 2 r R1 R2 r R1 R22 1487 R21 p1 ðtÞ ¼ 2D1 þ 2D2 R21 p1 ðsÞHðt sÞds t1 8 t < Z1 1 p0 ðsÞR2 ðsÞHðt1 sÞds þ 2D1 þ 2D2 R21 : 0 9 Zt = þ p0 ðsÞR2 ðsÞHðt sÞds : ð24Þ ; ð19Þ whilst the stresses on the second liner are R2 R22 q1 ðtÞ; rrL2 ¼ 1 23 2 r R2 R23 R2 R22 q1 ðtÞ: rhL2 ¼ 1 þ 23 2 r R2 R23 Zt 0 ð20Þ Specifying the function H = H(t) according to the viscoelastic model of interest, the analytical expression for the supporting pressure acting after the construction of the first liner can be obtained from Eq. (24). 3.3 Determination of the Supporting Pressure After Construction of the First Liner 3.4 Determination of the Supporting Pressure After Construction of the Second Liner Having already imposed the boundary condition on the stresses at the interface between the first liner and the rock, the only boundary condition left concerns the displacements: In the derivation of the solution, two boundary compatibility conditions will be imposed; the first one is at the boundary between rock and the first liner: ur ðR1 ; tÞ ur ðR1 ; t1 Þ ¼ urL1 ðR1 ; tÞ with t t1 : ur ðR1 ; tÞ ur ðR1 ; t1 Þ ¼ urL1 ðR1 ; tÞ with ð21Þ According to Eq. (16), the increment of radial displacement in the rock from time t1 until a generic time t with t\t2 is ur ðr; tÞ ur ðr; t1 Þ 8 t Z1 1< ¼ p0 ðsÞR2 ðsÞHðt1 sÞds 2r : p0 ðsÞR2 ðsÞHðt sÞds þ R21 Zt t1 0 whilst the second one is at the boundary between the two liners: urL1 ðR2 ; tÞ urL1 ðR2 ; t2 Þ ¼ urL2 ðR2 ; tÞ with 9 = p1 ðsÞHðt sÞds : ; Substituting into Eq. (21) yields the following secondtype Volterra integral equation: 8 t Z1 Zt 1 < 2 p0 ðsÞR ðsÞHðt1 sÞds p0 ðsÞR2 ðsÞHðt sÞds 2R1 : 0 0 9 Zt = þR21 p1 ðsÞHðt sÞds ; t1 1 R1 R 2 1 þ mL1 R3 ¼ 2 2 2 p1 ðtÞ 2 1 2 p1 ðtÞ: 2GL1 R1 R2 KL1 R1 R2 ð23Þ the parameters R2 R2 D1 ¼ 2G1L1 R21R22 1 L1 D2 ¼ 1þm KL1 R21 R21 R22 ð26Þ 0 and Zt 2 p0 ðsÞR ðsÞHðt sÞds þ 0 þR21 Zt t2 R21 Zt2 p1 ðsÞHðt sÞds t1 9 = p2 ðsÞHðt sÞds : ; ð27Þ Substituting Eq. (27) into Eq. (25), the following is obtained: 8 t Z1 Zt 1 < 2 p0 ðsÞR ðsÞHðt1 sÞds p0 ðsÞR2 ðsÞHðt sÞds 2R1 : 0 0 9 Zt2 Zt = þR21 p1 ðsÞHðt sÞds þ R21 p2 ðsÞHðt sÞds ; t1 2 , and rearranging Eq. (23) for p1 ðtÞ, the following is obtained: t t2 : ur ðr; tÞ ur ðr; t1 Þ 8 t Z1 1< ¼ p0 ðsÞR2 ðsÞHðt1 sÞds 2r : ð22Þ Defining ð25Þ The increment of radial displacement in the rock from time t1 until a generic time t, with t [ t2 , is 0 Zt t t2 ; ¼ t2 D1 ½p2 ðtÞ q1 ðtÞ ½D2 p2 ðtÞ D3 q1 ðtÞ R1 ; R1 ð28Þ 123 1488 H. N. Wang et al. R2 1 unknown functions. 2 R2 L2 2 D4 ¼ 1þm KL2 R2 R2 ; D5 ¼ Defining 2 R22 R23 1 2GL2 R22 R23 , ηM E M (G M ) L1 2 where D3 ¼ 1þm KL1 R2 R2 , q1 ðtÞ and p2 ðtÞ being as yet 3 and substituting Eqs. (17) and (18) into Eq. (26) yields D1 D1 ½p2 ðtÞ q1 ðtÞ ½D2 p2 ðtÞ D3 q1 ðtÞ R2 þ p1 ðt2 Þ R2 R2 D5 þ D2 p1 ðt2 Þ R2 ¼ q1 ðtÞ D4 q1 ðtÞ R2 : ð29Þ R2 D þD R2 1 2 2 Defining D6 ¼ D5 þD1 þD 2 2 , then rearranging, one 4 R þD3 R 2 2 Fig. 3 Maxwell viscoelastic physical model Maxwell model and incompressible behavior, the constitutive parameters for the rock (see Eq. 3) become G GðtÞ ¼ GM e ð30Þ Substituting Eq. (30) into Eq. (28), the equation for p2 ðtÞ is obtained as M ; KðtÞ ¼ 1: ð32Þ Substituting Eq. (32) into Eq. (13) yields HðtÞ ¼ obtains q1 ðtÞ ¼ D6 ½p2 ðtÞ p1 ðt2 Þ: gMt 1 1 dðtÞ þ ; GM gM IðtÞ ¼ 0: ð33Þ The radial displacement in the absence of liners is 2 3 Zt 2 1 p ðtÞR ðtÞ 1 0 þ p0 ðsÞR2 ðsÞds5 for any t: u0r ðr; tÞ ¼ 4 2r GM gM 0 R21 p2 ðtÞ ¼ 2ðD1 D1 D6 D2 R21 þ D3 D6 R21 Þ Zt p2 ðsÞHðt sÞds ð34Þ 4.1 Supporting Pressure and Displacements After Construction of the First Liner t2 Substituting Eq. (33) into Eq. (24) and defining k1 ¼ 1 2ðD1 D1 D6 D2 R21 þ D3 D6 R21 Þ 8 t <Z 1 p0 ðsÞR2 ðsÞHðt1 sÞds : Gg M D17 and D7 ¼ 1 þ 2GM DR21 þ 2GM D2 , the standard þ M p1 ðtÞ ¼ k1 0 Zt 0 p0 ðsÞR 2 ðsÞHðt sÞds þ R21 Zt2 Zt kM ðt; sÞ p1 ðsÞds þ fM1 ðtÞ: ð35Þ t1 p1 ðsÞHðt sÞds t1 2D1 D6 p1 ðt2 Þ 2D3 D6 R21 p1 ðt2 Þ 1 integral equation becomes ) : ð31Þ Hence, the equations for the supporting pressures p2 ðtÞ and q1 ðtÞ after construction of the second liner are given in Eqs. (30) and (31) by specifying the function H = H(t) according to the viscoelastic model of interest. The kernel of this integral equation is kM ðt; sÞ 1, and the free term is fM1 ðtÞ k1 p0 ðt t1 Þ. According to the theory of integral equations (Chambers 1976), the iterated kernel can be determined by iteration as kM1 ðt; sÞ ¼ kM ðt; sÞ ¼ 1; Zt kM2 ðt; sÞ ¼ kM ðt; uÞ kM1 ðu; sÞdu ¼ t s; s kM3 ðt; sÞ ¼ Zt kM ðt; uÞ kM2 ðu; sÞdu ¼ ðt sÞ2 =2; . . .; s 4 Analytical Solution for the Maxwell Model Let us consider weak, soft or highly jointed rock masses, and/or rock masses subject to high stresses, which are prone to excavation-induced continuous viscous flows. The Maxwell viscoelastic model (Fig. 3) is suitable to simulate their rheology, since it accounts for both primary and secondary rock creep. Now, assuming the validity of the 123 kMn ðt; sÞ ¼ ðt sÞn1 =ðn 1Þ! ð36Þ Then, the kernel function of Eq. (35) can be written as WM ðt; s; k1 Þ ¼ 1 X kn1 1 kMn ðt; sÞ ¼ n¼1 k1 ðtsÞ ¼e 1 X n¼1 : kn1 1 ðt sÞn1 ðn 1Þ! ð37Þ Analytical Solutions for the Construction of Deeply Buried Circular Tunnels Finally, the solution of Eq. (35) can be expressed as p1 ðtÞ ¼ fM1 ðtÞ þ k1 Zt WM ðt; s; k1 ÞfM1 ðsÞds ¼ k1 p0 ðt t1 Þ p0 Zt ek1 ðtsÞ ðs t1 Þds: p2 ðtÞ ¼ k2 t1 ð38Þ Then, after integration and simplifying, the following solution is obtained: p1 ðtÞ ¼ p0 p0 e k1 ðtt1 Þ ð39Þ : Substituting Eq. (39) into Eq. (16), the radial displacement of the rock mass at a time t with t1 t\t2 can be expressed as p0 GM GM R21 ek1 ðtt1 Þ 1 þ u1r ðr; tÞ ¼ R21 2GM r gM k1 gM k1 Zt0 o GM GM 2 þ R2 ðsÞds þ R1 ðt1 t0 Þ : ð40Þ gM gM 0 Hence, the obtained displacement varies with time according to an exponential function. Substituting Eq. (39) into Eq. (11) yields the following expressions for the stress 8 2 < p0 1 R ðtÞ with 0 t t1 r2 rr ¼ ; : R2 p0 þ p0 ek1 ðtt1 Þ r21 with t [ t1 8 ð41Þ 2 < p0 1 þ R ðtÞ with 0 t t1 r2 rh ¼ : R2 p0 p0 ek1 ðtt1 Þ r21 with t [ t1 Now considering the case of an instantaneous excavation, that is, R(t) = R1 (with t [ 0) and t0 = 0, the expressions for the displacements and stresses reduce to p0 R21 GM GM GM k1 ðtt1 Þ e 1þ þ t1 ur ðr; tÞ ¼ 2GM r gM k1 gM k1 gM with t 0; ð42Þ rr ¼ p0 þ p0 ek1 ðtt1 Þ with t 0: R21 r2 4.2 Supporting Pressure and Displacements After Construction of the Second Liner Substituting the constitutive parameters into Eq. (31), the integral equation for p2 ðtÞ can be obtained as t1 k21 ; rh ¼ p0 p0 ek1 ðtt1 Þ 1489 R21 r2 ð43Þ The solution appearing in Eq. (42), which is valid only for the particular case of an instantaneous excavation, coincides with the solution provided by Nomikos et al. (2011), who considered a Burgers viscoelastic model for the rock mass, in case the spring of the Kelvin element is infinitely stiff, GK ! 1. Zt kM ðt; sÞ p2 ðsÞds þ fM2 ðtÞ; ð44Þ t2 where kM ðt; sÞ 1, fM2 ðtÞ k2 p0 ðt t2 Þ þ kk21 D p0 ½1 ek1 ðt2 t1 Þ þ D89 p1 ðt2 Þ, k2 ¼ Gg M D19 ; M D8 ¼ 2GM DR1 D2 6 2GM D3 D6 ; and D9 ¼ D7 þ D8 : By 1 using the same method outlined in Sect. 4.1, the following is obtained: p2 ðtÞ ¼ p0 p0 ek1 ðt2 t1 Þþk2 ðtt2 Þ : ð45Þ According to Eq. (30), q1 ðtÞ ¼ D6 p0 ek1 ðt2 t1 Þ ½ek2 ðtt2 Þ þ 1; ð46Þ so that the displacement of the rock at a generic time t with t t2 can be obtained as p0 GM 2 2 k1 ðt2 t1 Þþk2 ðtt2 Þ R1 e ur ðr; tÞ ¼ 1þ 2GM r gM k2 2 GM R1 k1 ðt2 t1 Þ 1 1 þ e k1 k2 gM Zt0 GM GM 2 2 GM R1 þ R2 ðsÞds þ R1 ðt1 t0 Þ : gM k1 g M gM 0 ð47Þ Now, for tunnel engineers it is of interest to know the total additional displacement occurring after the construction of the second liner, i.e., R2 p0 GM Du2tot ¼ ur ðr; 1Þ ur ðr; t2 Þ ¼ 1 þ 1 ek1 ðt2 t1 Þ ; 2GM r gM k2 ð48Þ and the total additional displacement occurring between the installation of the two liners, i.e., Du1tot ¼ ur ðr; t2 Þ ur ðr; t1 Þ h i R2 p0 GM ¼ 1 þ 1 ek1 ðt2 t1 Þ 1 : 2GM r gM k1 ð49Þ Substituting Eq. (46) into Eq. (11), the stresses arising after the construction of the second liner can be determined as R21 k1 ðt2 t1 Þþk2 ðtt2 Þ e ;; r2 R2 rh ¼ p0 p0 21 ek1 ðt2 t1 Þþk2 ðtt2 Þ r with t t2 : rr ¼ p0 þ p0 ð50Þ 123 1490 H. N. Wang et al. 0.18 4.3 Results and Discussion v=1 m .day -1 0.16 An in situ stress at infinity of p0 ¼ 15 MPa is assumed. In the example excavation process considered here, the radius of the tunnel grows from R0 ¼ 1 m until R1 ¼ 6 m at the end of the excavation process. The thicknesses of the first and second liner are 100 and 200 mm, respectively, so that R2 ¼ 5:9 m and R3 ¼ 5:7 m: For convenience of notation, the absolute value of the radial displacement will be presented in all the following figures, since radial displacements are always opposite to the radial coordinate r (i.e., the tunnel exhibits convergence). 4.3.1 Influence of the Excavation Rate First, the displacement progression over time is investigated for three values of excavation rate: 0:625 m/day, 1 m/day, and 5 m/day, corresponding to total excavation periods of 8, 5, and 1 day, respectively. In this example, the first liner is installed immediately after completion of the excavation process to reduce displacements as much as possible. The second liner instead is installed after a time interval of 7 days from the installation of the first liner. In Fig. 4, the radial displacements calculated at r ¼ R1 are plotted for the aforementioned values of excavation rate. The asterisk and filled-triangle symbols indicate the installation of the first and second liner, respectively. The general trend is that the radial displacement increases over time and reaches a constant value after around 30 days. 123 0.14 0.12 ur [m] To illustrate the influence of the excavation process and the installation times of the liners on the resulting stresses and displacements, an example is presented herein. Backanalysis is often used to identify the most suitable rheological model for the rock and its related parameters. Yang et al. (2001) derived rheological models and their constitutive parameters from in situ measurements during the excavation of a long tunnel, whereas Feng et al. (2006) derived them using genetic algorithms applied to the results of rock creep tests. Considering these experimental results, we have adopted the following values for the two parameters of the Maxwell model: GM ¼ 2; 000 MPa and gM ¼ 4; 000 MPa day; which lie in the ranges of values identified by Feng et al. (2006). Now, with regard to the elastic parameters for the concrete liners, GL1 ¼ GL2 ¼ 10; 000 MPa and mL1 ¼ mL2 ¼ 0:2 have been assumed; hence, the elastic bulk moduli result to be KL1 = KL2 = 40; 000MPa: An excavation process with a linear increase of radius is considered here, i.e., R0 þ vt 0 t t0 RðtÞ ¼ ð51Þ R1 t [ t0 0.1 0.08 v=5 m .day-1 0.06 v=0.625 m .day-1 0.04 0.02 0 0 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 t [day] Fig. 4 Radial displacement versus time for various excavation rates; asterisks indicate the installation times of the first liner, whilst filled triangles indicate the installation times of the second liner. In all cases, the first liner is installed at t = t0 = t1 The results show that a lower excavation rate implies a longer excavation time, which leads to a larger value of displacement at the end of the excavation process at time t1 = t0, since the tunnel is immediately supported by the first liner after completion of the excavation. In the following two stages (t1 t\t2 and t [ t2 ), there is no significant difference among the three curves in terms of additional displacement. Overall, faster excavation rates imply lower total displacements at the end of every stage, and also in the long term. In Fig. 4 it can be observed that the three curves intersect at around the 17th day: at the beginning (before the 17th day), high excavation rates imply larger displacements, whereas later on (after the 17th day), the opposite is true. So, it emerges that a fast excavation leads to high rates of displacement early on. However, the final stable state is reached earlier, with the final total displacement being lower than the case of slow excavation, as can be expected. In Fig. 5, the stress responses of the rock calculated at the interface between rock and the first liner, r = 6 m, where the highest hoop stress is expected to develop, are displayed for the analyzed excavation rates. In all three cases considered, the stresses are the same at the end of excavation and at the time of installation of the second liner. However, for lower excavation rates, the change in stress is more gradual. Absolute values of radial and circumferential stresses reach their minimum and maximum at the end of the excavation phase, and would remain unchanged if no liners were installed. After installation of the first liner, the radial stress increases whereas the circumferential one decreases, so that the rock mass becomes subject to a more isotropic state of stress, which is beneficial for the stability of the tunnel. Analytical Solutions for the Construction of Deeply Buried Circular Tunnels 0 -14 -2 -16 v=0.625 m .day -1 -4 -18 -6 v=1m .day -1 σθ [MPa] σr [MPa] 1491 -8 -10 v=5 m .day-1 v= 0.625 m .day -1 -22 v=1 m.day -1 -24 -12 -26 -14 -28 -16 v=5 m . day -1 -20 -30 0 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 0 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 t [day] t [day] Fig. 5 Stresses calculated at the interface between rock and the first liner (r = 6 m) versus time for various excavation rates. Asterisks indicate the installation times of the first liner, whilst filled triangles indicate the installation times of the second liner 0.25 t1=15 day 0.2 t1=12 day t1=10 day Du1þ ðr; tÞ u1r ðr; tÞ u1r ðr; t1 Þ i p0 R21 GM h k1 ðtt1 Þ 1þ 1 ¼ e 2GM r gM k1 ur [m] with 0.15 t1=8 day 0.1 0.05 0 0 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 t [day] ð53Þ t1 t\t2 : Here, the influence of the installation time of the first liner was analyzed for an excavation rate of 0:625 m/day; which implies an excavation period of 8 days ðt0 ¼ 8Þ: Four options were considered, with the first liner installed on the 8th, 10th, 12th, and 15th day. In all the cases, the second liner is installed on the 15th day. In Fig. 6, the resulting radial displacements, calculated at the interface between rock and the first liner, are displayed. It can be noted that earlier Fig. 6 Radial displacement versus time for various installation times of the first liner ðv ¼ 0:625 m/dayÞ: Asterisks indicate the installation times of the first liner 0.08 0.07 4.3.2 Influence of the First Liner Installation Time Du1 ðr; tÞ u0r ðr; tÞ u1r ðr; tÞ p0 R21 k1 ðtt1 Þ ¼ GM 1þ gM k1 Δ u-2 [m] The analytical expression for the reduction of the radial displacements in the rock due to the presence of the first liner results as t1 =10 day 0.06 0.05 t1=6 day 0.04 t1=14 day 0.03 1e 2GM r GM GM þ þ ðt t1 Þ ; with t1 t\t2 : ð52Þ gM k1 gM Du1 depends on the installation time of the first liner. The earlier the first liner is put in place, the larger the reduction of displacement will be. The analytical expression for the incremental displacement occurring since the installation of the first liner results as 0.02 0.01 0 6 8 10 12 14 16 18 20 22 24 26 28 30 t2 [day] Fig. 7 Reduction of the radial displacement in the rock induced by the second liner calculated at the interface between rock and the first liner (r = 6 m) for various installation times of the first liner versus the installation time of the second liner (t2) 123 1492 H. N. Wang et al. installation of the liner reduces the rate of displacement, and also leads to a shorter time to reach the stable state. 4.3.3 Influence of the Second Liner Installation Time The analytical expression for the reduction of the radial displacements in the rock due to the presence of the second liner results as Du2 ðr; tÞ u1r ðr; tÞ u2r ðr; tÞ i p0 R21 ek1 ðt2 t1 Þ h k2 ðtt2 Þ e ek1 ðtt2 Þ ¼ 2GM r GM ek1 ðtt2 Þ ek2 ðtt2 Þ GM 1 1 þ ; gM k1 k2 gM k1 k2 ð54Þ t t2 : with According to Eq. (54), it emerges that Du2 depends on the time interval between the installation of the first and the second liner, i.e., t2 t1 . Earlier installation of the first liner leads to smaller reduction of displacements due to the installation of the second liner. In Fig. 7, curves representing the reduction of displacement versus the installation time of the second liner, t2, are plotted for three values of t1. From the figure, it emerges that, in order to minimize deformations, the second liner has to be put in place as soon as possible. Conversely, postponing the installation of the second liner leads to more pressure acting on the rock and the first liner, so that a more economical design of the second liner can be achieved. Now we consider the case of the first liner being built immediately after completion of the excavation process on the 8th day, with the second liner being installed at 0.2 t 2= 20 day t 2= 15 day ur [m] 0.15 different dates, namely the 8th, 15th, and 20th day. In Fig. 8, the displacements calculated at the interface between rock and the first liner (r ¼ 6 m) are displayed. Early installation of the second liner leads to smaller displacements, with the stable state reached earlier. In Fig. 9, the stresses in the rock at the interface between rock and the first liner are plotted for the following time intervals between the construction of the two liners: 2, 6, and 10 days, with v = 0.625 m/day and t0 = 8 days. It is worth noting that early installation of the second liner leads to a smaller radial stress and a larger circumferential one. The incremental displacement occurring since the installation of the second liner is Du2þ ðr; tÞ u2r ðr; tÞ u2r ðr; t2 Þ i p0 R21 ek1 ðt2 t1 Þ GM h k2 ðtt2 Þ ¼ 1þ 1 e 2GM r gM k2 with t t2 : ð55Þ This incremental displacement depends on the time period t2 t1 and on the installation time of the second liner. The larger t2 is, the larger the value of Du2þ will be. 5 Analytical Solution for the Boltzmann Model For rock masses with good mechanical properties or subject to low stresses, the exhibited mechanical behavior shows limited viscosity. For this type of behavior, the Boltzmann viscoelastic model (Fig. 10) is commonly employed. The material parameters adopted in the model are the two elastic shear moduli GB1 and GB and the viscosity coefficient gB . Assuming that the rock is incompressible, the two relaxation moduli appearing in the constitutive equations (see Eq. 3) are as follows: GðtÞ ¼ G þG G2B1 GB GB1 B1 B t e gB þ ; GB1 þ GB GB1 þ GB KðtÞ ¼ 1: ð56Þ t 2 =8 day 0.1 Substituting Eq. (56) into Eq. (13) yields HðtÞ ¼ 0.05 1 1 GB t dðtÞ þ e gB ; IðtÞ ¼ 0: GB1 gB ð57Þ Substituting Eq. (57) into Eq. (15), and according to the properties of the Laplace transform, the analytical expression for the radial displacement can be derived as 0 0 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 t [day] Fig. 8 Radial displacement versus time for various installation times of the second liner v ¼ 0:625 m/day). The asterisk indicates the installation time of the first liner, whilst filled triangles indicate the installation times of the second liner 123 ur ðr; tÞ ¼ 1 R2 ðtÞ½pðtÞ p0 ðtÞ 2GB1 r Zt GB 1 Gg B t s B e R2 ðsÞ½pðsÞ p0 ðsÞe gB ds: þ 2gB r 0 ð58Þ 1493 0 -14 -2 -16 -4 -18 t 2=10 day -6 t 2=14 day -8 t 2=18 day -10 σ θ [MPa] σr [MPa] Analytical Solutions for the Construction of Deeply Buried Circular Tunnels -20 -22 t 2=14 day t2=18 day -24 -12 -26 -14 -28 -16 t 2=10 day -30 0 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 0 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 t [day] t [day] Fig. 9 Stresses calculated at the interface between rock and the first liner (r = 6 m) versus time for various installation times of the second liner. The asterisk indicates the installation time of the first liner, whilst filled triangles indicate the installation times of the second liner Integrating and rearranging, the final solution is obtained as 2 t 3 Z0 GB GB D11 p0 Gg B t1 4 g s t e B R2 ðsÞe gB ds B R21 e gB 0 5 u1 ðtÞ ¼ 2D10 gB R1 GB 0 G GB k tþ B t k t t ð61Þ e 3 gB 1 3 1 e gB ; EB (GB) E B1(G B1 ) ηB Fig. 10 Boltzmann viscoelastic physical model GB with D11 ¼ GB g B k3 5.1 Supporting Pressure and Displacement After Construction of the First Liner Substituting Eq. u1 ðtÞ p1 ðtÞe R1 R22 R21 R22 GB gB t (58) ,k3 ¼ into 2DR101g B ; (21), and D10 ¼ and defining R1 2GB1 þ 2G1L1 R3 u1 ðtÞ ¼ k3 Zt 2 kB ðt; sÞ u1 ðsÞds þ fB1 ðtÞ ð59Þ kB ðt; sÞ 1, fB1 ðtÞ 2g GB t GB t p0 B R1 D10 G e g B t1 B ( G p0 R21 D11 Bt ¼ e gB 1 2GB1 r 2D10 gB R1 2 t 3 Z0 GB GB g s t B 2 2 0 4 R ðsÞe gB ds R e gB 5 GB 1 u1r ðr; tÞ t1 with liner before the second liner is installed is obtained as 2 t 3 Z0 GB GB D11 p0 Gg B t1 4 g s t p1 ðtÞ ¼ e B R2 ðsÞe gB ds B R21 e gB 0 5 2D10 gB R1 GB 0 h i G ðk3 g B Þðtt1 Þ B 1 with t1 t\t2 : ð62Þ e Substituting Eq. (62) into Eq. (58), the analytical expression for the radial displacement of the rock mass for t1 t\t2 is achieved as L1 1 þ 1þm KL1 R2 R2 , the integral equation becomes 1 . Thus, the pressure acting on the first hR t0 0 GB s R2 ðsÞe gB ds 0 GB t GgBB R21 e gB 0 ðe gB 1 e gB Þ. Following the methodology shown in Sect. 4.1, solving the integral equations yields 2 t 3 Z0 G GB GB p0 g g B t1 4 s t u1 ðtÞ ¼ e B R2 ðsÞe gB ds B R21 e gB 0 5 2D10 gB R1 GB 0 2 3 Zt GB GB GB GB t t t s 4e gB 1 e gB þ k3 ek3 ðtsÞ ðe gB 1 e gB Þds5: t1 ð60Þ h G ðk3 g B Þðtt1 Þ e B i 1 1 ) p0 Gg B t e B 2gB r "Zt0 (Zt0 GB s R2 ðsÞe gB ds 0 GB GB gB R21 Gg B t D11 R1 t s e B e gB 0 R2 ðsÞe gB ds GB 2D10 gB 0 # ) gB 2 Gg B t0 1 k3 ðtt1 Þ gB Gg B ðtt1 Þ gB 1 R eB e eB þ : GB 1 GB G B k3 k3 þ ð63Þ 123 1494 H. N. Wang et al. When t1 t\t2 , the incremental displacement occurring after the installation of the first liner is Du1þ ðr;tÞ u1r ðr;tÞur ðr;t1 Þ 2 t 3 Z0 GB GB p0 R1 g s t Gg t1 4 B 2 2 ¼ e R ðsÞe gB ds R1 e gB 0 5 4D10 gB GB1 r GB 0 h i p GB G G 0 ðk B Þðtt1 Þ t Bt e gB e gB 1 1 e 3 gB 2gB r 2 t 3 0 Z GB GB g s t 4 R2 ðsÞe gB ds B R21 e gB 0 5 GB 0 2 t 3 Z0 GB GB D11 p0 R1 Gg B t 4 g s t R2 ðsÞe gB ds B R21 e gB 0 5 þ e B GB 4D10 g2B r 0 1 k3 ðtt1 Þ gB Gg B ðtt1 Þ gB 1 B e e þ : k3 GB GB k3 ð64Þ According to Eqs. (62) and (63), the supporting pressure and displacements are related to the supporting time and the excavation process, which was not the case for the solution obtained for the Maxwell model. Substituting Eq. (62) into Eq. (11) leads to the following expressions for the stresses: rr ¼ rh ¼ 8 R2 ðtÞ > > p0 1 2 > > r > < GB D1 D1 D6 R1 t e gB p2 ðtÞ þ D 2 R1 D 3 D 6 R1 þ R1 R1 2GB1 Zt G GB B R1 D1 D6 ¼ e gB s p2 ðsÞds þ D3 D6 R1 e gB t p1 ðt2 Þ 2gB R1 t2 GB p0 ðtt Þ ½1 e gB 1 þ 2gB R1 GB s e gB ds þ p 0 R1 2gB Zt GB 2 R ðsÞe 0 s e gB ds t0 GB gB s 1 ds R1 2gB p0 R1 Gg B ðtt1 Þ eB 2gB Zt1 Zt2 p1 ðsÞ t1 GB s e gB ds; t0 ð66Þ where p1 ðt2 Þ can be calculated by Eq. (62) as 2 t 3 Z0 GB GB D11 p0 Gg B t1 4 g s t p1 ðt2 Þ ¼ e B R2 ðsÞe gB ds B R21 e gB 0 5 2D10 gB R1 GB 0 h i G ðk B Þðt t Þ e 3 gB 2 1 1 : ð67Þ Assuming that GB t u2 ðtÞ p2 ðtÞe gB ð68Þ 0 t\t1 with 2 t 3 Z0 h i p R2 2 GB > GB GB G D p R g R > 11 0 1 0 g t1 4 B 1 gB t0 5 ðk3 gBB Þðtt1 Þ 2 > gB s B > e p e R ðsÞe ds e 1 þ 21 > : 0 2D10 gB r 2 GB r 8 R2 ðtÞ > > with p0 1 þ 2 > > r > < Zt0 with t1 t\t2 ; 0 ð65Þ 0 t\t1 2 t 3 Z0 h i p R2 2 GB > GB GB G D p R g R > 11 0 1 0 g t1 4 B 1 gB t0 5 ðk3 gBB Þðtt1 Þ 2 > gB s B > e p þ e R ðsÞe ds e 1 21 0 > : 2D10 gB r 2 GB r with t1 t\t2 : 0 Hence, also the stresses turn out to depend on the excavation procedure. 5.2 Supporting Pressure and Displacement After Construction of the Second Liner According to the analysis in Sect. 3.4, the integral equation for the supporting pressure p2 = p2(t) is obtained by substituting Eq. (57) into (31) as 123 R1 and D12 ¼ DR11 DR1 D1 6 þ D2 R1 D3 D6 R1 þ 2G , the integral 1 equation for u2 ðtÞ can be obtained from Eq. (66) after some rearrangements as u2 ðtÞ ¼ k4 Zt kB ðt; sÞ u2 ðsÞds þ fB2 ðtÞ; t2 R1 where kB ðt; sÞ 1, k4 ¼ 2g D112 , and B ð69Þ Analytical Solutions for the Construction of Deeply Buried Circular Tunnels D1 D6 1 Gg B t fB2 ðtÞ þ D 1 D 6 R1 e B p1 ðt2 Þ D12 R1 Zt0 GB GB p0 ðtt Þ s 1 ½1 e gB R2 ðsÞe gB ds þ 2gB R1 D12 8 G Zt1 gBt < 2 GB B R e s 2 1 p0 R2 ðsÞe gB ds ½p2 ðtÞp0 þ ur ðr;tÞ¼ 2GB1 r 2gB r : 0 þR21 0 R1 2gB D12 Zt2 GB s p1 ðsÞ e gB ds þ t1 p0 R1 Gg B ðtt1 Þ eB 2gB D12 Zt1 e GB gB s p 0 R1 2gB D12 Zt GB u2 ðtÞ ¼ fB2 ðtÞ þ k4 t0 ds: ð70Þ ð71Þ The analytical expression for the radial displacement of the rock mass for t t2 can be obtained by substituting p1 ðtÞ (Eq. 62) and p2 ðtÞ into Eq. (58) and rearranging: 0.06 0.05 v=5 m .day-1 ur [m] 0.03 v=1 m .day-1 v=0.625 m .day-1 0 0 2 4 6 ½p2 ðsÞp0 e t2 9 = ds : ; R21 ½p2 ðtÞ Du2þ u2r ðr; tÞ ur ðr; t2 Þ ¼ 2GB1 r G 1 Gg B t Bt e B e gB 2 p2 ðt2 Þ 2gB r 2 t 3 0 Zt2 Z GB GB s s 4 p0 ðsÞR2 ðsÞe gB ds R21 p1 ðsÞ e gB ds5 t1 0 0 0.01 dsþR21 GB gB s The incremental displacement occurring in the second liner stage is So, the expression for p2 ðtÞ can be obtained from Eq. (68). Since the integral expression in Eq. (70) is very long, the explicit expression is here omitted. Substituting Eqs. (67) and (70) into Eq. (30), we obtain ( G D11 p0 Bt q1 ðtÞ ¼ D6 p2 ðtÞ e gB 1 2D10 gB R1 2 t 3 ) Z0 GB GB GB g s t ðk Þðt t Þ B 4 R2 ðsÞe gB ds R2 e gB 0 5½e 3 gB 2 1 1 : GB 1 0.02 ½p1 ðsÞp0 e Zt ð72Þ t2 0.04 GB gB s t1 s t0 WB ðt; sÞfB2 ðsÞds: Zt2 e gB ds The kernel function of Eq. (69) is written as WB ðt; sÞ ¼ ek4 ðtsÞ . Thus, the solution for the integral equation can be expressed analytically as Zt 1495 8 10 12 14 16 18 20 22 24 26 28 30 t [day] Fig. 11 Radial displacement versus time for various excavation rates; asterisks indicate the installation times of the first liner, whilst filled triangles indicate the installation times of the second liner R21 Gg B t e B 2gB r Zt t0 p0 ðsÞe Zt GB s p2 ðsÞ e gB ds þ t2 GB gB s R2 G B t ds 1 e gB 2 2gB r R21 Gg B t e B 2gB r Zt2 GB s p0 ðsÞe gB ds: t0 ð73Þ 5.3 Results and Discussion According to the experimental data available (Feng et al. 2006), reasonable values for the constitutive parameters of the viscoelastic rock are: GB ¼ 1; 000 MPa, GB1 ¼ 2; 000 MPa, and gB ¼ 10; 000 MPa day. With regard to the concrete employed for the liners, its properties are outlined in Sect. 4.3. The same geometry (tunnel geometry and thicknesses of the liners), in situ stress state, excavation process, and excavation rates as in Sect. 4 were assumed. The only difference from Sect. 4 is the rock model applied. The displacement response calculated at the interface between rock and the first liner (r ¼ 6 m) for various values of excavation rate is illustrated in Fig. 11. Trends similar to the response obtained for the Maxwell model, but with faster convergence, are shown. To assess the influence of the installation times of the first and second liners, an excavation rate of 0.625 m/day as in Sect. 4.3.2 was assumed. Four options were considered, with the first liner installed on the 8th, 10th, 12th, and 15th day. In all the cases, the second liner was installed on the 15th day. In Fig. 12, the resulting radial displacements, calculated at the interface between rock and the first liner (r ¼ 6 m), are displayed. Again, it can be noted that early installation of the liner reduces the rate of displacement, and also leads to a shorter time to reach the stable state. 123 1496 H. N. Wang et al. 0.06 t1=12 day t1=10 day t1=15 day 0.05 ur [m] 0.04 t1=8 day 0.03 0.02 0.01 0 0 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 t [day] Fig. 12 Radial displacement versus time for various installation times of the first liner (v = 0.625 m/day). Asterisks indicate the installation times of the first liner 0.06 t 2=15 day t 2=12 day t 2=10 day 0.05 ur [m] 0.04 t2=8 day 0.03 0.02 0.01 0 0 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 t [day] Fig. 13 Radial displacement versus time for various installation times of the second liner (v = 0.625 m/day). Filled triangles indicate the installation time of the second liner 0 -15 v=0.625 m .day-1 v=1 m .day-1 -2.5 -17.5 v=5 m .day-1 -20 σθ [MPa] -5 σr [MPa] Considering now different times for the installation of the second liner, assuming that the first liner was installed immediately after completion of the excavation process, the radial displacements calculated at the interface between rock and the first liner are shown in Fig. 13. Comparing Figs. 12 and 13 with Figs. 6 and 8, respectively, it emerges that the trends are similar for both models; however, from a quantitative point of view, the influence of the time of installation of the liners on the radial displacements is more significant in the Maxwell model. With regard to the influence of the excavation rate on the state of stress within the rock mass, in Fig. 14 the hoop and radial stresses developed within the rock mass at the interface with the first liner are plotted. As in Sect. 4, it was assumed that the first liner was installed immediately after excavation. In comparison with the Maxwell model (Sect. 4.3.4), the trends shown are similar, although the quantitative variation of the stress level over time is remarkably less significant. Finally, looking at the analytical expression derived for the pressure acting on the first liner for the Maxwell model (Eqs. 39, 45, 46), it can be observed that the supporting pressure is independent of the excavation process. However, when applying the Boltzmann model instead, the supporting pressures pðtÞ and qðtÞ depend on the excavation rate, as shown in Figs. 15 and 16. In Fig. 15, the supporting pressure acting on the first liner is plotted against the time difference Dt ¼ t t1 ; with t1 being the installation time of the first liner, whilst in Fig. 16, the supporting pressure acting on the second liner is plotted against the time difference Dt0 ¼ t t2 ; with t2 being the installation time of the second liner. From these figures it emerges that the supporting pressure is larger for higher excavation rates. -7.5 -10 -22.5 -25 v=5 m .day-1 -12.5 -27.5 -15 -30 v=1 m.day-1 v=0.625 m .day-1 0 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 t [day] 0 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 t [day] Fig. 14 Stresses calculated at the interface between rock and the first liner (r = 6 m) versus time for various excavation rates. Asterisks indicate the installation times of the first liner, whilst filled triangles indicate the installation times of the second liner 123 Analytical Solutions for the Construction of Deeply Buried Circular Tunnels 3.5 v=5 m .day -1 3 v=1 m .day -1 p [MPa] 2.5 v=0.625m .day -1 2 1.5 1 0.5 0 0 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 32 34 36 38 40 Δ t [day] Fig. 15 Pressure on the first liner versus time for various excavation rates. Filled triangles indicate the installation times of the second liner 1.5 v=5 m .day-1 1 v=1 m .day-1 q [MPa] v=0.625 m.day -1 0.5 0 0 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 32 34 36 38 40 1497 supporting pressures, stresses, and displacements in the rock and the liners could be derived. The Maxwell viscoelastic model accounts for primary and secondary creep commonly observed in rock masses with weak mechanical properties or subject to high compressive stresses. In this case, radial displacements after liner installation increase exponentially over time, and reach a stable value asymptotically. Radial displacements are a function of the excavation process and of the installation time of the liners. Assuming that the first liner is installed immediately after excavation, a parametric analysis for various excavation rates showed that slow rates lead to smaller displacements in the short term but to larger ones in the long term, so that longer times are required for the stresses to stabilize to a constant value. Then, a parametric analysis for various times of liner installation was carried out, showing that early construction results in smaller displacements in the long term. The Boltzmann viscoelastic model is commonly employed for rock masses exhibiting limited viscosity. Unlike the Maxwell model, the closed-form solutions obtained for the Boltzmann model showed that the development of pressure on the liners depends on the excavation process and the times of liner installation. Although the obtained analytical solutions are rigorously applicable only for axisymmetric plane-strain conditions, according to the recent work of Schuerch and Anagnostou (2012), these solutions can be applied to a much wider range of ground conditions and to several cases of noncircular tunnels. Δ t' [day] Fig. 16 Pressure on the second liner versus time for various excavation rates 6 Conclusions Closed-form analytical expressions for stresses and displacements of deeply buried circular tunnels excavated in a viscoelastic medium supported by two liners were derived for any installation time of the liners. An initial hydrostatic stress field was assumed, with the rock mass modeled as linearly viscoelastic and the liners as purely elastic. To simulate realistically the process of tunnel excavation, solutions were developed for a time-dependent excavation process with the radius of the tunnel growing from zero until a final value according to a time-dependent function to be specified by the designers. The integral equations for the supporting pressures were established according to the given boundary conditions. Solutions of the equations were obtained assuming either the Maxwell or the Boltzmann viscoelastic model for the rock mass so that explicit closedform analytical expressions for the time-dependent Acknowledgments This work is supported by the National Natural Science Foundation of Shanghai City (grant No. 11ZR1438700), the Marie Curie Actions—International Research Staff Exchange Scheme (IRSES): GEO—geohazards and geomechanics (grant No. 294976), the National Natural Science Foundation of China (grants No. 10702052 and 51179128), and the China National Funds for Distinguished Young Scientists (grant No. 51025932). These supports are greatly appreciated. References Ahmad F, Farshad MT, Ahmadreza H, Arash V (2010) Analytical solution for the excavation of circular tunnels in a visco-elastic Burger’s material under hydrostatic stress field. Tunn Undergr Space Technol 25:297–304 Brady B, Brown E (1985) Rock mechanics for underground mining. George Allen & Unwin, London Brown CB, Green DR, Pawsey S (1968) Flexible culverts under hight fills. J Struct Div ASCE 94(4):905–917 Carranza-Tores C, Fairhurst C (1999) The elastoplastic responds of underground excavations in rock masses that satisfy the HoekBrown failure criterion. Int J Rock Mech Min Sci Geomech Abst 36:777–809 Cao ZY (2000) Viscoelastic solution of time-varying solid mechanics. Acta Mechanica Sinica 32(4):497–501 (in Chinese) 123 1498 Chambers LG (1976) Integral equations: a short course. International Textbooks, London Chehade FH, Shahrour I (2008) Numerical analysis of the interaction between twin-tunnels: influence of the relative position and construction procedure. Tunn Undergr Space Technol 23: 210–214 Christensen RM (1982) Theory of viscoelasticity: an introduction, 2nd edn. Academic, New York Christiaon PP, Chuntranuluk S (1974) Retaining wall under action of accreted backfill. J Geotech Engrg Div ASCE 100(4):47l–476 Einstein HH, Schwartz C W (1979) Simplified analysis for tunnel supports. J Geotech Eng Div (ASCE), GT4(April):499–518 Feng XT, Chen BR, Yang C, Zhou H, Ding X (2006) Identification of visco-elastic models for rocks using genetic programming coupled with the modified particle swarm optimization algorithm. Int J Rock Mech Min Sci 43:789–801 Flügge W (1975) Viscoelasticity 2nd edn. Springer, New York Gnirk PF, Johnson RE (1964) The deformational behavior of a circular mine shaft situated in a viscoelastic medium under hydrostatic stress. In: Proceeding of 6th symposium rock mechanics: University of Missouri, Rolla pp 231–259 Gurtin ME, Sternberg E (1962) On the linear theory of viscoelasticity. Arch Ration Mech Anal 11:2914–356 Ladanyi B, Gill D (1984) Tunnel lining design in creeping rocks. In: Symposium on Design and Performance of Underground Excavations, ISRM, Cambridge Lee EH (1955) Stress analysis in viscoelastic bodies. Q Appl Math 13:183 Mason DP, Stacey TR (2008) Support to rock excavations provided by sprayed liners. Int J Rock Mech Min Sci 45:773–788 Mason DP, Abelman H (2009) Support provided to excavations by a system of two liners. Int J Rock Mech Min Sci 46:1197–1205 Namov VE (1994) Mechanics of growing deformable solids-a review. J Eng Mech 2:207–210 123 H. N. Wang et al. Nomikos P, Rahmannejad R, Sofianos A (2011) Supported axisymmetric tunnels within linear viscoelastic Burgers rocks. Rock Mech Rock Eng 44:553–564 Peck RB, Hendron AJ Jr, Mohraz B (1972) State of the art of softground tunneling. In: Proceedings of the rapid excavation tunneling conference, Chicago vol 1, pp 259–285 Prazeres Plinio GC, Klaus Thoeni, Gernot Beer (2012) Nonlinear analysis of NATM tunnel construction with the boundary element method. Comput Geotech 40:160–173 Rashba EI (1953) Stress determination in bulks due to own weight taking into account the construction sequence. Proc. Inst. Struct. Mech. Acad. Sci. Ukrainian SSR 18:23–27 (in Russian) Savin GN (1961) Stress concentration around holes. Pergamon, London Schuerch R, Anagnostou G (2012) The applicability of the ground response curve to tunnelling problems that violate rotational symmetry. Rock Mech Rock Eng 45(1):1–10 Sulem J, Panet M, Guenot A (1987) An analytical solution for timedependent displacements in circular tunnel. Int J Rock Mech Min Sci Geomech Abst 24(3):155–164 Wang MB, Li SC (2009) A complex solution for stress and displacement field around a lined circular tunnel at great depth. Int J Numer Anal Meth Geomech 33:939–951 Wang HN, Nie GH (2010) Analytical expressions for stress and displacement fields in viscoelastic axisymmetric plane problem involving time-dependent boundary regions. Acta Mechanica 210:315–330 Wang HN, Cao ZY (2006) Time-varying analytics study of random expanding hole in plane viscoelasticity. Acta Mechanica Solida Sinica 27(3):319–323 (in Chinese) Yang ZF, Wang ZY, Zhang LQ, Zhou RG, Xing NX (2001) Backanalysis of viscoelastic displacements in a soft rock road tunnel. Int J Rock Mech Min Sci 28:331–341