AN ABSTRACT OF THE THESIS OF HISASHI ISHIYAMA (Name of student)

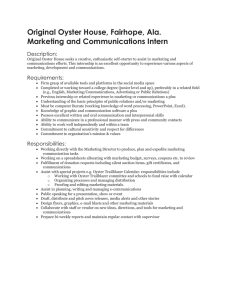

advertisement