Document 12915628

advertisement

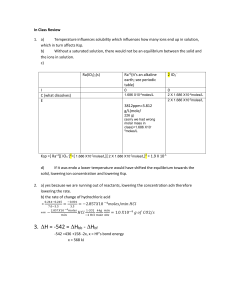

International Journal of Engineering Trends and Technology (IJETT) – Volume 28 Number 8 - October 2015 Control of Response at Payload Base using Isolation System for a Typical Launch Vehicle with Strap-On-Boosters Jiji Jolly#1, Rajesh A.K*2 # * M tech student, Ilahia college of Engineering and Technology Asst. Prof. Ilahia college of Engineering and Technology Abstract: Large solid motors are found to produce oscillations in chamber pressure resulting in thrust fluctuations during their operation. If the frequency of these oscillations matches with any of the longitudinal/lateral modes of the launch vehicle, then large responses are possible on the launch vehicle and at satellites. Generally isolation systems are designed as solution to such problems. The magnitude of response depends on the amplitude of thrust oscillation .Dynamic response studies are carried out with finite element model of the launch vehicle. Analysis is also carried out by incorporating an isolation system at the strap-on core attachment location and the results are compared with that of non-isolation system which shows the effectiveness of the isolation system. The pressure and thrust data obtained from static firing test of solid motor are analysed for characterizing the input excitation for the dynamic response studies. From this study, frequency and the amplitude of the thrust oscillation was obtained. This study shows that the acceleration responses at satellite locations with and without isolation system. Keywords: LV (Launch Vehicle), SC (Space craft), Thrust, Pressure, Oscillation, Acceleration, Frequency . I. INTRODUCTION Satellites are perhaps among the most amazing products in use today, used for many purposes from communications to reconnaissance to weather prediction, and much more. Excessive dynamic and shock loads during ascent can be a satellite killer causing permanent damage to electronics, optics, and other sensitive equipment. In order for the spacecraft to survive a trip to orbit, one of two choices must be made: (1) design all structure, payloads, and systems on the spacecraft to be strong enough to survive the high launch loads, or (2) reduce the magnitude of the high launch loads. The former is not a good choice because it typically requires additional cost, schedule, and weight. The latter is the preferred choice, launch dynamic loads can be reduced through the use of vibration isolation. The goal of a vibration isolation system is to reduce the dynamic loads on a payload by reducing the transmission of dynamic loads to the payload. Whole-spacecraft vibration isolation systems significantly reduce the dynamic loads in both the low frequency range (coupled loads analysis range) and in the high frequency range (shock loading range). The isolation system explained in above literature review has some limitations. The above papers explain the isolation system which is provided on top of the launching vehicle. This only protects the parts above the isolation system. But in my study we are giving isolation system on the connecting element between strap on boosters and the core. It will protect all the sensitive packages in ISSN: 2231-5381 the core vehicle from the thrust oscillation of the strap-on-boosters. II. DETAILS OF THE STRUCTURE In present study, a typical launching vehicle is considered. The total height of the launching vehicle is approximately 54 m. It consists of two solid boosters which having the height of 27.5 m. The diameter of the solid boosters is 3 m and the diameter of the core is 3.8m at the bottom and 4.8 m at the top. The material used for core is aluminium and for solid booster is steel. Stiffeners are provided at the inter stages and also ring stiffeners are provided on both of the solid boosters at an interval of 5 m. Rods are used for the connection between core and solid boosters. The weight of the solid booster is 230T and weight of the liquid in the four tanks is 150 T, 100 T, 30 T and 20 T respectively. The layout of the launching vehicle is shown in Figure 1. http://www.ijettjournal.org Page 392 International Journal of Engineering Trends and Technology (IJETT) – Volume 28 Number 8 - October 2015 Fig 2: Isometric view of a launch vehicle III. NORMAL MODE ANALYSIS There are many reasons to compute the natural frequencies and mode shapes of a structure. One reason is to assess the dynamic interaction between a component and its supporting structure. The mode shapes of the launch vehicle obtained from normal mode analysis are as shown in Figure 3. These results characterize the basic dynamic behavior of the structure and are an indication of how the structure will respond to dynamic loading. Each mode shape is associated with a specific natural frequency. Table 1 shows the mode number and frequency from Normal Mode Analysis of the launch vehicle. Fig 1: Layout of the launch vehicle Table I Mode Number and Frequency from Normal Mode The launching vehicle was modelled with the help of the software MSC.Patran. The geometry of the structure was modelled as shown in Figure 2. Points and curves were used to create the geometry of the structure. Once the geometry of the structure was created, finite element descritization was done followed by meshing. Once the model was generated, material of the structural elements was assigned. The material used for core is aluminium and for solid boosters are steel. Rods were used for the connection between core and solid boosters. The diameter of the rod was 0.040 m. Ring stiffeners were provided on solid boosters as well as the core and straight stiffeners were provided at inter stages. Ring stiffeners were provided as channel sections and straight stiffeners were provided as hat sections. ISSN: 2231-5381 Analysis Mode numbers Frequency (Hz) 1 2.16 2 2.64 3 3.05 4 4.02 5 4.65 6 4.70 7 5.60 8 6.18 9 6.53 10 7.33 http://www.ijettjournal.org Page 393 International Journal of Engineering Trends and Technology (IJETT) – Volume 28 Number 8 - October 2015 IV. MODELING OF ISOLATION SYSTEM In present study, Steel laminated rubber bearings are used to protect sensitive electronic packages from deleterious effects of vibration during flight. Steel rubber is known for its very good damping and isolation characteristics. Steel rubber laminates could be easily compounded to give a high value of hysterics damping. It exhibits little change in transmissibility and resonant frequency. The isolator is modelled using Bush element (CBUSH).The bush element was introduced at the connecting element between solid boosters and core. Initially they are connected by using beam sections. This beam section was replaced by the isolator. The isolator is designed based on the excitation frequency. The excitation frequency is from 20 Hz to 30 Hz. The force applied was unit force at the base of the strap on boosters. Isolator performs best when the excitation frequency is greater than .Where is the excited frequency. Stiffness of the isolator is determined by the equation, (1) Mode Shape 1 Mode Shape 2 In this study, the isolator was designed for of the first excitation frequency,20 Hz(125.78 rad/sec).Mass of the solid boosters is 230 T. Stiffness of the isolator, k = 8.0 *107 N/ m. V. FREQUENCY RESPONSE ANALYSIS Frequency response analysis is a method used to compute structural response to steady state oscillatory excitation. In frequency response analysis the excitation is explicitly defined in the frequency domain. All of the applied forces are known at each forcing frequency. Forces can be in the form of applied forces and/or enforced motions. The important results obtained from a frequency response analysis usually include the displacements, velocities, and accelerations of grid points as well as the forces and stresses of elements. Frequency response analysis was carried out for different cases. The different cases were For 230T solid boosters with unit force. For 100 T solid boosters with unit force. For actual force (30 T) at the time of ignition. Mode Shape 3 Mode Shape 4 Fig 3: Various Mode Shapes ISSN: 2231-5381 All the above conditions were checked with isolation system .First two cases were done for finding the effective stiffness of the isolator. At the first stage of the trip, solid boosters was with a weight of 230 T, so the first condition was checked and found the reduction in the amplitude. At the second stage the weight of the solid boosters was reduced to 100 T, so the second case was http://www.ijettjournal.org Page 394 International Journal of Engineering Trends and Technology (IJETT) – Volume 28 Number 8 - October 2015 considered and evaluates the results. According to this reduction in amplitude, the effective stiffness of the isolator can be found out. VI. RESULTS AND DICUSSIONS The structure is analyzed in MSC. Nastran 2012 to find out the displacement and acceleration response after introducing the isolation system .The structure was analyzed with different conditions. After the Normal mode analysis, next step is Frequency response analysis In this study, the Frequency Response analysis was carried out to compute the structural response under thrust oscillation. The response was taken at the node 56633; the node having the satellite weight is concentrated. The variation in the acceleration without and with the isolation system is explained by using graphs. The excitation frequency was taken around the range of 20H z to 30 Hz. For each point the corresponding acceleration frequency response was found out. The maximum acceleration occurred at 24.6Hz.The amount of reduction in the acceleration in 20 Hz was about 59 %.So by using isolation system, the acceleration in each point can be reduced. CASE II For 100 T solid boosters with unit force CASE I For 230T solid boosters with unit force Acceleration-Frequency response for 100 T without isolator Acceleration-Frequency response without isolator Acceleration-Frequency response for 100 T with isolator Some parts of the launch vehicle were dispatched few seconds after ignition. The weight of solid boosters was reduced approximately to 100T. So 100 T condition was checked and there was a large reduction in displacement. So the selected stiffness value is suitable for all conditions. Again it is checked for different damping ratios, while the selected bush having small percentage of damping. Acceleration-Frequency response with isolator ISSN: 2231-5381 http://www.ijettjournal.org Page 395 International Journal of Engineering Trends and Technology (IJETT) – Volume 28 Number 8 - October 2015 CASE III For actual force (30 T) at the time of ignition. Table 2 and Table 3 shows the percentage of reduction of acceleration with and without isolation system. From the above graph we can conclude that by using isolation system on the launch vehicle interface spacecraft, there is a large reduction in the axial vibration of the launch vehicle. Acceleration-Frequency response without isolator Acceleration-Frequency response with isolator ISSN: 2231-5381 http://www.ijettjournal.org Page 396 International Journal of Engineering Trends and Technology (IJETT) – Volume 28 Number 8 - October 2015 Table II Reduction in acceleration without and with isolation system for 230 T Solid boosters with unit force Sl No: Acceleration without Acceleration with isolator Frequency (Hz) isolator (m/s2) (m/s2) Reduction in % 1 20 5.15*10-5 2.11*10-5 59.02 2 20.5 5.13*10-5 2.24*10-5 56.33 3 21 5.23*10-5 2.44*10-5 53.33 4 21.5 5.49*10-5 2.70*10-5 50.81 5 22 5.97*10-5 3.10*10-5 48.07 6 22.5 6.79*10-5 3.73*10-5 45.06 7 23 8.21*10-5 4.76*10-5 42.02 8 23. 5 1.09*10-4 6.79*10-5 37.70 9 24 1.77*10-4 1.21*10-4 31.63 10 24.5 4.05*10-4 2.82*10-4 30.37 11 25 2.23*10-4 1.29*10-4 42.15 12 25.5 1.05*10-4 7.003*10-5 33.30 13 26 7.16*10-5 5.27*10-5 26.39 14 26.5 5.02*10-5 4.17*10-5 16.93 15 27 3.84*10-5 3.67*10-5 4.42 16 27.5 3.4*10-5 3.10*10-5 8.82 17 28 3.8*10-5 2.64*10-5 30.59 18 28.5 4.71*10-5 2.28*10-5 51.59 19 29 7.53*10-5 2.05*10-5 72.77 20 29.5 1.92*10-5 1.09*10-4 43.22 21 30 4.58*10-5 1.96*10-5 57.20 ISSN: 2231-5381 http://www.ijettjournal.org Page 397 International Journal of Engineering Trends and Technology (IJETT) – Volume 28 Number 8 - October 2015 Table III Reduction in acceleration without and with isolation system for 30 T force Sl No: Acceleration without Acceleration with isolator Frequency (Hz) isolator (m/s ) (m/s2) Reduction in % 1 20 1.55 0.634 59.03 2 20.5 1.54 0.674 56.13 3 21 1.56 0.732 54 4 21.5 1.64 0.812 50.4 5 22 1.79 0.932 47.93 6 22.5 2.03 1.11 45.32 7 23 2.46 1.42 42.27 8 23.5 3.28 2.03 38.10 9 24 5.31 3.63 31.6 10 24.5 12.15 8.46 30.37 11 25 6.70 3.89 41.94 12 25.5 3.15 2.10 33.33 13 26 2.15 1.58 26.51 14 26.5 1.50 1.25 16.67 15 27 1.15 1.10 4.34 16 27.5 0.931 0.910 2.25 17 28 0.784 0.656 16.32 18 28.5 0.684 0.601 12.13 19 29 0.617 0.587 4.86 20 29.5 0.577 0.506 12.3 21 30 0.563 0.499 11.4 ISSN: 2231-5381 2 http://www.ijettjournal.org Page 398 International Journal of Engineering Trends and Technology (IJETT) – Volume X Issue Y- Month 2015 VII. CONCLUSIONS Application of the isolation system is one of the most effective used in launch vehicle for controlling the dynamic response. From this analytical study of a launch vehicle whose natural frequency is around 2.16 Hz. It was observed that The thrust oscillation produced by at the time of ignition was very significant without damper. From the analytical study it was observed that the isolation system reduces the response by about 59 % for unit application of force. With original force of 30 T, the acceleration of launch vehicle without isolation system is 10.29 m/s2 and the acceleration of launch vehicle with isolation system is 8.96 m/s2.so the reduction is 12.96%. By providing isolation system, the response is obtained as 8.96 m/s2 at 24.5 Hz ,that is the acceleration is reduced below 1g m/s2 (10 m/s2). There by we can protect all the sensitive packages in the core vehicle from the thrust oscillation of the strap-on-boosters. spacecraft.launch vehicle”, Smart structure and Material passive damping and isolation Newport Beach C A March 2000. [7] Paul S. Wilke, Kenneth R. Darling;”Whole-spacecraft vibration isolation flown on the launch vehicle”, Aerospace Mechanisms Symposium, Langley Research Center, Sepember 12-18,2009. ACKNOWLEDGEMENT I would like to express my heartfelt gratitude to Mr. Rajesh A K, my faculty guide, Assistant Professor, Department of Civil Engineering, Ilahia College of Engineering and Technology, Muvattupuzha for providing his valuable suggestions during my research. REFERENCES [1 Conor D. Johnson† and Paul S. Wilke;” Protecting , satellites from the Dynamics of the Launch environment,Proceeding of the38”Aerospace Mechanisms symposium, Langely Reasearch Center, May 17-19,2006 [2] Conor D. Johnson and Paul S. Wilke” Vibration control of Satellites from the dynamics of the Launch Environment” ” Smart structure and Materials passive Damping and isolation Newport Beach A ,December 2004. [3] Joseph R. Maly, Paul S. Wilke, Emily C. Fowler “EELV Secondary Payload Adapter with Whole -Spacecraft Isolation For Primary and Secondary Payloads”, Smart structures and Materials passive Damping and isolation Newport Beach,C A March 2000. [4] Kenneth RDarling and Conor D Johnson,”Vibration control of flexible Satellites using a new isolator”, Aerospace Mechanisms symposium, Langely Reasearch Center, August 04-09,2007. [5] Megahed S.M and A.K.H. Abdel-Razik “Vibration control of two degrees of freedom system using variable inertia vibration absorbers”; Department of Military Technical Academy,June 6-19,2011. [6] Patrick J. Grosserode and Dino Sciulli “Passive axial vibration isolation system for a system for a ISSN: 2231-5381 http://www.ijettjournal.org Page 399