Electric Vehicle Charging Infrastructure Deployment Guidelines British Columbia

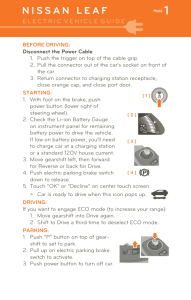

advertisement