í ' ^ 4 í 5

advertisement

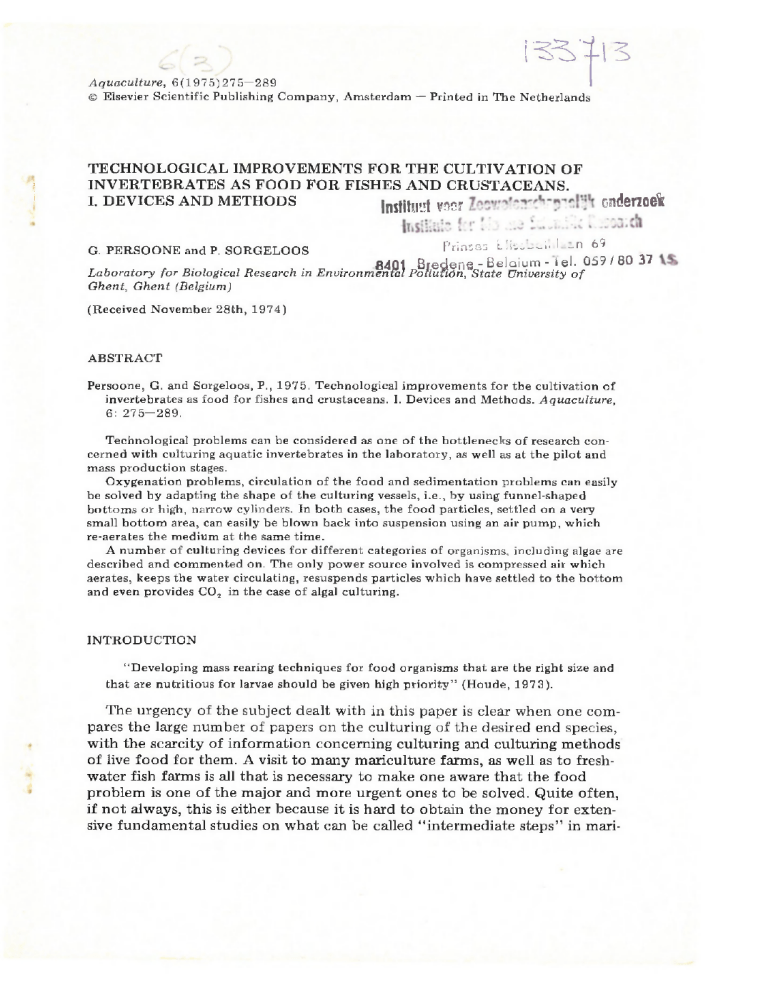

í ' ^ 4 í 5 A q u a c u ltu re , 6 ( 1 9 7 5 ) 2 7 5 - 2 8 9 © E lsevier S c ie n tific P ublishing C o m p an y , A m ste rd am — P rin te d in T h e N eth e rla n d s TECHNOLOGICAL IMPROVEMENTS FO R THE CULTIVATION OF INVERTEBRATES AS FOOD FO R FISHES AND CRUSTACEANS, i. d e v i c e s a n d m e t h o d s Instituât vssr G. P E R S O O N E a n d P. S O R G E L O O S Prlnsss 8401 B red e n s - L!í í j - - ¡ - l-~ n B eloium cnderzoe% 69 - i el. 0 5 9 / 8 0 L a b o ra to ry fo r B iological R esearch in E n v iro n m e n ta l P otluFiôn,'S ta te U niversity o f G h en t, G h e n t (B elg iu m ) (R eceiv ed N o v em b er 2 8 th , 1 9 7 4 ) A BSTRA CT P e rso o n e, G. an d S orgeloos, P., 1 9 7 5 . T ech n o lo g ic al im p ro v e m e n ts fo r th e c u ltiv a tio n o f in v e rte b ra te s as fo o d fo r fishes a n d cru sta c e an s. I. D evices a n d M eth o d s. A q u a c u ltu re , 6: 275—289. T ech n o lo g ical p ro b lem s can be c o n sid ered as one o f th e b o ttle n e c k s o f re se a rc h c o n ­ c e rn e d w ith cu ltu rin g a q u a tic in v e rte b ra te s in th e la b o ra to ry , as w ell as a t th e p ilo t and m ass p ro d u c tio n stages. O x y g e n a tio n p ro b le m s, c irc u la tio n o f th e fo o d an d se d im e n ta tio n p ro b le m s can easily be solved b y ad ap tin g th e sh ap e o f th e c u ltu rin g vessels, i.e ., b y using fu n n el-sh ap ed b o tto m s o r high, n arro w cy lin d ers. In b o th cases, th e fo o d p a rtic les, se ttle d o n a very sm all b o tto m area , can easily be b lo w n b a c k in to su sp e n sio n using an a ir p u m p , w h ich re -a e ra te s th e m ed iu m a t th e sam e tim e. A n u m b e r o f cu ltu rin g devices fo r d iffe re n t c ateg o ries o f organism s, in clu d in g algae are d esc rib e d a n d c o m m e n te d on. T h e o n ly p o w e r so u rc e involved is co m p re sse d air w h ich ae ra te s, k eep s th e w ater c ircu latin g , re s u sp en d s p a rtic le s w h ich have s e ttle d to th e b o tto m a n d even p ro v id es C 0 2 in th e case o f algal cu ltu rin g . IN T R O D U C T IO N “ D evelopin g m ass rearin g te c h n iq u e s fo r fo o d org an ism s th a t are th e rig h t size and t h a t are n u tritio u s fo r larvae sh o u ld be given high p r io r ity ” (H o u d e , 1 9 7 3 ). The urgency of the subject dealt with in this paper is clear when one com ­ pares the large num ber of papers on the culturing of th e desired end species, w ith the scarcity of inform ation concerning culturing and culturing m ethods o f live fo o d for them . A visit to m any m ariculture farm s, as well as to fresh­ w ater fish farm s is all th a t is necessary to m ake one aware th a t the food problem is one o f the m ajor and m ore urgent ones to be solved. Q uite often, if n o t always, this is either because it is hard to obtain the m oney for exten­ sive fundam ental studies on w hat can be called “interm ediate steps” in mari- 37 276 culture, or th a t scientists are unwilling to spend m uch tim e or e ffo rt in solving these apparently “secondary” problem s. Failure or difficulties in culturing these live food species is n o t even re­ stricted to the field of “applied sciences” . Indeed, in 1969, in the opening address o f th e International Sym posium on “ Cultivation of Marine Orga­ nisms and its Im portance for Marine Biology” Kinne (1970) pointed o u t th a t less th an 2% of all known m arine organisms could be reared throu g h o u t their whole life cycle under controlled conditions, w hich of course results in “ a severe bottleneck in th e flow of inform ation on life in the seas” . In our opinion, b o th fundam ental culture research in laboratories and extrapolation of the results to mass culturing, are slowed down by a lack of suitable tech ­ niques. Too m any scientists are still using conventional item s such as beakers, flasks or aquaria, as the only culturing equipm ent in th eir experim ents. They will invariably be confronted w ith three o f th e m ajor difficulties in keeping organisms alive in a laboratory: (a) oxygenation problem s; (b) circulation of the food; (c) sedim entation problem s. We have been trying to overcome these problem s in our laboratory for years, so we decided to adapt the shape of our culturing vessels to alleviate the aeration, circulation and suspension prob­ lems, instead of trying to solve them in conventional culturing jars, w ith the help o f elaborate or cum bersom e air-supplying or pum ping devices. With very few exceptions, all our culturing vessels have either funnelshaped bo tto m s o r are high, narrow cylinders, both o f which have a very small base area from which the sedim entated food particles are easily “ blown back” into suspension by airbubbling. A num ber o f key rules should, in our opinion, always be observed in the elaboration of new devices or new research techniques on prom ising species: (1) To oxygenate the m edium w ith o u t disturbing the animals. (2) To keep the food in suspension so as to insure its optim um availability to the cultured species and to avoid sedim entation w ith subsequent bacterial developm ent. (3) To try to avoid com plex (usually expensive) systems in which one of the num erous com ponents m ay fail a t any m om ent. (4) To autom ate the technique as m uch as possible to reduce labour. (5) To use, whenever possible, in ert sources o f food to m inimize the num ber o f living links necessary to culture the desired species. (6) To avoid laboratory system s and techniques which are clearly impossi­ ble to adapt to mass culturing purposes. The application of these rules in o u r laboratory has led to the develop­ m en t o f a certain num ber o f devices and techniques. These we shall describe briefly together w ith some results. A L G A L C U L T U R IN G A lthough we have em phasized in “ key rule 5 ” th a t one should avoid the 277 use o f live food as m uch as possible in culturing invertebrates, we partly agree w ith T aub (1971) th a t presently algal cultures provide the only practical m ethod o f mass feeding aquatic filter-feeders” . T aub describes briefly the advantages of living algae as food b u t also points o u t th a t there are many disadvantages, am ong which is the need to culture large num bers of algae sim ultaneously w ith th e filter feeders, if possible in the same facility or cer­ tainly near by. She emphasizes th a t there is always a risk o f failure, m ore frequently due to m echanical causes th an to biological ones. F o r certain filter feeders, however, (e.g., crustaceans, Brown, 1972; Sorgeloos, 1974) it has been proved th a t th ey can be successfully fed on frozen or dried algae; and this certainly solves a num ber o f practical culturing problem s. O n the oth er hand, o th er larval organisms (e.g., m ollusks) can only be reared on a diet of suitable live food. Before discussing mass culture, we should like to m ention briefly two small-scale culturing vessels which we use regularly; the first for fundam ental studies (n u tritio n al requirem ents or bioassays) on algae, and the second for culturing high density stocks (prior to mass cultures in large volumes). The first device (F ig .l), a m odification of the small tube w ith a sealed-in aeration tu b e m entioned by V enkataram an (1969), is simply a glass cylinder w ith a long funnel-shaped b ottom , closed a t the to p by a ru b b er stopper with tw o holes. Through one o f these holes, a small glass tube extends to the b o tto m o f the cylinder; the outside end o f this aeration tube is connected w ith an air supply, th e inside end a t the very b o tto m o f th e tu b e tapers to a capillary. C onstant bubbling of air into this culturing vessel keeps the algal cells in suspension, provides them w ith the necessary C 0 2 and insures a co n stan t c o n ta c t w ith the nutrients. The advantages o f this system over th at described by V enkataram an are the following: (1) Because th e tube has an oblong funnel shape at the b o tto m , the air bubbling resuspends the algae m ore effectively. (2) The independent air tube can easily be rem oved, cleaned, renew ed and replaced. The second device (Fig.2) is a classical glass serum b o ttle used daily in hospitals. I t is hung upside dow n, w ith th eir norm al iron wire clamps, in fro n t o f a bench of fluorescent tubes. A ir is bubbled through a small piece of glass tu b e, fitting into the rubber stopper. The continuous supply of air from th e b o tto m provides exactly the same advantages as in th e culturing cylinder described above. It is sim ple to sample small aliquots from these bottles while th ey are still hanging, by inserting th e needle o f a syringe through the ru b b er stopper and w ithdraw ing the desired volume; it is easier still to slightly incline the hanging b o ttle u n til the outlet tu b e is subm erged. The pressure inside due to th e air being pum ped in, will enable th e suspension to flow dow n th e air o u tle t tube, from w hich it can be collected. It is w o rth m entioning th a t for several reasons, we do n o t w ork axenically even in th e small 100 m l cylinders: 278 AIR OUTLET i AIR INLET iflet F ig .l. 100-m l algal cu ltu rin g tu b e . F ig .2. G lass-serum b o ttle as u sed fo r c u ltu rin g algae. (1) As long as the algae are in the exponential phase of grow th, the num ber of bacteria remains quite low. We have n o t y e t had any serious contam i­ nation or toxicological problem s caused by this accom panying m icro­ flora. (2) Even when starting w ith axenic cultures, it is alm ost impossible, or at least very expensive and cum bersom e, to take the necessary precautions to mass culture the algae in large volum es w ithout bacterial contam ina­ tion. We never enrich the supplied air w ith e x tra C 0 2 as m any researchers do. Experience has shown th a t even w ith o u t this enrichm ent, algal grow th is very fast and apparently n o t ham pered by lack of C 0 2. Moreover, in high density cultures, photosynthesis seems to be lim ited m ore by the high optical density o f the culture than by an insufficient supply of C 0 2. The following species are regularly and successfully cultured in th e tw o described devices: Phaeodactylum tricornutum , Dunaliella viridis, N anno­ chloris oculata, Tetraselmis suecica and C hlam ydom onas coccoides. Species 279 such as M onochrysis lutheri, Isochrysis galbana and Thalassiosira pseudonana could also be cultured quite easily. However, i t always appeared th a t, al­ though th e food value of the latter was excellent, it was m uch m ore difficult to culture it regularly in large quantities w ith o u t taking special care because the cultures are easily contam inated, either by other, less sensitive algae, by bacteria or protozoa. The vats (Fig.3) w hich we use for mass culturing purposes are transparent, very thin (0.2 mm) polyethylene cylinders w ith an inner diam eter of approx­ im ately 15 cm and 2 m deep. The extrem ities o f th e plastic sheet are clamped to tw o sh o rt PVC cylinders o f 1 cm thickness, the to p one o f w hich is open and the b o tto m one closed w ith a w aterproof PVC b o tto m . The culturing cylinder, w ith a volume of 30 1, is m ounted vertically in a m etal fram e which bears tw o, three or fo u r fluorescent tubes placed vertically a t a distance of a b o u t 10 cm from the cylinder. A eration is provided as usual, from the b o t­ tom . The system can be drained w ith a stopcock also m ounted in the PVC b o tto m su p p o rt. These 30 1 culturing colum ns can be considered as an enlarged b u t extrem ely cheap version o f the “ Algen K ultur R o h re ” used by Von W itsch (1970) and co-workers in Germ any for the cultivation of freshPVC jupport A hcet F ig .3. 30-1 c y lin d e rs fo r m ass c u ltu rin g o f algae. 280 w ater algae. The disadvantage of the Algen K u ltu r R ohre, however, is th a t they are m ade o f glass or transparent plastic m aterial several m m th ick (for exam ple, Perspex), both of which are very expensive w hen com pared to the few cents th a t the polyethylene sheets cost. The advantages of vertical culturing colum ns com pared to classical algal tanks w ith flat bottom s are quite num erous: (1) No sedim entation of the algae. (2) Steady circulation o f the nutrients th ro u g h o u t th e entire colum n and a continuous supply of C 0 2 present in the air. (3) Much higher densities of algae than in conventional system s. A lthough the intense green colour of the algal cultures w ould norm ally slow dow n the photosynthesis considerably beyond a certain optical density due to lack o f light, th e steady m ovem ent of the algae by the air bub­ bling and the small diam eter of the cylindrical culturing vessel insure a regular exposure to the lights closely surrounding the system. (4) T hrough its vertical construction, th e culturing colum n takes up little space (only 30 by 30 cm ), as com pared to conventional system s which are m ostly placed horizontally. Last b u t n o t least, as has already been m entioned, the plastic sheets are n o t only very inexpensive b u t their replacem ent (m aintenance) is very cheap, simple and quick. A lthough we are quite aware of the fact th a t there are m any suitable species w hich could be mass cultured in such 30 1 colum ns, till now we have used th em a few tim es for th e diatom P haeodactylum tricornutum , b u t we daily culture the phytoflagellate Dunaliella viridis, which seems to be one of the easiest algae to mass culture and is at the same tim e an excellent food source fo r m any aquatic herbivores. The diatom Phaeodactylum tricornutum reached a density of 18 X IO6 cells/m l in 14 days, from an initial density of 0.5 X IO6 cells/m l. Cultures o f th e green alga Dunaliella viridis started w ith 0.2 X IO6 cells/m l, attained 4.2 X IO6 cells/m l in a week and 7 X IO6 cells/ ml in 12 days. The culturing m edium , w ith w hich we o b tain excellent results, is a m odi­ fication o f th a t described by Walne (1956). His m edium is m odified by the addition of glycocol, a grow th prom oting am ino acid. Stock Solution F e S 0 4 -7H20 NaH2P 0 4-2H20 N aN 03 MnCl2-4H20 G lycocol Distilled w ater 0.278 g 3 g 30 g 0.47 g 50 g 11 We usually distribute the stock in small quantities which are deep-frozen. The culture m edium is m ade by diluting 1 p a rt of th e stock solution with 100 parts sea water. 281 S’ ÆO S « 5 Z'O u cp .2 > > o «b a ^ « g « + -I 0 O <N >5"3 o co d ° 0C3 ^2 Q Cl­ (M CO o o eo Some results of culturing different species of m onocellular algae in the described devices a; ,Q O z -3 ccöp Û0 « g q-i — 0 iS >i "3 O CO iH ^ -cbu CO = 4 -1 O Öfl . -). C J <L) *+ O M £d T3 o 03 <M LO LO o lo o o o o 03 C Oo 0 3 r—i P cc¡ bD ^ Ö lw— 0b"3 £ P d « 03 0<P dd 0 3 LO tH LO IM O »H OO tH 03 o d O 03 282 Table I gives some data about small-scale culturing of algae in the above m entioned m edium , a t a tem perature of 22—23°C, w ith continuous aeration and w ith the culturing devices placed a b o u t 1 0 cm from tw o 60-w a tt fluo­ rescent tubes. I t should be emphasized, how ever, th a t the described algal m edium , although excellent for mass culturing, does n o t fulfill the nutritional requirem ents o f algae “in the long-run”. We always keep the stocks in a more com plete m edium , nam ely, a m ixture of the m edia described by Schreiber (1927), Walne (1956) and Provasoli et al. (1957). C U L T U R IN G O F IN V E R T E B R A T E S A ND F IS H L A R V A E The best philosophy to start this p art of o u r paper is undoubtedly th a t w ritten by Rice and Williamson (1970) as one o f the summ arizing conclu­ sions of their excellent paper on “ M ethods f o r rearing larval decapod crus­ tacea”. “ ... N o single re arin g te c h n iq u e is su itab le fo r a ll species a n d all situ a tio n s, th e ch o ice o f te c h n iq u e in a n y p a rtic u la r case w ill, th e r e fo re , d ep e n d larg ely o n th e aim in view , w h e th e r i t be ta x o n o m ic , phy sio lo g ical, b e h a v io u ra l, o r c o m m e rc ia l.” It is certainly beyond the scope of this publication, outlining our own culturing techniques, to com pare them in detail w ith o th er existing devices and m ethods, m any of which have proved to be excellent. M oreover, we should like to em phasize th at, although we are using our equipm ent for cul­ turing a restricted num ber o f interesting species or groups of animals, there are m any o th er possible uses for which the equipm ent m ight be interesting or convenient. As the following devices have been constructed for very dif­ ferent purposes, we shall com m ent on each o f them separately, m entioning th a t the only relation betw een them are the first tw o o f our “ key rules” nam ely: aeration and circulation (of the m edium ) which in our system s are always achieved sim ultaneously by using com pressed air. 1. The flow -through colum n (Fig.4) This is an inexpensive laboratory-scale device suitable for culturing all kinds o f organisms either im m otile or m otile b u t non-swimming. I t has proved to be excellent fo r hatching ou t fish eggs and even for high density culturing of ciliates. The system , conceived in 1972 (M ertens and Persoone), simply consists of piled up plastic petri dishes and a collecting—feeding vessel from which a classic air—w ater lifting tu b e raises the m edium to the to p o f th e colum n (Fig.4 B). A fter it has passed through the system the w ater flows back to the collecting vessel (which can be filled w ith sea water, either w ith or w ithout food particles). The peculiarity o f this flow -through colum n is th a t th e petri dishes are assembled in a particular way, i.e., by glueing the bo tto m p a rt on to the lid (Fig.4 A) creating w hat we call a “u n it” . These units can be piled at will, w ith possible rem oval o f each u n it and exam ination under a dissection Fig.4. T h e flo w -th ro u g h co lu m n (fro m M erten s and P e rso o n e , 1 9 7 2 ): A, a single u n it m ade w ith a p e tri dish; B, th e assem b led flo w -th ro u g h co lu m n w ith its piled u n its, reser­ voir and air—w a te r lift. m icroscope w ithout disturbing the organisms in the others. The w ater flow from each unit to the one beneath is insured by a small piece of plastic tubing glued into a hole drilled close to the wall of each unit. When the water has filled a u n it to the level of the overflow tube, it will start to flow into the lower one, the splashing insuring a good re-oxygenation. Placing the units w ith the connecting holes diam etrically opposed gives a gentle w ater current in each petri dish. Although we are n o t w orking w ith decapod larvae, we suppose th a t it could be a useful and space-saving system to cultivate, e.g., cannibalistic species in large versions of such colum ns. Creeping or flowing of the animals from one unit to another can be prevented by covering the overflow tube w ith a gauze of appropriate mesh size. 2. Sim ple culturing vessels fo r pelagic organisms The first culture vessel (Fig.5) is simply a glass cylinder w ith a funnelshaped bo tto m connected to an air—w ater lifting tube which steadily circu­ lates and aerates the m edium . The idea o f keeping the organisms in suspen­ sion in this way came from the well-known fact th a t vigorous air-bubbling in culturing system s (see, e.g., our algal culturing tubes) is deleterious to many 284 organisms, especially larvae (F orster and Wickins, 1967; Greve, 1968; Rice and Williamson, 1970). The slow and gentle rise o f the air bubbles in the air—w ater lift proved, on the contrary, to be harmless. Some algae even seemed to prefer such a circulation cylinder t o th e previously q u oted cul­ turing vessel w ith vigorous air-bubbling (cf p a rt algae). Thalassiosira pseudonana, for exam ple, could be cultured in such a culturing vessel very quickly in high densities, while it could n o t survive in our classical algal cul­ turing tubes. We shall com m ent fu rth er on the types o f organisms for which this device is best suited. The cyclic falling of the organisms in the w ater droplets from the opening of th e air—w ater lift onto the w ater surface is n o t ideal fo r very sensitive species. T herefore, we recently retu rn ed to the original algal cul­ turing cylinder w ith aeration tube (F ig .l) as another possible culturing vessel for small aquatic invertebrates. Instead of providing continuous and vigorous air-bubbling, we decided to try an in term itten t, very gentle flow of air bubbles from the b o tto m , every half hour for a b o u t 15 sec, in order to insure the necessary re-oxygenation of the water, the resuspension o f th e food particles and an even redistribu­ tion of the species in the culturing vessel. These tentative tim e lapses should of course be adjusted to each particular case by trial and error. Very sensitive freshw ater rotifers w ith o u t lorica, such as Epiphanes senta, could be cultured F ig .5. C u ltu re vessel 1 (fro m S o rg elo o s a n d P e rso o n e , 1 9 7 2 ): glass c y lin d e r B w ith aii^w a te r lift A. F ig .6. C u ltu re vessel 2 (fro m S orgeloos a n d P e rso o n e , 1 9 7 2 ): c u ltu re vessel B w ith air—w a te r lift A , rem o v a b le in te rn a l b a sk e t C, w aste d ra in D an d o v erflo w E. 285 in this way in densities o f m ore than 2 5 0 /m l in 100 ml tubes. Experim ents in progress actually reveal th a t this figure can be im proved upon. Moreover, results w ith other organisms such as crustaceans (copepods, cladocerans) indicated th a t the disturbance caused by sh o rt periods o f aeration th a t were n o t to o vigorous did n o t seem to harm th e cultured species. The idea of a cyclic, very sh o rt remixing and aerating of the contents of the culture vessel by air bubbles, has gained our entire attention and is being used more and m ore both in laboratory-scale and mass culturing experim ents. Nevertheless, in some cases, it is possible th a t even in te rm itte n t and gentle air-bubbling can disturb the cultured species either physiologically or ethologically. For these cases culture vessel 2 (Fig.6) is w orth considering. Culture vessel 2 is a broader version o f culture vessel 1 w ith an internal rem ovable cylinder, the b o tto m of which consists of a plankton gauze with a mesh small enough to keep th e cultured species above the screen, b u t suf­ ficiently large to let the food particles pass through. The im provem ent, com ­ pared to culture vessel 1, is th a t the organisms are n o t carried into the air— w ater lift tube, while the m edium (containing the food) is steadily circulated and aerated. Thus the food steadily “ passes the m o u th ” of the cultured ani­ mals, which, according to Shelbourne (in Costlow, 1969) appears to be of crucial im portance for the successful rearing of m any fish larvae. A nother advantage of this system is th a t the internal cylinder can be lifted o u t in one m ovem ent, thus collecting all the organisms on the gauze. As the animals grow, this cylinder can be replaced at will by another one w ith a gauze of larger mesh either to avoid its clogging or to feed the organisms with larger food particles. Last b u t n o t least, as well as food, fresh sea w ater can be added continuously, the lateral overflow insuring evacuation of excess water. The system really does m eet the requirem ents o f continuous culturing or long-term experim ents. We have developed a m ore sophisticated version of system 2; this has a lateral waste drain and a w ater collector w ith siphon (Fig.7). The waste drain has tw o stopcocks. With the to p one (stopcock 1) closed any desired volume can be siphoned ou t of the culturing vessel through stopcock num ber 2. With stopcock 1 open, only a lim ited volum e o f w ater will be siphoned o u t when opening stopcock 2 (i.e., th a t volum e corresponding to the contents o f the culturing vessel between w ater levels a and b). The advantage of the second procedure is th a t foul w ater can regularly be drained off. This could be au to ­ m ated w ith an electro-m agnetic valve com m anded by a tim e switch. The lateral w ater collecting tu b e w ith siphon from which the contents flow into the culturing vessel a t regular intervals (instead o f a continuous dropping of the m edium from the air—w ater lift as in vessels 1 and 2) seems in m any cases to be beneficial. Indeed, the sudden draining of a substantial volum e o f w ater into the culture vessel creates an upwelling cu rren t which sweeps the gauze bo tto m clean, a fact which is m ost im portant w ith regard to p o tential clogging or fouling o f th e latter. It also insures th a t the oxy­ genated w ater from the collector is m ore thoroughly m ixed w ith the con­ tents o f th e culture vessel. 286 Fig.7. C u ltu re vessel 3 (fro m S o rg elo o s a n d P e rso o n e , 1 9 7 2 ): c u ltu re vessel 2 (see F ig .6), p ro v id ed w ith a la te ra l w aste d ra in D a n d a w a te r c o lle c to r F w ith sip h o n G. As we have described these th ree culturing systems in detail (Sorgeloos and Persoone, 1972) we shall n o t en ter here into the details of construction. Most parts of these devices are m ade o f glass and polyethylene tubing. Culture vessel 1 was well suited for high density culturing o f pelagic orga­ nisms which are no t to o sensitive b u t are too small to be separated from the food particles by a screen, as in culturing vessel 2 and 3. This is tru e for ciliates, rotifers, copepods and A rtem ia larvae. Systems 2 and 3 seem to be very convenient for som ew hat larger pelagic or benthic organisms which norm ally catch th eir food from the w ater. We obtained excellent results in culturing fish larvae and small fishes w ith both live food (ciliates, rotifers, A rtem ia larvae) and inert food particles. We think th a t it would be very easy to construct large-scale versions of these systems for mass culturing purposes, although we have n o t y e t a t­ tem pted to do so. 3. A culturing system with continuous separation o f the progeny “ F o r e x p e rim e n ta l research it is h ig h ly d esirab le to have a t o n e ’s disposal a flo w ­ th ro u g h cu ltu rin g sy ste m fo r a d u lt org an ism s w h ich is k e p t u n d e r c o n tro lle d environ- 287 m e n ta l c o n d itio n s , an d e q u ip p e d w ith a n a u to m a tic m e c h a n ism fo r c o n tin u o u s sep ara­ tio n o f th e o ffsp rin g ” (S o rg eloo s a n d P e rso o n e, 1 9 7 3 ). A lthough we initially built this culturing system up for herbivorous crus­ taceans such as A rtem ia and Daphnia (Sorgeloos and Persoone, 1973), it can certainly be used in enlarged versions for m any o th er herbivorous organisms o r particle feeders, pelagic, as well as benthic ones (fish, crustaceans and m olluscs). As usual the only pow er supply involved is com pressed air which (as a good conductor) has m any different functions: aeration, circulation, resuspension and even providing C 0 2 for algae in cases where herbivorous organisms are being fed. The apparatus (Fig.8) consists essentially o f four 13 F ig .8 . C u ltu rin g vessel w ith a u to m a tic se p a ra tio n o f th e p ro g e n y (fro m S orgeloos an d P e rso o n e , 1 9 7 3 ): A , algal c u ltu rin g c y lin d e r; B, a d u lt re a rin g vessel c o n n e c te d to C; C, larval co llectin g c a m b e r; D , w a te r su p p ly c y lin d e r c o n n e c te d to E ; E, w a te r c o lle c to r w ith s ip h o n ; F , fo o d air—w a te r lif t sy stem . 288 transparent cylinders w ith funnel-shaped b ottom s, a w ater collector and a food— air— w ater lifting system w ith term inal collecting vial and overflow. All these parts are connected by polyethylene tubing of various diam eters. C ylinder A is the food vessel where the algae or in ert food particles are k ep t in m ovem ent by steady aeration from th e b o tto m . They are continu­ ously raised by an ai:r-w ater lift to vial F th e excess flows from here back into the cylinder. Vessel B contains the adults. A t the bo tto m is a gauze with a large enough mesh to allow the progeny to pass. The w ater collector E is either periodically or continuously filled by another air^ w a ter lift which drains w ater from cylinder D. When w ater siphoned from collector E starts to flow into culture vessel B, it creates low pressure in vial F which also em pties into cylinder B through siphon num ber 5. T hus the adults receive food at regular intervals and a t the same tim e there is a supply o f oxygenated water. Since the w ater level in B will, m om entarily, be higher than in cylin­ der C (with which B is connected by tu b e n um ber 8) w ater will drain from vessel B to vessel C carrying the offspring through the gauze into cylinder C. There can be a flow of w ater from the adult vessel to the progeny vessel every second or third m inute, depending on th e size o f the w ater collector, insuring an autom atic and com plete separation o f adults and juveniles, and excluding any possibility o f ingestion of the latte r by the form er as is often encountered w ith many types o f organisms. T hus the offspring can be har­ vested at will through stopcock 11, situated close to the bo tto m of larval cham ber D. A C K N O W LED G EM EN TS We are very indebted to D r Ir E. Jaspers for her p atien t help in p ro o f­ reading the m anuscript. We are also indebted to the editors o f Marine Biology, Archiv fü r Hydrobiologie and Biologisch Jaarboek D odonaea for th eir per­ mission to use some figures from our previous publications. REFERENCES B ro w n , A ., 1 9 7 2 . E x p e rim e n ta l te c h n iq u e s fo r preserving d ia to m s used as fo o d fo r larval P enaeus a ztecu s. Proc. N atl. S hellfish . A ssoc., 6 2 : 21—25. C ostlow , J.D ., 1 9 6 9 . M arine B io lo g y . P ro c. V In t. In te rd is e . C o nf. G o rd o n a n d B reach, N .Y ., 6 0 6 pp. F o rs te r, J.R .M . an d W ickins, J .F ., 1 9 6 7 . E x p e rim e n ts in th e c u ltu re o f th e p ra w n P alaem on serratus (P en n an t). ICES-CM 1 9 6 7 —E 1 3 , F ish e ries Im p ro v e m e n t C o m m ., C o n w ay , 8 pp. G reve, W., 1 9 6 8 . T h e “P la n k to n k re is e l” , a n ew device fo r c u ltu rin g Z o o p lan k to n . Mar. B iol., 1 : 2 0 1 - 2 0 3 . H o u d e , E .D ., 1 9 7 3 . Som e re c e n t ad v an ces an d unso lv ed p ro b le m s in th e c u ltu re o f m arin e fish larvae. P ro c. III A n n u . W o rk sh o p W orld M aricu ltu re S oc., 3: 83—1 1 2 . K inne, O ., 1 9 7 0 . In te rn a tio n a l S y m p o siu m “ C u ltiv a tio n o f m arin e org an ism s a n d its im ­ p o rta n c e fo r m arin e b io lo g y ” . O p en in g ad d ress. H elgol. Wiss. M eeresu n ters., 2 0 : 1—5. M erten s, J . a n d P erso o n e, G ., 1 9 7 2 . T h e flo w -th ro u g h c o lu m n , a sim ple an d m u ltip u rp o se rearin g device. Biol. Ja a rb ., 4 0 : 2 7 1 —2 7 5 . 289 P rovasoli, L ., M cL aughin, J.J.A . a n d D ro o p , M .R ., 1 9 5 7 . T h e d e v e lo p m e n t o f artificial m ed ia f o r m arin e algae. A rc h . M ik ro b io l., 2 5 : 3 9 2 —4 2 8 . R ice, A .L ., an d W illiam son, D .I., 1 9 7 0 . M e th o d s fo r re a rin g larval d e c a p o d c ru stacea. H elgol. Wiss. M eeresu n ters., 20 : 4 1 7 —4 3 4 . S ch reib er, E ., 1 9 2 7 . D ie R e in k u ltu r v o n m a rin e m P h y to p la n k to n u n d d e re n B ed eu tu n g fü r die E rfo rsc h u n g d e r P ro d u k tio n sfä h ig k e it des M eeresw assers. Wiss. M eeresu n ters., 16: 1 - 3 4 . S o rg elo o s, P ., 1 9 7 4 . T h e in flu e n c e o f algal fo o d p re p a ra tio n o n its n u tritio n a l efficien cy fo r A r te m ia salina L. larvae. T halassia Ju g o sl., in press. S orgeloos, P ., an d P erso o n e, G., 1 9 7 2 . T h ree sim p le c u ltu re devices fo r a q u a tic in v erte­ b ra te s a n d fish larvae w ith c o n tin u o u s re c irc u la tio n o f th e m e d iu m . M ar. B iol., 1 5 : 2 5 1 -2 5 4 . S o rg elo o s, P., an d P e rso o n e, G ., 1 9 7 3 . A c u ltu re sy ste m fo r A r te m ia , D aphnia, a n d o th e r in v e rte b ra te s, w ith c o n tin u o u s se p a ra tio n o f th e larvae. A rch. H y d ro b io l., 7 2 : 133—1 3 8 . T au b , F . B., 1 9 7 1 . Algal c u ltu re as a so u rce o f feed. P ro c. I A n n u . W o rk sh o p W orld M a ric u ltu re S o c., 1: 1 0 1 —117. V e n k a ta ra m a n , G .S ., 1 9 6 9 . T h e c u ltiv a tio n o f algae. In d ia n C o u n c. A grie. R es., N ew D elh i, 3 1 9 pp. V on W itsch, H ., 1 9 7 0 . M ikro- u n d M akroalgen als N a h ru n g sm itte l. E in Ü b erb lick . Ber. D tsch. B o t. G es., 8 3 : 5 1 9 —526. W alne, P .R ., 1 9 5 6 . E x p e rim e n ta l rearing o f th e larvae o f O strea ed u lis L . in th e la b o ra ­ to ry . F ish . Inv est. L o n d ., Ser. 2, 2 0 : 1—23. t V i i ! i rv) O,ú--