MSL952001A MSS11 Collect routine site samples

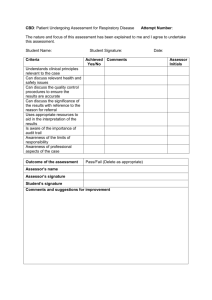

advertisement

MSS11 Diploma of Environmental Monitoring & Technology MSL952001A Collect routine site samples Completion Summary Trainee Name Click here to enter text. Assessment Result Click here to enter text. Date of Completion Click here to enter text. Signature of Trainee Click here to enter text. Signature of Assessor Click here to enter text. Trainee Assessment Guide Evidence collection guide for RPL cffet.net/env MSL952001A – Collect routine site samples TAG Table of contents UNIT INTRODUCTION 2 Description Application Resources Grading Critical aspects 2 2 2 2 2 HOW DO I COMPLETE THIS UNIT? 3 Step 1 - Interview Step 2 - Collect Step 3 - Submit 3 3 3 ASSESSMENT GUIDE 4 Elements & Performance Criteria Physical evidence of competence Evidence of required knowledge Evidence of skills demonstration Other methods of assessment 4 7 8 11 12 RANGE STATEMENT 13 Codes of practice Standards, codes, procedures and/or enterprise requirements Site hazards Safety procedures Types of samples Materials sampled Sampling tools and equipment Maintenance of integrity of samples Services Minimising environmental impacts Workplace health and safety (WHS) and environmental management requirements FINAL ASSESSMENT REPORT 16 Trainee assessment readiness Workplace assessor details RTO assessor details Competence assessment Chemical, Forensic, Food & Environmental Technology [cffet.net/env] Version 1.0 30/05/2016 13 13 13 13 14 14 14 14 14 14 15 16 16 16 16 Page | 1 MSL952001A – Collect routine site samples TAG Unit Introduction Description This unit of competency covers the ability to collect samples at field or production sites using specified equipment and standard or routine procedures. Application This unit of competency is applicable to production operators, field assistants and laboratory assistants in all industry sectors. Resources Resources for this unit may be available at cffet.net/env. Speak to your assessor about the need for these resources. Grading Your result will be recorded and reported to you as Achieved Competency (AC) or Not yet Competent (NC). Critical aspects Assessors must be satisfied that the candidate can competently and consistently apply the skills covered in this unit of competency in new and different situations and contexts. Critical aspects of assessment and evidence include: ◗ correctly follow sampling procedures and plans when collecting samples ◗ collect samples efficiently, safely and with minimal environmental impact ◗ maintain the integrity and security of samples following the traceability requirements ◗ recognise limitations and seek timely advice Chemical, Forensic, Food & Environmental Technology [cffet.net/env] Version 1.0 30/05/2016 Page | 2 MSL952001A – Collect routine site samples TAG How do I complete this unit? Step 1 - Interview The easiest way to get RPL is credit transfer from another course. If you think you can get 100% credit transfer for this unit from another course, do not continue with this guide. With this document in hand, contact your assessor and ask for an RPL interview. After the interview, you will be able to use this document to map out how you will collect you evidence. ◗ Using the table of Elements & Performance Criteria, speak with your assessor and identify what you can and cannot provide evidence for. ◗ Discuss how you will prove your competence by using the How can I show I can do this task? column form the table by using the bold words from the table to help you choose the most appropriate form of evidence collection. Step 2 - Collect Once you have mapped how you are going to prove your competence with your assessor, use the following sections of this guide to collect all your evidence. ◗ Complete the Physical evidence of competence section which will collect all the paperwork evidence for you such as training records, policies, procedures, audits etc. ◗ Answer questions in the Evidence for Required Knowledge section which covers the minimum amount of theoretical knowledge for the unit. These can be performed verbally to your assessor if required. ◗ Perform any practical demonstrations of your skills to the assessor, and record these in the Demonstrations & Observations Table. Under some circumstances you may be asked by your assessor to demonstrate competence using techniques that are not listed here. These will need to be recorded in the Other Methods of Assessment table. Examples include workplace projects, exams, external licences or any other method such as third party reporting. Step 3 - Submit Once you have completed the collection of evidence for this unit, you need to submit you’re the evidence to your assessor (by email, post, however you want). You assessor will review the evidence and identify any gaps. ◗ If no gaps are found, you ask for the Final Assessment Report to be signed off by your assessor and workplace supervisor (if required under rules of traineeships). ◗ If gap training is required, you will need to fill those gaps under the guidance of your assessor to achieve competence. Chemical, Forensic, Food & Environmental Technology [cffet.net/env] Version 1.0 30/05/2016 Page | 3 MSL952001A – Collect routine site samples TAG Assessment Guide Elements & Performance Criteria This table lists the Elements (E) and Performance Criteria (PC) for the unit. The Elements describe the broader functions or activities of a job, while the Performance Criteria outline the specific skills and knowledge you must gain competency in. Read through the table of PC’s and identify those that you can and cannot do. Speak with your assessor about the types of evidence you can provide and write comments as to how you can show you are competent. Elements (E) Prepare for sampling Performance Criteria (PC) 1.1 Confirm the purpose, priority and scope of the sampling request 1.2 Liaise with relevant personnel to arrange site access and all necessary clearances/permits 1.3 Identify site hazards and review enterprise safety procedures 1.4 Confirm what samples are to be collected, from where, how and when 1.5 Assemble all specified sampling equipment, safety equipment, materials and containers 1.6 Conduct pre-use and cleanliness checks of all items to ensure they are fit for purpose 1.7 Check all items against given inventory and stow them to ensure safe transport Can I do this task? How do I show that I can do this task? (examples) Provide plan to assessor ☐ Click here to enter text. Explain to assessor ☐ Click here to enter text. Provide a report ☐ Click here to enter text. Provide a report ☐ Click here to enter text. Demonstrate to assessor ☐ Click here to enter text. Demonstrate to assessor ☐ Click here to enter text. Demonstrate to assessor ☐ Click here to enter text. Chemical, Forensic, Food & Environmental Technology [cffet.net/env] Version 1.0 30/05/2016 Page | 4 MSL952001A – Collect routine site samples Elements (E) Conduct sampling Performance Criteria (PC) 2.1 Locate sampling points and services at the site 2.2 Remove security devices, such as locks and covers as required 2.3 Seek advice if the required samples cannot be collected or if procedures require modification 2.4 Select and use required sampling equipment in accordance with given procedures 2.5 Closely follow sampling procedures to obtain required samples and maintain their integrity 2.6 Record all labelling information in accordance with enterprise/legal traceability requirements 2.7 Record sample appearance, environmental conditions and any other factors that may impact on sample integrity 2.8 Replace security devices, such as locks and covers as required Finalise sampling 3.1 Follow enterprise procedures for the cleaning/decontamination of equipment and vehicle as necessary TAG Can I do this task? How do I show that I can do this task? (examples) Provide map to assessor ☐ Click here to enter text. Demonstrate to assessor ☐ Click here to enter text. Explain to assessor ☐ Click here to enter text. Demonstrate to assessor ☐ Click here to enter text. Demonstrate to assessor ☐ Click here to enter text. Demonstrate to assessor ☐ Click here to enter text. Demonstrate to assessor Click here to enter text. ☐ Demonstrate to assessor ☐ Click here to enter text. Demonstrate to assessor ☐ Click here to enter text. Chemical, Forensic, Food & Environmental Technology [cffet.net/env] Version 1.0 30/05/2016 Page | 5 MSL952001A – Collect routine site samples Elements (E) Performance Criteria (PC) 3.2 Check all equipment, materials and samples against inventory and stow for safe transport 3.3 Liaise with relevant personnel to restore normal production and/or services as necessary 3.4 Maintain integrity of samples during transportation Maintain a safe work environment 4.1 Use established work practices and personal protective equipment to ensure personal safety and that of others 4.2 Minimise environmental impacts of sampling and generation of waste 4.3 Dispose of all waste in accordance with enterprise procedures TAG Can I do this task? How do I show that I can do this task? (examples) Demonstrate to assessor ☐ Click here to enter text. Explain or demonstrate ☐ Click here to enter text. Explain or demonstrate ☐ Click here to enter text. Explain or demonstrate Click here to enter text. ☐ Explain or demonstrate ☐ Click here to enter text. Explain or demonstrate ☐ Click here to enter text. Chemical, Forensic, Food & Environmental Technology [cffet.net/env] Version 1.0 30/05/2016 Page | 6 MSL952001A – Collect routine site samples TAG Physical evidence of competence When you include physical items as evidence of competence for this unit, make sure you key it in this table so your assessor can relate it back to the elements and performance criteria. NOTE: Only submit what you need. Providing 100 pieces of evidence does not make you more competent, it just wastes everyone’s time. Evidence number Evidence name E.g. 1 SWMS ASG23.4 V3 – Chlorine cylinder installation 1 Click here to enter text. 2 Click here to enter text. 3 Click here to enter text. 4 Click here to enter text. 5 Click here to enter text. 6 Click here to enter text. 7 Click here to enter text. 8 Click here to enter text. 9 Click here to enter text. 10 Click here to enter text. 11 Click here to enter text. 12 Click here to enter text. 13 Click here to enter text. 14 Click here to enter text. 15 Click here to enter text. Chemical, Forensic, Food & Environmental Technology [cffet.net/env] Version 1.0 30/05/2016 Page | 7 MSL952001A – Collect routine site samples TAG Evidence of required knowledge Provide brief answers for the following questions. 1. What is the difference between a sample and its population? Click here to enter text. 2. What does the term representative mean in relation to sampling? Click here to enter text. 3. List the different types of materials (matrix) that you sample in your workplace. Click here to enter text. 4. For one sampling procedure that you follow at work, identify the standard or guideline that the procedure was derived from. Click here to enter text. 5. What types of information must be recorded when performing sampling. Click here to enter text. 6. Identify the types of samples that you collect in your workplace (i.e. grab, composite, weighted etc). Click here to enter text. 7. For the sample types identified above, explain why the sampling method achieves representativeness? Chemical, Forensic, Food & Environmental Technology [cffet.net/env] Version 1.0 30/05/2016 Page | 8 MSL952001A – Collect routine site samples TAG Click here to enter text. 8. Explain how your sample sites are identified geographically. Why is it important for sample sites to be clearly identifiable? Click here to enter text. 9. Explain the decontamination techniques you use in your workplace. Why is decontamination necessary? Click here to enter text. 10. Identify potential hazards that can exist when sampling. How are these hazards controlled? Click here to enter text. 11. What is a chain of custody? Why is it essential when performing sampling for potentially legal reasons? Click here to enter text. 12. Sometimes special equipment is required to sample (i.e. extension poles, pumps etc). What specialised equipment do you use in your workplace? Click here to enter text. 13. Identify the different types of sample container that you use when sampling. For three different sample containers, identify the reasons for the container material. Click here to enter text. Chemical, Forensic, Food & Environmental Technology [cffet.net/env] Version 1.0 30/05/2016 Page | 9 MSL952001A – Collect routine site samples TAG 14. DO any of the samples you take require preservatives of some sort. Explain. Click here to enter text. 15. Why do samples need to be kept cool before analysis? Click here to enter text. Chemical, Forensic, Food & Environmental Technology [cffet.net/env] Version 1.0 30/05/2016 Page | 10 MSL952001A – Collect routine site samples TAG Evidence of skills demonstration Can you prove your competence for some or all of the skills in this unit via a demonstration of some kind? If so, organise the demonstration with your assessor and the assessor will record the details of the demonstration on this page. Task being observed Comments Date E PC E.g. Chlorine cylinder installation E.g. Michael was observed replacing the empty chlorine cylinder with a new one. Task was completed in accordance with SWMS. 2/4/14 1, 2 1.2, 2.3, 2.5-7 Click here to enter text. Click here to enter text. Enter date Click here to enter text. Click here to enter text. Enter date Click here to enter text. Click here to enter text. Enter date Click here to enter text. Click here to enter text. Enter date Click here to enter text. Click here to enter text. Enter date Click here to enter text. Click here to enter text. Enter date Click here to enter text. Click here to enter text. Enter date Click here to enter text. Click here to enter text. Enter date Click here to enter text. Click here to enter text. Enter date Chemical, Forensic, Food & Environmental Technology [cffet.net/env] Version 1.0 30/05/2016 Page | 11 MSL952001A – Collect routine site samples TAG Other methods of assessment Use this table to record methods of assessment not recorded elsewhere in this guide. Stipulate the type of assessment in the first column and provide details of the assessment event, location and other pertinent details in the ‘details’ column. Your assessor will complete the E and PC columns. Type of assessment Details E.g. External training and certification E.g. Completed confined space training with private RTO. Photocopy of training records attached (see evidence log) Click here to enter text. Click here to enter text. Click here to enter text. Click here to enter text. Click here to enter text. Click here to enter text. Click here to enter text. Click here to enter text. Click here to enter text. PC 3, 4 3.2, 4.5-9 Click here to enter text. Click here to enter text. Click here to enter text. Click here to enter text. Click here to enter text. Click here to enter text. Click here to enter text. Chemical, Forensic, Food & Environmental Technology [cffet.net/env] Version 1.0 30/05/2016 E Page | 12 MSL952001A – Collect routine site samples TAG Range statement The range statement relates to the unit of competency as a whole. It allows for different work environments and situations that may affect performance. Bold italicised wording, if used in the performance criteria, is detailed below. Essential operating conditions that may be present with training and assessment (depending on the work situation, needs of the candidate, accessibility of the item, and local industry and regional contexts) may also be included. Codes of practice Where reference is made to industry codes of practice, and/or Australian/international standards, it is expected the latest version will be used Standards, codes, procedures and/or enterprise requirements Standards, codes, procedures and/or enterprise requirements may include Australian and international standards, such as AS ISO 1000-1998 The international system of units (SI) and its application, AS ISO 17025-2005 General requirements for the competence of testing and calibration laboratories, AS/NZS ISO 14000 Set:2005 Environmental management standards set, AS/NZS ISO 9000 Set:2008 Quality management systems set, calibration and maintenance schedules, enterprise recording and reporting procedures, enterprise sampling procedures for specific samples, sites and clients, environmental legislation and regulations, equipment manuals, equipment startup, operation and shutdown procedures, industry codes of practice, maps and site plans, material safety data sheets (MSDS), material, production and product specifications, National Association of Testing Authorities (NATA) documents regarding construction materials testing, national measurement regulations and guidelines , occupational health and safety (OHS) national standards and codes of practice, quality manuals, safety procedures, standard operating procedures (SOPs) Site hazards Site hazards may include solar radiation, dust and noise, wildlife, such as snakes, spiders and domestic animals, biohazards, such as micro-organisms and agents associated with soil, air and water, chemicals, such as acids and hydrocarbons, sharps and broken glassware, manual/handling of heavy sample bags and containers, crushing, entanglement and cuts associated with moving machinery and hand tools, falling objects, uneven surfaces, heights, slopes, wet surfaces, trenches and confined spaces, vehicle handling in rough terrain and boat handling in rough or flowing water Safety procedures Safety procedures may include use of MSDS, use of personal protective equipment, such as hard hats, heavy protection, gloves, safety glasses, goggles, faceguards, coveralls, gowns, body suits, respirators and safety boots, correct labelling of hazardous materials handling and storing hazardous material and equipment in accordance with labels, MSDS,, Chemical, Forensic, Food & Environmental Technology [cffet.net/env] Version 1.0 30/05/2016 Page | 13 MSL952001A – Collect routine site samples TAG manufacturer's instructions and enterprise procedures and regulations, regular cleaning and/or decontamination of equipment, machinery guards, signage, barriers, service isolation tags, traffic control and flashing lights, lockout and tag-out procedures Types of samples Types of samples may include grab samples, disturbed or undisturbed materials, composite samples, such as time, flow proportioned and horizontal/vertical cross section, quality control samples, such as controls, background, duplicate and blanks Materials sampled Materials sampled may include gas or air samples, water, wastewater, stormwater, sewage and sludge, soils, construction materials, solid wastes, such as commercial, industrial and mining, raw materials, start, middle, end of production run samples and final products for a wide range of manufactured items, including food and beverages, hazardous materials and/or dangerous goods Sampling tools and equipment Sampling tools and equipment may include front-end loader, backhoe, excavator and drill rig, shovels, augers and bucket , sampling frames, sampling tubes, dip tubes, spears, flexible bladders and syringes, access valves, sample thief, weighted sample bottles, bottles, plastic/metal containers and disposable buckets, sterile containers, pipettes, inoculating loops and disposable spoons, pumps and stainless steel bailers Maintenance of integrity of samples Maintenance of integrity of samples could include appropriate containers and lids (e.g. glass, plastic, amber and opaque), sealing of sample containers, purging of sample lines and bores, decontamination of sampling tools between collection of consecutive samples, use of appropriate preservatives (e.g. sodium azide, toluene or antibiotics), wrapping container in foil or wet newspaper, temperature control, which may involve prevention of direct contact between the sample and coolant, transfer of sterile sample into sterile container, monitoring of storage conditions, enterprise/legal traceability through appropriate sample labelling and records Services Services may include water supply, gas and electricity, telecommunications, irrigation, stormwater and drainage systems, production plant Minimising environmental impacts Minimising environmental impacts may involve replacement of soils and vegetation, driving to minimise soil erosion and damage to fauna and vegetation, disposal of surplus, spent or purged materials, recycling of non-hazardous wastes, appropriate disposal of hazardous waste, cleaning of vehicles to prevent transfer of pests and contaminants. Chemical, Forensic, Food & Environmental Technology [cffet.net/env] Version 1.0 30/05/2016 Page | 14 MSL952001A – Collect routine site samples TAG Workplace health and safety (WHS) and environmental management requirements OHS and environmental management requirements all operations must comply with enterprise OHS and environmental management requirements, which may be imposed through state/territory or federal legislation - these requirements must not be compromised at any time, all operations assume the potentially hazardous nature of samples and require standard precautions to be applied, where relevant, users should access and apply current industry understanding of infection control issued by the National Health and Medical Research Council (NHMRC) and State and Territory Departments of Health Chemical, Forensic, Food & Environmental Technology [cffet.net/env] Version 1.0 30/05/2016 Page | 15 MSL952001A – Collect routine site samples TAG Final Assessment Report Trainee assessment readiness Name of Employee Signature of employee Date I agree that: : Click here to enter text. : Click here to enter text. : Click here to enter text. I am comfortable with completing this assessment task I understand why the assessment is taking place I understand my right of appeal Competency based assessment has been explained to me ☐ Discussion about special considerations or needs I have has taken place WH&S issues relating to the assessment task have been considered My Assessor has related my work role to the range statement ☐ ☐ ☐ ☐ ☐ ☐ Workplace assessor details Workplace technical assessor: Workplace assessor position: Signature: Date: Click here to enter text. Click here to enter text. Click here to enter text. Click here to enter a date. RTO assessor details RTO: RTO Representative(s): Signature: Date: Hunter TAFE Click here to enter text. Click here to enter text. Click here to enter a date. Competence assessment Result: Achieved Competency (AC) Date Click here to enter a date. ☐ Not Yet Competent NC) ☐ COMMENTS ASSESSOR/EMPLOYEE: Click here to enter text. ACTION PLAN GAPS/TRAINING REQUIRED: Click here to enter text. Chemical, Forensic, Food & Environmental Technology [cffet.net/env] Version 1.0 30/05/2016 Page | 16