Air Handling Unit using Programmable Logic Controller Pooja C. Oswal

advertisement

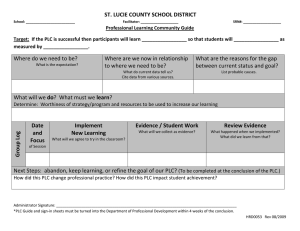

International Journal of Engineering Trends and Technology (IJETT) – Volume 33 Number 7- March 2016 Air Handling Unit using Programmable Logic Controller Pooja C. Oswal#1, Shweta A. Raut#2, Supriya V. Shirke#3,Prof.R. A.Jain#4 # Department of Electronics and Telecommunication engineering Sinhgad Academy of Engineering, Kondhwa Bk, Pune 411048, India Abstract—In this paper programmable logic controller (PLC) is designed to develop an Air Handling Unit (AHU). The main scope of AHU is to maintain the air flow in mall or a building. The aim is to conserve electrical energy by utilizing the available energy in an efficient manner which would reduce electricity bills. In this system, sensing devices are used to sense the number of people inside the mall and accordingly AHU fans are controlled by the control unit. A supervisory control and data acquisition (SCADA) screen is designed to monitor, supervise and acquiesces the process data in AHU. fire, the exhaust fan will suck out the smoke n hot air outside the mall and buzzer will alert the people. During such emergencies LED strip will direct the people. Keywords—AHU (Air Handling Unit), PLC (Programmable Logic Controller), SCADA (Supervisory Control and Data Acquisition) I. INTRODUCTION Use of microcontroller or microprocessor in building AHU is complex. So by using PLC, programmer can easily build any complicated application with many inputs as well as many outputs. AHU used in malls is manually operated which consumes lot of energy which leads to high electricity bills. So by designing a system using PLC will reduce power consumption as well as electricity bills.In this system sensing devices are used to sense no. of people inside the mall according to which AHU fans will be controlled. In case of fire, AHU using PLC can handle the situation by turning OFF all AHU fans and by turning ON exhaust fan. II. PROJECT OVERVIEW Air handling unit for proper control of air flow system will be using PLC, SMPS, AHU fans, exhaust fan, backup fan, sensors, buzzer, LED strips, ducts and battery. The controller PLC will be getting the input from sensors to control all the outputs of system including AHU fans, backup fan, exhaust fan, buzzer and LED strip. Ducts will distribute the air thus regulating the air flow inside the mall. Sensor at the entrance will sense the numberof people entering the mall and sensor at the exit will sense the people leaving the mall. In case if power supply cuts off battery will provide supply to backup fan. In case of ISSN: 2231-5381 Fig.1:Overview of system III. HOW IT WORKS In AHU, diffusion sensor at the entrance will sense people entering the mall. The counter will increment on each entry. This input will be provided to PLC as a parameter. This parameter will be processed and manipulated by PLC according to logic implemented. PLC will give signals to AHU fans and thus AHU fans will operate. Diffusion sensor at exit will sense people leaving the mall and accordingly counter will decrement. The processing would be done by PLC as per the program downloaded in PLC. As a result, switching OFF of fans will take place. At the time of fire, all AHU fans will switch off and exhaust fan will turn ON automatically. Also, a buzzer will produce sound in order to alert the people inside the mall. If power supply cuts off, backup fan will take supply from battery and it will operate thus avoiding suffocation inside the mall. LED strip will direct the people in order to avoid chaos. http://www.ijettjournal.org Page 320 International Journal of Engineering Trends and Technology (IJETT) – Volume 33 Number 7- March 2016 16. If power supply turns off, all AHU fans will be turned off. Back up ventilator which is battery operated will turn ON. IV. SOFTWARE TOOLS AND SPECIFICATIONS In this project, two softwares of ABB Company are used which are easy to understand and good for simulation work. These softwaressupport programming languages which provides flexibility to programmer to program in any desired language. They are: 1. Fig.2:Our entire system Control builder plus Control builder plus 2.3.0 based on CoDeSys Automation platform by 3S- Smart Software solution Gmbh. Release build 339 Active version profile CBP 2.3.0 2. CoDeSys (Controlled Development System) Fig.3:Flow of project Algorithm for Air Handling Unit using PLC 1. Start Controlled Development System provides development environment for PLC which supports IEC standard and additional online functions such as setting program variable, inputs and outputs at certain values and flow control. 2. Entry sensor detects person at entrance. 3. Counter is incremented. 4. PLC gets the signal from the counter. 5. AHU fans turns ON automatically. 6. This is monitored on the SCADA screen. 7. If no. of people inside mall <=3 then 1 AHU fans will turn ON. 8If no. of people inside mall <=6 and greater than 3 then 2 AHU fans will turn ON. 9. If no. of people inside mall <=10 and greater than 6 then 3 AHU fans will turn ON. So on…. Fig 4: SCADA model screen design 10. Exit sensor will detect the person at the exit. 11. Counter is decremented. 12. PLC gets the signal. 13. AHU fans turns off automatically depending on the person inside the mall. 14. This is monitored on SCADA screen. 15. If fire gets detected PLC get signal shown on SCADA screen. Turn off the button to turn off all AHU fans. ISSN: 2231-5381 Fig 5:shows number of fans ON and number of people inside http://www.ijettjournal.org Page 321 International Journal of Engineering Trends and Technology (IJETT) – Volume 33 Number 7- March 2016 AHU using PLC utilizes energy efficiently as compared to manually controlled AHU system in which there is lot of consumption of energy. AHU system also provides safety in case of fire situation. VII. FUTURE SCOPE As in this project energy is being utilized efficiently so it can be effectively implemented for any realworld application like in buildings, malls, offices. In case of fire sprinkler can be used to control fire .Using same PLC with extension module of inputs and outputs it is possible to implement another application like automatic street light control in parking which can be used in mall along with AHU. Fig 6: shows counter value and time duration foe each fan V. PROGRAMABLE LOGIC CONTROLLER USED PLC used in this project is PM554 TP ETH which is powerful compact and cost effective. This PLC uses Ethernet protocol to download program in to PLC. Expansion of system is possible because of its modular design includes wide range of modules. PM554 TP ETH consists of 8 inputs and 6 outputs and memory unit of 128 KB flash EEPROM and control processing unit. Interfacing of PLC to the real world is done by I/O unit. I/O parameters are given to PLC as an input from real world. Inputs from real world are manipulated based on logic implemented by programmer. All operations such as logic control, data transfer and manipulation are done by central processing unit of PLC. Depending upon the requirement of number of inputs and outputs, power requirement and type of application, PLC and CPU range is selected. Factors like air quality, ratio of CO2 in air, concentration of oxygen, temperature and humidity can be easily measured from safety point of view by using different sensors. VIII. [1] [2] [3] [4] REFERENCES About control builder plus 2.3.0 and CoDeSys online help from ABB. “Programmable Logic Controller, programming methods and applications” by John R. Hackworth and Frederick D. Hackworth, Jr. “Programmable Logic Controller, principles and applications” by John W. Webb and Ronald A. Reis, fifth edition Automated Air Handling Unit system using SCADA with PLC; International Journal of Ethics in Engineering and Management Education, Volume !, Issue 4, April 2014. VI. CONCLUSION This project concludes that, Air Handling Unit Using Programmable logic Controller with SCADA monitoring is effective solution over manually controlled AHU system .This system would be easily controlled by SCADA screen. AHU using PLC provides many advantages over microcontroller such as availability of large number of inputs and outputs. This system is more stable than the one which has been build using microcontroller.PLC also provides direct inter-operatabilityto industrial devices. Cost required for its maintenance is less as compared to microcontroller.Inputs and Outputs of PLC can be easily extended which is not possible with any microcontroller. Most of the industrial applications can bebuilt by using PLC because it is mini CPU as it has its own O.S., microcontroller and microprocessor. ISSN: 2231-5381 http://www.ijettjournal.org Page 322