Design and Validation of a Casting Die Priyanka Vispute , Digambarchaudhari

advertisement

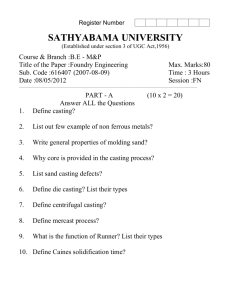

International Conference on Global Trends in Engineering, Technology and Management (ICGTETM-2016) Design and Validation of a Casting Die Priyanka Vispute#1, Digambarchaudhari*2, Reeti Mukherjee#3 # Department of Mechanical Engineering, Gokhale Education Society’s, R H Sapat C.O.E.M&R, Nashik,422005,India * Asst. Prof. at Department of Mechanical Engineering, Gokhale Education Society’s, R H Sapat C.O.E.M&R, Nashik,422005,India # Asst. Prof. at Department of Mechanical Engineering, VignanaBharathi Institute Of Technology, Hyderabad, 501301, India Abstract—The function of casting die is to hold the molten metal in the shape of desired casting so that the molten metal get solidify and finally removed out of die as a solidified casting. The design of the die is vital in determining the quality of the part produced. This paper mainly focus on the design phase for the die for an automobile component made of aluminium alloy (AIDC12). The design phase for the casting die involves discrete selection of design parameters namely, type of gate, location of the gate, Type of runner and its geometry, position for overflows and so on. Work involves designing the Casting die while securing crucial inputs from the `flow simulation’ for the calculation of number of air vents. The same is validated using the radiography tests. The Results shall be documented for offering as a quick generic reference for all the other part akin in form and features. Keywords—Analysis, Design, Die Casting, Flow Simulation I.INTRODUCTION Die casting has increasing application in automobile aerospace, household appliances industries due to high strength and good performance.Four basic functions of the casting die-(1) hold the molten metal in the shape of desired casting (2) provide a means for the molten metal to get into the space where it is to be held in the desired shape(3) remove heat from the molten metal to solidify the metal and (4) provide for the removal of the solidified casting. Hence quality of casting component is determined by the die with which the component is formed. [6] The Design phase for the Die Casting Die involves discrete selection of Design parameters namely, type of Gate, location of the Gate, Type of runner and its geometry, number of air vents and position for overflows. Overflow locations are placed appropriately based on flow simulations. Die casting enterprises need to produce high quality die castings in shorter period with lower cost. The production period of casting can be significantly reduced by introducing CAE system with computerized casting analysis that will reduce the cost and time required. Due to the complex shape of casting components large scale Different employed methods for casting simulation are - Finite Difference Method (Solid Cast), Finite volume Method (MagamaSoft), Finite Element ISSN: 2231-5381 Method (ProCast), and Vector Element Method (Auto Cast). Out of these our focus is on Magma Soft In the current study a casting die is designed andinvestigated for best solution. Numerical simulations have been found to be very useful in finding the best solution amongst calculated designs and also for defect proofing of die from various possible defects like gas porosity, cold shut, shrinkage cavity, air bubbles etc. Validation of work is performed by radiographic experimentation of component manufactured through die. II. LITERATURE STUDIES - Alexandre (2012) studied the rate of metal flow in the channel is much higher than the solid-liquid interface velocity. The flow in the thin cavity is treated as two-dimensional after integrating the momentum and continuity equations over the thickness of the channel, while the heat transfer is modeled as a one-dimensional phenomenon in the thickness direction. - Bodhayanaet al. (2014) investigated that die casting was a versatile manufacturing technique in which molten metal is poured into die. The die consists of core and cavity, an impression is formed when these core and cavity are closed together. This impression forms the shape and size of the component. The main challenge in die casting is design and manufacturing of die. Integration of design and analysis yields to better results. - Swamyet al. (2012)investigated on conventional gating design casting defects such as shrinkage and gas porosities were found in front axle housing a critical automotive component. This component is generally made out of spheroid graphite iron. A flawed gating system was found to be the reason for improper fluid flow and melt solidification which in turn produced casting defects - Sung et al. (2008) carried out computer simulations to analyze the flow of molten metal and analyze effective mould design. Optimal conditions are calculated through simple equations examined using experimental outputs. http://www.ijettjournal.org Page 67 International Conference on Global Trends in Engineering, Technology and Management (ICGTETM-2016) III. PROBLEM DEFINITION For current work, the die cast component named Case Gear Meter is considered for research over the most suitable design for Die. The design for the components has focused on aesthetics and function. The design and development phase is aimed to be short and effective. The Design for the Die holds a key in effecting a good quality product in a lesser turnaround period of development. The problem here was to identify the design parameters for the die casting die while manipulating the inputs for desirable responses i.e. output parameters. The same have been deployed through analytical tool for simulation of the die casting process with the result for key variation made for the best outcome for product quality i.e. minimization of defects through suitable Design. The design parameters namely, the type and location of the Gate, the Runner system and the overflow have been studied for concluding the design phase for the die. IV.SOLUTION METHODOLOGIES The flow simulation represents the analytical solution for the problem. Suitable CAE software would be deployed for modeling the problem and applying the constraints with the input parameters. The working conditions were defined over the interface along with application of the properties for the melt. The simulation have determined the nature of flow; fill time for the die, occurrence of any defect in the form of blow holes or deflection upon cooling. The nature and the magnitude or prominence of the defect would be evident while realizing the solution using this Analytical tool. This approach of problem solving have deployed CAD and CAE practices for arriving at the most suitable solution to the design problem at hand. The geometry would be modelled using CATIA for the dimensions of the product. This imported in the interface of the pre-processor for discretising the geometry. Further, flow simulation carried out using Magma Soft. Then deployed for evaluating the nature of flow with respect to time taken during filling as well as identifying potential threats to quality in terms of defects like blow holes, shrinkage, porosity, unfilled cavity. The characteristics of this component in terms of the aspects of quality is evaluated for determining the success of the design phase. V.DESIGN Product information Fig.1-3D diagram of Component to be manufacture ( made up of material- Aluminium alloy AIDC 12) Design of Case Gear Meter Casting Die System Die Material: Hot Die Steel H-13 .Principal Design Feature of this alloy is one of the Hot Work, Chromium type tool steel. It also contains molybdenum and vanadium as strengthening agents. The chromimum content assists this alloy to resist softening if used at higher temperature .[8] Table No. I: Chemical Composition of H-13[7] content Wt.(%) carbon 0.32-0.45 chromium 4.75-5.5 molybdenum 0.2-0.5 Phosphrous 1.1-1.75 Sillicon 0.03 max Sulpher 0.8-1.2 Vanadium 0.03 max Table No. II : Physical properties of H-13[7] Density(lb/cu.in.) 0.283 Specific Gravity 7.8 Melting point(0F) 2600 Modulus of Elasticity 29 Model calculation: 1) Part Projected Area: 2428.00mm2 ISSN: 2231-5381 http://www.ijettjournal.org Page 68 International Conference on Global Trends in Engineering, Technology and Management (ICGTETM-2016) 2) Overflow Projected Area:364.00mm2 3) Slide Projected Area= ( *6*6*2*tan 10)[5] =19.93mm2 4) Total Part Projected Area=(Part Projected area)+(Overflow Projected Area)+(Slide ProjectedArea)[5]= (2428)+(364)+(19.93) = 2 5623.86mm 5) Runner Projected Area=(Part Projected Area)+(3040% More) [5]=3797.00mm2 6) Total Projected Area=(Total Part Projected area)+(Runner Projected Area)[5] = 9420.86 mm2 7) Tonnage of Machine = (Total Projected Area)+(Casting Pressure)+(Die Locking Force)[5]=210 Tonnes VI. MODELLING AND MESHING Fig.3- Layout of casting die 8) Shot Weight = (Weight Per Cavity) + (Runner+Biscuits)[5]= 313.00gm 9) Filling Ratio= [5] = 3.73 10) Cavity Fill Time (t) =K*T* = . [6] 0.034 Where, K-Emperical constant=0.034 sec/mm. T-Casting thickness =4 mm Ti-Temperature of molted metal as it enters the die =6800c. Tf-Minimum flow temperature =6300c Td- Temperature of die cavity surface =1200c S-Allowable percent solid fraction Its selection depends upon casting thickness, per 4mm thickness its 20. z-Units convergion factor =3.8 [5] 11) Gate Area= = 63.180 mm2 Hence, Gate length=32 mm Gate Thickness=2 mm Above diagram shows the meshing diagram of Case Gear Meter die. Solver used for meshing is Magmasoft version 5. Total number of elements are 83328. Solid mesh type mesh is chosen.we have chosen this type of mesh as per the geometry.t This is mapped mesh. Element type is tetrahedral. Element size is 4. Accuracy of mesh quality is confirmed on basis of following criteria: Warpages > 5.00 Aspect ratio > 5.00 Skewness > 60.00 Net collaps < 0.5 Jacobian < 0.7 and trial faces: Minimum angle < 20 and Maximum angle > 20 [5] 12) Flow Rate = 3 = 2527233.115 mm /sec 13) Plunger velolcity = = 2011.10 mm/sec Plunger velocity = 2.01 m/sec ISSN: 2231-5381 Fig.2- Mesh diagram of casting die VII.RESULT AND DISCUSSION [5] After calculating all the design parameters like gate velocity, Gate area, metal temperatureand cavity fill time next task was to finalize total numbur of air vents for die. Total number of air vents are decided byback pressure analysis in magmasoft. According to the standard if the value of back pressure of entrapped air in casting cavity is more than 2 bar then it will lead to air porosity after machining of casting. http://www.ijettjournal.org Page 69 International Conference on Global Trends in Engineering, Technology and Management (ICGTETM-2016) Table No. III : Calculated nput boundary conditions for magmasoft analysis Parameters Values HighVelocity (m/sec) 2.0 Switch over point (mm) 339 2 Gate area (mm ) 62 Gate Velocity (m/sec) 41 Cavity FillTime (sec) 35 Material temp (oc) 680 o Die temp ( c) analysis result with one air vent where air pressure value observed is upto 4.1 bar. by adding one more air vent in further analysis along with same boundary conditions. Fig.7 shows that air pressure valuewithtwo air vents is reduced to 1.3 max with two air vents. Hence, two number of air vents are finalized. VIII.EXPERIMENTAL RESULTS OF RADIOGRAPHIC TEST 150 Above boundary conditions are given and results of back air pressure are documented as follows: Fig.6- radiographic test results Fig.4- Air pressure analysis result with one air vent After finalizing all the parameters of the die.The castingdie has been manufactured. For validating the manual design calculations and analysis with magmasof,t rediographic test has been performed on the first componant manufactured from die. Fig.6 showsthe results of resiographic test. From figure it can be clearly seen that product is not having any defects like air bubbles,hot spots, shrinkage cavities, gas porosity on it’s surface. Hence design paremeters are validated. IX.CONCLUSION [1] From above disscusion Design parameters are calculated as gate velocity 41 m/sec, metal temperature 680 deg.Gate area 62 mm2 and cavity fill time 35 sec. [2] It have been seen that value of maximum back pressure should be less than 2 bar to avoid air entrapped and gas porocity hence maximum back pressure is reduced upto 1.3 bar with aditional venting. [3] Total number of air vents finallized from analysis are two. [4] From rediographic test result it have been seen that there are no defects on the surface of componant hence, design is validated by radiographic test result. Fig.5- Air pressure analysis result with 2 air vents REFERENCES This result shows the back pressure of entrapped air in casting cavity. As alresdy discussed if this value is more than 2 bar then gas porosity difect will occure on the surface of componant after machining of casting. Fig.5shows the air pressure [1] Alexandre Reikhe ―Numerical Analysis of Die-Casting Process in Thin Cavities Using Lubrication Approximation‖ The University of Wisconsin-Milwaukee, December 2012, PP. 65-70. [2] Bodhayana M. R., N. Ramesha ―Tool design for pressure dies casting of Housing Component‖ International Journal on Theoretical and Applied Research in Mechanical Engineering Volume -3, Issue-2, 2014, PP. 30-33. ISSN: 2231-5381 http://www.ijettjournal.org Page 70 International Conference on Global Trends in Engineering, Technology and Management (ICGTETM-2016) [3] ManjunathSwamy H. M., J. R. Nataraj, C. S. Prasad ―Design Optimization of Gating System by Fluid Flow and Solidification Simulation for Front Axle Housing‖ International Journal of Engineering Research and Development, Volume 4, Issue 6 October 2012,PP. 83-88. [4] B.S. Sung, I.S. Kim ―The molding analysis of automobile parts using the die-casting system‖journal of materials processing technology, 20 1 (2008) 635–639. [5] E.A.Herman―Die casting dies‖ 2ndEdition ,Society of die casting Engineers,USA 1985 PP.7-287. [6] http://www.NADCA.com. [7] http://www.suppliersonline.com. ISSN: 2231-5381 http://www.ijettjournal.org Page 71