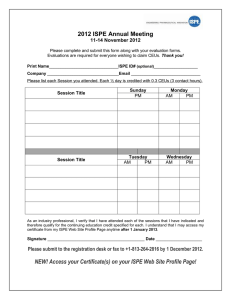

ISPE Annual Meeting Thriving In A Survival Environment

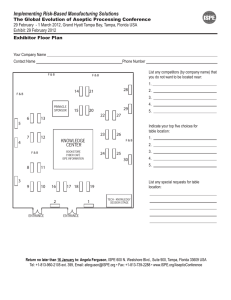

advertisement