Selective Synthesis of Citric Acid from Molasses Aspergillus Niger

advertisement

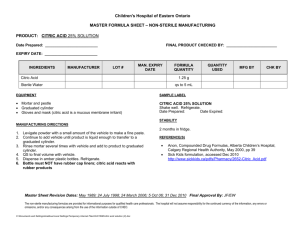

International Journal of Engineering Trends and Technology (IJETT) – Volume 9 Number 1 - Mar 2014 Selective Synthesis of Citric Acid from Molasses using Aspergillus Niger Jayant.K.Pohnerkar#1 , S.A.Desai#2 1 Tatyasaheb Kore Institute of Engg. & Tech.,Warananagar, Dist.Kolhapur India 2 Prof. in chemical Engg.Deptt. Of chemical Engg.,T.K.I.E.T.Warananagar, Dist. Kolhapur, India Abstract - Selective synthesis of Citric Acid from local cane molasses using Aspergillus niger was studied. A local stain of A.niger isolated from lemon tree leaves & cultured. A.niger stain ATCC-595 were separately studied for the Bioconversion of local molasses into citric acid. The molasses fermentation was carried out at 30°C in a flask. The results showed increased efficiency for citric acid production when compared with wild type. It produced 210.12 gm/lit of citric acid as compared to wild stain 102.5 gm/lit. The maximum citric acid production is on the 9th day of fermentation by used stain and 11th day by the wild type. This investigation is one of the ecofriendly technology can be used for economic development & environmental protection in india. By recycling & reusing waste material from cane Industries Citric acid production can be easily done. Keywords: Citric acid; Fermentation; Aspergillus niger ; Surface culture I. INTRODUCTION Citric acid (CH2COOH.COH.COOH.CH2COOH) is a carboxylic acid, soluble in water with a pleasant taste is the important acid used in the food Industries. It exists in nature when carbohydrates are oxidized to CO2 , Carbon dioxide. Because of its high solubility ,palatability & low toxicity it can be used in food, bio chemical & pharmaceutical industries. It is needed for inhibition of oxidization, conservation of pickles, neutralization etc. These uses have placed greater stress on increased Citric acid production& search for more efficient fermentation process. The worldwide demand of citric acid is above 80 Lac. tons/year & it is bound to increase day by day. Various processes are used for Citric acid production. Surface culture process is still being used form 1940s, but not effective due to low output of Citric acid. New methods of submerged fermentation improved the production of Citric acid. ISSN: 2231-5381 Different other methods were being used for Citric acid production , Extraction of Citric acid from fruits & its chemical synthesis, Citric acid from whey & other dairy product wastes, Citric acid from beet molasses as substrates etc. But most commercially used method for production of Citric acid is by Aspergillus niger using cane molasses as an example of fungal overflow metabolism. Many microorganisms such as fungi & bacteria can produce Citric acid but Aspergillus niger remained the organism of choice for production of Citric acid due to its genetic stability , high yields , capacity of using cheaper raw material (like cane molasses) & absence of undesirable reactions. |According to various researches the mutant stains might show several fold increase in citrate production compared to wild type. Cane molasses is still the substrate of choice of Citric acid production by Aspergillus niger . In the middle eastern region (Jordan) large amounts of whey are produced as a by product of cheese & other dairy products manufacturing. From this using Aspergillus niger Citric acid can be produced. In the country like |Republic of China, Sugar is produced from beet. The beet molasses are used for citric acid production using Aspergillus niger in China. In India sugar cane factories are large in number & local cane molasses are easily available due to their waste disposal problems. Using A.niger from local cane molasses Citric acid production can be done using different stains. India spents lot of money for the importation of citric acid. Alsot there is disposal problems of cane molasses. Both problems can be solved by citric acid production. Thus our work consists of search for stain of A.niger & fermentation process which is very efficient for the bioconversion of these deposits of local molasses to citric acid to insure the self supply of this acid to local industries, & the environment protection. http://www.ijettjournal.org Page 7 International Journal of Engineering Trends and Technology (IJETT) – Volume 9 Number 1 - Mar 2014 II.METHODS & MATERIALS drops under a more/less vigorous A. Isolation of Aspergillus niger The used A.niger (wild type) was isolated from leaves of Citrous lemon & an A.niger ATCC595 stockculture was reactivated &cultivated by streaking a loopful of culture on petridishes containing Potato Dextrose Agar (PDA) & incubated at 25-30 °C for 10-15 days. Different colonies that appeared were biochemically & morphologically characterized & used as inoculums for the fermentation process. B. Fermentation Conditions Fermentation was carried out in a Bioreactor with 0.71 working volume. |The surface culture was used & the inocubating temperature was 30°C . PH adjusted to 6 with NaOH (1gm/lit). Incubation periods are 4days, 6days, 8,10,12,14 days. C. Pretreatment of substrate Cane molasses obtained from Sugar Factory was used depending on the volume of used flasks, 200gm of molasses were diluted in 180ml of Distilled water, PH was adjusted to 6 with NaOH. To inhibit proliferation of micro-organisms ,mixture was sterilized at 121°C for 15min. D. Inoculation of Substrate & sampling The cellular suspensions of A.niger were prepared & transferred to the flasks. The fermentation was carried at 30°C . E. Measurement of Citric acid content Citric acid was determined titrimetrically by using 0.1N NaOH & Phenolfthalein as indicator & calculated as % according to following formula: % Citric Acid = Normality * Vol. of NaOH* Equivalent Weight of Citric acid/ Weight of sample (gm)*10 Using a graduated pipette ,1ml of supernatant was diluted in 49ml of distilled water to increase discoloration &5drops of phenolphthalein were used to serve as color indicator. The Citric acid was titrated by addition of NaOH(1gm/lit) in ISSN: 2231-5381 http://www.ijettjournal.org Page 8 agitation. International Journal of Engineering Trends and Technology (IJETT) – Volume 9 Number 1 - Mar 2014 ACKNOWLEDGEMENT The author gratefully acknowledges the N.C.I.M. National Collection of Industrial Microorganisms a division of National Chemical Laboratory (N.C.L.) Pune, India for supplying |Aspergillus niger srain used in this study. Our sincere thanks to the authorities of the Tatyasaheb Kore Institute of Engg. & Technology, Warananagar, Dist. Kolhapur, India for their unlimited hospitality and their priceless moral as well as material support during this study.Also we are greatly indebted to the Deptt. Of Biotechnology , Tatyasaheb Kore Institute of Engg. & Technology, Warananagar, Dist. Kolhapur, India for allowing us to use their laboratories. REFERENCES [1] Kabera Justin, Ugirinshuti Viateur ,Mukantirenganya Prudentienne (2010) , Use of nitrous acid mutant of Aspergillus niger for citric acid production from local cane molasses, African Jornal of Microbiology Research Vol.4(13) pp.1446-1452 , 4 July 2010 [2] Murad A.El-Holi and Khalaf S.Al-Delaimy (2003),Citric acid production from Whey with Sugars and additives by Aspergillus niger, African Jornal of Microbiology Research Vol.2(10) pp.356359 , October 2003 [3] Wang Jianlong,Wen Xianghua, Zhou Ding (2000), Production of citric acid from molasses integrated with in-situ product separation by ion-exchange resin adsorption, ELESEVIER Bioresource Technology 75(2000) ,231-234 III.RESULTS & DISCUSSION After 5days of incubation , the whole surface of culture media was invaded by a mixture of whitish & blackish colonies of mycelia. Individualized & cultivated , the black mushroom formed the granular colonies with balck spores whereas the mycelia of white mushroom still remained on the surface of the culture media. Different measurements were done during fermentation within the intervals of time which were equal. |The precipitates observed during the fermentation would have been caused by the accumulation of debris from digested substrate. Consumption of sugars contained in molasses was very intense from 2nd day to 5th day of fermentation. In the initial days the enzyme showed slow sugar compared with the wild parent. Fermentation must be stopped before the ageing of the mold to prevent those reactions. The temperature of 30°C played a great role in optimizing the production of this acid. [4] Baryraktar E. Mehmetoglu U(2000) , Production of citric acid using immobilized conidia of |Aspergillus niger, Appl. Biochem. Biotechnol. 87:117-125 [5] Gupta S (1994) , Continuous production of citric acid form sugar cane molasses using a combination of submerged immobilized and surface stabilized cultures of Aspergillus niger, KCU520, Biotechnol. Lett. 16:599-604. [6] Hossain M. Brooks JD.Moddax IS(1985) , Galactose inhibition of citric production from glucose by Aspergillus niger, Appl. Microbiol. Biotechnol. 22:98-102. [7] Lu MY (1995) , Citric acid production by Aspergillus niger in solid substrate fermentation , Bioresour. Technol.54:235-573 [8] Hendrickson R.Kersterson JW (1971) , Citrous molasses , FL Agr.Exp. Sta.Tech. Bulletin, p.677 [9] Ikram-ul-Haq SA, Qadeer MA,Iqbal J(2001) , Citric acid fermentation by mutant strain of Aspergillus niger GCMC-7 using molasses based medium, Microbiol. Biotechnol.17(1):35-37 [10] Mattey M. Allan A (1990), Glycogen accumulation in |Aspegillus niger, Transient Biochemical Solicits,18(5):1020-1022 [11] Rohr M. Kubicek CP,Kuminek J(1983), Citric acid In Rehm HJ,Reed, G, (eds), Biotechnology, pp.3341-3352 ISSN: 2231-5381 http://www.ijettjournal.org Page 9