Document 12908520

advertisement

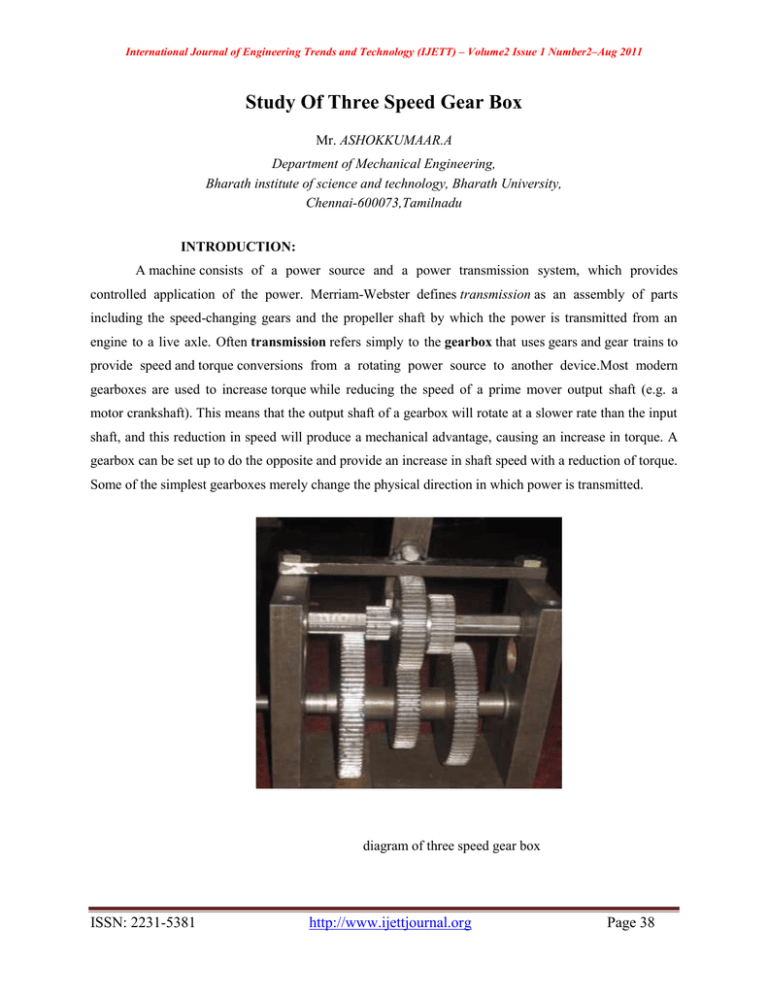

International Journal of Engineering Trends and Technology (IJETT) – Volume2 Issue 1 Number2–Aug 2011 Study Of Three Speed Gear Box Mr. ASHOKKUMAAR.A Department of Mechanical Engineering, Bharath institute of science and technology, Bharath University, Chennai-600073,Tamilnadu INTRODUCTION: A machine consists of a power source and a power transmission system, which provides controlled application of the power. Merriam-Webster defines transmission as an assembly of parts including the speed-changing gears and the propeller shaft by which the power is transmitted from an engine to a live axle. Often transmission refers simply to the gearbox that uses gears and gear trains to provide speed and torque conversions from a rotating power source to another device.Most modern gearboxes are used to increase torque while reducing the speed of a prime mover output shaft (e.g. a motor crankshaft). This means that the output shaft of a gearbox will rotate at a slower rate than the input shaft, and this reduction in speed will produce a mechanical advantage, causing an increase in torque. A gearbox can be set up to do the opposite and provide an increase in shaft speed with a reduction of torque. Some of the simplest gearboxes merely change the physical direction in which power is transmitted. diagram of three speed gear box ISSN: 2231-5381 http://www.ijettjournal.org Page 38 International Journal of Engineering Trends and Technology (IJETT) – Volume2 Issue 1 Number2–Aug 2011 Specification The gear box having involute six spur gear which maximum speed are 150 or minimum speed is 300.to given structure formula we calculate the arrangement of gear and calculate progression ratio is 2.236 ad different speed are 300,671&1500. Driver has 20 numbers of teeth and pitch circle diameter of 30 mm. Driven gear is having 120 numbers of teeth and pitch circle diameter 150 mm, both shafts is parallel to each other. The gear arrangement structural formula is z=p1(x1)p2(x2)p3(x3)=3(1)1(3). The driver gear is manually rotated which leads to the rotation of driven gearand when we shift the liver left and right wee got three different speed. Components used in the fabrication of design in three speed gear box a) Gears b) Bearings c) Shaft d) Washer e) Nuts and Bolts f) Base, Handle, Column, liver Gear A gear is a rotating machine part having cut teeth, or cogs, which mesh with another toothed part in order to transmit torque. Two or more gears working in tandem are called a transmission and can produce a mechanical advantage through a gear ratio and thus may be considered a simple machine. A gear or more correctly a "gear wheel" is a rotating machine part having cut teeth which meshwith another toothed part in order to transmit torque. Two or more gears working in tandem are called a transmission and can produce a mechanical advantage through a gear ratio and thus may be considered a simple machine. Geared devices can change the speed, torque, and direction of a power source. The most common situation is for a gear to mesh with another gear; however a gear can also mesh a non-rotating toothed part, called a rack, thereby producing translation instead of rotation. When two gears of unequal number of teeth are combined a mechanical advantage is produced, with both the rotational speeds and the torques of the two gears differing in a simple relationship. In transmissions which offer multiple gear ratios, such as bicycles and cars, the term gear, as in first gear, refers to a gear ratio rather than an actual physical gear. The term is used to describe ISSN: 2231-5381 http://www.ijettjournal.org Page 39 International Journal of Engineering Trends and Technology (IJETT) – Volume2 Issue 1 Number2–Aug 2011 similar devices even when gear ratio is continuous rather than discrete, or when the device does not actually contain any gears, as in a continuously variable transmission. Nomenclature of Gear Types of Gears 1.Spur Gears Spur gears are by far the most common type of gear and with the exceptions of the "cog" the type of gear that has been around the longest. Spur gears have teeth that run perpendicular to the face of the gear. Spur gears or straight-cut gears are the simplest type of gear. They consist of a cylinder or disk with the teeth projectingradically, and although they are not straight-sided in form, the edge of each tooth is straight and aligned parallel to the axis of rotation. These gears can be meshed together correctly only if they are fitted to parallel shafts. ISSN: 2231-5381 http://www.ijettjournal.org Page 40 International Journal of Engineering Trends and Technology (IJETT) – Volume2 Issue 1 Number2–Aug 2011 Spur gear 2. Helical Gears Helical gears are very similar to spur gears except the teeth are not perpendicular to the face. The teeth are at an angle to the face giving helical gears more tooth contact in the same area. Helical or "dry fixed" gears offer a refinement over spur gears. The leading edges of the teeth are not parallel to the axis of rotation, but are set at an angle. Since the gear is curved, this angling causes the tooth shape to be a segment of a helix. Helical gears can be meshed in parallel or crossed orientations. The angled teeth engage more gradually than do spur gear teeth causing them to run more smoothly and quietly. The angled teeth engage more gradually than do spur gear teeth causing them to run more smoothly and quietly. 3.Herringbone Gears Herringbone gears resemble two helical gears that have been placed side by side. They are often referred to as "double helical" 4. Bevel / Miter Gears ISSN: 2231-5381 http://www.ijettjournal.org Page 41 International Journal of Engineering Trends and Technology (IJETT) – Volume2 Issue 1 Number2–Aug 2011 Bevel gears are used mostly in situations that require power to be transmitted at right angles (or applications that are not parallel). Bevel gears can have different angles of application but tend to be 90°. 5. Worm gears Worm gears are used to transmit power at 90° and where high reductions are required. The worm resembles a thread that rides in concaved or helical teeth. 6. Internal Gears Internal gears typically resemble inverted spur gears but are occasionally cut as helical gears ISSN: 2231-5381 http://www.ijettjournal.org Page 42 International Journal of Engineering Trends and Technology (IJETT) – Volume2 Issue 1 Number2–Aug 2011 7. Racks A rack is basically a straight gear used to transmit power and motion in a linear movement. Gear Material Numerous nonferrous alloys, cast irons, powder-metallurgy and plastics are used in the manufacture of gears. However steels are most commonly used because of their high strength to weight ratio and low cost. Plastic is commonly used where cost or weight is a concern. A properly designed plastic gear can replace steel in many cases because it has many desirable properties, including dirt tolerance, low speed meshing, and the ability to "skip" quite well. The module system Countries which have adopted the metric system generally use the module system. As a result, the term module is usually understood to mean the pitch diameter in millimeters divided by the number of teeth. When the module is based upon inch measurements, it is known as the English module to avoid confusion with the metric module. Module is a direct dimension, whereas diametric pitch is an inverse dimension (like "threads per inch"). Bearing A bearing is a device to allow constrained relative motion between two or more parts, typically rotation or linear movement. Bearings may be classified broadly according to the motions they allow and according to their principle of operation as well as by the directions of applied loads they can handle. Types of bearing There are many types of bearings, each used for different purposes. These include ball bearings, roller bearings, ball thrust bearings, roller thrust bearings and tapered roller thrust bearings. 1. Ball Bearings 2. Roller Bearings ISSN: 2231-5381 http://www.ijettjournal.org Page 43 International Journal of Engineering Trends and Technology (IJETT) – Volume2 Issue 1 Number2–Aug 2011 3. Ball Thrust Bearing 4. Roller Thrust Bearing 5. Tapered Roller Bearings Ball bearing Ball bearings are widely used in a number of industrial applications. Extremely useful, ball bearings are used to facilitate rolling elements for smooth radial or axial motion within a spinning system. This type of bearing uses balls to maintain the separation between the moving parts of the bearing. The ball bearing reduces rotational friction and support axial and radial loads. Ball bearings reduce the amount of friction between components in a system and this helps in the movement of heavier objects smoothly and with less effort. These ball bearings provide smooth movement of parts or complete pieces of equipment.One of the least expensive types of rolling element bearing is the ball bearing. The cost of producing balls in these ball bearings is not very costly and hence ball bearings can be found in everything from the washing machines to computers. Features of ball bearings 1. The ball bearing system requires a thin film of lubricant for high-speed applications to reduce friction and facilitate heat dissipation, corrosion prevention, and long bearing life. 2. The raceways and the balls both have a fine surface finish. 3. With proper lubrication, less noise, less torque and long life, all can be achieved in ball bearings. 4. Ball bearings requireone time lubrication. 5. Ball bearings may fail due to improper lubrication, excessive temperature or if the bearing or the raceway has been damaged. Ball bearings assembly All ball bearings are manufactured with four essential parts: the inner ring, the outer ring, the rolling elements or balls, and the separator. The in-expensive ball bearings usually do not have the separator , however this is very important and is a must in ball bearings to prevent ISSN: 2231-5381 http://www.ijettjournal.org Page 44 International Journal of Engineering Trends and Technology (IJETT) – Volume2 Issue 1 Number2–Aug 2011 rubbing contact between the bearing balls and side walls. A ball bearing Materials used in Making Ball Bearings 1. Stainless Steel 2. Chrome Steel 3. Ceramic Series available in ball bearings Manufacturers and suppliers produce ball bearings in various series: Series 100: Extra light series Series 200: Light series Series 300: Medium series Series 400: Heavy series The size of the ball increases as the series increases and the larger size of the ball, the greater the load carrying capacity. Most ball bearings are manufactured to meet every standards of roundness, since any deformation can cause the moving parts to fail. Applications of Ball Bearings The application of ball bearings is seen. 1. Ball bearings are used in medical instruments, especially dental instrument. In dental and medical hand tools, it is required that the pieces withstand sterilization and corrosion. ISSN: 2231-5381 http://www.ijettjournal.org Page 45 International Journal of Engineering Trends and Technology (IJETT) – Volume2 Issue 1 Number2–Aug 2011 Because of this requirement, they are made of 440 degree C stainless steel, which allows smooth rotations at fast speeds. 2. It is said that ball bearings were very important to the German war industry during World War II. The ball bearing factories were often a target of allied aerial bombings during war time. 3. In aerospace industry, ball bearings are used on commercial, private and military aircraft , including gearboxes, pulleys and jet engine shafts. 4. The wheels in a skateboard contain two ball bearings in each of the four wheels. 5. Some manufacturers experimented with making balls in space on the space shuttle. 6. Applications for ball bearings include machine tools, precision spindles, radar mounts, truck cranes and numerous others Selection of used bearings 01. Deep groove ball bearings series 63 ISI No:-25BC03 Material: chrome steel Boundary dimension A: 25 B: 62 C: 17 Bearing Dimension Shafts A shaft is a rotating machine element which is used to transmit power from one place to another place. MATERIALS USED FOR SHAFTS a) Should have high strength. b) Should have good machinability. c) Should have great heat treatment properties. d) Should have high wear resistant properties. The material used for ordinary shaft is carbon steel of grades 40C8, 45C8, 50C4 and 50C12. ISSN: 2231-5381 http://www.ijettjournal.org Page 46 International Journal of Engineering Trends and Technology (IJETT) – Volume2 Issue 1 Number2–Aug 2011 WASHER, BOLT & NUT In the assembly we have taken two washer of mild steel, two M10 size bolts, one nut and bolt of size M5 all made up of cast iron. DESIGN AND CALCULATION CALCULATION OF TEETH The sliding block consists if three gears. For this block it is recommended that the number of teeth on adjacent gears must differ by atleast four. This is to avoid interface of gears one shaft with the gears of the other shaft while shifting. (Addendum circle of gears 1& 5 may foul on gear 4 while shifting the block rightward and leftward respectively.) (Z2 – Z5) > 4; (Z3 – Z1) > 4 Maximum reduction ray gives reduction from 300 rpm to 1500 rpm. Corresponding gears are 5 and 6. Z5/Z6 = N6/N5 assume Z5 = 20 (driver) 20/ Z6 = 300 / 1500 Z6 = 100 Consider next ray line 1500 to 671 rpm Z1 / Z2 = N2 / N1 Z1 / Z2 = 671 /1500 Z1 + Z2 = Z5+ Z6 Z1 + Z2 = 120 Z1 / Z2 = 0.488 Z1 = 0.488 * Z2 0.488 Z2 + Z2 = 120 1.448 Z2 = 120 Z2 = 120 / 1.448 = 82.87 = 83 (APPROX) Z1 = 120 – 83 = 37 Next ray speed is 1500 to 1500 Z3 / Z4 = N3 / N4 = 1500 / 1500 Z3 = Z4 Z3 + Z4 = Z5 + Z6 2Z3 = 120 Z3= 60 Z4 = 60 CONDITION 1 Z3 – Z5> 4 60 – 20 > 4 40 > 4 CONDITION 2 Z3 – Z1> 4 60 – 37 > 4 23 > 4 So the conditions are getting satisfied ISSN: 2231-5381 http://www.ijettjournal.org Page 47 International Journal of Engineering Trends and Technology (IJETT) – Volume2 Issue 1 Number2–Aug 2011 Z1 = 37 Z2 = 83 Z3 = 60 Z4 = 60 Z5 = 20 Z6 = 100 CALCULATION OF MODULE Assume power = 2.5 kw Lowest speed is 300 rpm to obtained by the machine of gear 5 and 6. Therefore Τ300rpm = (P * 60) / 2∏N Τ300rpm =79.577=80kw T = Ft6 * r6 r6 = pitch circle radius of gear 6 Therefore r6 = Z6 m / 2 = 100 m / 2 = 50 m Now use the formula m = (Ft / ψmM) m2 = (Ft / ψmM) Ft6 = T / r6 Where Ft = tangential force on the pitch circle of the gear. M = material constant making 80 for 15 Ni2 crl M 15 Ψm = gear transmission Ψm = b / m = 10 m3= 1600/800=2 m=1.25=1.5(standard) Calculate center distance of stage 1 a1 =( Z1 + Z2)m 2 = 90mm Calculation center distance of stage 2 a2 = (Z5 + Z6) (m/2) = 90mm LENGTH OF SHAFT Distance between the gear and gear box wall is to be about 10 mm. Distance between the adjacent group of gear is to be about 20 mm. Total length requirement for 2 pairs – group and 3 pair – group are to be 4b and 7b respectively. Thus the length of the shaft is obtained as L = 30 + 10 + 4b + 20 + 7b + 20 + 7b + 10 + 30 ISSN: 2231-5381 http://www.ijettjournal.org Page 48 International Journal of Engineering Trends and Technology (IJETT) – Volume2 Issue 1 Number2–Aug 2011 L=220 Calculate pitch circle diameter (d) d = Zm for gear 1 (d1) = Z1 * m =55.5 for gear 2 (d2) = Z2 * m =124.5 for gear 3 (d3) = Z3 * m =90 for gear 4 (d4) = Z4 * m =90 for gear 5 (d5) = Z5 * m =30 for gear 6 (d6 = Z6* m = 150 Calculate Tip diameter (da) da = (Z + 2f0)m f0 = 1 for full length(from design book) for gear 1 (da1) = (Z1 + 2f0) m =58.5 for gear 2 (da2) =(Z2 + 2f0)m =127.5 for gear 3 (da3) = (Z3 + 2f0)m=93 for gear 4 (da4) = (Z4 + 2f0)m=93 for gear 5 (da5) = (Z5+ 2f0)m=33 for gear 6 (da6) = (Z6 + 2f0)m=153 Calculate root diameter (df) df = (Z- 2f0)m – 2C C = bottom clearance = 0.625 For gear 1 (df1) = (Z1 – 2f0)m – 2C=51.87 For gear 2 (df2) = (Z2 – 2f0)m – 2C=120.87 For gear 3 (df3) = (Z3 – 2f0)m – 2C=86.37 For gear 4 (df4) = (Z4 – 2f0)m – 2C=86.37 For gear 5 (df5) = (Z5 – 2f0)m – 2C=26.37 For gear 6 (df6) = (Z6 – 2f0)m – 2C=146.37 Shaft diameter calculation Pressure angle(α)=20 Fn=ft/cosα Fn=1135.12mm Bm=fn*l =62.431Nm2 4 Tc=√Bm2+t62 Tc=101.47 16*Tc ∏ds3<40 ds3 =12919.56 ds =23.47=25(standard) Bearing selection Series 63 ISSN: 2231-5381 http://www.ijettjournal.org Page 49 International Journal of Engineering Trends and Technology (IJETT) – Volume2 Issue 1 Number2–Aug 2011 ISI number 25BC03 D = 62 d = 25 r=2 B = 17 Bearing selection: Inner diameter Outer in mm diameter Thickness in mm Basic load rating Static in mm designation Dynamic (C) (Co) 25 62 17 1040 1660 SKF6305 DEEP GROOVE BALL BEARING BASIC MACHINING OPERATION WHICH IS DONE ON LATHE MACHINE Turning Turning is the process whereby a single point cutting tool is parallel to the surface. It can be done manually in a traditional form of lathe which frequently requires continuous supervision by the operator or by using a computer controlled and automated lathe. This type of machine tool is referred to as having computer numerical control, better known as CNC and is commonly used with many other types of machine tool besides the lathe. ISSN: 2231-5381 http://www.ijettjournal.org Page 50 International Journal of Engineering Trends and Technology (IJETT) – Volume2 Issue 1 Number2–Aug 2011 When turning, a piece of material (wood, metal, plastic, or stone) is rotated and a cutting tool is traversed along 2 axes of motion to produce precise diameters and depths. Turning can be either on the outside of the cylinder or on the inside (also known as boring) to produce tubular components to various geometries. Although now quite rare early lathes could even be used to produce complex geometric figures even the platonic solids although until the advent of CNC it had become unusual to use one for this purpose for the last three quarters of the twentieth century. It is said that the lathe is the only machine tool that can reproduce itself. Turning Operation This operation is one of the most basic machining processes. That is, the part is rotated while a single point cutting tool is moved parallel to the axis ofrotation. Turning can be done on the external surface of the part as well as internally (boring). The starting material is generally a work piece generated by other processes such as casting, forging, extrusion, or drawing. It involves moving the cutting tool at right angles to the axis of rotation of rotating work piece. Turning operation Facing It is part of the turning process. It involves moving the cutting tool at right angles to the axis of rotation of the rotating work piece. This can be performed by the operation of the crossslide, if one is fitted, as distinct from the longitudinal feed (turning). It is frequently the first operation performed in the production of the work piece, and often the last- hence the phrase "ending up". ISSN: 2231-5381 http://www.ijettjournal.org Page 51 International Journal of Engineering Trends and Technology (IJETT) – Volume2 Issue 1 Number2–Aug 2011 Facing operation Grooving Grooving is like parting, except that grooves are cut to a specific depth by a form tool instead of severing a completed/part-complete component from the stock. Grooving can be performed on internal and external surfaces, as well as on the face of the part (face grooving or trepanning). Grooving operation Drilling Drilling is used to remove material from the inside of a workpiece. This process utilizes standard drill bits held stationary in the tail stock or tool turret of the lathe. ISSN: 2231-5381 http://www.ijettjournal.org Page 52 International Journal of Engineering Trends and Technology (IJETT) – Volume2 Issue 1 Number2–Aug 2011 Gear cutting Processes 1.1 Broaching 1.2 Hobbing 1.3 Machining Broaching ` For very large gears or splines, a vertical broach is used. It consists of a vertical rail that carries a single tooth cutter formed to create the tooth shape. A rotary table and a Y axis are the customary axes available. Some machines will cut to a depth on the Y axis and index the rotary table automatically. The largest gears are produced on these machines. Hobbing Hobbing is a method by which a hob is used to cut teeth into a blank. The cutter and gear blank are rotated at the same time to transfer the profile of the hob onto the gear blank. The hob must make one revolution to create each tooth of the gear. Used very often for all sizes of production runs, but works best for medium to high. ISSN: 2231-5381 http://www.ijettjournal.org Page 53 International Journal of Engineering Trends and Technology (IJETT) – Volume2 Issue 1 Number2–Aug 2011 Shaping The old method of gear cutting is mounting a gear blank in a shaper and using a tool shaped in the profile of the tooth to be cut. This method also works for cutting internal splines.Another is a pinion-shaped cutter that is used in a gear shaper machine. It is basically when a cutter that looks similar to a gear cuts a gear blank. The cutter and the blank must have a rotating axis parallel to each other. This process works well for low and high production runs. Welding Welding is a fabrication or sculpturalprocess that joins materials, usually metals or thermoplastics, by causing coalescence. This is often done by melting the workpieces and adding a filler material to form a pool of molten material that cools to become a strong joint, with pressure sometimes used in conjunction with heat, or by itself, to produce the weld. This is in contrast with soldering and brazing, which involve melting a lower-melting-point material between the workpieces to form a bond between them, without melting the workpieces. Many different energy sources can be used for welding, including a gas flame, an electric arc, a laser, an electron beam, friction, and ultrasound. While often an industrial process, welding may be performed in many different environments, including open air, under water and in outer space. Welding is a potentially hazardous undertaking and precautions are required to avoid burns, electric shock, vision damage, inhalation of poisonous gases and fumes, and exposure to intense ultraviolet radiation. ISSN: 2231-5381 http://www.ijettjournal.org Page 54 International Journal of Engineering Trends and Technology (IJETT) – Volume2 Issue 1 Number2–Aug 2011 Types of Welding Arc Welding Arc welding is a type of welding that uses a welding power supply to create an electric arc between an electrode and the base material to melt the metals at the welding point. They can use either direct (DC) or alternating (AC) current, and consumable or non-consumable electrodes. The welding region is usually protected by some type of shielding gas, vapor, and/or slag. Gas metal arc welding Gas metal arc welding (GMAW), sometimes referred to by its subtypes metal inert gas (MIG) welding or metal active gas (MAG) welding, is a semi-automatic or automatic arc welding process in which a continuous and consumable wireelectrode and a shielding gas are fed through a welding gun. A constant voltage, direct current power source is most commonly used with GMAW, but constant current systems, as well as alternating current, can be used. There are four primary methods of metal transfer in GMAW, called globular, short-circuiting, spray, and pulsedspray, each of which has distinct properties and corresponding advantages and limitations.Originally developed for welding aluminum and other non-ferrous materials in the 1940s, GMAW was soon applied to steels because it allowed for lower welding time compared to other welding processes. The cost of inert gas limited its use in steels until several years later, when the use of semi-inert gases such as carbon dioxide became common. Further developments during the 1950s and 1960s gave the process more versatility and as a result, it became a highly used industrial process. Today, GMAW is the most common industrial welding process, preferred for its versatility, speed and the relative ease of adapting the process to robotic automation. The automobile industry in particular uses GMAW welding almost exclusively. Unlike welding processes that do not employ a shielding gas, such as shielded metal arc welding, it is rarely used outdoors or in other areas of air volatility. Gas tungsten arc welding Gas tungsten arc welding (GTAW), also known as tungsten inert gas (TIG) welding, is an arc welding process that uses a nonconsumabletungstenelectrode to produce the weld. The weld area is protected from atmospheric contamination by a shielding gas (usually an inert gas such as argon), and a filler metal is normally used, though some welds, known as autogenous welds, do not require it. A constant-currentwelding power supply ISSN: 2231-5381 http://www.ijettjournal.org Page 55 International Journal of Engineering Trends and Technology (IJETT) – Volume2 Issue 1 Number2–Aug 2011 ELECTRIC-ARC CUTTING Electric-arc cutting is a method of melting or oxidizing metal by applying heat from an electric arc to the work-metal surface along a line of cut. Because of the extremely high temperature developed, the electric arc can be used to cut any metal that conducts electricity. Modifications of the basic process include the use of compressed gases to cause rapid oxidation (or to prevent oxidation) of the work metal, thus incorporating some aspects of gas cutting. Electric-arc cutting includes several processes, of which the following are of commercial importance: air-carbon arc cutting, oxygen arc cutting, plasma arc cutting, and the exo-process. Other, seldom-used processes, which largely have been superseded by the aforementioned, are briefly described in the last section of this article. Electric arc cutting can be used on ferrous and nonferrous metals for rough severing, such as removing risers or scrap cutting, as well as for more closely controlled operations. Each process has particular capabilities and limitations. Special applications include shape cutting, grooving, gouging, and underwater cutting. Operation on the part of the assemblies GEAR Facing, Taper turning, Drilling, broaching, hobbling, Gear tooth cutting of module 1.5. SHAFT Facing, Turning, Grooving, Drilling, 4key way sloting. HANDLE Facing, Turning, Drilling and internal thread cutting. BASE & COLUMN Drilling, Boring, Surface Grinding, Electric arc welding. All operation has been done with specific dimension. ISSN: 2231-5381 http://www.ijettjournal.org Page 56 International Journal of Engineering Trends and Technology (IJETT) – Volume2 Issue 1 Number2–Aug 2011 COST ESTIMATION COST OF THE STANDARD COMPONENTS Sl. Name of the components Quality Cost/piece in Rs. Total cost in Rs. Bearing (25 mm inner 04 122 488 No. 01 diameter) 02 Hexagonal M10 nut 04 12 48 04 M40 nut and bolt 03 02 06 TOTAL COST IN RUPEES 542 MATERIAL COST Sl. Name of the component Material Quantity Cost in rupees 01 Gear Mild steel 06 360 02 Shaft Mild steel 02 140 03 Supporting plate of base Mild steel 01 95 04 Supporting plate for column Mild steel 02 190 06 Handle Mild steel 01 40 07 Bed Mild steel 01 250 08 Washer Mild steel 02 20 09 Liver Mild steel 01 750 No. TOTAL COST IN RUPEES 1845 MACHINING COST Sl. Machine Operation Cost in rupees No. ISSN: 2231-5381 http://www.ijettjournal.org Page 57 International Journal of Engineering Trends and Technology (IJETT) – Volume2 Issue 1 Number2–Aug 2011 01 Gear teeth cutting Gear 9000 Hibbing 02 Shaft Turning faceing 03 Spine shaft 200 4 key way spline shaft 04 Lathe (finishing) 0 Fabrication and assembly 01. Lathe 1350 Facing, turning, finishing 600 Facing, turning, grooving 750 Arc welding 300 Drilling 200 Surface finishing 150 02. Welding 03. Milling machine 04. Grinding machine TOTAL COST IN RUPEES 12550 TOTAL COST OF DESIGN AND FABRICATION OF THREE SPEED GEAR BOX Sl. Particular Cost in rupees 01 Cost of standard component 542 02 Material cost 1845 03 Machining cost 12550 04 Transportation and allowances 900 05 Name plate and painting 200 No. TOTAL COST IN RUPEES 16037 PART AND ASSEMBLY DRAWING 1. Nut 2. Bolt 3. Bearing ISSN: 2231-5381 http://www.ijettjournal.org Page 58 International Journal of Engineering Trends and Technology (IJETT) – Volume2 Issue 1 Number2–Aug 2011 4. Shaft 5. Gear 6. Base support 7. Column 8. Washers 9. Assembly Drawing Nut Bolt ISSN: 2231-5381 http://www.ijettjournal.org Page 59 International Journal of Engineering Trends and Technology (IJETT) – Volume2 Issue 1 Number2–Aug 2011 Bearing spineShaft spurGear ISSN: 2231-5381 http://www.ijettjournal.org Page 60 International Journal of Engineering Trends and Technology (IJETT) – Volume2 Issue 1 Number2–Aug 2011 Bills of the materials: Sl.No. Part Description Quantity Material 01 Gear 06 Mild steel 02 Bearing 04 Mild steel 03 Shaft 02 Mild steel 04 Base support 01 Mild steel Liver 01 Mild steel 07 Supporting plate 02 Mild steel 08 Nut 04 Cast iron 09 Bolt 04 Cast iron 10 Handle 01 Mild steel 11 Washer 02 Mild steel SNAPSHOTS: ISSN: 2231-5381 http://www.ijettjournal.org Page 61 International Journal of Engineering Trends and Technology (IJETT) – Volume2 Issue 1 Number2–Aug 2011 ISSN: 2231-5381 http://www.ijettjournal.org Page 62 International Journal of Engineering Trends and Technology (IJETT) – Volume2 Issue 1 Number2–Aug 2011 REFERENCES 1. Gitin M Maitra, (2002) ‘Hand book of gear design’second edition, 2. S.K.F Industries (1991) ‘ bearing design table’p.p 9-10 3. T.Jayachandraprabhu (2011) ‘ design of transmission elements’gear box page no:20.4 WORK PLACE ADDRESS: 01. NEW DELTA GEAR PVT. LTD. PALLAVAN, CHENNAI- 600032 02. S.R.M. ENGINEERING WORKS No. – 30/27, POONAMALLIEE ROAD, EKKATTUTHANGAL, CHENNAI-600032 ISSN: 2231-5381 http://www.ijettjournal.org Page 63

![Machine Elements [Opens in New Window]](http://s3.studylib.net/store/data/009054465_1-76bd66345967cd60934cd86eccae6fad-300x300.png)