Mathematical Modeling and Analysis of Free

advertisement

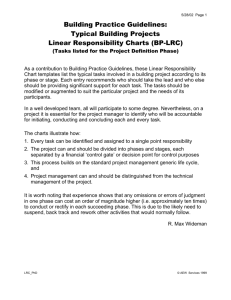

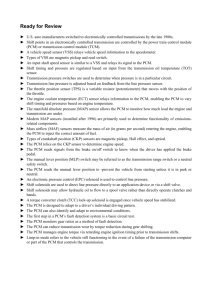

International Journal of Engineering Trends and Technology (IJETT) – Volume 34 Number 3- April 2016 Mathematical Modeling and Analysis of Free Cooling using PCM Filled Air Heat Exchanger for Energy Efficiency in Building ThambiduraiMuthuvelana, Karthikeyan. Sb, Krishna Mohan Na, VelrajRc* a b Department of Mechanical Engineering, Annamalai University, Chidambaram 608 002 Department of Mechanical Engineering, Arunai Collage of Engineering, Thiruvanamalai, India c Institute for Energy Studies, Anna University, Chennai 600 0025 Abstract — Power shortage and unstable power supply remain serious problems. Conventional cooling technologies that utilize harmful refrigerants consume more energy and cause peak loads leading to negative environmental impacts. As the world grapples with the energy and environmental crisis, there is an urgent need to develop and promote environmentally benign sustainable cooling technologies. Thermal storage systems are essential to overcome the disadvantage of the intermittent nature of energy and variation in cooling demand. The advantages of LHTES in comparison with sensible storage are a greater density of stored energy and a narrow operational temperature range. In this work empirical relationships were developed to estimate the PCM temperatures during charging and discharging by incorporating independent heat exchanger parameters (mass flow rate of air, air inlet temperature, charging and discharging time) using statistical design of experiments (DoE) concept. A central composite rotatable design with three factors and five levels was chosen to minimize the number of experimental conditions. Within the scope of the design space, the mass flow rate and the charging and discharging time appeared to be the most significant two parameters affecting the PCM temperature among the three investigated heat transfer parameters. Further, ANOVA analysis also proved that all the considered factors are significant and these models can be effectively used for prediction purpose. Keywords — Free cooling; Heat transfer; PCMHS29, Design of Experiments; ANOVA analysis. I. INTRODUCTION Thermal Energy Storage [TES] technologies are very important in various fields of engineering applications. The most common TES technologies are sensible heat storage and latent heat storage. Latent heat thermal storage units have received greater attention by the scientists and engineers working in the areas of solar heating/ cooling, energy management in buildings and waste heat recovery applications due to their high energy storage capacity and isothermal behaviour. ISSN: 2231-5381 Mathematical modeling of phase change phenomenon involves greater complexity as the solid and liquid domains change continuously with respect to time. There are several methods being adopted to model and solve for the temperature variation in the domain of interest. Many researchers have investigated experimentally and theoretically the transient behaviour of the PCM encapsulated in different geometries and PCM based storage systems in different configurations particularly shell and tube, packed bed with capsule of different geometries. II. PROBLEM DEFINITION The rate of PCM temperature change in the LHTES depends on the air flow rate and the temperature conditions at the storage inlet and the temperature difference between the air and the paraffin, respectively. This rate is important during the selection of an apparent heat capacity function, which should be determined based on measurements at approximately the same heating or cooling rate. A comparison of the numerical and experimental results showed that the apparent heat capacity, capp (T), a parameter that describes how the latent heat of the PCM evolves over the temperature range, should also include an additional influential parameter a heating or cooling rate [1]. The charging and discharging processes were numerically simulated by one dimensional governing equation for heat transfer fluid (HTF) and PCM using implicit finite difference method. The effect of inlet fluid temperature, mass flow rate of HTF, diameter of the capsule and porosity of the packed bed on the solidification and temperature distribution of the packed bed were analyzed [2]. The temperature of freezing/melting is one of the primary considerations when selecting a PCM. As an application guideline, a temperature difference of 3 - 4 0C is needed between the cooling medium, in this case cooling water and the freezing temperature of the PCM were considered. For melting, a similar temperature difference is required. Thus, combining both, the cooling water freezing the PCM needs to be approximately 8 ºC cooler than the cooling water melting the PCM. Most of the published literature mainly focused on effect of heat transfer mode, design of heat exchanger, effect of phase change http://www.ijettjournal.org Page 106 International Journal of Engineering Trends and Technology (IJETT) – Volume 34 Number 3- April 2016 materials on heat transfer, effect of experimental parameters, and comparison on experimental and numerical model results [3]. Of the various PCM integration and applications in buildings, free cooling is one of the novel concept in which the cool energy is stored in an external PCM based air- heat exchanger. A detailed review on phase change material storage for free cooling of buildings was carried out [6–13].The free cooling potential for different climatic locations in Europe was studied and reported that the PCM with wider phase change temperature range (12ºC) was found to be most efficient. The optimal size of the LHTS for free cooling of building is between 1 and 1.5 kg of PCM per m3/hr of fresh ventilation air [14]. The free cooling potential for Bangalore and Pune cities was analysed and the appropriate technologies to provide comfort conditions within the temperature range of 25 ± 3ºC was suggested in order to reduce the energy requirement of the building [15-18]. This paper focuses on developing a mathematical relationship to predict the PCM temperature during charging and discharging. Further to develop a mathematical relationship also to estimate room temperature to cool the room. III. MATERIALS AND METHODS To simulate the weather conditions of Pune, the present experiments were conducted from 1.30 a.m. in the early mornings during the month of November and December as this duration matches well with the major weather conditions prevailing in Pune city. Considering the climatic conditions of Pune city, a suitable PCM - HS 29 PCM (commercial grade PCM)with phase transition temperature of approximately 28°C to 30°C was chosen for the present study. IV. EXPERIMENTAL DESIGN MATRIX An initial step in the design of experiments is to select parameters for the experimental parameter. For economic (time requirements) and theoretical reasons (interdependence of parameters) it is not possible to control all possible parameter variations. From the literature [4 and 5] the predominant factors which are having more influence on PCM temperature were identified. They are as follows: 1. Mass flow rate of heat transfer fluid 2. Inlet air temperature during charging 3. Inlet air temperature during discharging. 4. Charging time. 5. Discharging time. A large number of experimental trials were conducted to identify the feasible working limit of the heat exchanger to transfer the heat from fluid medium to phase change material (PCM) solidification temperature and PCM to fluid medium to reduce the temperature of the room. From the trials the following parameters were identified for the solidification of the PCM and given in Table 1 ISSN: 2231-5381 and for melting of the PCM and also room cooling temperature are given in Table 2. V. DEVELOPING THE EXPERIMENTAL DESIGN MATRIX By considering all the above conditions, the feasible limits of the parameters were chosen in such a way that heat transfer experiments were carried out by solidification, melting of PCM and reduction of room temperature. Central composite rotatable design of second order was found to be the most efficient tool in response surface methodology to establish the mathematical relation of the response surface using the smallest possible number of experiments without losing its accuracy. Due to wide range of factors, it was decided to use three factors, five levels and central composite design matrix to develop mathematical models for the experimental conditions. Central composite design is the most popular response surface method design, which has three groups of design points such as, factorial points, axial or star points and center points. In the factorial part of the design consists of all possible combinations of the upper (+1) and lower levels (-1) of the factors. The star points have all of the factors set to 0, the midpoint, except one factor, which has the value +/- Alpha (+/- 1.682) for both rotatability and orthogonality of blocks. Center points, as implied by the name, are points with all levels set to coded level 0 -the midpoint of each factor range. The center points (In this investigation, 15-20) are usually repeated 4-6 times to get a good estimate of experimental error (pure error). To summarize, central composite designs require 5 levels of each factor: -Alpha, -1, 0, 1, and +Alpha. One of the commendable feature of the central composite design is that its structure lends itself to sequential experimentation. Table 3 shows the 20 sets of coded conditions used to form the design matrix. The second-order polynomial (regression) equation is used to represent the response surface Y is given by, Y = β0 + ∑βi Xi + ∑βii Xi2+ ∑βijXiXj (1) The selected model should include the effects of main and interaction effects of all the factors. With the view of considering this criterion, for the three factors, the selected polynomial can be expressed as, Y = b0 + b1(A) + b2(B) + b3(C) + b12(AB) + b13(AC) + b23(BC) + b11(A2) + b22(B2) + b33(C2) (2) where b0 is the average of the responses and b1, b2, b3,…,b33 are regression coefficients that depend on respective linear, interaction, and squared terms of factors. In order to estimate the regression coefficients, a number of experimental design techniques are available. In this work, central composite rotatable design was used which fits the http://www.ijettjournal.org Page 107 International Journal of Engineering Trends and Technology (IJETT) – Volume 34 Number 3- April 2016 second order response. The fitted regression equation to predict PCM temperature and room temperature are given below, PCM Temperature during discharging = 30.22+ 0.38A+0.11B +0.21C-0.089AB+0.013AC-0.013BC0.96A2-1.06B2-0.75C2 (4) PCM Temperature during charging = 27.53089A+0.68B-0.061C+0.088AB+0.51AC+0.41BC+ 0.85A2+1.1B2+0.64C2 (3) Room Temperature during discharging = 29.160.55A-0.33B+0.89C+.58AB+0.31AC+0.28BC+ 0.49A2 + 0.53B2 +0.1C2 (5) Table 1 Important experimental parameters and their levels for charging Levels Notations Units -1.682 -1 0 1 No. Parameters 1 Mass flow rate A kg/s 0.05 0.09 0.15 0.21 0.25 2 Inlet air temp. B °C 24 25 27 28 30 3 Charging time C min 30 84 165 245 300 No. Table 2 Important experimental parameters and their levels during discharging Levels Parameters Notations Units -1.682 -1 0 1 +1.682 +1.682 1 Mass flow rate A kg/s 0.02 0.09 0.15 0.21 0.1 2 Inlet air temp. B °C 26 27.6 30 32.4 34 3 Discharging time C min 10 57 125 193 240 Table 3 Experimental parameters and its response during charging Sl. No Coded Value Original Value Response1 Mass flow rate Inlet temp. Charging time A B C PCM Temp (A) (B) (C) (kg/s) (ºC) (min.) (ºC) 1 -1 -1 -1 0.09 25.22 84.73 31.5 2 1 -1 -1 0.21 25.22 84.73 28.4 3 -1 1 -1 0.09 28.78 84.73 31.7 4 1 1 -1 0.21 28.78 84.73 29.2 5 -1 -1 1 0.09 25.22 245.27 29.4 6 1 -1 1 0.21 25.22 245.27 28.6 7 -1 1 1 0.09 28.78 245.27 31.5 8 1 1 1 0.21 28.78 245.27 30.8 9 -1.682 0 0 0.05 27.00 165.00 31.4 10 1.682 0 0 0.25 27.00 165.00 28.4 11 0 -1.682 0 0.15 24.00 165.00 29.4 12 0 1.682 0 0.15 30.00 165.00 31.8 13 0 0 -1.682 0.15 27.00 30.00 29.4 14 0 0 1.682 0.15 27.00 300.00 29.2 15 0 0 0 0.15 27.00 165.00 27.5 16 0 0 0 0.15 27.00 165.00 27.6 17 0 0 0 0.15 27.00 165.00 27.5 18 0 0 0 0.15 27.00 165.00 27.5 19 0 0 0 0.15 27.00 165.00 27.5 20 0 0 0 0.15 27.00 165.00 27.6 ISSN: 2231-5381 http://www.ijettjournal.org Page 108 International Journal of Engineering Trends and Technology (IJETT) – Volume 34 Number 3- April 2016 Table 4 Experimental design matrix and its response during discharging Expt. No Mass flow rate Inlet air temp. Discharging time Response 1PCM Temp. Response 2 Room Temp. kg/s ºC Min ºC ºC 1 0.02 30 125 26.9 31.5 2 0.08 27.6 57 27.6 28.5 3 0.06 30 125 30.2 29.2 4 0.06 34 125 27.4 30.1 5 0.06 30 125 30.2 29.1 6 0.08 27.6 193 28.1 30.4 7 0.06 26 125 27 31.2 8 0.06 30 240 28.5 30.9 9 0.04 27.6 193 27.1 32 10 0.1 30 125 28.2 29.6 11 0.04 32.4 57 27.1 29.1 12 0.08 32.4 193 28.1 31.4 13 0.04 27.6 57 26.7 31.4 14 0.04 32.4 193 27.4 30.8 15 0.06 30 125 30.2 29.1 16 0.06 30 125 30.3 29.2 17 0.06 30 10 27.8 27.9 18 0.06 30 125 30.2 29.2 19 0.06 30 125 30.2 29.1 20 0.08 32.4 57 27.6 28.5 Table 5 ANOVA for response surface quadratic model for PCM temperature during charging Source Sum of Squares df Mean Square F Value p-value Prob> F Model 49.19 9 5.47 850.38 < 0.0001 A-Mass flow rate 10.8 1 10.8 1680.7 < 0.0001 B-Inlet temperature 6.38 1 6.38 993.16 < 0.0001 C-Charging time 0.051 1 0.051 7.97 0.0181 AB 0.061 1 0.061 9.53 0.0115 AC 2.1 1 2.1 326.96 < 0.0001 BC 1.36 1 1.36 211.82 < 0.0001 2 10.39 1 10.39 1616.76 < 0.0001 B 2 17.33 1 17.33 2696.58 < 0.0001 C 2 5.85 1 5.85 909.84 < 0.0001 3.82 0.0838 A Residual 0.064 10 6.43E-03 Lack of Fit 0.051 5 0.01 Pure Error 0.013 5 2.67E-03 Cor Total 49.25 19 Significant not significant Std. Dev.=0.08R-Squared = 0.9987 Mean = 29.29Adj R-Squared = 0.9975 C.V. % = 0.27Pred R-Squared = 0.9908 PRESS = 0.45Adeq Precision = 74.999 ISSN: 2231-5381 http://www.ijettjournal.org Page 109 International Journal of Engineering Trends and Technology (IJETT) – Volume 34 Number 3- April 2016 Table 6 ANOVA for response surface quadratic model for PCM temperature during discharging Source Sum of Squares df Mean Square F Value p-value Prob> F Model 34.43 9 3.83 28402.42 < 0.0001 2.02 1 2.02 15014.11 < 0.0001 0.15 1 0.15 1120.24 < 0.0001 0.6 1 0.6 4447.54 < 0.0001 AB 0.064 1 0.064 474.25 < 0.0001 AC 1.27E-03 1 1.27E-03 9.44 0.0118 BC 1.27E-03 1 1.27E-03 9.44 0.0118 A2 13.25 1 13.25 98336.04 < 0.0001 B2 16.34 1 16.34 1.21E+05 < 0.0001 59632.83 < 0.0001 0.052 0.9972 A-Mass flow rate B-Inlet air temp. C-Discharging time C 2 8.03 1 8.03 Residual 1.35E-03 10 1.35E-04 Lack of Fit 6.62E-05 5 1.32E-05 Pure Error 1.28E-03 5 2.56E-04 Cor Total 34.43 19 Significant not significant Std. Dev. = 0.12 R-Squared = 0.987 Mean = 28.33 Adj R-Squared = 0.99 C.V. % = 0.041 Pred R-Squared = 0.99 PRESS = 2.39E-03 Adeq Precision = 433.647 Table 7 ANOVA for response surface quadratic model of room temperature Source Sum of Squares df Mean Square F Value p-value Prob> F Model 27.36 9 3.04 4001.21 < 0.0001 4.13 1 4.13 5437.58 < 0.0001 1.51 1 1.51 1981.93 < 0.0001 10.82 1 10.82 14249.19 < 0.0001 AB 2.7 1 2.7 3557.89 < 0.0001 AC 0.75 1 0.75 987.69 < 0.0001 BC 0.62 1 0.62 818.27 < 0.0001 2 3.51 1 3.51 4624.93 < 0.0001 B 2 3.98 1 3.98 5240.24 < 0.0001 C 2 201.57 < 0.0001 6.01 0.0355 A-Mass flow rate B-Inlet air temp. C-Discharging time A 0.15 1 0.15 Residual 7.60E-03 10 7.60E-04 Lack of Fit 6.51E-03 5 1.30E-03 Pure Error 1.08E-03 5 2.17E-04 Cor Total 27.36 19 Significant Significant Std. Dev.= 0.028 R-Squared=0.9997 Mean=29.92 Adj R-Squared =0.9995 C.V. % =0.092 Pred R-Squared=0.998 PRESS= 0.054 Adeq Precision =210.202 All the coefficients were obtained applying central composite rotatable design using the Design Expert statistical software package (Version 8.07.1). The significance of each coefficient was determined by Student’s t test and p values, which are listed in Table5-7.In all the cases, A,B, C, AB, AC, BC, ISSN: 2231-5381 A2,B2 and C2 are significant model terms, values of ―Prob>F‖ less than 0.05 indicates that model terms are significant. After determining the significant coefficients (at 95% confidence level), the final empirical relationships were constructed using only these coefficients. http://www.ijettjournal.org Page 110 International Journal of Engineering Trends and Technology (IJETT) – Volume 34 Number 3- April 2016 empirical relationships can be effectively used for VI. CHECKING ADEQUACY OF THE DEVELOPED prediction purpose. The normal probability plot of RELATIONSHIPS the residual dilution is shown in Fig. 2, which reveals that the residuals are falling on the straight Analysis of variance (ANOVA) technique was line, indicating that the errors are distributed used to check the adequacy of the developed normally. Similar results were found for the empirical relationships. In this investigation, the developed mathematical model to predict PCM desired level of confidence was considered to be temperature and room temperature and the related 95%. The relationship may be considered to be results are shown in Figs. 3 – 6. adequate provided that (a) the calculated value of the F ratio Design-Expert® of the modelSoftware Predicted vs. Actual PCM TEMP developed should not exceed the standard tabulated Color points by value of value of F ratio and PCM TEMP: 31.8 (b) the calculated value of the R ratio of the 27.5 developed relationship should exceed the standard tabulated value of R ratio for a desired level of confidence. It is found that the model is adequate. The value of probability > F in Tables 5-7 for the empirical relationships are less than 0.05, which indicates that the empirical relationships are significant. Lack of fit 42 42 was not significant for all the developed empirical relationships as desired. The Fisher’s F test with a very low probability value (P model > F= 0.0001) Actual demonstrates a very high significance. The goodness Fig.1 Correlation graph between experimental actual temperature of fit of the model was checked by the determination and predicted temperature coefficient (R2). The coefficient of determination (R2) Design-Expert® Software Normal Plot of Residuals PCM TEMP This was calculated to be 0.9987 for response. implies that 99.87 % of experimental Color data points confirms by value of 99 PCM TEMP: the compatibility with the data predicted 31.8 by the 95 model, and the model does not explain27.5 only about 90 0.12 % of the total variations. The R2 value is always 80 70 between 0 and 1, and its value indicates aptness of 50 the model. 30 2 For a good statistical model, R value should be 20 2 10 close to 1.0. The adjusted R value reconstructs the 5 expression with the significant terms. The value of 1 the adjusted determination coefficient (Adjusted 2 R =0.9999) also high to advocate for a high significance of the model. The Predicted R2 (0.99) -1.66 -0.66 0.34 1.34 2.34 implies that the model could explain 95% of the Internally Studentized Residuals variability in predicting new observations. This is in 2 reasonable agreement with the Adjusted R of PCM Fig.2 Normal probability plot of residuals for PCM temperature temperature. The value of coefficient of variation is during charging. Design-Expert® Software also around 0.041 indicates that the deviations Predicted vs. Actual PCM Temp. between experimental and predicted values are low. 2 Color points by value of Adequate precision measures the signalPCM to Temp.: noise 30.3 ratio. A ratio greater than 4 is desirable. In this 26.7 investigation the ratio (433) which indicates an adequate signal. This model can be used to navigate the design space and able to predict the responses for a given input in coded form. Tables 6 and 7 show the ANOVA analysis for the models developed to predict the PCM during discharging temperature and room temperature shows that the models are significant as desired and co-efficient of variation, determination coefficient, and adequate precision are showing good results as Experimental PCM temp desired. Further, correlation graphs were drawn Fig.3 Correlation graph between experimental PCM and predicted relating experimental values and predicted values as PCM temperature during discharging. shown in Fig. 1 and it is found that the developed 31.80 Predicted 30.73 29.65 28.57 27.50 28.57 29.65 30.73 28.13 29.19 31.80 Normal % Probability 27.50 30.30 Predicted 29.23 28.15 27.07 26.00 26.00 ISSN: 2231-5381 http://www.ijettjournal.org 27.06 30.25 Page 111 International Journal of Engineering Trends and Technology (IJETT) – Volume 34 Number 3- April 2016 VII. olor points by value of CM Temp.: 30.3 99 95 90 Normal % Probability 26.7 CONCLUSION Normal Plot of Residuals esign-Expert® Software CM Temp. 80 70 50 30 20 10 5 1 -1.63 -0.57 0.49 1.54 2.60 Internally Studentized Residuals Fig.4 Normal probability plot of residuals during discharging Predicted vs. Actual gn-Expert® Software m Temp. 3 2.1 0 points by value of m Temp.: .0 3 1.0 5 Predicted .9 3 0.0 0 2 2 8.9 5 2 7.9 0 2 7.9 5 2 8.9 7 3 0.0 0 3 1.0 2 3 2.0 5 Experimental room temp Fig. 5 Correlation graph between experimental and predicted room temperature. Normal Plot of Residuals esign-Expert® Software oom Temp. olor points by value of oom Temp.: 32.0 99 It was experimentally seen that the use of design of experiments coupled with the statistical fitting model strategy is a simple, effective, and efficient way to develop robust, highly efficient and quality experimental procedure to analyze heat transfer characteristics. Based on the experimental results, the following conclusions have been drawn. Mathematical model was developed using response surface methodology to estimate charging and discharging temperature of the PCM and room temperature. The models can be effectively used to predict charging and discharging temperature of the PCM and room temperature within the limits of chosen factors. Charging temperature of the PCM is influenced by mass flow rate of air, air inlet temperature and charging time. Of the three factors considered, mass flow rate of air has the highest effect (Fisher ratio = 1680) and inlet air temperature (Fisher ratio=7.97) has the lowest effect on the solidification temperature of the PCM. Discharging temperature of the PCM is influenced by mass flow rate of air, air inlet temperature and charging time. Of the three factors considered, mass flow rate has the highest effect (Fisher ratio = 15014), inlet temperature (Fisher ratio=1120) has the lowest effect on the melting temperature of the PCM (Table 5). However, discharge time (14249) has a major effect on room cooling temperature as shown in Table 6 followed by mass flow rate of air (Fisher ratio=5437). Developed empirical relationships can be effectively used to predict the temperature of HS 29 PCM during charging and discharging, and room temperature during discharging within the range of parameters considered in this investigation. The established procedures can possibly be extended to other materials. Normal % Probability 95 27.9 REFERENCES 90 80 70 50 30 20 10 5 1 -2.12 -0.95 0.21 1.37 2.53 Internally Studentized Residuals Fig. 6 Normal probability plot of residuals for room temperature during discharging ISSN: 2231-5381 [1]. Arkar Cand Medved S. ―Influence of accuracy of thermal property data of a phase change material on the result of a numerical model of a packed bed latent heat storage with spheres‖. ThermochimicaActa (2005)438, 192–201. [2]. Antony Aroul Raj, V., and Velraj, R., ―Review on free cooling of buildings using phase change materials‖. Renewable and Sustainable Energy Review, (2010), 14, 2819–2829 [3]. Walsh B.P, Murray S.N and O’Sullivan D.T.J. ―Freecooling thermal energy storage using phase change materials in an evaporative cooling system‖. Applied Thermal Engineering (2013) 59, 618-626. [4]. Karthikeyan. S, R. Velraj, ―Numerical investigation of packed bed storage unitfilled with PCM encapsulated spherical containerse - A comparison between various mathematical models‖.International Journal of Thermal Sciences (2012) 60 153-160 http://www.ijettjournal.org Page 112 International Journal of Engineering Trends and Technology (IJETT) – Volume 34 Number 3- April 2016 [5]. Stritih U andButala V. ―Energy saving in building with PCM cold storage‖. International Journal of Energy Research(2007) 31, 1532–44. [6]. Antony Aroul Raj, V., and Velraj, R., ―Review on free cooling of buildings using phase change materials‖. Renewable and Sustainable Energy Review,(2010), 14, 2819–2829 [7]. AdeelWaqas., and ZiaUdDin. ―Phase change material (PCM) storage for free cooling of buildings —A review‖. Renewable and Sustainable Energy Reviews, (2013), 18, 607–625 [8]. SaeedKamali. ―Review of free cooling system using phase change material for building‖ Energy and Buildings (2014), 80, 131–136 [9]. Ruben Baetensa., BjørnPetterJelle., and ArildGustavsen., ―Phase change materials for building applications: A state-of-the-art review‖. Energy and Buildings, (2010), 42, 1361–1368 [10]. Cabeza, L.F., Castell, A., Barrenechea, C., de Graciaa, A., and Fernándezb, A.I. ―Materials used as PCM in thermal energy storage in buildings: A review‖. Renewable and Sustainable Energy Reviews, (2011), 15, 1675–1695 [11]. Parfait Tatsidjodoung, NolwennLePierres., and LingaiLuo., ―A review of potential materials for thermal energy storage in building applications‖. Renewable and Sustainable Energy Reviews,(2013), 18, 327–349 [12]. Ling T.C., and Poon C.S. ―Use of phase change materials for thermal energy storage in concrete: An overview‖. Construction and Building Materials, [1] (2013), 46, 55- 62 ISSN: 2231-5381 [13]. Thambidurai M., Karthik P., Krishna Mohan N., Velraj R. ―Review on Phase Change Material based free cooling of buildings-The way towards sustainability‖. Journal of Energy Storage, (2015), 4, 74-88. [14]. Arkar, C., and Medved, S. ―Free cooling of a building using PCM heat storage integrated into the ventilation system‖. Solar Energy, (2008), 1, 1078–87. [15]. Rajagopal M, Solomon R.G, Jayasudha K and Velraj, R. ―Free cooling potential and technology options for thermal energy management of a commercial building in Bangalore city, India‖ Energy Engineering: Journal of the Association of Energy Engineers, (2014) 111, 11-24. [16]. Thambidurai M, Krishnamohan N, Rajagopal M, and Velraj. R.―Free cooling feasibility of a typical commercial building in Pune city, India‖. International Journal of Applied Engineering Research, (2015), 10, 4419-4435. [17]. S. Karthikeyan, V. Balasubramanian, R. Rajendran, Developing empirical relationships to estimate porosity and Young’s modulus of plasma-sprayed YSZ coatings, Applied surface science 296 (2014) 31– 46. [18]. V.Sukumar, S.Sivaprakasam and V.Manieniyan,‖ Optimization Studies on Bio Oil Production from sweet lime Empty Fruit Bunch by Pyrolysis Using Response Surface Methodology, International Journal of Engineering Trends and Technology (IJETT) –25 (2015) 196-201. http://www.ijettjournal.org Page 113