Temperature Monitoring System Of Conductors Based On GSM SMS And Zigbee

advertisement

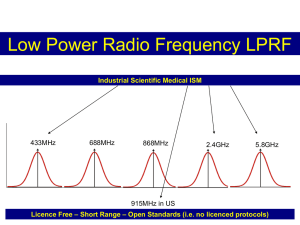

International Journal of Engineering Trends and Technology (IJETT) – Volume 4 Issue 10 - Oct 2013 Temperature Monitoring System Of Conductors Based On GSM SMS And Zigbee 1 Y.Viswanatha Reddy , K.Jyothi 2 1 2 M.Tech, Dept of ECE, CMR College of Engineering and Technology, Hyderabad, AP-India, Assistant Prof, Dept of ECE, CMR College of Engineering and Technology, Hyderabad, AP-India, Abstract— Temperature Monitoring System of Conductors based on GSM SMS and Zigbee is produced in this paper. The temperature of conductors can be monitored in real-time and some accidents caused by the increased temperature can be avoided. The principle and the feature of ARM7, GSM SMS and Zigbee communication are analyzed The construction of this system is outlined, and the force modal of calculating the variety of the sag due to the increased temperature of conductors is built. The ARM7 is a general purpose 32-bit microprocessor, which offers high performance and very low power consumption. The ARM architecture is based on Reduced Instruction Set Computer. GSM is a global digital mobile communication system.GSM SMS is a kind of short message service, by which the limited data or text message can be transmitted. Zigbee is a free open source protocol which can be used for wireless applications. Using this protocol overall development cost can be reduced. Using this application engineers can easily calculate the variations in conductors due to change in temperature. This paper will provide block diagram and its detail applications and hardware and software requirement for developing this application. Keywords— ARM7, GSM, Zigbee, Temperature Sensor. I.INTRODUCTION The demand of electricity is higher and higher, and the problem between lag of construction of network and inadequacy of transmission capacity becomes increasingly prominent, which exacerbates the unharmonious contradictions of development between power grids and power generation structure As long as electrical transmission lines are kept clean, they last up to 100 years at least a lifetime, says John kassakin, professor of electrical engineering. Designed to hold up in adverse weather conditions, the transmission lines primarily use ACSR conductors: aluminum cable wrapped around steel-reinforced cores. The aluminum conductors the electricity; the steel adds strength to prevent the line ISSN: 2231-5381 from sagging. There are two kinds of electrical lines: transmission lines that conduct power from a generating source to substations, and distribution lines that send power on to individual homes and businesses. Some provinces and cities have begun to take power limited policies to alleviate contradiction of the current electricity supply-demand, how to resolve this problem has become imperative responsibility for many power workers. Recently, in order to prevent overloading of transmission lines, domestic power system usually adopts the static, conservative transmission capacity value in design, which is a conservative static value based on the severest weather conditions. However, such severe weather conditions rarely occurred, and it has resulted in the inefficient use of potential transmission capacities in most time. The transmission capacity can be increased only by adding transmission lines. However, it is becoming more and more difficult to build new transmission lines with the transmission lines increased. From the perspective of sustainable development and environmental protection, we should pay more attention from power grids expansion to increase the potential transmission capacity of available transmission lines, and enhance the transmission capacity of power grids, so as to resolve the problems between high requirement of electricity and difficulty of new transmission line. At present, some areas adopt the allowable temperature value of 70°C to 80°C or even 90°C. Properly increasing the allowable temperature of existing conductors can increase stable carrying capacity of transmission lines, thereby the normal transmission capacity is improved. The method is a breakthrough of current technical regulations, the impact caused by improving conductor temperature on conductors, the mechanical strength and the lifespan of matched fittings, the increase in sag and so on should be studied. In addition, if the conductor temperature and the sag can be real-timely monitored, the dynamic regulation of the transmission capacity, such as day and night, cloudy and sunny, summer and winter under the different environmental conditions can be realized to http://www.ijettjournal.org Page 4449 International Journal of Engineering Trends and Technology (IJETT) – Volume 4 Issue 10 - Oct 2013 improve the transmission capacity. A new direct method for the measurement of overhead conductor temperature and sag factors based on GSM SMS and ZIGBEE has been proposed in this dissertation work for the purpose of DTLR. This temperature and sag monitoring device responds to the weather conditions. The main advantages of the method include the accurate measurement of conductor sag and temperature values without recourse to simplified assumptions that could otherwise affect its accuracy. With this method, errors caused by insulator swings could be eliminated. To be able to directly monitor and display the conductor temperature and sag values in real time will enable prospective. Engineers to physically capture the conductor behavior, and to take judicious steps towards a reliable system loading. In order to meet these demands Temperature Monitoring System of Conductors based on GSM SMS and Zigbee. II. RELATED WORK A.ARM7: The ARM7TDMI-S is a general purpose 32bit microprocessor, which offers high performance and very low power consumption. The ARM architecture is based on Reduced Instruction Set Computer (RISC) principles, and the instruction set and related decode mechanism are much simpler than those of micro programmed Complex Instruction Set Computers. This simplicity results in a high instruction throughput and impressive real-time interrupt response from a small and cost-effective processor core. Pipeline techniques are employed so that all parts of the processing and memory systems can operate continuously. Typically, while one instruction is being executed, its successor is being decoded, and a third instruction is being fetched from memory. The ARM7TDMI-S processor also employs a unique architectural strategy known as THUMB, which makes it ideally suited to high-volume applications with memory restrictions, or applications where code density is an issue. The key idea behind THUMB is that of a super-reduced instruction set. Essentially, the ARM7TDMI-S processor has two instruction sets: • The standard 32-bit ARM instruction set. • A 16-bit THUMB instruction set. The THUMB set’s 16-bit instruction length allows it to approach twice the density of standard ARM code while retaining most of the ARM’s performance ISSN: 2231-5381 advantage over a traditional 16-bit processor using 16-bit registers. This is possible because THUMB code operates on the same 32-bit register set as ARM code. THUMB code is able to provide up to 65% of the code size of ARM, and 160% of the performance of an equivalent ARM processor connected to a 16bit memory system. B. GSM: The GSM standard allows a maximum throughput of 9.6 kbps, which allows transmission of voice and low-volume digital data, for example text messages SMS OR MMS .GSM (Global System Mobile Communications) is a global digital mobile communication system, whose coverage is the most widely, phone owners is the largest, and reliability is very high. SMS (Short Message Service) is a kind of short message service, by which the limited data or text message can be transmitted. In fact, the information transmission is achieved by receiving and sending text message in the businesses center between mobile phones and other short message carriers, and the businesses center is an independent operating system of GSM network whose main function is submitting, storing, and transferring short message. SMS is a special and important service as well as calling for users by GSM system. In this paper, a self-designed industrial GSM module is selected to finish the transmission and the decoding of the monitoring data through AT command and coding of short message PDU (Protocol Data Unit). C. ZIGBEE: ZigBee wireless network technology is a new standard launched and made by ZigBee Alliance. The alliance, founded in August 2001, is a fast-growing and non-profit organization, and it aims is to provide consumers with more flexible and easier electronic products. The second half of 2002, four large corporations including the British company Invensys, Mitsubishi Electric Corporation, Motorola and the Dutch giant Philips Semiconductor Corporation jointed together to announce that they would join the "ZigBee Alliance" to invent the nextgeneration wireless communication standards named "ZigBee", which became a significant milestone in the development process. In October 2004, the ZigBee Alliance announced a version 1.0 of ZigBee protocol, and in December 2005 version 1.1. ZigBee uses free frequency bands of 2.4 GHz and 900 MHz, and its transmission rate is 20 kbps to 250 kbps. In this paper, the perfect chip cc2430 is selected to design the wireless hardware platforms of ZigBee, a standard ZigBee wireless network module is http://www.ijettjournal.org Page 4450 International Journal of Engineering Trends and Technology (IJETT) – Volume 4 Issue 10 - Oct 2013 produced, and a reduced version of ZigBee wireless network protocol is programmed. The Zigbee module and protocol have been successfully applied to power system, medical and some other fields. ZigBee lets you easily and cost-effectively add intelligent new features that improve the efficiency, safety, security, reliability and convenience of your products. You can help your customers save both energy and money, or give them the tools they need to gain control of their homes. It's even possible to help people maintain their independence and allow them to closely monitor their health and fitness. D. Temperature Sensor (LM35): The LM35 series are precision integratedcircuit LM35 temperature sensors, whose output voltage is linearly proportional to the Celsius (Centigrade) temperature. The LM35 series are precision integrated-circuit LM35 temperature sensors, whose output voltage is linearly proportional to the Celsius (Centigrade) temperature. The LM35 sensor thus has an advantage over linear temperature sensors calibrated in ° Kelvin, as the user is not required to subtract a large constant voltage from its output to obtain convenient Centigrade scaling. The LM35 sensor does not require any external calibration or trimming to provide typical accuracies of ±¼°C at room temperature and ±¾°C over a full 55 to +150°C temperature range. Low cost is assured by trimming and calibration at the wafer level. The LM35's low output impedance, linear output, and precise inherent calibration make interfacing to readout or control circuitry especially easy. It can be used with single power supplies, or with plus and minus supplies. As it draws only 60 µA from its supply, it has very low self-heating, less than 0.1°C in still air.. The LM35 is rated to operate over a -55° to +150°C temperature range, while the LM35C sensor is rated for a -40° to +110°C range (-10° C with improved accuracy). III. SYSTEM IMPLEMENTATION Temperature Monitoring System of Conductors based on GSM SMS and Zigbee is mainly composed of the communication unit, the temperature monitoring unit and the expert software, the topology of system is shown in Fig.1. The communication unit is installed on the tower with both GSM and Zigbee communication modules, and the temperature monitoring unit on the corresponding conductors with the same potential. According to the sampling interval time set up remotely by the ISSN: 2231-5381 monitoring center, the communication unit can regularly or real-timely call the temperature monitoring units controlled by the communication unit in turn by Zigbee communication. The temperature monitoring unit, installed on the conductor or its connectors in a local meteorological area, can measure the actual operating temperature of conductors under local weather conditions, send the temperature of conductor to the communication unit by Zigbee communication whose frequency is 2.4 GHz. All the temperatures of conductors coming from various monitoring points will be packed as GSM SMS to send to the municipal monitoring center by GSM communication module. All the information of the temperature of various points can be managed by the expert software, and the current capacities from the SCADA system can be realtimely stored into the database. Then the expected temperature of conductors, the expected current capacities, the expected time, the real-time sag, the expected sag of conductors and so on can be calculated according to the computing model, and shown in graphic. When the measured or calculated temperature or the safe distance exceeds the allowable value, an alarm message can be send by GSM SMS to some managers. The operating parameters of the communication unit, such as time interval, system time of unit and requests of real-time data etc., can be remotely modified by GSM communication. By comparing with allowable temperature and analyzing, the transmission capacity will be enhanced with no break of the available technical regulations. Of course, the operating temperature of conductors can also be monitored by this system when the transmission capacity is increased. The Municipal monitoring system Temperature Monitoring System Communication unit Temperature Monitoring System Figure 1: Topology of the System In order to improve the transmission capacity of conductors with no break of the available technology, the monitoring of the conductor temperature is very important. However, the traditional wireless temperature measurement methods cannot meet requirements, for example, using infrared to measure temperature should keep the distance close (within 5m) and the accuracy of measurement is low. Using fiber temperature http://www.ijettjournal.org Page 4451 International Journal of Engineering Trends and Technology (IJETT) – Volume 4 Issue 10 - Oct 2013 measurement will not be able to meet the requirements of insulation for the high-voltage and long-distance transmission lines. Using radio to transmit data directly will be difficult to organize an effective star network with multi-points to one. The temperature of conductor is the most direct and important parameter during the operation of transmission lines, how to real-timely and accurately monitor the temperature of conductor is the key technique to solve this problem. The temperature of environment, conductor, and the crossing, can be measured by the temperature unit, which is composed of power module ARM Zigbee communication module, temperature sensors and so on, as shown in Fig2. Communication Unit: Structure of temperature monitoring device: Figure 4: Communication Unit Figure2: Structure of temperature monitoring device IV. RESULTS The temperature monitoring system of conductors based on GSM SMS and Zigbee is developed in this paper, by which the temperature controlling of transmission lines conductors is realized and the stoppage caused by raised temperature can be avoided. In the transmitting section,By using LM35 module we can measure the temperature.It is in analog form and it will be move to ARM7 processor,so that it will converted to digital.The measured temperature value transmitted to receving section by using Zigbee module. Municipal Monitoring Center: GSM based mobile device Monitoring system Figure 3: Municipal Monitoring Center Figure5: Temperature transmitting section ISSN: 2231-5381 http://www.ijettjournal.org Page 4452 International Journal of Engineering Trends and Technology (IJETT) – Volume 4 Issue 10 - Oct 2013 conductor temperature monitoring devices, but also can be used for auxiliary monitoring modules in other high-voltage monitoring equipment, such as temperature monitoring module in monitoring system of icing of conductors and so on. The Monitoring System of Conductors based on GSM SMS and Zigbee, it is only single monitoring along the long distance of transmitting power lines. So the future scope we have to increase the monitoring sections along the long distance. We can send acquisition data to municipal monitoring section. So we can monitor all temperature values along with the distance of transmitting line. Figure 6: Temperature monitoring section Finally the recevied temperature value is display on the LCD module.If temperature value exceed the critical value then the ARM7 processor directly send the signsals to GSM module.So that by using the GSM module the temperature value is send to corresponding user and server. V. CONCLUSION AND FUTURE WORK The temperature monitoring system of conductors based on GSM SMS and Zigbee is developed in this paper, by which the temperature controlling of transmission lines conductors is realized and the stoppage caused by raised temperature can be avoided. The power grids gradually increasing and the new lines building difficult, improving allowable temperature of conductors can fully exploit massive transmission capacity of existing transmission lines, and the number of new lines or the cost of investment in new lines can be deduced, the economic and social benefits brought by it is very large. it has a wide application backgrounds, not only can be used for ISSN: 2231-5381 REFERENCES [1] Ye Hongsheng, Gong Renwei, Huang Weizhong. Feasibility Study on Increasing Conductor Allowable Temperature and Engineering Practice[J]. Power construction, 2004 (10) . [2] Zhang Xuezhe,Li Xiaoqing,Liu Changqing,and so on.Discussing on Measurement of Improving Conductor Transmission Capacity - Improving Conductor Allowable Temperature[J]. For electricity, 2005 (6) . [3] Ma Guodong. Transmission Capacity of Wire and Cable [M]. Beijing: China Electric Power Publishing House,2003. [4] Zhao Chen,HE Bo, Wang Rui. A Design for ZigBee Wireless Communication Based on CC2420 RF transceiver. Micro-Computer Information, 2007, 23 (1-2). [5] Zhou Yuexia, Sun Chuanyou. DS18B20 Hardware Interface and Software Program. Sensor World,2001,(12). http://www.ijettjournal.org Page 4453