X-R F : A

advertisement

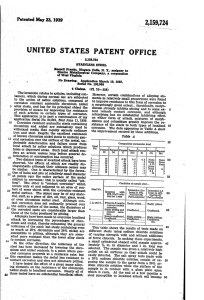

X-RAY FLUORESCENCE: APPLICATIONS X1 Last Revised: August 2014 1. PURPOSE This exercise examines the application of X‐ray fluorescence to qualitative and quantitative analysis. 2. REAGENTS & EQUIPMENT 2.1 Panalytical Minipal 4 XRF spectrometer 2.2 Chromium ore 2.3 Steel standards 406‐410 2.4 Australian coins (2c, 10c, $1) 2.5 Paint 2.6 Meteorite sample (supplied by DB) 2.7 Plastic tweezers 2.8 Silica 2.9 Sodium chloride 2.10 Borax 3. PROCEDURE 3A. Prework 3.1 Which of the following substances will not generate an XRF spectrum? (a) silica (b) sodium chloride (c) borax (NaB4O7) 3B. Sample preparation 3.2 Obtain a tin of coloured paint, mix well by shaking and apply to a 5 x 5 cm piece of cardboard. Place in a warm oven for 30 minutes (or until dry). 3.3 Grind the substance chosen in Prework to a fine powder. 3C. Startup 3.4 With your teacher’s guidance, follow the instructions to switch the machine on. 3.5 Record the spectrum of the substance chosen in Prework. Use the conditions specified in the table below. kV uA Auto 3.6 3.7 Filter Time (s) Helium None 30 Yes Carry out the spectrum deconvolution as shown. Record the peak position (keV) and identity of the significant lines. 3D. Qualitative analysis 3.8 Record the spectra of the following (use 30 kV and the Auto kV/uA setting): 2c coin 10c coin $1 coin chromium ore paint on cardboard (cut to fit the sample holder) meteorite (handle carefully with plastic tweezers and place pieces large face down in centre of holder) 3.9 Record the peak position (keV), intensity and identity of significant lines. 3E. Quantitative analysis 3.10 Create a new application, by using the Copy Old button (select AIT015 Steel and ensure that Copy results is not checked). Name it X1 followed by your initials. 3.11 Go to the Standards screen and add a standard named 406. 3.12 Using the information in the steels box lid, enter the concentrations of all elements. Fe is not shown, but is assumed to be the balance of the 100%. Save your changes. 3.13 Follow the provided procedure for recording the standards, and samples: steel 410 and chromium ore. Record the measured % for each element. 3.14 Record (from the boxlid or bottle) the true % composition for steel 410 and the %Cr for the ore. 4. REPORT Calculations calculate % relative errors for the steel “sample” and the chromium ore Discussion explain the choice of “X‐ray transparent” solid explain what causes the source lines identify likely pigments in each paint sample (see webpage) comment on the accuracy of the quantitative analysis of the steel sample and the chromium ore Questions 1. What is the typical composition of each type of Australian coins (see webpage)? How does this compare with what you found in the scans. 2. Are the steels used in the exercise stainless steels? Explain your answer. 3. What is the most common chromium mineral? Is it likely that the sample analysed contains this mineral? 4. Explain why XRF is such a good technique for qualitative analysis. 5. Describe the limitations of XRF for quantitative analysis. 6. X1 What is the upper limit for elements to be measured using their K line on this instrument? p2