IS It Easy Being : Building a Sustainable Science

advertisement

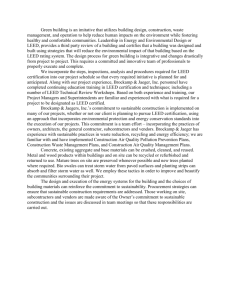

It IS Easy Being Green: Building a Sustainable Science Building on Smith College Campus, Northampton, MA Allison Crosby, Jes Hill, Amanda Wenczel Environmental Science and Policy Seminar May 2004 ABSTRACT In order to accommodate the growing science and engineering programs at Smith College in Northampton, Massachusetts, plans for a new science building have been made, with scheduled groundbreaking to begin in spring 2006. Through interviews with key figures in the science departments and physical plant, information was gathered that would allow for increasing sustainability plans for the new chemistry and engineering building. Using the science building’s projected LEED scorecard, sustainability options in the following categories were explored: sustainable sites, water efficiency, energy and atmosphere, materials and resources, indoor environmental quality, and innovation and design process. A close analysis involving ways in which sustainable technology from each of these categories could be implemented into the building followed. Smith College can indeed build a sustainable LEED certified chemistry and engineering building, especially if technology such as a microturbine, central vacuum system, renewable energy resources and recycled material are used. Smith College should use the sustainable construction of the first building as a tool in approaching future building projects on campus. INTRODUCTION "We thrive and survive on planet earth as a single human family. And one of our main responsibilities is to leave to successor generations a sustainable future." -UN Secretary-General Kofi A. Annan1 As human beings continue to utilize natural resources, produce massive amounts of waste, and contribute to the release of greenhouse gases into the atmosphere, the need to live in a sustainable manner becomes more and more apparent. The benefit of realizing the impact humans are having on the Earth’s environment is the opportunity to change the way in which we live, the opportunity to consume less, produce less, and leave less of an impact on our surroundings. There are many ways in which these objectives can be attained, one of which is by the construction of sustainable buildings that minimally disturb the environment in their construction, consume less energy and resources, produce less waste, and serve as an example and tool in the education of sustainability. The United States Green Building Council (USGBC) is an organization of people from across the country, dedicated to the building of “environmentally responsible, profitable, and healthy places to work and live.”2 The members of the USGBC have developed the LEED (Leadership in Energy and Environmental Design) Green Building Rating System, a voluntary standard for developing sustainable buildings. While LEED certification is completely voluntary, and uncertified buildings can still be sustainable ones, there are several reasons why Smith College should aim for LEED certification, and they include: the provision of a framework for assessing building performance and meeting sustainability goals, emphasis of state of the art strategies for sustainable site development, water savings, energy efficiency, materials selection and indoor environmental quality, recognition of achievements and promotion of expertise in green building through a comprehensive system offering project certification, professional accreditation, 1 Kofi A. Annan from http://www.sustainable.org/information/quote_archive.html 2 http://www.usgbc.org training and practical resources.3 LEED certification can be given on several levels based on a point system, with the certified level requiring the least points, followed by silver, then gold, with the platinum level certification requiring the most points. Total cost to become a LEED certified building is $2,250, and certification is valid for the life of the building. Certification is important because it establishes recognized leadership in the green building sector and in other environmentally conscious circles, it validates achievement through third party review, allows the building to qualify for a growing array of state and local government incentives, and contributes to a growing green building knowledge base on campus.4 LEED certification is not the only reason that a sustainable science building has been proposed, nor is it the sole focus of this project. What the LEED certification guidelines have provided is a framework for addressing the most pressing environmental issues in constructing a new building or refurbishing an older one. Smith College has often shown its commitment to sustainability: through the establishment of an Environmental Science and Policy Program, a campus committee on sustainability, creation of an engineering program that includes environmental engineering courses, and the signing of the partnership with Clean Air-Cool Planet, a pledge to work towards a reduction in greenhouse gas production and sustainability education and promotion among the Smith College community. The college has been placing increasing importance on lowering the negative environmental impact of the college, reducing waste, and becoming a more sustainable campus, and these priorities are being reflected in the proposal to build a sustainable, LEED certified science building. The new science building complex will eventually provide new facilities for all of the sciences (Fig. 2), but currently, Phase I is being planned. This involves the deconstruction of certain buildings on Green Street and Belmont Ave to construct a new building that will house the following departments: Chemistry, Computer Science, and Engineering, and perhaps some 3 http://www.usgbc.org/LEED/LEED_main.asp 4 https://www.usgbc.org/LEED/Project/certprocess.asp#why Biochemistry facilities. Building a sustainable LEED certified science building that will include building challenges such as chemistry labs and sophisticated computer equipment is no easy task, as these components make LEED certification more difficult, requiring careful planning for efficiency and optimal performance. With an approved budget of $45 million and 75,000ft2 of available space, budget and space constraints are definitely a concern. Using the LEED worksheet (Fig 1.) as a guideline, Jes Hill, Amanda Wenczel and I, Allison Crosby, have attempted to address certain unresolved aspects in the building plan in hopes of not only obtaining the highest possible LEED certification, but also in an attempt to make the chemistry and engineering building as sustainable and efficient as possible. Our aim is to aid in the design of a building that is going to be environmentally friendly, but also energy and cost efficient. We also hope that the building will serve as an example for other colleges and universities considering including a sustainable building on campus. Finally, this building is meant to be used as a teaching tool. Students must learn from this building, and learning must not only be applied in the classroom; the new chemistry and engineering building must have the technology applicable to “real life” situations. Students and visitors must experience the new science building and come away with a practical idea of what sustainability entails and the ways in which it can and must be incorporated into daily life. MATERIALS AND METHODS Interviews Interviews were a key component in beginning the process of assessing the possibility of a sustainable building on Smith College campus. Geology professor John Brady , was interviewed first, and after an extensive meeting, in which he outlined the science center building process, he provided detailed plans of the new building, as well as the two Programming and Masterplan Document volumes written by the building architect firm, Bohlin, Cywinski and Jackson. Tom Litwin, director of the Clark Science Center, was interviewed on two separate occasions. He addressed questions regarding the building process, such as space and budget, as well as provided names of other faculty members and administrators that could be contacted to gather further, more detailed information. Margaret Rakas, Manager of Inventory at the Clark Science Center, answered questions regarding chemistry lab waste disposal. Bob McCullough, in charge of Campus Operations and Facilities, supplied a myriad of information in a nearly 2-hour interview. Not only did he provide the LEED Scorecard Draft developed by Bohlin, Cywinski, and Jackson, but he deconstructed each section of the LEED Scorecard and predicted the subcategories of LEED certification that could be met without a doubt, those that could definitely not be met, and those that were open for discussion as to whether or not Smith College could incorporate these requirements into the new chemistry and engineering building. LEED Scorecard The LEED Scorecard, developed by the United States Green Building Council served as a guideline for determining sustainable technology needed to be considered for installation, and whether or not it was feasible for use in the new building, as well as areas that required further study to determine their practicality in terms of use in the new building. Though addressing each subcategory that had a “?” rating, research not only addressed whether or not points could be gained for LEED certification, but also the implementations that could add to the sustainability of the science building. Research In addition to interviews, Internet research was an integral part of finding methods and materials for constructing a green science building. The April 14, 2004 lecture based around Smith College’s signing of an agreement with Clean Air, Cool Planet for campus sustainability was an excellent resource in gathering information about alternative power sources. A fieldtrip to Mt. Holyoke College’s new and renovated LEED certified science building provided us with a few minor details about sustainable accessories that could be incorporated into the building at Smith College. Project Division Because of the scope and breadth of this project, the only option for effectively addressing each subcategory of LEED certification and developing a sustainable plan for the science building while discussing both of these topics in depth, was to assign a particular focus to each of the group members. Allison Crosby researched and discussed options for water efficiency, indoor environmental quality and innovation in design, while Amanda Wenczel addressed sustainable sites and materials and resources, and Jes Hill undertook the immense task of researching the energy and atmosphere aspects of the project. RESULTS Given the commitment of Smith College to build a sustainable, LEED certified science building, a green building is certainly attainable. Interviewees were open to the idea of building a green building and were supportive of the initiatives to make it as sustainable as possible. Water Efficiency Water efficiency is a major proponent of constructing a sustainable building. The architects are committed to designing water efficient landscaping, utilizing neither potable water resources nor irrigation. At this stage of design planning, it does not seem as though a 30% reduction in water use is attainable, however, with the incorporation of subcategory 2 in the Water Efficiency category of LEED, Innovative Wastewater Technologies, and a 30% reduction may be possible, with a definite water use reduction of at least 20%. A natural gas powered miniturbine is one innovative technology that is being considered for installation in the chemistry and engineering building; this turbine would allow for the use of rainwater in installations such as toilets. The use of rainwater in irrigation and for supplying non-potable water resources in other areas is an additional possibility for reducing water consumption and waste. Low flow toilets are major sources of water conservation and must be installed, as well as automatic sensors and aerators on faucets. Automatic sensors will ensure that the faucets are turned off and on only when needed, and aerators will increase the amount of air in the water stream coming out of the faucet, increasing spray velocity, and reducing splash, thereby conserving both water and energy.5 Chemistry labs are possibly the main source of water waste in the current science building. The fitting of efficient fixtures on laboratory sinks would reduce water waste, but an even larger reduction would occur with the installation of a central vacuum pumping system that supplied each of the chemistry labs with the ability to practice vacuum filtration techniques without using water. Indoor Environmental Quality The commitment to the indoor environmental quality of the new science building is already very high, and Smith College is dedicated to fulfilling at least 12 of the 15 possible credits in this LEED category, through the design of a construction air quality plan, use of low-emitting materials, and a thermal comfort system. The controllability of perimeter and non-perimeter systems remains in question, though controllability of most systems is most likely an attainable goal, especially in non-lab environments where constant pressure, light, temperature, and ventilation does not to need to be as meticulously maintained. While the architects do not predict that credit 8.1 can be met (providing a minimum percentage of daylight for 75% of spaces) this credit must be re-evaluated as a more finite plan is designed for the building. Innovation and Design Process This section of LEED credit is set aside specifically for buildings that will be utilizing a particularly innovative and new piece of technology. Architects anticipate Smith including at least one piece of technologically innovative equipment in the new building, the miniturbine being the most likely candidate to qualify for innovative design credit. Sustainable Sites Results outside the focus of this report include those gathered by individual group members and the group as a whole. In the Sustainable Sites category, a majority of the alternative 5 http://www.amconservationgroup.com/aerators.htm transportation and site disturbance credits can be met through use of existing resources. A defined landscape plan has been developed by the Smith College Botanic Gardens that will address the reduction of heat islands. Energy and Atmosphere In the Energy and Atmosphere, while some credits cannot possibly be fulfilled, such as the 60%optimization of energy performance, and the use of 20% renewable energy, alternative energy sources, such as solar and wind power, as well as the installation of a cogeneration system would all contribute to the reduction of energy use and the increase of renewable energy resources. A measurement and verification system must be implemented into the design, as it would serve as both a teaching tool and a way to track the efficiency of the science building. The use of green power is an option that must be considered in careful detail; it may not be a suitable option at present, but could be as more buildings are added to the science complex. Materials and Resources In the Materials and Resources category, most of the credits can be earned. While it is likely that 5% of the materials deconstructed from the building site will be usable for construction, reusable materials must be specified, and this information may not be available until deconstruction of existing buildings begins. Also in question is the use of rapidly renewable materials. While these materials, such as bamboo and wheat board are available for use in the building, their practicality is still in question. TABLES and FIGURES Version 2.1 Registered Project Checklist Conceptual Design Phase Smith College Engineering and Chemistry Building Yes 3 Y ? 7 No 4 Northampton , MA Sustainable Sites 14 Points Prereq 1 Erosion & Sedimentation Control Required Y N N ? Y ? ? ? ? ? N ? Y N Yes 2 ? 2 1 Water Efficiency N Credit 1.1 Water Efficient Landscaping, Reduce by 50% Credit 1.2 Water Efficient Landscaping, No Potable Use or No Irrigation Credit 2 Innovative Wastewater Technologies Credit 3.1 Water Use Reduction, 20% Reduction Credit 3.2 Water Use Reduction, 30% Reduction ? ? 3 ? 5 5 Points 1 1 1 1 1 No 6 Y Y Y Y ? N N Y N ? 1 1 1 1 1 1 1 1 1 1 1 1 1 1 No Y Y Yes Credit 1 Site Selection Credit 2 Development Density Credit 3 Brownfield Redevelopment Credit 4.1 Alternative Transportation, Public Transportation Access Credit 4.2 Alternative Transportation, Bicycle Storage & Changing Rooms Credit 4.3 Alternative Transportation, Alternative Fuel Vehicles Credit 4.4 Alternative Transportation, Parking Capacity and Carpooling Credit 5.1 Reduced Site Disturbance, Protect or Restore Open Space Credit 5.2 Reduced Site Disturbance, Development Footprint Credit 6.1 Stormwater Management, Rate and Quantity Credit 6.2 Stormwater Management, Treatment Credit 7.1 Landscape & Exterior Design to Reduce Heat Islands, Non-Roof Credit 7.2 Landscape & Exterior Design to Reduce Heat Islands, Roof Credit 8 Light Pollution Reduction Energy & Atmosphere 17 Points Prereq 1 Fundamental Building Systems Commissioning Prereq 2 Minimum Energy Performance Prereq 3 CFC Reduction in HVAC&R Equipment Credit 1 Optimize Energy Performance Credit 2.1 Renewable Energy, 5% Credit 2.2 Renewable Energy, 10% Credit 2.3 Renewable Energy, 20% Credit 3 Additional Commissioning Credit 4 Ozone Depletion Credit 5 Measurement & Verification Required Required Required 1 to 10 1 1 1 1 1 1 ? Yes 7 ? 2 4 N N N Y Y ? N Y Y Y Y ? Y Yes ? No 12 2 1 ? ? Y 1 Materials & Resources 13 Points N Y Y Y Y Y Y Y Y Y Y Y Y Credit 6 Green Power Prereq 1 Storage & Collection of Recyclables Required Credit 1.1 Building Reuse, Maintain 75% of Existing Shell 1 Credit 1.2 Building Reuse, Maintain 100% of Shell 1 Credit 1.3 Building Reuse, Maintain 100% Shell & 50% Non-Shell 1 Credit 2.1 Construction Waste Management, Divert 50% 1 Credit 2.2 Construction Waste Management, Divert 75% 1 Credit 3.1 Resource Reuse, Specify 5% 1 Credit 3.2 Resource Reuse, Specify 10% 1 Credit 4.1 Recycled Content, Specify 5% (post-consumer + ½ post-industrial) 1 Credit 4.2 Recycled Content, Specify 10% (post-consumer + ½ post-industrial) 1 Credit 5.1 Local/Regional Materials, 20% Manufactured Locally 1 Credit 5.2 Local/Regional Materials, of 20% Above, 50% Harvested Locally 1 Credit 6 Rapidly Renewable Materials 1 Credit 7 Certified Wood 1 Indoor Environmental Quality 15 Points Prereq 1 Minimum IAQ Performance Prereq 2 Environmental Tobacco Smoke (ETS) Control Credit 1 Carbon Dioxide (CO2 ) Monitoring Credit 2 Ventilation Effectiveness Credit 3.1 Construction IAQ Management Plan, During Construction Credit 3.2 Construction IAQ Management Plan, Before Occupancy Credit 4.1 Low-Emitting Materials, Adhesives & Sealants Credit 4.2 Low-Emitting Materials, Paints Credit 4.3 Low-Emitting Materials, Carpet Credit 4.4 Low-Emitting Materials, Composite Wood & Agrifiber Credit 5 Indoor Chemical & Pollutant Source Control Credit 6.1 Controllability of Systems, Perimeter Credit 6.2 Controllability of Systems, Non-Perimeter Credit 7.1 Thermal Comfort, Comply with ASHRAE 55-1992 Required Required 1 1 1 1 1 1 1 1 1 1 1 1 Y N Y Yes ? Innovation & Design Process Credit 1.1 Innovation in Design: Provide Specific Title Credit 1.2 Innovation in Design: Provide Specific Title Credit 1.3 Innovation in Design: Provide Specific Title Credit 1.4 Innovation in Design: Provide Specific Title Credit 2 LEED™ Accredited Professional ? Y 28 ? 1 1 1 No 1 1 Yes Credit 7.2 Thermal Comfort, Permanent Monitoring System Credit 8.1 Daylight & Views, Daylight 75% of Spaces Credit 8.2 Daylight & Views, Views for 90% of Spaces 5 Points 1 1 1 1 1 No 19 16 Project Totals (pre-certification estimates) 69 Points Certified 26-32 points Silver 33-38 points Gold 39-51 points Platinum 52-69 points Figure 1 LEED Certification Worksheet (Conceptual Design Plan as of 10/2003) Seelye West Street Green Street Phase I Figure 2 Concept Plan of New Science Complex Phase I (paper focus) outlined in red Figure 5 Conceptual Entry Level Plan showing the North/South placement of building *please note, compass in incorrect, “N” should actually read “E” Water Efficiency DISCUSSION In terms of LEED certification for Smith College, credits in this category are closely tied together. The use of water efficient landscaping is directly tied to both innovative wastewater technologies and water use reduction. Water efficient landscaping, credits 1.1 and 1.2 in this LEED category, have always been part of the original plan for the new science building. In the Site Program and Site Concept Plan, a section of the Programming and Masterplan, it has been stipulated that the landscape designers, in conjunction with Michael Marcotriciano, Director of the Botanic Garden, will “select plant materials to emphasize native materials, thereby minimizing maintenance and the need to irrigate and fertilize. They will…reduce heat islands, absorbs storm water, shelter the building from winter winds and summer suns, and reduce soil compaction.6 Innovative wastewater technology could supply what little water is necessary for the landscaping surrounding the building. One of the most important pieces of equipment in the building is the mini- or microturbine. Most buildings that utilize microturbines use them for the generation of electricity, since they are a cleaner, more efficient way to do so. In Smith’s case, MassElectric distributes electricity through a central source, Physical Plant, which in turn, supplies the entire campus with power. The installation of a microturbine at phys plant to power the entire campus is completely impractical. There are other ways to employ this technology without using it for electricity generation, however, and it may play an important role in the use of rainwater. Rainwater collection ducts would need to be installed into the roof surfaces, and the water, after being filtered for larger debris, such as sticks and leaves, would flow down a storage vessel associated with the microturbine system housed in the basement. The natural gas-powered turbine 6 Bohlin, Cywinski and Jackson 2003: 3.2 would then power the flow of water throughout the building to be used in irrigation and in toilets, as there is no need to used potable or pure water for either. The benefit of using a microturbine, besides the fact that it allows for the conservation of water by redirecting rainwater that would normally run off into city sewers, is that it is not powered by coal, but by natural gas. Natural gas, though it is still a hydrocarbon fuel source, has many benefits, and in conjunction with the microturbine, benefits would include: very low air emissions without use of expensive emission control devices, fewer moving parts, relatively low operation and maintenance costs, compact size, light weight, small footprint, highly reliable and durable. 7 As more technological advances are being made to microturbine systems, some are being developed that are powered by alternative fuel sources, which may be an option by the time the system is ready for installation in the chemistry and engineering building. A major drawback to the installation of the miniturbine may be the initial cost, but given the turbine’s high performance potentials once installed, high-energy efficiency, fuel flexibility, low emissions, and the possibility of Department of Energy funding for installation and use, the initial cost of the microturbine would soon be outweighed by the benefits.8 Low flow toilets will be an essential part of the water use reduction plan in the chemistry and engineering building. Currently, most of the toilets in the existing science buildings are older models that use up to 23 liters per flush (lpf). New water efficient models made by all the major toilet manufacturers nationwide only use 6 liters per flush. While there are no estimates of the number of toilets that will be installed, even a rough estimate of 20 toilets, being flushed (a conservative estimate) of 50 times daily; in one day, the low flow toilets would save 17,000 liters. In an EPA conducted study, 6 lpf toilets have been shown to reduce toilet water use by 23% to 46% and save 7 http://www.sdenergy.org/ContentPage.asp?ContentID=47&SectionID=49 8 http://www.eere.energy.gov/de/pdfs/micro_indgas_conf_02/debbie_haught.pdf and Bob McCullough, pers. comm. an average of 41 liters per person daily.9 Cost of low flow toilets would not be an issue, either, as even the most standard toilet models on the market are low flow. The only area in which cost could potentially be increased is in models where flush valve size increases, reducing the chance that the toilet has to be flushed more than once to clear its contents. It should be noted, however, that even if a toilet needs to be flushed twice, the low flow toilet still only uses half as much water as older models. Aerators should be installed in all sinks, including laboratory sinks. While laboratory designs (Fig. 3, Fig. 4) appear to centralize sinks to reduce the of water utilized per student, aerators should still be used to “increase spray velocity, reduce splash and save water and energy.”10 These products are available in bulk and at a minimum expense, and there is no reason why they cannot be used on all sinks. Motion or infrared sensors should also be used on all suitable sinks, particularly those in restrooms. Sensor sinks are available from most major sink manufacturers, although Moen has produced a recent model, intended for high capacity use, that not only turns on when it senses motion, but has an adjustable sensor that turns off anywhere from 1 to 8 seconds after motion is no longer detected.11 With settings at the minimum for shutoff and use of an aerator, sinks could become a major source of water conservation. Chemistry labs are major consumers of water. Besides the fact that water is an essential factor to many wet lab experiments, used for heating and cooling, and used to clean equipment, an important procedure in lab work is vacuum distillation. This process requires the creation of a vacuum to separate solutes from solutions, and traditionally, this is done by letting the sink run at full power. Even though the water is running through the lab equipment and going down the drain, the rushing water creates suction. This method, however, wastes an incredible amount of water. In 9 http://www.epa.gov/owm/water-efficiency/toilets.htm 10 http://www.amconservationgroup.com/aerators.htm 11 http://www.moen.com/Consumer/press/Article.cfm?ArticleId=266 her May 2003 report on sustainable chemistry at Smith College, Environmental Science and Policy student Molly Williams quotes chemistry lab professor David Bickar, reporting that he “estimates that water aspirators alone use more than a million gallons of water each semester.”12 A central vacuum system would eliminate the need for water use altogether. Many models use neither water nor oil to run and create suction,13 and have been very successfully integrated into laboratories at prestigious institutions, such as Dartmouth and Princeton.14 If the amount of water wasted in experiments where vacuums are required is truly as grim as the “millions of gallons” estimated by one professor, a central vacuum system is an essential part of the new science building, almost regardless of cost. While this machine may require the use of natural gas and may be costly (cost estimates were not available from distributors at the time of completion) the amount of water that will be saved will quickly outweigh initial cost and gas use. Furthermore, the use of this technology may allow Smith to regain points for LEED credit; a 30% reduction in water was decidedly impossible because of the addition of the chemistry program to the building, and a 20% reduction in water use remained questionable. If a centralized vacuum system is combined with the microturbine for irrigation and toilet water, low flow toilets, and aerated, motion sensor sinks, a 20% reduction in water is certainly attainable, and perhaps even the 30% reduction. In addition to the above-mentioned methods of water conservation, other laboratories throughout the country that are certified at highest LEED ratings employ other methods for water conservation. Pharmacia Building Q in Skokie, Illinois, a LEED gold certified building, employs a closed-loop process for water for cooling lab equipment, as opposed to a once-through tap water system.15 In addition to using reclaimed water for irrigation and toilets, Donald Bren Hall on the 12 David Bickar, pers. comm. In Williams 2003: 5 13 http://www.vacuubrand.net/ 14 www.princeton.edu and www.dartmouth.edu 15 http://labs21.lbl.gov/docs/pharmacia.pdf University of California’s Santa Barbara campus, a LEED platinum certified building, waterless urinals were installed, each of which saves upwards of 171,000 liters of water a year.16 Indoor Environmental Quality Indoor Environmental Quality is a high priority in the building and design of the new science center, and it is the category in LEED certification where the most “yes” points will be gained. A plan for minimum indoor air quality performance has been established, as well as an environmental tobacco smoke plan, which is attainable due in part to the fact that buildings on campus are smoke free, and any smoking on campus must take place a minimum of twenty feet from buildings. Both plans comply with codes and standards set by the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), as does the thermal comfort plan, which not only complies with ASHRAE, but will be installed with a permanent monitoring system, ensuring proper levels of humidification and air-temperature are maintained at all times. A carbon dioxide monitoring system will also be installed in the building, and “green” monitoring systems are available. As the construction of the building begins, several factors to control the indoor environmental quality must be implemented. First of all, the architects must establish a written Indoor Air Quality plan, which explains and ensures that the proper measures will be taken to keep the building properly ventilated during construction, and ensuring the protection of any absorptive building materials from construction fumes and particles. After construction is complete, another assessment of the building must be made, to make sure the building has been properly “flushed” of all particles and debris from construction and ensuring that the air is of suitable quality. Low-emitting materials, those lacking Volatile Organic Compounds (VOC’s) will be used in construction, and these include adhesives and sealants, paints, carpet, and composite wood. Special ventilation is planned for the control of indoor chemical and pollutants, and walk-off mats will be used to control pollutants being tracked in on shoes from outside. 16 http://www.labs21century.gov/pdf/cs_bren_508.pdf Because all the rooms in the new building will be located on the perimeter, over 90% of the spaces will have views, complying with LEED credit 8.2. Credit 8.1 remains in question; this is the requirement for 75% of all spaces to have a minimum “daylight factor” of 2%.17 This requirement means that at least 75% of all rooms in the building must receive a certain amount of daylight. This credit must be reviewed as construction draws closer; depending on the amount of windows that are planned for the building, including skylights and wall windows, the amount of daylight received by each room may vary greatly, especially since the building will be constructed on an north/south axis (Fig 5.), with a majority of the windows facing either east or west, which, in the winter especially, will minimize the amount of daylight certain rooms will receive. The ability to control certain systems with in the building is also an area where gaining LEED credit is somewhat questionable. The ability to control perimeter systems, i.e. windows, would be easily attainable in rooms that do not require stringent controls in terms of temperature and ventilation, such as faculty offices, classrooms, and other non-lab spaces. Controllability of nonperimeter systems would allow individuals to control ventilation, heating and cooling, and lighting. Once again, control of these systems is attainable in a non-lab setting, and would be highly beneficial, especially given the sometimes variable New England weather; students and professors would be more likely to turn off heating systems and open windows on a warm day in the early spring or late fall, and make other appropriate, energy-saving changes in temperature and ventilation when necessary. Attaining credit in these two areas may take additional planning, but will prove to be beneficial not only improving energy use but also beneficial to comfort levels of building inhabitants, as they will have more control over the internal environment. 17 http://www.usgbc.org/Docs/LEEDdocs/v2.docreq.8.14.00.pdf Innovation and Design Process Innovation and Design Process is a series of LEED credits set aside for the buildings that incorporate new, innovative, and efficient methods and technology into their building. The microturbine would be one such innovative piece of equipment. As this technology is still in its testing phase, especially in the case of green powered turbines, and used mostly for electricity generation, the use of a microturbine to redistribute rainwater would certainly gain LEED credit.18 The Pharmacia Q building earned innovative design credit for its incorporation of green housekeeping products not only into its LEED certified building, but its entire multi-building campus. The green cleaning products used were biodegradable over short periods of time, nontoxic, phosphate, ether, alkali, and distillate free.19 Other buildings that have received credit for innovative design have implemented the following: “Exemplary on-site occupant recycling program that incorporates an educational guidebook, reuse of office supplies, and a composting program. Integrated pest management program for interior and exterior minimizes use of pesticides. Exemplary use of recycled content products,” in the Department of New York State Department of Environmental Conservation Environmental Conservation in Albany,20 the use of Energy Star appliances and office products in the Conservation Law Foundation Extension Building in Boston,21 and a sustainability education plan at the Audubon Center at Debs Park in Los Angeles. 22 A final credit can be earned in this category through the use of a LEED accredited professional being involved in the building process. 18 Bob McCullough, pers.comm. 19 http://labs21.lbl.gov/docs/pharmacia.pdf 20 http://www.usgbc.org/Docs/Certified_Projects/0006NYSDECcaseStudy2.pdf 21 http://www.usgbc.org/Docs/Certified_Projects/Cert_Reg90.pdf 22 http://www.usgbc.org/Docs/Certified_Projects/Cert_Reg100.pdf Sustainable Sites Credits cannot be attained in several of the sustainable sites categories due to the fact that they simply do not apply to the Smith College site, or they are not feasible for the site. The construction will involve neither urban or brownfield redevelopment, nor will the facility have the capacity to treat stormwater, as stormwater will be collected by city sewers. Light pollution reduction is not possible on campus because the reduction in lights in any area of campus is a major safety concern.23 Overall, a sustainable site has been chosen for the construction of the building. LEED accreditation guidelines require the selection of a “practical” site on which construction will cause the least impact.24 Since the site Smith College has chosen for construction already has buildings on it, there will be very little environmental impact, especially as plans for deconstruction are going to be rigorously controlled. Furthermore, the existing Dickinson Lot may be closed to cars to house construction equipment, and Green Street and Belmont Ave provide the necessary access for construction equipment. This means that no land will have to be cleared or roads built in order to accommodate construction equipment.25 Alternative Transportation credits remain somewhat in question. While public transportation is accessible, LEED certification requires that access to public transportation, at least two different routes, is accessible within ¼ mile of the building. The PVTA qualifies as alternate transportation, and both nearby stops at John M. Greene Hall and the Academy of Music service more than one bus route. Distance from the new science building remains questionable, however, and the distance between JMG and the science building will have to be carefully measured in order to determine 23 Bob McCullough, pers.comm. 24 http://www.usgbc.org/Docs/LEEDdocs/3.4xLEEDRatingSystemJune01.pdf 25 Tom Litwin, pers.comm. whether or not the bus stop is within ¼ mile of the building.26 Parking capacity also remains in question, but increased use of the parking garage will ensure space for visitors, students, and faculty alike, as personal observations confirm that the parking garage is rarely full to capacity except during special occasions. Smith College has a specific landscape plan for the grounds surrounding the new chemistry and engineering building. A green roof is planned to not only reduce roof heat islands, but to be used as a teaching tool as well.27 An impressive landscape plan has been established, and is described in great detail in the Site Program and Site Concept Plan contained in the Masterplan document. It involves the conversion of the new science center lawn into a “large-scaled Olmstedian space” while maintaining access to the building for students and public safety vehicles.28 The Dickinson Parking Lot will be removed and “greened” with trees and plantings, which will work to reduce non-roof heat islands. Energy and Atmosphere Because the new science building will contain laboratories, a reduction in energy use of more that 30% is impossible. Many steps to optimize energy performance can be taken, however, and many of them are as minor as changing a light bulb. In the Masterplan document, Smith has already stipulated their plans for sustainable energy use. A cogeneration system has been proposed for use as the science building complex expands, though implementation of this technology in the first phases of building are doubtful.29 This system would make it possible to combine heat and power generating systems, with steam recovery options for converting steam byproducts into chilled water.30 The cogeneration system will also reduce the demands on physical plant and remove the need for expensive additions to the phys plant facilities. 26 Bob McCullough, pers.comm. 27 Bob McCullough, pers.comm. 28 Bohlin, Cywinski and Jackson 2003: 3.1 29 Bob McCullough, pers. comm. 30 http://www.aceee.org/energy/chp.htm Variable air volume, variable exhaust volume, constant face velocity, usage based, fume hood control system has been proposed to maintain constant airflow in laboratory fume hoods; this will ensure constant air circulation in the fume hoods, but will adjust the amount of air flowing through them according to whether or not the fume hoods are in use.31 Fume hood ventilation flow control was a major source of energy use reduction in both the Skokie, Illinois and Santa Barbara, California LEED certified labs mentioned earlier.32 Electricity use is additional factor in the reduction of energy use, and Smith has made plans to address power issues as well. Occupancy sensor devices will be used in all classrooms and, pending approval, laboratories, and daylighting will be used to the “maximum extent possible throughout the building.”33 The use of energy-efficient light bulbs is a must, and options include various forms of halogen and fluorescent light bulbs that have a much longer life than standard incandescent bulbs, and reduce energy use as well.34 Renewable energy and the purchase of off-sight green power are two other options that have been discussed to some extent; at this point, it appears that a 5% use of renewable energy will be the more feasible of the two. Because of the central electricity providing system at phys plant, it is very difficult to purchase green power; if individual buildings were powered by individual sources, options might be different. Renewable energy can be gathered on site, however, and the most practical way to do so may be through solar energy. Collection of solar energy would involve simple installation of the proper equipment, and the slanted rooftops proposed by the architects would be the perfect site for collection panels.35 31 Bohlin, Cywinski and Jackson 2003: 3.26 32 http://labs21.lbl.gov/docs/pharmacia.pdf and http://www.usgbc.org/Docs/LEEDdocs/v2.docreq.8.14.00.pdf 33 Bohlin, Cywinski and Jackson 2003: 3.36 34 http://www.ftc.gov/bcp/conline/pubs/products/ffclight.htm 35 Bohlin, Cywinski and Jackson 2003: 4.4 Materials and Resources As in the case of certain Energy and Atmosphere credits, Smith does not qualify for certain Materials and Resources credits, as they are not applicable to the new building. These include building reuse, and 10% resource reuse, which are not possible because a new building is being constructed and because probably no more that 5% of building materials can be salvaged from the deconstruction of existing buildings, given the nature of the materials used in the deconstructed buildings. The architects have made definite plans for the disposal and use of certain building materials. A plan to divert construction at least 75% of construction materials from landfills through reuse, recycling and other methods has been established. The use of at least 50% recycled carpet, including indoor materials such as carpets, has been agreed upon as well, as has the use of local materials from within 500 mile radius of campus, and certified wood use, that would ensure all wood is harvested in conformance with the Forest Stewardship Council and at least 50% of all products containing wood have been constructed using certified wood. The use of rapidly renewable materials must be further researched in order to assess the usability of products in the building. The significance of this project is not its focus on LEED certification, though this framework was the basis for determining ways in which the new chemistry and engineering building could be made sustainable. A highly sustainable science building is a possibility and would have an important place on Smith College campus. The suggestions made above are those that are recognized as most pressing and important in the sustainability of not only the new science building, but that of Smith College campus as a whole. The following recommendations must be implemented in the new science building, in the entire science complex and throughout Smith campus in order to uphold the college’s commitment to creating a more sustainable campus and serving as an example to other college communities and the world as a campus dedicated to the betterment of the environment: • Install the following technology to reduce water waste: low flow toilets, aerators, motion sensor sinks, and most importantly, a microturbine and central vacuum system • Ensure the accessibility of alternative transportation sources • Utilize renewable energy sources, especially solar on-site sources • Reduce energy by installing energy-efficient equipment, such as double-glazed windows, energy efficient light bulbs and lighting structures, such as motion activated lights, and airflow adjusting fume hoods • Reuse materials from deconstruction and recycled materials for construction whenever possible • Promote the “greening” of the campus, such as the conversion of Dickinson Parking Lot to green space, whenever and wherever possible • Install a measurement and verification system that not only serves as a monitor for energy consumption but as an educational tool illustrating the sustainability of the building • Obtain LEED certification-silver certification is attainable, as is gold if the following recommendations are all implemented • Ensure that all future buildings on Smith Campus have at least the minimum LEED requirements • Develop a sustainability awareness education course, with a focus on the new science building Resources Cited Bickar, David. May 2003. Personal Communication in Williams, Molly. Making Smith College Chemistry More Sustainable? Unpublished Research Bohlin, Cywinski and Jackson. 5 September 2003. Smith College Northampton, Massachusetts, Programming and Masterplan Document, Clark Science Ceter, Engineering and Chemistry Building. Vol 1 & 2 Working Drafts . Homepage: AM Conservation Group, Inc. 2001 http://www.amconservationgroup.com/aerators.htm Homepage: American Council for an Energy-Efficient Economy. 5 May 2004. http://www.aceee.org/energy/chp.htm Homepage: Dartmouth College. 5 May 2004. http://www.dartmouth.edu Homepage: Environmental Protection Agency. 5 May 2004. http://www.epa.gov Homepage: Federal Trade Commission. 5 May 5, 2004. http://www.ftc.gov Homepage: Labs for the 21st Century. 29 April 2004. http://www.labs21century.gov Homepage: Moen. 16 January 2004. http://www.moen.com Homepage: Princeton University. 5 May 2004. http://www.princeton.edu Homepage: San Diego Regional Energy Office. 2004. http://www.sdenergy.org/index.asp Homepage: Sustainable Communities Network 13 April 2004 http://www.sustainable.org Homepage: United States Department of Energy Distributed Energy Program. 4 May 2004. http://www.eere.energy.gov/de Homepage: United States Green Building Council 13 April 2004 http://www.usgbc.org Homepage: Vacuubrand, Inc. 2002. http://www.vacuubrand.net/ Interview: 2 April 2004. John Brady. Geology Professor. Interview: 2 April 2004, 14 April 2004. Tom Litwin. Science Center Director. Interview. 8 April 2004. Margaret Rakas. Manager, Inventory and Reg Affairs, Clark Science Center. Interview. 12 April 2004. Bob McCullough. Manager of Capital Projects, Physical Plant. Laboratories for the 21st Century: Case Studies. December 2002. Pharmacia Building Q, Skokie, Illinois. http://www.labs21.lbl.gov/docs/pharmacia.pdf Laboratories for the 21st Century: Case Studies. February 2004. Donald Bren Hall, Santa Barbara, California. http://www.labs21century.gov/pdf/cs_bren_508.pdf Acknowledgments I would like to thank the following people for providing support and assistance throughout this project: Fellow group members Jes Hill and Amanda Wenczel for their hard work and dedication Professor L. David Smith for guidance and advice Professor John Brady for helping us get started on the right foot Tom Litwin for seeing our group always spur of the moment and still answering our many questions Margaret Rakas for her information regarding toxic waste removal Bob McCullough for taking a significant amount of time out of his schedule to provide us with the basis of this paper The Smith College community for their general support of this project and increased sustainability on campus Melissa Cullen-DuPont, Rachel Dwyer, Elizabeth Eyerer, and all the residents of Hubbard House and B2 who patiently listened with interest (feigned or not) to Amanda, Jes and I rant about the “coolness” of sustainability