Portable Air Compressor Using DC Power: A Study 6

advertisement

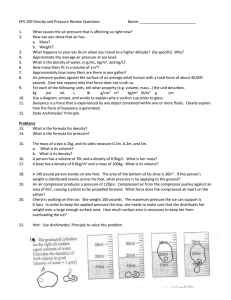

International Journal of Engineering Trends and Technology (IJETT) – Volume 21 Number 6 – March 2015 Portable Air Compressor Using DC Power: A Study Aniket A. Nerlikar#1, Pravin B. Rane*2, Nikhil B. Dhake#3, Harshit Sharma*4, Roshan R. Surwade#5, Mr. A. R. Bhardwaj*6 #1,2,3,4,5 UG Student, Department of Mechanical Engineering, SSBT’S COET Jalgaon (MH), India, 425001 #6 Assistant Professor & Workshop Superintendent Department of Mechanical Engineering, SSBT’S COET Jalgaon (MH), India, 425001 Abstract— In today’s era, automobile industry is growing day by day. There is not a single place where you can’t get to see automobiles. The Automobiles run on the tires that are filled with the compressed air. Till so far, the system that provides compressed air is very huge in size, consumes large amount of electricity (AC) and are not feasible to carry with. Considering these aspects, we can say that there is a drastic need of an air compressor that should be energy efficient (DC), small in size and portable to carry with. Hence here we propose a design of a system that will provide the optimum compressed air by utilizing minimum amount of power (DC) and will be able to run on device such as batteries. Keywords— AC, BDC, DC, RPM, TDC. I. INTRODUCTION With the advent in the field of science and technology, several aspects have been brought forward in order to enhance the human living exposure. Innovations in the field of science have made our life easy and comfortable. There are several aspects that are put forward to enhance our day to day workability. Now, each and every field is in influence with the technological advancements. We cannot find a single field without technological aspects. Among all innovations, revolution in the field of automobiles has made our life exciting and easier. Today automobile industry is at its peak. Huge amount of development has been done till so far to nourish the industry demands. Every day we see numerous vehicles running all over. For a human, vehicles play a very important role. Automobile vehicles constitute several parts that help to run efficiently. Wheels are the base for a vehicle. Wheels are the running base of the automobiles. These wheels comprises of tires that are filled with the compressed air. Everywhere we get to see compressed air filling points. It may be at the garage or may be near to the petrol/diesel or gas filling stations. Today, the way compressed air is gained is too tedious and complex procedure. [1] Every time there is need of compressed air for our automobiles, we need to rush to the nearest air filling point, which is a headache for us especially when time constraint matters. Even if we rush to the air filling point, it is a matter of fact that we may get compressed air if we are that much lucky because one cannot say supporting environment will be on our side such as electricity or availability of stored air etc. These points to a need of a well improved option for providing compressed air at our place, ISSN: 2231-5381 wherever we want and with minimum resources such as electricity etc. Considering the need and unavailability of such option, a better approach can be suggested to furnish these requirements. A new system can be manufactured to provide such functionalities. In such scenario, a portable air compressor can be well functional and can fulfill situation’s requirements. II. EXISTING SYSTEM Compressors are the most important tool in the industry. Several techniques have been brought forward to design an efficient air compressor to compress air. Till so far, compressors are drive using steam power, turbines and electrical energy (AC). [2] At this instant, if you go to fill compressed air in your automobile tires then you may find an assembly that is too large, heavy and bulky to operate. The present air compressor consists of several parts such as Electrical Motor (AC), Piston Cylinder arrangement, Oil Rings and a Storage tank etc. The major disadvantages of the existing system are that these systems requires large amount of electricity (AC), place dependent and complex to operate. Figure depicts how exactly current air compressor system works. Fig. 1 Existing Compressor III. MODIFIED DESIGN The drawbacks of existing air compressor can be minimised by changing the existing system to a certain level. Here we propose a design of an air compressor that will definitely fulfil the situation’s requirements. A. Proposed System http://www.ijettjournal.org Page 287 International Journal of Engineering Trends and Technology (IJETT) – Volume 21 Number 6 – March 2015 Following figure shows a modified approach. The modified system can be manufactured by using several components such as DC Motor, Spur Gear, Single Cylinder Piston Arrangement and Pressure Gauge. Here’s the block diagram of the modified approach. C. Spur Gear Fig. 4 Typical Gear Fig. 2 Portable Air Compressor Each sub part in this system contributes a major role. Major component of this system may include following parts. The Spur Gear can be used in the assembly as a bridge in between DC Motor and Piston Cylinder Arrangement.[4] It can be used for transmitting torque from one shaft to another shaft. D. Single Cylinder Piston Arrangement B. DC Motor Fig. 3 Typical DC Motor Dc Motor will be the fundamental part of this proposed system. The whole assembly will work by using the energy provided by the DC Motor. It is expected that DC Motor will be functional at 12 volt power.[3] The main advantage of using DC Motor is, it provides high Torque at higher RPM. ISSN: 2231-5381 Fig. 5 Single Cylinder Piston This part can be used to accomplish the major task of the proposed system i.e. the task of generating the compressed air. As this part reciprocates from Bottom Dead Centre (BDC) to Top Dead Centre (TDC), when the piston is at BDC then the inlet valve gets opened and it takes surrounding air. As the http://www.ijettjournal.org Page 288 International Journal of Engineering Trends and Technology (IJETT) – Volume 21 Number 6 – March 2015 piston reaches to TDC, side by side the air gets compressed automatically.[5] E. Pressure Gauge At last the compressed air can be measured by using a pressure gauge. The proposed system will work effectively and efficiently as far as the sub components are concerned. At first this system will be start functional at 12 volt DC power supply from battery of automotive. As the system gets initiated all the sub parts will work as expected to generate the compressed air. ACKNOWLEDGMENT We thank to the Principal, Head of Department and North Maharashtra University for their constant encouragement and support. REFERENCES [1] [2] [3] CONCLUSION This way a better modified approach can be suggested to gain compressed air by using DC Power so as to minimize the complexity of the system and to achieve portability in terms of compactness. ISSN: 2231-5381 [4] [5] Konstantin O. Boinov, Elena A. Lomonova.” Surge Control of the Electrically Driven Centrifugal Compressor”,IEEE Transactions on Industry Applications, vol. 42, no. 6, november/december 2006 Saeed Zahadi,”Energy Saving in DC/AC Drive Compressors & Pumps using ZCTF PWM Inverter:A Study”, Proceedings of the World Congress on Engineering 2011 Vol II WCE 2011, July 6 - 8, 2011, London, U.K. Malakondaiah naidu,thomas w. Nehl,suresh gopalakrishnan,& lukas würth ieee industry applications magazine july|aug 2005 Parveen Kumar, Harsh Raghuvanshi “Design & Analysis of a Spur Gear in different Geometric Conditions”, International Journal of Engineering and Advanced Technology (IJEAT) ISSN: 2249 – 8958, Volume-3, Issue-2, December 2013 Wenyu mo , “ Air Compressor Control System for Energy Saving in locomotive Service plant” , j. Electromagnetic analysis & applications, 2009, 2: 114-117 doi:10.4236/jemaa.2009.12018 published online june 2009 http://www.ijettjournal.org Page 289