CLEANER PRODUCTION MONROE AUSTRALIA PTY LTD

advertisement

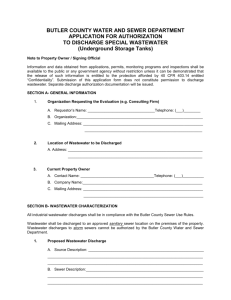

CLEANER PRODUCTION CASE STUDY THE WORLD'S BEST SHOCK ABSORBERS MONROE AUSTRALIA PTY LTD SUMMARY The company implemented a major waste minimisation strategy that enables them to process liquid waste, reduce water usage, chemical and waste disposal costs.The new equipment, a Microsep industrial wastewater treatment plant, treats wastewater to remove emulsified fats and oils, grease, heavy metals and all forms of suspended, colloidal and some dissolved solids. Mains water usage was reduced by over 10 ML per annum and wastewater discharge to sewer was reduced by 50%. The new technology has brought a saving of $250,000 per annum with a payback period of 2 years. CASE STUDY CASE STUDY CASE STUDY CASE STUDY MONROE AUSTRALIA PTY LTD Business Profile Monroe Australia is a leading manufacturer of shock absorbers and strut suspension units for the automotive industry.The company had a turnover of over $100 million in 1998 and has 450 employees. A significant percentage of the company’s total production is exported to Asia, North America and Europe. Financial assistance provided An interest free loan of $50,000 for purchasing the new equipment was provided by the EPA’s Cleaner Industries Demonstration Scheme. Measures implemented Major waste minimisation strategy; Microsep wastewater treatment plant and ancillary equipment; reverse osmosis pure water generation unit; water recycling. Cleaner production motivators The need to identify and focus on: reducing all forms of waste generation; conserving water; generating and maintaining a healthy environment for employees and surrounding community. TRADITIONAL APPROACH An inherent part of the process of manufacturing shock absorbers and strut suspension units for motor vehicles involves various chemicals that contribute to the liquid waste stream. CLEANER PRODUCTION INITIATIVES Benefits recommended and implemented Installation of Microsep wastewater treatment plant and ancillary equipment Installation of reverse osmosis pure water generation unit Installations of water recycling pumps and pipework The Microsep unit is a combination of chemical reactor and clarifier within a single plant able to treat many forms of liquid waste.The plant pretreats chemicals when necessary, then allows the resultant solids including gelatinous precipitates, oils and grease to rapidly settle out.The plant can also filter previously unfilterable solids for disposal. #1 CASE STUDY CASE STUDY CASE STUDY CASE STUDY CASE WASTE MANAGEMENT The process 1) Waste directly to sewer generating waste From two sources: as rinse water from the hard chromium electroplating process and from the metal pretreatment process before the finished product is painted.Total discharge flow was 45 kL per day. 2) Waste treated for disposal Oily water waste streams comprising metal turning, cutting and grinding lubricants and coolants from the machining centres with a daily volume of 10,000 L. Regular removal and replacement of chemical solutions required average daily volume of 2000 L. Waste stream In 1994 this processing used over 70 ML of water and generated almost 15 ML of liquid waste. Excess water cost in 1994 was $50,358 with wastewater streams of 52 ML. 12 ML per annum of purified water was generated for process requirements. Water in all forms—clean, treated or contaminated—represented a significant volume and cost burden on the company’s operation. Waste composition The effluent contained a mixture of amines, olamines, amides, surfactants and wetting agents (generally organic in nature), refined mineral oils and synthetic machining and grinding fluids; plus a high content of heavy metals such as chromium, zinc, copper, aluminium; and oil and grease, and iron. Cost of disposal Total costs for disposal of non-sewerable liquid waste in 1995: approx $403,000. Mains water Electroclean rinse Chemical Machining Cooling Domestic processing coolants/ towers lubricants tanks Process solutions Oily water Bulk Bulkwater rinse Bulk Microsep plant waste water treatment Sludge Process flow diagram—water treatment and recycling Filter press Cake Landfill VICr removal Top up chrome solution Clean water Top up phosphate Clean water storage Post chrome rinse area Water purification unit Stage 3 rinse paint shop Pure water Bulk storage Stage 5 paint shop rinse Rectifier cooling water Air scrubbers Horticulture Excess water Direct sewer discharge Non-sewerable wastewater streams are blended with rinse water (directed to the sewer traditionally) to provide a homogenous feed to the Microsep facility.The products from this processing step are sludge and clean water.The sludge is then fed to a filter press to yield approx 7 t dry cake in 7–10 days, and further clean water.The clean water is used directly instead of mains water, for rectifier cooling and overflow rinses in the paint shop and chromium plating areas. Excess clean water is drained into the sewer and is the only water discharged in the process. #2 BENEFITS ENVIRONMENTAL Water usage • Mains water usage reduced by over 10 ML per annum • Direct discharge of wastewater reduced by 50% from 10.8 ML per annum to 5.4 ML per annum • Mains water consumption reduced by reusing treated water. Liquid waste • All liquid waste processed on site. • Reduced environmental impact by generating cleaner wastewater for direct sewer discharge.The quality of the wastewater has improved significantly and with volume reduction has reduced the load on municipal sewage. Solid contaminant loadings are up to 20 times lower than the traditional discharge levels.The levels of contaminants per discharge are well below the limits set in SA for trade waste. In terms of loading all contaminants especially chromium, oil and grease, zinc and total suspended solids (TSS) were reduced substantially. Chromium content was reduced by 96.3%.TSS figures after Microsep treatment are below 10 ppm. • Elimination of acid and alkali use for regeneration of resins used in de-ionised water production. Solid waste • Substantial reduction of extracted solids/sludge volume, previously disposed at a landfill. ECONOMIC Investment • $530,000 (includes EPA contribution) Productivity • The plant is cost effective and saves space. • Land usage savings. Savings, outcomes Material resource savings $ per annum Generated savings: • Savings on mains water usage 9,011 • Savings on liquid waste transport and treatment off-site 289,988 • Chemical costs of pure water generation 36,000 Operating costs: • Microsep processing costs (water treatment) 75,000 • Landfill costs (cake disposal) 9,360 • Total savings Payback period • 2.12 years. BENEFITS RECOMMENDED AND BEING CONSIDERED As chemical analyses show suitable results, dry cake has the potential to be mixed with garden soil as a rich source of nutrients. WHERE TO FIND ADDITIONAL INFORMATION Mr B Bond Principal contact officer Monroe Australia Pty Ltd 1326 South Road Clovelly Park SA 5042 Ph: (08) 8374 5222 250,639