AN ABSTRACT OF THE THESIS OF DAVID LEE HOLST

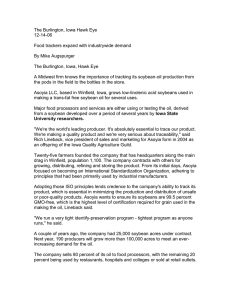

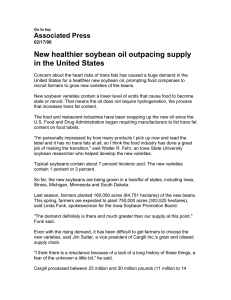

advertisement