MECHANICS OF SOFT MATERIALS

advertisement

MECHANICS OF SOFT MATERIALS

K. Y. Volokh

Faculty of Civil and Environmental Engineering

Technion – Israel Institute of Technology

Contents

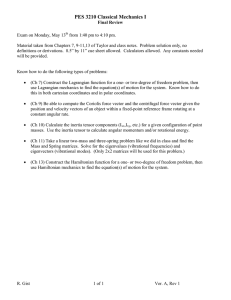

Mechanics of Soft Materials

1. Tensors

2

2. Kinematics

16

3. Balance laws

28

4. Isotropic elasticity

37

5. Anisotropic elasticity

49

6. Viscoelasticity

56

7. Chemo-mechanical coupling

64

8. Electro-mechanical coupling

71

9. Appendix

79

Volokh 2010

1 Tensors

1.1 Vectors

Vectors are tensors of the first order/rank, by definition, while scalars are zero-order

tensors.

x3

a

b

e3

e2

e1

x2

x1

We consider Cartesian coordinate system with mutually orthogonal axes, xi , and base

vectors

1

0

0

e1 0 , e 2 1 , e 3 0 .

0

0

1

(1.1)

Within this coordinate system we define arbitrary vector a as follows

3

a a1e1 a2e 2 a3e 3 ai e i ,

(1.2)

i 1

where ai are the components of the vector.

Notation in (1.2) is excessive and it is worth simplifying it by using the Einstein rule

3

a e

i 1

i i

ai e i ,

(1.3)

which means that the symbol of the sum can be dropped when the summation is performed

over two repeated indices. Such indices are called dummy because they can be designated by

any character

ai ei a j e j ame m .

Using Einstein’s rule we can write down the scalar or dot product of two vectors a

and b as follows

a b (ai ei ) (b j e j ) ai b j ei e j .

Mechanics of Soft Materials

2

(1.4)

Volokh 2010

The scalar product of base vectors is zero for different base vectors and one for the

same vector

1, i j

ei e j

ij ,

0, i j

(1.5)

where we introduced the (Leopold) Kronecker delta for short notation.

Substituting (1.5) in (1.4) we have

a b ai b j e i e j ai b j ij ai bi a j b j a1b1 a2b2 a3b3 ,

(1.6)

b j ij b1 i1 b2 i 2 b3 i 3 bi .

(1.7)

ij

where

By using the dot product of base vector ei with vector a we find ai

ei a ei (a j e j ) a j ei e j a j ij ai .

(1.8)

The Kronecker delta was introduced through the scalar products of the Cartesian base

vectors. It is also very convenient to introduce the permutation (Tulio Levi-Civita) symbol by

using triple product of base vectors

1, ijk 123; 231; 312

e i (e j e k ) 1, ijk 321; 213; 132 ijk .

0, ijk ...

(1.9)

The permutation symbol allows us to write the components of the vector product in a

short way

ci e i c e i (a b) e i {( a j e j ) (bk e k )} {e i (e j e k )}a j bk ijk a j bk .

(1.10)

ijk

c

It is important that there is no summation over index i in (1.10). Such index is called

free. Computing (1.10) for varying i we get

c1 a2b3 a3b2 , c2 a3b1 a1b3 , c3 a1b2 a2b1 .

(1.11)

1.2 Second-order tensors

To define a second-order tensor we introduce dyadic or tensor product, , of base

vectors

1

1 0 0

e1 e1 e e 0 1 0 0 0 0 0 ,

0

0 0 0

T

1 1

Mechanics of Soft Materials

3

Volokh 2010

1

0 1 0

e1 e 2 e e 0 0 1 0 0 0 0 ,

0

0 0 0

T

1 2

…

0

0 0 0

e 3 e 3 e e 0 0 0 1 0 0 0 ,

1

0 0 1

T

3 3

(1.12)

ei e j e j ei .

By analogy with vectors, we define second-order tensors as a linear combination of

base dyads

A A11e1 e1 A12e1 e 2 A13e1 e3

A21e 2 e1 A22e 2 e 2 A23e 2 e3 .

(1.13)

A31e3 e1 A32e3 e 2 A33e3 e3

By using short notation we can rewrite (1.13) as follows

3

3

A Aij ei e j Aij ei e j .

(1.14)

j 1 i 1

The components of the second-order tensor can be written in the matrix form

A11

A21

A

31

A12

A22

A32

A13

A23 .

A33

In the considered case of Cartesian coordinates, the tensor can be interpreted as a

matrix of its components. In the case of curvilinear coordinates, the situation is subtler and

various matrices of components can represent the same tensor. The latter will be discussed

below.

A second-order tensor (or matrix) maps one vector into another as follows

c Ab ( Aij e i e j )(bm e m ) Aij bm e i (e j e m ) Aij bm jm e i Aij b j e i ,

jm

bj

(1.15)

ci

or

c1 A11

ci Aij b j , c2 A21

c A

3 31

A12

A22

A32

A13 b1

A23 b2 .

A33 b3

Product of two second-order tensors is defined as follows

Mechanics of Soft Materials

4

Volokh 2010

F AD ( Aij e i e j )( Dmne m e n ) Aij Dmn (e j e m )e i e n

jm

,

Aij Dmn jme i e n Aij D jn ei e n

(1.16)

Fin

or

F11

Fin Aij D jn , F21

F

31

F12

F22

F32

F13 A11

F23 A21

F33 A31

A12

A22

A32

A13 D11

A23 D21

A33 D31

D12

D22

D32

D13

D23 .

D33

Double dot product of two tensors is a scalar

A : D ( Aij ei e j ) : ( Dmne m e n ) Aij Dmn (ei e m )(e j e n )

im

jn

Aij im Dmn jn Amj Dmj A11 D11 A12 D12 .... A33 D33

Amj

.

(1.17)

Dmj

By using the double dot product we can calculate components of a second-order

tensor as follows

e i e j : A e i e j : ( Amne m e n ) Amn (e i e m )(e j e n ) Aij .

im

(1.18)

jn

Since the second-order tensor can be interpreted as a matrix then all subsequent

definitions for tensors are analogous to the matrix definitions. For example, the second-order

identity tensor is defined as

1 ij ei e j e1 e1 e 2 e 2 e3 e3 ,

(1.19)

and it enjoys the remarkable property

A1 1A A .

(1.20)

The transposed second-order tensor is

AT ( Aij ei e j )T Aij e j ei Ajiei e j .

(1.21)

It allows us to additively decompose any second-order tensor into symmetric and

skew (anti)-symmetric parts

1

1

A A sym A skew , A sym ( A AT ) ATsym , A skew ( A AT ) ATskew .

2

2

(1.22)

The inverse second order tensor, A 1 , is defined through the identity

A1A AA1 1 .

Mechanics of Soft Materials

5

(1.23)

Volokh 2010

Finally, we consider the eigenproblem for a symmetric second-order tensor A AT .

The eigenvalue (principal value) and the eigenvector (principal direction) n of the tensor

are defined by the following equation

An n .

(1.24)

The eigenproblem defines the principal directions of tensor A where vector n is

mapped into itself scaled by factor . We rewrite the eigenproblem by moving all terms onto

the left hand side

( A 1)n 0 ,

(1.25)

or

A11

A21

A

31

A12

A22

A32

A13

A23

A33

n1 0

n2 0 .

n 0

3

This equation possesses a nontrivial solution when the determinant of the coefficient

matrix is singular

det(A 1) 3 2 I1 ( A) I 2 ( A) I 3 ( A) 0 .

(1.26)

Here the principal invariants of tensor A have been introduced

I1 (A) A11 A22 A33 trA ,

(1.27)

1

I 2 ( A) {( trA) 2 tr( A 2 )} ,

2

(1.28)

I 3 (A) det A .

(1.29)

Since tensor A is symmetric then all roots of (1.26), 1 , 2 , 3 , are real and it is

possible to find three mutually orthogonal principal directions corresponding to the roots. The

unit vectors in principal directions, n (1) , n ( 2) , n ( 3) , obey the orthonormality conditions

n (i ) n ( j ) ij .

(1.30)

Now tensor A can enjoy the spectral decomposition based on the solution of the

eigenproblem

A 1n(1) n(1) 2n( 2) n( 2) 3n(3) n(3) ,

(1.31)

A ( 1 2 )n(1) n(1) 2 1 ,

(1.32)

A 11 .

(1.33)

if 1 2 3 , or

if 1 2 3 , or

Mechanics of Soft Materials

6

Volokh 2010

if 1 2 3 .

Based on the spectral decomposition it is convenient to introduce the logarithm and

the square root of a symmetric positive definite tensor, i 0 ,

3

ln A (ln k )n ( k ) n ( k ) ,

(1.34)

k 1

3

A k n(k ) n(k ) .

(1.35)

k 1

The spectral decomposition also allows us to calculate the principal invariants simply

I1 (A) 1 2 3 ,

(1.36)

I 2 (A) 1 2 1 3 2 3 ,

(1.37)

I 3 ( A ) 1 2 3 .

(1.38)

Finally, we derive the useful Cayley-Hamilton formula pre-multiplying (1.26) with

n (i ) and accounting for A a n (i ) ia n (i )

A 3 A 2 I1 ( A) A I 2 ( A) 1I 3 ( A) 0 .

(1.39)

1.3 Tensor functions

Tensors can be arguments of functions: f (A) ; f ( Aij ) ; f (A) ; f m ( Aij ) ; F(A) ;

Fmn ( Aij ) . Let us calculate a differential of a scalar function f with respect to tensor

argument A

df

f

dAij .

Aij

(1.40)

Here the components of the tensor increment can be written as (see (1.18))

dAij ei e j : dA ,

and, consequently, (1.40) takes form

df

f

f

e i e j : dA

: dA ,

Aij

A

(1.41)

where the derivative with respect to the second-order tensor has been defined

f

f

ei e j .

A Aij

(1.42)

Analogously, it is possible to define the derivative of a second-order tensor

Mechanics of Soft Materials

7

Volokh 2010

C

A

A A

e i e j mn e m e n e i e j .

B Bij

Bij

(1.43)

C mnij

This is the fourth-order tensor, which is formed by a combination of base tetrads

e m e n e i e j that can be interpreted, by analogy with dyads, as tables (matrices) in 4D

space.

The double dot product of the fourth- and second- order tensors is defined as follows

D C : B (Cmnij e m e n ei e j ) : ( Bkle k el )

Cmnij Bkle m e n (ei e k )(e j el ) Cmnij Bij e m e n .

ik

jl

(1.44)

Dmn

As an example let us differentiate a second-order tensor with respect to itself

A Amn

e m e n ei e j mi nj e m e n ei e j .

A Aij

(1.45)

In the case of symmetric tensor A (A AT ) / 2 the symmetry should be preserved

in the derivative

A 1 ( A AT ) 1

( mi nj ni mj )e m e n ei e j .

A 2

A

2

(1.46)

Further important formulas are obtained by differentiating the principal invariants of

A AT

I1 ( A) Akk

ei e j ki kj ei e j 1 ,

A

Aij

(1.47)

I 2 ( A) 1 ( Akk All Amn Anm )

ei e j I1 ( A)1 A .

A

2

Aij

(1.48)

ij

The derivative of the third invariant I 3 (A) det A is less trivial and we start with

calculating the increment of it with the help of (1.26)

1

det(A dA) det A det(A

A (

1) 1)

d

tensor

.

eigenvalue

1

1

(1.49)

1

det A{1 I1 ( A dA) I 2 ( A dA) I 3 ( A dA)}

Ignoring higher-order terms in (1.49) we have

det( A dA) det A det A I1 ( A 1dA) det A (det A) A T : dA ,

(1.50)

A T :dA

and, consequently,

Mechanics of Soft Materials

8

Volokh 2010

I 3 ( A) (det A)

(det A) A T .

A

A

(1.51)

1.4 Tensor analysis

We turn to tensor analysis and define the following differential operators for vectors

and second-order tensors in Cartesian coordinates

grad

grad a

div a

curl a e i

ei ,

x xi

(1.52)

a

a a

ei j e j ei ,

x xi

xi

(1.53)

a

a

a

ei j e j ei i ,

xi

xi

xi

(1.54)

a j

a j

a

ei e j

kij e k

xi

xi

xi

a a

a a

a

a

e1 3 2 e 2 1 3 e 3 2 1

x1 x2

x2 x3

x3 x1

div A

,

(1.55)

A

A

A

e i mn (e m e n )e i mn e m

xi

xi

xn

A

A

A

11 12 13 e1

x2

x3

x1

A

A

A

21 22 23 e 2

x2

x3

x1

.

(1.56)

A

A

A

31 32 33 e 3

x2

x3

x1

Now we refresh our memories concerning the divergence theorem (Gauss, Green, and

Ostrogradskii) which is an important tool for transforming volume and area integrals. Its

simplest version in one-dimensional case is the famous Newton-Leibnitz rule

n(a )

n(b)

a

b

x

b

dy

dx dx (1) y(b) (1) y(a) n(b) y(b) n(a) y(a) .

a

In a three-dimensional case we can write

Mechanics of Soft Materials

9

Volokh 2010

n

V

A

y

x

i

dV ni ydA .

(1.57)

The powerful generalization of this formula is

Bij

x

j

dV

Bi1

B

B

dV i 2 dV i 3 dV

x1

x2

x3

Bi1n1dA Bi 2 n2 dA Bi 3n3dA ,

(1.58)

Bij n j dA

or, shortly,

divB dV BndA .

(1.59)

Of course, the second-order tensor B can be replaced by scalar b or vector b

gradb dV bndA ,

(1.60)

divb dV b ndA .

(1.61)

Another useful formula is due to Stokes who related the contour integral over curve l

to surface A built on it

n

A

l

b dx (curl b) ndA ,

(1.62)

where dx is the infinitesimal element of the curve l .

1.5 Curvilinear coordinates

Some problems are easier to solve in curvilinear rather than Cartesian coordinates.

We consider curvilinear coordinates ( 1 , 2 , 3 ) which can be defined through the Cartesian

Mechanics of Soft Materials

10

Volokh 2010

coordinates ( x1 , x2 , x3 ) and vice versa. For example, in the case of cylindrical coordinates we

have

gz

x3

g

e3

e1

gr

e2

x2

z

r

x1

1 r; 2 ; 3 z ,

(1.63)

x1 r cos ; x2 r sin ; x3 z ,

(1.64)

r x12 x22 ; arctan

x2

;

x1

z x3 .

(1.65)

We define the natural (co-variant) base vectors in curvilinear coordinates

si

x j

i

ej,

(1.66)

which take the following form in cylindrical coordinates

x3

x1

x2

s r r e1 r e 2 r e 3 cos e1 sin e 2

x

x1

x

e1 2 e 2 3 e 3 r sin e1 r cos e 2 .

s

x

x1

x

e1 2 e 2 3 e 3 e 3

s z

z

z

z

(1.67)

We also define the dual (contra-variant) base vectors

si

i

ej ,

x j

(1.68)

which take the following form in cylindrical coordinates

r r

r

r

e1

e2

e 3 cos e1 sin e 2

s

x

x

x

1

2

3

sin

cos

e1

e2

e3

e1

e2 .

s

x

x

x

r

r

1

2

3

z z

z

z

e1

e2

e3 e3

s

x1

x2

x3

Mechanics of Soft Materials

11

(1.69)

Volokh 2010

The natural and dual base vectors are mutually orthogonal

j

x j

x j j 1, i j

x

.

si s j mi em

en mi

mn mi

xm i 0, i j

xn xn

(1.70)

Now vectors and tensors may have various representations in curvilinear coordinates

a a i si aisi ,

(1.71)

A Aij si s j Aij si s j A.ij si s j Ai. j si s j ,

(1.72)

where a i a si are contra-variant components; and ai a s i are co-variant components;

Aij A : (s i s j )

are contra-variant components;

Aij A : (s i s j )

are co-variant

components; and Ai. j A : (s i s j ) and A.ij A : (s i s j ) are mixed components.

In the case where the base vectors are mutually orthogonal it is possible to normalize

them. For example, in the case of the cylindrical coordinates we have

cos

sin

0

s

sr

sr

s

sz

sz

gr

r sin , g

cos , g z

z 0 .

sr

s

s

s

s

s

z

0

0

1

(1.73)

The normalized base vectors allow introducing the so-called physical components of

vectors and tensors with the same units

a ar g r a g a z g z ,

(1.74)

A Arr g r g r Ar g r g Arz g r g z

Ar g g r A g g Az g g z .

(1.75)

Azr g z g r Az g z g Azz g z g z

Now we calculate differential operators in curvilinear coordinates

grad a

a

a

j

a

ei

ei

sj ,

j

j

xi

xi

(1.76)

sj

curl a e i

a j

a

a

ei

sj

,

j

xi

xi

j

(1.77)

sj

divB

B

B j

B j

ei

ei

s .

j

xi

xi

j

(1.78)

sj

In the case of cylindrical coordinates we have, for example,

Mechanics of Soft Materials

12

Volokh 2010

(...)

(...)

(...)

sr

s

sz

r

z

.

(...)

1 (...)

(...)

gr

g

gz

r

r

z

grad(...)

(1.79)

In calculating the derivatives of vectors and tensors one should not forget that the

natural and dual and physical base vectors depend on coordinates! In the considered case of

cylindrical coordinates we have the following derivatives of the physical base vectors

g

g r

g z

0;

0;

0

r

r

r

g

g r

g z

g ;

g r ;

0.

g

g r

g z

0;

0;

0

z

z

z

(1.80)

Besides the considered cylindrical coordinates it is useful to list the basic relationships

for spherical coordinates

g g

x3

gr

e3

e1

r

x2

e2

x1

1 r; 2 ; 3 ,

(1.81)

x1 r cos sin ; x2 r sin sin ; x3 r cos ,

(1.82)

r x12 x22 x32 ; arccos

x3

x12 x22 x32

; arctan

x2

,

x1

(1.83)

cos sin

cos cos

sin

g r sin sin , g cos sin , g cos ,

cos

sin

0

(1.84)

(...)

1 (...)

1 (...)

gr

g

g ,

r

r

r sin

(1.85)

grad(...)

Mechanics of Soft Materials

13

Volokh 2010

g

g

g r

0;

0;

0

r

r

r

g

g

g r

.

g ;

g r ;

0

g

g

g r

g sin ;

g cos ;

g r sin g cos

(1.86)

1.6 Homework

1. Prove:

sm sn sp

det km kn kp ,

tm tn tp

skt mnp

(1.87)

skt snp kn tp kp tn ,

(1.88)

skt skp 2 tp ,

(1.89)

skt skt 2 tt 6 .

(1.90)

2. Prove (1.20).

3. Prove for second-order tensors A, B:

1

det A ijk stp Asi Atj Apk ,

6

(1.91)

1

,

det A

(1.92)

(AB) 1 B1A1 ,

(1.93)

(AT )1 (A1 )T AT .

(1.94)

det A 1

4. Prove (1.37).

5. Prove (1.48).

6. Prove for second-order tensors A, B:

tr(A 1B) A T : B .

(1.95)

curl grad 0 .

(1.96)

div curl a 0 .

(1.97)

7. Prove for scalar :

8. Prove for vector a :

9. Prove (1.84).

10. Prove (1.85).

Mechanics of Soft Materials

14

Volokh 2010

11. Prove (1.86).

Mechanics of Soft Materials

15

Volokh 2010

2 Kinematics

2.1 Deformation gradient

0

dx

u

x3

dy

x

y

e3

e1

e2

x2

x1

We consider deformation of a body shown in its reference and current states. The law

of motion of material points, i.e. infinitesimal material volumes, is defined by

y y (x, t ) ,

(2.1)

where x and y are the reference and current positions of the point. It is usually convenient,

yet not necessary, to assume that the reference state is the initial one: x y (x, t 0) .

If we consider x as an independent variable then we follow motion of a material

point that was fixed at x in the reference configuration. Such description is called referential

or material or Lagrangean. If, alternatively, we consider y as an independent variable then

we follow motion of various material points passing through y in the current configuration.

The latter description is called spatial or Eulerian. The Eulerian description is preferable

when the evolution of continuum boundaries is known beforehand like in many problems of

fluid mechanics while the Lagrangean description is preferable when the evolution of

continuum boundaries is not known beforehand like in many problems of solid mechanics.

An infinitesimal material fiber at points x and y before and after deformation

accordingly can be described by the linear mapping (transformation)

d y Fd x ,

(2.2)

where

Mechanics of Soft Materials

16

Volokh 2010

y yi

ei e j

x x j

F

(2.3)

is the tensor of deformation gradient. This tensor is related to two configurations

simultaneously and because of that it is called two-point.

Alternatively, we can use the displacement vector, u y x , to get

F

(x u)

1 H ,

x

(2.4)

H

u ui

ei e j

x x j

(2.5)

where

is the displacement gradient tensor.

It is possible to calculate any deformation when the deformation gradient is known.

We start with the volume deformation

dx (3)

dV0

dV

F

dx ( 2)

dy (3)

dy ( 2)

dy (1)

dx (1)

dyi( m ) Fij dx (jm ) ,

dy1(1)

dV dy1( 2 )

dy1(3)

dy2(1)

dy2( 2)

dy2(3)

dy3(1)

F1 j dx(j1)

dy3( 2 ) F1 j dx(j2)

dy3(3) F1 j dx(j3)

(2.6)

F2 j dx(j1)

F2 j dx(j2)

F2 j dx(j3)

F3 j dx(j1)

F3 j dx(j2)

F3 j dx(j3)

dx1(1) dx2(1) dx3(1) F11 F21 F31

dx1( 2 ) dx2( 2 ) dx3( 2) F12 F22 F32 JdV0

dx1(3) dx2(3) dx3(3) F13 F23 F33

,

(2.7)

det F

dV0

where

J det F 0 .

(2.8)

In the case of the area deformation we have

Mechanics of Soft Materials

17

Volokh 2010

dx

dy

n

n0

dV0

dV

dA

dA0

dV0 n0 dA0 dx ,

(2.9)

dV ndA dy ndA Fdx .

(2.10)

ndA Fdx Jn0 dA0 dx ,

(2.11)

(FT ndA Jn 0 dA0 ) dx 0 .

(2.12)

Using (2.7) we derive

Since dx is arbitrary we can write the Nanson formula

ndA JF T n0 dA0 .

(2.13)

Now we define the fiber stretch in direction m; m 1

m

dy

dx

(m)

dy F dx

Fm .

dx

dx

(2.14)

We can also define the change of angle between two fibers by using stretches as

follows, for example,

Mechanics of Soft Materials

18

Volokh 2010

dy 2

dx 2

0

dy 1

dx1

cos

dy1 dy 2

Fm1 Fm2

,

dy1 dy 2 (m1 ) (m 2 )

(2.15)

dx1 dx 2

m1 m 2 ,

dx1 dx 2

(2.16)

cos 0

1

F T F 1 m 2 .

(m1 ) (m 2 )

(m1 , m 2 ) cos cos 0 m1

(2.17)

To illustrate the above formulas we consider the Simple Shear deformation

x2

x1

x3

tan( / 2 ) cot ,

y1 x1 x2

,

y2 x2

y x

3

3

F

yi

ei e j e1 e1 e 2 e2 e3 e3 e1 e2 1 e1 e 2 ,

x j

(e1 ) (Fe1 ) Fe1 e1 e1 1 ,

(e2 ) (Fe2 ) Fe2 (e2 e1 ) (e2 e1 ) 1 2 ,

cos

Mechanics of Soft Materials

(Fe1 ) (Fe2 ) e1 (e 2 e1 )

,

Fe1 Fe2

1 2

1 2

19

Volokh 2010

0 / 2 arccos

1 2

2

arccos

cos / sin

1 (cos / sin ) 2

2.

arccos(cos ) / 2 / 2

2.2 Polar decomposition of deformation gradient

Let us square the expression for stretch (2.14) and rewrite it as follows

2 (m) (Fm) (Fm) m FT Fm m Cm ,

(2.18)

C FT F

(2.19)

where

is the right Cauchy-Green tensor.

In the case where direction m is the principal direction of tensor C we have

2 (m(i ) ) m(i ) Cm(i ) m(i ) im(i ) i ,

(2.20)

where i and m (i ) are the eigenvalues and eigenvectors of C.

The above equation means that eigenvalues of the right Cauchy-Green tensor are

equal to the squared stretches in principal directions. Thus we can write the following

spectral decomposition of C in the form

C 12m(1) m(1) 22m( 2) m( 2) 32m(3) m(3) .

(2.21)

Now we define the right stretch tensor as the square root of the right Cauchy-Green

tensor

U C 1m(1) m(1) 2m( 2) m( 2) 3m (3) m (3) ,

(2.22)

where all principal stretches are nonnegative.

We assume now that any deformation can be multiplicatively decomposed into stretch

and some additional deformation which we designate R

F RU ,

(2.23)

which is called the polar decomposition of the deformation gradient and, consequently,

R FU1 .

(2.24)

Let us analyze properties of R. First, we observe that it is orthogonal

T

R T R (FU 1 )T (FU 1 ) U T F

F U 1 U T U 2 U 1 U T UT UU 1 1 .

U

(2.25)

2

Orthogonal tensors do not change lengths

dy dy dy (Rdx) (Rdx) dx R T Rdx dx dx dx .

Mechanics of Soft Materials

20

(2.26)

Volokh 2010

Besides, we observe

det(FT F)

det F

det FT det F

det C

det U 2 det U

det R

1 . (2.27)

det U

det U

det U

det U

det U

det U

Equations (2.25) and (2.27) mean that R is the proper orthogonal or rotation tensor.

Finally we notice that the meaning of the polar decomposition, F RU , is the

successive stretch and rotation.

Rdx

R

V

F RU VR

dx

dy RUdx

VRdx

F dx

Udx

R

U

It is possible, of course, to change the order of stretch and rotation

F VR ,

(2.28)

V FR1 FRT RURT VT ,

(2.29)

where V is called the left stretch tensor.

By direct computation we have

which means that the left stretch tensor is the rotated right stretch tensor, and consequently

they have the same eigenvalues – principal stretches, while their principal directions are

different.

With account of the spectral decomposition of U we have

V 1n(1) n(1) 2n( 2) n( 2) 3n(3) n(3) ,

(2.30)

n(i ) n(i ) Rm(i ) Rm(i ) .

(2.31)

where

To clarify the meaning of the principal directions of V we square the tensor as follows

V 2 RURT RURT (RU)(RU)T FFT B ,

Mechanics of Soft Materials

21

(2.32)

Volokh 2010

B 12n (1) n (1) 22n ( 2) n ( 2) 32n (3) n (3) ,

(2.33)

where B is the left Cauchy-Green tensor, which principal directions coincide with the

principal directions of V while the principal values of B are squared principal stretches.

Unfortunately, we cannot directly write the relations between the directions of the

principal stretches in the reference and current configurations because these directions are not

defined uniquely and can always be changed to the opposite sign! However, we can define

the principal directions uniquely by the following procedure. Assume, for example, that the

principal directions in the reference configuration, m(i ) , are uniquely chosen then we

calculate the principal directions in the current configuration as follows

n(i ) Rm(i ) .

(2.34)

Of course, we could start with the current configuration otherwise.

Finally, we can calculate the spectral decomposition of the deformation gradient

F RU 1Rm(1) m(1) 2 Rm( 2) m( 2) 3Rm(3) m(3)

1n(1) m(1) 2n( 2) m ( 2) 3n(3) m(3)

.

(2.35)

Let us consider the following deformation (Marsden and Hughes, 1983) as a

numerical example

y1 3 x1 x2

.

y2 2 x2

y x

3

3

In this case we have

3 1 0

F 0 2 0 ,

0

0

1

1 6 , m

(1)

1

1

3 ,

2

0

3

C 3

0

2 2 , m

3 3 3 3

0

1

3 3 1 3 3

U

0 ,

2 2

0

2 2

0

U 1

1 3

3 1 0

1

1 3 1 3

R

0 ,

2 2

0

2 2

0

Mechanics of Soft Materials

( 2)

22

3 0

5 0 ,

0 1

3

1

1 ,

2

0

3 1, m

( 3)

0

0 ,

1

1 3 3

3 3

0

1

3 3 3 3

0 ,

4 6

0

4 6

0

1 3

3 1

1

3 1 1 3

V

2

0

0

0

0 .

2

Volokh 2010

2.3 Strains

The strain measures can be introduced in various ways. We start with 1D measures

for the change of the length of a material fiber.

L

L0

We can introduce the engineering strain

L L0

1,

L0

(2.36)

L

dL

L

ln

ln ,

L

L0

L0

(2.37)

G

L2 L20 1 2

( 1) .

2 L20

2

(2.38)

E

or the logarithmic strain

L

or the Green strain

In order to generalize 1D to 3D strains we assume that formulas (2.36)-(2.38) are

valid in the principal directions of the reference configuration. In this case, the 3D strain

tensors take forms

3

ε E (i 1)m ( i ) m ( i ) U 1 ,

(2.39)

i 1

3

ε L (ln i )m ( i ) m (i ) ln U ,

(2.40)

3

1

1

ε G (i2 1)m (i ) m ( i ) (U 2 1) .

2

i 1 2

(2.41)

i 1

The Green strain tensor is the most popular and it can be rewritten by dropping the

suffix

ε

1 2

1

1

1

(U 1) (C 1) (FT F 1) (H HT HT H) .

2

2

2

2

(2.42)

2.4 Motion

Velocity and acceleration are defined as material time derivatives accordingly

Mechanics of Soft Materials

23

Volokh 2010

v

d

y (x, t ) y x u u ,

dt

(2.43)

dv

v .

dt

(2.44)

a

When the Eulerian or spatial description is used it is necessary to use the chain rule

for differentiation of any function, f (y(t ), t ) :

df

f f y f f

f (y (t ), t )

v,

dt

t y t t y

a

(2.45)

dv

v v

v

v.

dt

t y

(2.46)

Another important kinematic quantity is the velocity gradient, L ,

d y y v v y

F

LF ,

dt x x x y x

L

(2.47)

v 1

FF .

y

(2.48)

It can be decomposed into symmetric and skew symmetric parts

L d ω, d

1

1

(L LT ), ω (L LT ) ,

2

2

(2.49)

where d and ω are the deformation rate and the spin (vorticity) tensors accordingly.

2.5* Deformation gradient in curvilinear coordinates

We consider the deformation gradient in curvilinear coordinates. To be specific we

choose the deformation law in cylindrical coordinates before {R, , Z } and after {r , , z}

deformation:

r r ( R, , Z ); ( R, , Z ); z z ( R, , Z ) .

(2.50)

To treat this deformation we introduce the natural curvilinear base vectors for the

reference and current configurations accordingly

Mechanics of Soft Materials

cos

sin

0

G R sin ; G cos ; G Z 0 ,

0

0

1

(2.51)

cos

sin

0

g r sin ; g cos ; g z 0 .

0

0

1

(2.52)

24

Volokh 2010

Now the deformation gradient can be written as follows

F

y

1 y

y

GR

G

GZ ,

R

R

Z

(2.53)

where

y y1e1 y2e 2 y3e 3

rcos

(cos g r sin g ) rsin

(sin g r cos g ) z

g .

y3 z

y1

y2

e1

e2

(2.54)

e3

r g r zg z

We have with account of g z constant

(r g r z g z )

(r g r z g z )

(r g r z g z )

GR

G

GZ

R

R

Z

gr

r

z

gr G R r

GR

gz GR

R

R

R

,

r g r

r

z

g r G

G

g z G

R

R

R

r g r

r

z

gr G Z

GZ

gz GZ

Z

Z

Z

F

(2.55)

where

g r g r r g r g r z

R r R R z R R g

g r g r r g r g r z

g .

r

z

g r g r r g r g r z

g

r Z Z z Z Z

Z

(2.56)

Finally, we have

r

r

r

gr G R

g r G

gr GZ

R

R

Z

r

r

r

g G R

g G

g G Z .

R

R

Z

z

z

z

gz GR

g z G

gz GZ

R

R

Z

F

(2.57)

2.6 Homework

1. Find principal directions and stretches for the following deformation law

Mechanics of Soft Materials

25

Volokh 2010

y1 (1 ) x1 x2

y2 x1 (1 ) x2 ,

y x

3

3

(2.58)

where constant .

2. Make the polar decomposition of the deformation gradient for the deformation law

presented in (2.68).

3. Calculate the Cartesian components of the Green strain for the deformation law presented

in (2.68).

4. Read Section 2.5.

Mechanics of Soft Materials

26

Volokh 2010

3 Balance laws

3.1 Material time derivatives of integrals

We start with the computation of the material time derivative of a volume integral.

For the field quantity (y (t ), t ) over a “moving” region, V (t ) , whose configuration depends

on time t , we have the following formula (regarding the integral as an infinite sum)

d

d

dV (t ) ( dy1 (t )dy2 (t )dy3 (t ))

dt

dt

d

(

dy1dy2 dy3 dv1dy2 dy3 dy1dv2 dy3 dy1dy2 dv3 )

dt

d

v

v

v

(

1 2 3 )dV

,

dt

y1

y2

y3

(3.1)

d

div v)dV

dt

(

div( v ))dV

t

(

where the last equality is obtained as follows

d

yi

v

v ( vi )

div v

i

vi i

.

dt

t

yi t

yi

t

yi

yi

t

yi

3.2 Mass conservation

The law of mass conservation can be written as follows

m dV constant ,

(3.2)

where is mass density.

Differentiating (3.2) with respect to time we have

dm d

d

dV ( div v)dV ( div( v))dV 0 .

dt dt

dt

t

(3.3)

Since the equality is obeyed for any volume we can localize the condition for the

infinitesimal volume

d

div v

div( v) 0 .

dt

t

(3.4)

3.3 Balance of linear momentum

Mechanics of Soft Materials

27

Volokh 2010

We start with the balance of linear momentum for a volumeless particle – Newton's

law –

d

(m v) p ,

dt

(3.5)

where m v is the linear momentum and p is the force resultant.

By analogy with Newton’s law Euler considered the balance of the linear momentum

for a continuum volume V bounded by surface A

d

vdV b dV tdA ,

dt

(3.6)

where b is the body force per unit mass and t is the surface force or traction per unit area.

Let us localize the Euler law. First, differentiating the left-hand side of (3.6) we get

d

d ( v )

vdV (

v div v)dV .

dt

dt

(3.7)

Then we rewrite the Euler law in the form

fdV t dA ,

(3.8)

where

f b

d ( v )

v div v

dt

(3.9)

is the generalized body force.

Now it is necessary to transform the area integral into a volume integral. This is

possible due to the Cauchy assumption

n

t

A

Mechanics of Soft Materials

28

Volokh 2010

t

t ( y , n) .

A 0 A

t lim

(3.10)

The first corollary of the Cauchy assumption is the Newton law of action and

counteraction.

A1

n

V1

A*

n

V2

A2

For every part of the body we have

f dV t dA t(n)dA * .

f dV t dA t(n)dA *

1

1

2

2

(3.11)

Summing the equalities we get

f dV t dA [t(n) t(n)] dA * .

(3.12)

Substitution of (3.8) in (3.12) yields

[t(n) t(n)] dA * 0 .

(3.13)

This equality is correct for any surface; consequently, we can localize it and get the

third Newton law

t (n) t (n) .

(3.14)

The second corollary of the Cauchy assumption is the appearance of the stress tensor.

y3

C

t (n)

n

e3 h

e2

e1 O

D

y1

Mechanics of Soft Materials

29

B

y2

Volokh 2010

We define a tetrahedron of height h in direction n at point y . The direction cosines

ni allow us to calculate the following areas of the tetrahedron

CDB A, COB An1 , COD An2 , DOB An3 .

(3.15)

Now, we apply the linear momentum balance to the tetrahedron:

f dV t(n) dA t(e )dA t(e

1

CDB

COB

2

)dA

COD

t(e )dA .

3

(3.16)

DOB

According to the mean value theorem and with account of (3.15) we have

f

hA

t (n) A t (e1 ) An1 t (e 2 ) An2 t (e 3 ) An3 ,

6

(3.17)

where the barred quantities are calculated inside the proper volume or area.

Simplifying (3.17) and setting h 0 we obtain

0 t(n) t(e1 )n1 t(e 2 )n2 t(e3 )n3 ,

(3.18)

ni ei n .

(3.19)

where

Substituting (3.19) in (3.18) and accounting for (3.14) we get

t (n) t (e1 )(e1 n) t (e 2 )(e 2 n) t (e 3 )(e 3 n)

(t (e1 ) e1 t (e 2 ) e 2 t (e 3 ) e 3 )n ,

(3.20)

σ

σn

where we introduced the Cauchy stress tensor

σ t(e1 ) e1 t(e2 ) e2 t(e3 ) e3 .

(3.21)

To find its components we have to pre-multiply it with the base dyads

ij ei e j : σ .

For example, we have

22 e2 e2 : σ e2 t (e2 ) ,

12 e1 e2 : σ e1 t (e2 ) ,

32 e3 e2 : σ e3 t(e2 ) ,

which means that the components of the Cauchy stress tensor are projections of the stress

vector onto the axes of Cartesian coordinates.

Mechanics of Soft Materials

30

Volokh 2010

32

y3

t (e 2 )

t (e 2 )

e2

22

y2

12

y1

33

23

13

32

31

11

22

21

12

We return to the linear momentum balance (3.8) which can be rewritten using the

stress tensor

f dV σn dA .

(3.22)

Now the divergence theorem allows us to transform the surface integral into the

volume integral

σndA divσdV .

(3.23)

Then the linear momentum balance takes the form

(f divσ)dV 0 .

(3.24)

Localizing it and substituting from (3.9) we have finally

d ( v )

v div v divσ b

dt

.

v j ij

d (vi )

vi

bi

dt

y j y j

(3.25)

By way of example let us find traction t (n) , normal stress vector t n (n) , and tangent

stress vector t t (n) for the given stress tensor

σ 7e1 e1 2(e1 e3 e3 e1 ) 5e 2 e 2 4e3 e3

and area with normal

Mechanics of Soft Materials

31

Volokh 2010

2

2

1

n e1 e2 e3 .

3

3

3

By direct calculation we have

t σn 7e1 (e1 n) 2e1 (e3 n) 5e 2 (e 2 n) 2e3 (e1 n) 4e3 (e3 n) 4e1

t n (t n)n (4e1 n

10

e2 ,

3

10

44

88

88

44

e 2 n)n

n

e1 e 2 e3 ,

3

9

27

27

27

tt t tn

1

(20e1 2e 2 44e3 ) .

27

3.4 Balance of angular momentum

r

y3

C

y

y2

O

y1

In the case of a mass-point we have the angular momentum balance

d (m v)

rp,

dt

(3.26)

d (m r v)

r p .

dt

(3.27)

r

or

The latter is true because:

d

dr

dv

dv

dv

.

(mr v) m v m r

m v v mr

mr

dt

dt

dt

dt

dt

In the case of continuum we have instead of (3.27)

d

r vdV r b dV r t dA .

dt

(3.28)

It is convenient to manipulate this equation in Cartesian coordinates. In this case we

can rewrite the angular momentum balance as follows

d

rj vk dV rj bk dV rj tk dA 0 .

dt

ijk

Mechanics of Soft Materials

32

(3.29)

Volokh 2010

The first and the third terms in the equation above can be calculated by using the

material time derivative of the volume integral and the divergence theorem accordingly

d ( r j vk )

v

d

rj vk dV

rj vk m dV

dt

dt

ym

,

d ( vk )

vm

dV

rj

vk v j r j vk

dt

ym

r t

j k

(3.30)

dA r j kl nl dA

(r j kl )

yl

dV

kl ,

dV

jl kl rj

yl

kl

dV

kj r j

yl

(3.31)

where we used relation ri yi (OC )i with OC fixed.

Substituting (3.30)-(3.31) in (3.29) we get

d ( vk )

v

vk m bk kl vk v j kj ]dV 0 ,

ym

yl

dt

ijk [rj

(3.32)

0

where the term in the parentheses is the law of the linear momentum balance and it is equal to

zero.

Thus we have

ijk

( vk v j kj )dV ijk kj dV 0 .

(3.33)

The latter equation can be obeyed for the symmetric Cauchy tensor only

kj jk , σ σ T .

(3.34)

3.5 Master balance principle

All balance laws enjoy the same structure

d

α dV ξ dV φn dA ,

dt

(3.35)

where ξ is the volumetric supply of α and φ is the surface flux of α .

Differentiating the integral and using the divergence theorem we localize the balance

law

Mechanics of Soft Materials

33

Volokh 2010

dα

αdiv v divφ ξ .

dt

(3.36)

The considered balance laws are summarized in the table:

α

ξ

φ

Mass

0

0

Linear Momentum

v

b

σ

Angular Momentum

r v

r b

rσ

3.6 Lagrangean description

The description of balance laws was spatial or Eulerian because y was chosen as an

independent variable. In the case of solids (contrary to fluids) it is usually more convenient to

consider x as an independent variable, i.e. it is better to use the referential or Lagrangean

description. The transition from one description to another is simple when the formulas

relating volumes and surfaces before and after deformation are used (see (2.7) and (2.13))

dV dV0 det F JdV0 ,

(3.37)

ndA JF T n0 dA0 .

(3.38)

Substituting these equations in the master balance law we get

d

α 0 dV0 ξ 0 dV0 φ 0 n 0 dA0 ,

dt

(3.39)

where we defined the Lagrangean quantities

α 0 (x, t ) J α(y(x, t ), t ) ,

(3.40)

ξ 0 (x, t ) J ξ(y(x, t ), t ) ,

(3.41)

φ0 (x, t ) J φ(y (x, t ), t )F T .

(3.42)

We differentiate (3.39) with respect to time through the integral directly because the

volume does not change and we get the localized balance law in the Lagrangean form

α 0

Divφ 0 ξ 0 .

t

(3.43)

Here ‘Div’ operator is with respect to the referential coordinates

Div(...)

Mechanics of Soft Materials

34

(...)

ei .

xi

Volokh 2010

Particularly, the Lagrangean form of the previous table is

α0

ξ0

φ0

Mass

0

0

0

Linear Momentum

0 v

0b

T

Angular Momentum

r 0 v

r 0b

rT

where

T(x, t ) J σ(y(x, t ), t )F T

(3.44)

is the 1st Piola-Kirchhoff stress tensor (1PK).

The laws of mass, linear and angular momentum balance take the following forms

accordingly

0

0,

t

(3.45)

( 0 v)

DivT 0b

t

,

( 0 vi ) Tij

0bi

t

x j

(3.46)

TF T FTT ,

(3.47)

Since the 1st Piola-Kirchhoff stress tensor is not symmetric it is convenient to

introduce the 2nd Piola-Kirchhoff stress tensor (2PK)

S F 1T JF 1σF T .

Mechanics of Soft Materials

35

(3.48)

Volokh 2010

4 Isotropic elasticity

4.1 Hyperelasticity

E

The rheological model for elastic material is a spring. For the classical linear spring,

stress is equal to strain scaled by Young modulus, E ,

E .

(4.1)

This equation is called Hooke’s law in honor of Robert Hooke.

Evidently, this constitutive law is a linearization of a more general function describing

a nonlinear spring

( ) .

(4.2)

Although this function can be fitted in experiments only it is possible to draw some

conclusions about it considering the work of stress on strain

w ( )d .

(4.3)

In the case of an ideal elastic spring, this work does not depend on the loading history

and it only depends on the initial and final states of the spring – the integration limits in (4.3).

If the integral is path-independent then the integrand should be a full differential

dw ( )d .

(4.4)

It follows from (4.4) that stress in an ideal elastic spring should be a derivative of the

strain energy with respect to strain

dw

,

d

(4.5)

where in the case of Hookean elasticity we have: w E 2 / 2 .

The extension of the simplistic formula (4.5) to 3D is not trivial. Indeed, variety of

stresses and strains can be considered and it is not clear which stress works on which strain.

To clarify that we consider the work of external forces on displacement increments, du dy ,

over the whole 3D body

d dy t 0 dA0 dy 0bdV0 ,

Mechanics of Soft Materials

36

(4.6)

Volokh 2010

where t 0 and 0b designate prescribed tractions per the reference area and body forces per

the reference volume, including the inertia forces.

By using the equilibrium equation (3.46) we can rewrite (4.6) in the form

d t 0 dy dA0 (DivT) dy dV0 ,

(4.7)

where T is the 1st Piola-Kirchhoff stress.

We transform (4.7) as follows

d t0i dyi dA0

t0i dyi dA0

Tij

x j

dyi dV0

(Tij dyi )

x j

dV0 Tij

(dyi )

dV0

x j

y

(t0i Tij n0 j )dyi dA0 Tij d i dV0

x j

,

(4.8)

0 (boundary conditions )

Tij dFij dV0

T : dF dV0

where the boundary conditions on tractions have been used

Tn 0 t 0 .

(4.9)

Transformation (4.8) means that the incremental work of the external forces is equal

to the incremental work of the internal forces. The work of the internal forces per unit

volume can be designated as follows

dW T : dF .

(4.10)

Analogously to 1D case this work is path independent only in the case where

T

W (F)

W (F)

, Tij

.

F

Fij

(4.11)

Here W is called the strain energy and material obeying (4.11) is called hyperelastic.

Evidently, the 1st Piola-Kirchhoff stress makes a work-conjugate couple with the

deformation gradient. It is possible, however, to assume that the strain energy depends on the

Green strain, ε (F T F 1) / 2 , rather than on the deformation gradient. In this case we have

(prove it!)

Tij

W (ε(F)) mn W 1 ( Fkm Fkn mn ) W

Fim ,

mn

Fij

mn 2

Fij

mj

or

Mechanics of Soft Materials

37

Volokh 2010

TF

W

.

ε

(4.12)

On the other hand we have by definition, (3.48),

T FS ,

(4.13)

where S is the 2nd Piola-Kirchhoff stress tensor and, consequently,

S

W (ε)

W (ε)

,

, Sij

ε

ij

(4.14)

W (C)

W (C)

,

, Sij 2

C

Cij

(4.15)

or

S2

where C FT F 2ε 1 is the right Cauchy-Green tensor.

It is possible to show that the considered stress-strain pairs are work-conjugate by the

direct computation (prove it!)

T : dF S : dε .

(4.16)

The ‘true’ Cauchy stress is obtained from (4.14)-(4.15) with the help of (3.48) with

J det F

σ J 1F

W T

W T

F 2 J 1F

F .

ε

C

(4.17)

We showed that the strain energy could be defined as a function of various strains. Is

there any preference in the choice of strains? The answer is yes. The strains which are

insensitive to the Rigid Body Motion (RBM) are preferable.

t

Q (RBM)

t*

t 0

F

s

y2

y1

x2

y1

y

s*

2

x1

O

Indeed, let us consider RBM superposed on the current configuration of material

y* Q(t )y h(t ) ,

(4.18)

where QT Q1 (det Q 1) is the proper orthogonal tensor of rotation and h is a vector of

translation.

Mechanics of Soft Materials

38

Volokh 2010

This motion preserves the length and the angle. Indeed, we have

s* y 2 * y1* Q(y 2 y1 ) Qs ,

(4.19)

s * s * s * s QT Qs s 1s s s s ,

(4.20)

cos *

s * p * s QT Qp s p

cos .

s* p*

sp

sp

(4.21)

Thus, a material fiber deforms as follows

dy* Qdy QF

dx F * dx .

(4.22)

F*

It is natural to require that the magnitude of the strain energy is not affected by RBM

because there is no straining. The latter means that the function of the strain energy should

obey the following condition

W (F) W (QF) .

(4.23)

The right Cauchy-Green and Green strain tensor obey this condition automatically

because they are insensitive to RBM

T

C* F *T F* (QF)T (QF) FT Q

QF F T F C ,

(4.24)

1

ε* (C * 1) / 2 (C 1) / 2 ε .

(4.25)

4.2 Rivlin’s representation for isotropic material

Ronald Rivlin found (1948) the following representation for the strain energy of

isotropic materials, which is given without proof,

W (C) W ( I1 , I 2 , I 3 ) ,

(4.26)

I1 trC, I 2 {( trC) 2 tr (C2 )} / 2, I 3 detC ,

(4.27)

that is the strain energy depends on the invariants of the right Cauchy-Green tensor.

Based on this representation we can calculate the stress as follows

S2

W I1 W I 2 W I 3

W

,

2

C

I1 C I 2 C I 3 C

(4.28)

where (see (1.47), (1.48), (1.51))

I1

1,

C

I 2

I11 C,

C

I 3

I 3C1 .

C

(4.29)

Inserting (4.29) in (4.28) we have

Mechanics of Soft Materials

39

Volokh 2010

W

W

S 2

I1

I 2

I1

W

W 1

1

C I3

C .

I 2

I 3

(4.30)

Transition to the Cauchy stress gives us another form of the constitutive law

W

W

σ J 1FSFT 2 J 1

I1

I 2

I1

W 2

W

B

B I3

I 2

I 3

1 ,

(4.31)

where

B FFT

(4.32)

is the left Cauchy-Green tensor.

We remind that invariants of B coincide with the invariants of C: I a (C) I a (B) .

4.3 Representation in principal stretches

Sometimes, it is more convenient to formulate the constitutive equations in terms of

principal stretches, i , rather than to use invariants. To make the transition to the principal

stretches we need the spectral representation of the right Cauchy-Green tensor

C FT F 12m(1) m(1) 22m( 2) m( 2) 32m(3) m(3) ,

(4.33)

where 2a and m(a ) are eigenvalues and eigenvectors of C accordingly.

Since

I1 12 22 32 , I 2 12 22 12 32 22 32 , I 3 12 22 32 ,

(4.34)

the strain energy can be rewritten as a function of principal stretches i i2

W (C) W (1 , 2 , 3 ) ,

(4.35)

and we can calculate the energy increment as follows

dW (C) dW (1 , 2 , 3 )

W

W

W

d1

d2

d3 .

1

2

3

(4.36)

In order to find d1 we, firstly, get the increment of (4.33)

3

d C {2a da m ( a ) m ( a ) 2a dm ( a ) m ( a ) 2a m ( a ) dm ( a ) } .

(4.37)

a 1

Secondly, we pre-multiply it by m(1) m(1) as follows

(m(1) m(1) ) : d C 21d1 ,

(4.38)

where we accounted for m(1) m( a ) 1a and d (m(1) m(1) ) 0 dm(1) m(1) 0 .

Thus, we have from (4.38)

Mechanics of Soft Materials

40

Volokh 2010

d1

1

(m (1) m (1) ) : d C .

21

(4.39)

Repeating this argument for d2 and d3 we get

dW (C)

W

: dC ,

C

(4.40)

where

3

W

1 W ( a )

m m(a) .

C a1 2a a

(4.41)

Using this derivative we can write the 2nd Piola-Kirchhoff tensor in the form

S2

3

W

1 W ( a )

m m( a ) .

C a 1 a a

(4.42)

It is remarkable that 2PK stress is coaxial with the right Cauchy-Green tensor because

their principal directions coincide. The latter allows us to directly compute the principal 2PK

stresses

Sa

1 W

a a

(no sum) .

(4.43)

By using the spectral decomposition of the deformation gradient, (2.35), we can

compute the Cauchy stresses

σ J 1FSFT

3

1

123

a 1

a

W ( a )

n n( a ) ,

a

(4.44)

which is coaxial with the left Cauchy-Green tensor because their principal directions

coincide. The latter allows us to directly compute the principal Cauchy stresses

a

a W

12 3 a

(no sum) .

(4.45)

4.4 Incompressibility

Many soft materials resist volume changes much stronger than the shape changes.

This experimental observation makes it reasonable to assume the material incompressibility

dV

J det F 1 det F det F T det B det C I 3 .

dV0

(4.46)

This can be considered as a restriction imposed on deformation

(C) 1 I 3 (C) 0 .

(4.47)

The incremental form of the restriction can be written as follows

Mechanics of Soft Materials

41

Volokh 2010

d (C)

: dC 0 .

C

(4.48)

Here / C can be interpreted as a stress producing zero work on the strain

increment – the workless stress. Such stress is indefinite since it can always be scaled by an

indefinite parameter, p .

Adding the workless stress to the stress derived from the strain energy we have

T

W

σ 2 J 1F

p

F ,

C

C

(4.49)

or, substituting from (4.47) into (4.49),

σ 2F

W T

F p1 .

C

(4.50)

The unknown multiplier, p , should be obtained from the solution of equilibrium

equations.

In the case of isotropic material we have

σ p1 2(W1 I1W2 ) B 2W2B2 ,

(4.51)

where

Wa

W

.

I a

(4.52)

In terms of the principal stresses and stretches we have instead of (4.45)

a a

W

p (no sum) .

a

(4.53)

4.5 Examples of strain energy

In this section we consider some popular strain energy functions, W (C) , which in the

absence of residual stresses should meet the following conditions

W

(1) 0 ,

C

W (1) 0,

(4.54)

or, in the case where the strain energy is a function of principal stretches, W (1 , 2 , 3 ) ,

W

(1,1,1) 0 ,

a

W (1,1,1) 0,

(4.55)

We start with the Kirchhoff-Saint Venant material

W (ε)

Mechanics of Soft Materials

2

( trε) 2 ε : ε ,

42

(4.56)

Volokh 2010

where and are the Lame constants and the Green strain is ε (C 1) / 2 . Differentiating

the strain energy density with respect to the Green strain we obtain 2PK stresses

S ij

( mn mn )

W ( kk rr )

ij 2 ij

ij

kk

rr 2 mn mn ,

ij

ij

ki kj rr 2 mi nj mn

ij rr 2 ij

S

W

( trε)1 2 ε .

ε

(4.57)

Alternatively, we can rewrite (4.56) and (4.57) in principal stretches

W (1 , 2 , 3 )

8

(12 22 32 3) 2

4

{(12 1) 2 (22 1) 2 (32 1) 2 } ,

S a (12 22 32 3) / 2 2 (2a 1) / 2 .

(4.58)

(4.59)

This classical material model is generally not used for soft materials. In the case of

small strains, (4.57) is the generalized Hooke law. The use of nonlinear strains, however, is

crucial in order to suppress rigid body motions in finite element computations.

Next strain energy function defines the Neo-Hookean incompressible material

W c( I1 3) c(12 22 32 3),

J 12 3 1 ,

(4.60)

where c is a material constant.

The Neo-Hookean model is the simplest one for modeling soft materials. It is often

used as a starting point for the experimental calibration. A popular generalization of (4.60) is

the Yeoh material defined as a polynomial of the first principal invariant, I1 (C) . For example

Hamdi et al (Polymer Testing 25 (2006) 994-1005) calibrated the following Yeoh model for

natural rubber

W c1 ( I1 3) c2 ( I1 3) 2 c3 ( I1 3)3 , I 3 1 ,

(4.61)

where

c1 0.298 MPa, c2 0.014 MPa, c3 0.00016 MPa .

Another generalization of the Neo-Hookean model is the Mooney-Rivlin material

which defines the dependence of the strain energy on both the first and second principal

invariants. An example of the incompressible Mooney-Rivlin material was calibrated by

Sasso et al (Polymer Testing 27 (2008) 995-1004)

W c1 ( I1 3) c2 ( I 2 3) c3 ( I1 3) 2 c4 ( I1 3)( I 2 3) c5 ( I 2 3) 2 , I 3 1 , (4.62)

Mechanics of Soft Materials

43

Volokh 2010

where

c1 0.59 MPa, c2 0.039 MPa, c3 0.0028 MPa, c4 0.0076 MPa, c5 0.00077 MPa .

Further generalization of the previous models is the Ogden material defined as

p

(1 2 3 3), J 1 ,

p 1 p

N

W

where p p 0,

p

p

p

(4.63)

p 1,...N .

For example, Hamdi et al (Polymer Testing 25 (2006) 994-1005) calibrated the Ogden

model for styrene-butadiene rubber where N 2 and

1 0.638 MPa, 1 3.03, 2 0.025 MPa, 2 2.35 .

4.6 Biaxial test

Biaxial tension tests are usually used to calibrate material models. The theoretical

background for such tests can be readily developed. Let us consider the homogeneous biaxial

deformation of a thin isotropic incompressible sheet

x2 , y2

x1 , y1

11

22

y1 1 x1 ,

y2 2 x2 ,

y3 3 x3 .

(4.64)

By the direct computation we get

F

y

1e1 e1 2e 2 e 2 3e3 e3 .

x

(4.65)

Thus, the coordinate system coincides with the principal directions of stretches and

the constitutive law takes form

σ p1 2(W1 I1W2 ) B 2W2B2 ,

Mechanics of Soft Materials

44

Volokh 2010

11 p 2(W1 I1W2 ) 12 2W214

2

4

22 p 2(W1 I1W2 ) 2 2W22 .

2

4

33 p 2(W1 I1W2 ) 3 2W23

(4.66)

The stresses are homogeneous and the equilibrium equations are satisfied

automatically. From the traction-free boundary conditions on the sheet faces we have

33 0 p 2(W1 I1W2 ) 32 2W234 .

(4.67)

Substituting the Lagrange multiplier in the stress tensor we get

11 2(W1 I1W2 ) (12 32 ) 2W2 (14 34 )

.

22 2(W1 I1W2 ) (22 32 ) 2W2 (42 34 )

(4.68)

I1 tr B 12 22 32 ,

(4.69)

Since

we can rewrite stresses in the form (prove it!)

11 2(12 32 )(W1 W2 22 )

’

22 2(22 32 )(W1 W2 12 )

(4.70)

where the incompressibility condition enforces

3

1

12

.

(4.71)

Equations (4.70) are often used for the experimental calibration of soft materials

under varying ratio of the applied stresses.

4.7* Balloon inflation

Balloon inflation is another popular deformation used for calibration of soft materials.

r

h

q

2r

Mechanics of Soft Materials

45

Volokh 2010

Consider the centrally symmetric inflation of a thin sphere. Its deformation can be

presented in terms of principal stretches along the directions of the spherical coordinate

systems

2 r

r

2 R R

,

h

1

2

r

H

(4.72)

where r, R and h, H are the current and referential radii and thicknesses of the sphere

accordingly and the incompressibility condition is taken into account in the second equation.

The deformation gradient and the left Cauchy-Green tensors take the following forms

F 2 g r G R (g G g G ) ,

(4.73)

B FFT 4 g r g r 2 (g g g g ) .

(4.74)

The Cauchy stress is

σ rr g r g r (g g g g ) ,

(4.75)

rr p 2(W1 I1W2 ) 4 2W2 8

.

p 2(W1 I1W2 ) 2 2W2 4

(4.76)

Since the balloon is very thin we have approximately

rr p 2(W1 I1W2 ) 4 2W28 0 .

(4.77)

Substituting the unknown multiplier, p , from (4.77) into (4.76)2 we have

2(W1 I1W2 ) 2 (1 6 ) 2W24 (1 12 )

2W12 (1 6 ) 2W2 [(22 4 )(2 4 ) (4 8 )]

2W12 (1 6 ) 2W2 2 (2 4 )

.

(4.78)

2(W1 W2 2 )2 (1 6 )

To relate stresses to the internal pressure, q , we consider equilibrium of a half sphere

2 r h r 2 q ,

(4.79)

h

2 H

2H

4H

q2 2

3

(W W2 2 ) (1 6 ) .

r

R

R

R 1

(4.80)

or

This is the pressure-stretch curve. In the case of the Mooney-Rivlin material, for

example we have

W c1 ( I1 3) c2 ( I 2 3) ,

Mechanics of Soft Materials

46

(4.81)

Volokh 2010

W

c1 ,

I1

W1

W2

W

c2 ,

I 2

(4.82)

and

q

4H

(c1 c2 2 ) (1 6 ) .

R

(4.83)

1

0.8

q

4c1 H / R

c2 0.055c1

0.6

0.4

0.2

0

2.5

5

7.5

10

12.5

r/R

15

17.5

20

4.8 Homework

1. Prove (4.12).

2. Prove (4.16).

3. Derive constitutive equations for (4.60).

4. Derive constitutive equations for (4.61).

5. Derive (4.70) from (4.68)-(4.69).

6. Read Section 4.7.

Mechanics of Soft Materials

47

Volokh 2010

5 Anisotropic elasticity

Rubberlike materials are usually isotropic. It is possible, of course, to strengthen them

by embedding fibers in prescribed directions. Nature does so with the soft biological tissues

which usually consist of an isotropic matrix with the embedded and oriented collagen fibers.

The collagen fibers are aligned with the axis of ligaments and tendons forming one

characteristic direction or they can form two characteristic directions in the case of blood

vessels, heart etc.

5.1 Materials with one characteristic direction

Materials enjoying one characteristic direction are also called materials with

transverse isotropy, i.e. isotropy in the planes perpendicular to the preferred direction. Let us

designate the preferred direction by unit vector m0 in the reference configuration. In this

case the strain energy function W (C) W ( I1, I 2 , I3 , I 4 , I5 ) should additionally depend on two

more invariants

T

I 4 m m Fm0 Fm0 m 0 F

Fm 0 C : (m 0 m 0 ) ,

C

(5.1)

I 5 C2 : (m0 m0 ) ,

(5.2)

m Fm 0

(5.3)

m

m

where

is not a unit vector.

The fourth invariant, I 4 , has a clear physical meaning of the squared stretch in the

characteristic direction. The dyad in the parentheses is often called the structural tensor,

which characterizes the internal design of material.

Differentiating (5.1) and (5.2) with respect to C we get accordingly

I 4

m0 m0 ,

C

(5.4)

I 5

m0 Cm0 Cm0 m0 ,

C

(5.5)

Accounting for (4.29) and (5.4)-(5.5) we calculate the constitutive equation

Mechanics of Soft Materials

48

Volokh 2010

5

W

W I a

S2

2

C

a 1 I a C

,(5.6)

Wa

2{(W1 I1W2 ) 1 W2C I 3W3C1 W4m 0 m 0 W5 (m 0 Cm 0 Cm 0 m 0 )}

or

σ J 1FSFT

2 J 1{(W1 I1W2 ) B W2 B 2 I 3W3 1 W4m m W5 (m Bm Bm m)}

,

(5.7)

where B FFT is the left Cauchy-Green tensor.

In the case of incompressible material we have instead of (5.7)

σ p1 2{(W1 I1W2 ) B W2B2 W4m m W5 (m Bm Bm m)} .

(5.8)

5.2 Materials with two characteristic directions

In the case of two preferred directions we designate the second characteristic unit

vector with prime m0

in the reference configuration the strain energy function

W (C) W ( I1, I 2 , I3 , I 4 , I5 , I 6 , I 7 , I8 ) should additionally depend on three more independent

invariants

I 6 C : (m0 m0 ) ,

(5.9)

I 7 C2 : (m0 m0 ) ,

(5.10)

I 8 C : (m 0 m0 ) ,

(5.11)

m Fm0

(5.12)

where

is not a unit vector.

Invariants I 6 , I 7 are analogous to I 4 , I 5 while invariant I 8 is related to both

characteristic directions.

Differentiating (5.9) - (5.11) with respect to C we get accordingly

I 6

m0 m0 ,

C

(5.13)

I 7

m0 Cm0 Cm0 m0 ,

C

(5.14)

I8 1

(m0 m0 m0 m0 ) .

C 2

(5.15)

We notice that the last derivative preserves symmetry.

Mechanics of Soft Materials

49

Volokh 2010

Now the Cauchy stress takes form

Jσ 2(W1 I1W2 ) B 2W2 B 2 2 I 3W3 1

2W4m m 2W5 (m Bm Bm m)

.

2W6m m 2W7 (m Bm Bm m)

(5.16)

W8 (m m m m)

In the case of incompressible material we have instead of (5.16)

σ p1 2(W1 I1W2 ) B 2W2B 2

2W4m m 2W5 (m Bm Bm m)

.

2W6m m 2W7 (m Bm Bm m)

(5.17)

W8 (m m m m)

5.3 Fung model of biological tissue

The presented way of introducing characteristic directions is not unique for a

description of anisotropy. The classical works of Y.C. Fung and his disciples introduced

anisotropy by using the Green strain ε (C 1) / 2 as follows

1

W (ε) ε : α : ε ( 0 ε : β : ε) exp(γ : ε ε : κ : ε ...) ,

2

or

1

W ijkl ij kl ( 0 mnpq mn pq ) exp( ij ij ijkl ij kl ...) .

2

(5.18)

Here α, 0 , β, γ, κ are scalars, second- and fourth- order tensors of material constants which

should be defined in experiments.

The exponential function allows modeling stiffening typical of soft biological tissues.

As an example of the calibrated Fung strain energy we present the constitutive model of a

rabbit carotid artery

c

2

2

2

W {exp(c1 RR

c2

c3 ZZ

2c4 RR 2c5 ZZ 2c6 RR ZZ ) 1} ,

2

(5.19)

with c 26.95 KPa the dimensional and ci s are dimensionless: c1 0.0089 , c2 0.9925 ,

c3 0.4180 , c4 0.0193 , c5 0.0749 , c6 0.0295 .

5.4 Artery under blood pressure

We consider inflation of an artery under blood pressure. The corresponding Boundary

Value Problem (BVP) includes equations of momentum balance (equilibrium)

Mechanics of Soft Materials

50

Volokh 2010

div σ 0 ,

(5.20)

constitutive law

σ p1 F

W T

F ,

ε

(5.21)

and boundary conditions on placements and tractions

y y or σn t ,

(5.22)

where 'div' operator is with respect to the current coordinates y ; σ is the Cauchy stress

tensor; 1 is the second order identity tensor; p is an unknown multiplier of the workless

stress; ε (FT F 1) / 2 is the Green strain tensor; W is the strain energy; t is traction per

unit area of the current surface with the unit outward normal n ; and the barred quantities are

prescribed.

We consider the radial inflation of an artery as a symmetric deformation of an infinite

cylinder. Following Fung we assume the deformation law in the form

r

R 2 A2

a 2 , , z sZ ,

s

(5.23)

where a point occupying position {R, , Z } in the reference configuration is moving to

position {r , , z} in the current configuration; s is the axial stretch; 2 /(2 ) , where

is the artery opening angle in the reference configuration; A and a are the internal artery

radii before and after deformation accordingly.

Current state

{r , , z}

Reference state

{R , , Z }

A

B

No stress

a

Residual stress

g

b

Final stress

The opening central angle, , in a stress-free reference configuration is used to

represent residual stresses, which are one of the most intriguing features of mechanics of

living tissues. While the qualitative nature of residual stresses related to tissue growth is

understood reasonably well, the best way to quantify them remains to be settled.

Accounting for (5.23), the deformation gradient and the nontrivial components of the

Green strain take the following forms

Mechanics of Soft Materials

51

Volokh 2010

F

R

r

g r G R g G sg z G Z ,

sr

R

(5.24)

RR {( R / s r ) 2 1} / 2

2

{( r / R) 1} / 2 ,

2

ZZ {s 1} / 2

(5.25)

where G R , G , G Z and g r , g , g z are the orthonormal bases in cylindrical coordinates at

the reference and current configurations accordingly.

Accounting for (5.21), (5.23)-(5.25) and assuming that the stored energy depends on

the nontrivial strain components only we get the following nonzero components of the

Cauchy stress

R 2 W

p

rr

( sr ) 2 RR

(r ) 2 W

p

.

2

R

2 W

zz p s

ZZ

(5.26)

Besides, there is only one nontrivial equilibrium equation

rr rr

0.

r

r

(5.27)

The traction boundary conditions are

rr (r a) g

,

(

r

b

)

0

rr

(5.28)

where a, b are the inner and outer radii of the artery after the deformation, which were equal

to A, B before the deformation accordingly; and g is the internal pressure.

We integrate equilibrium equation (5.27) over the wall thickness with account of

boundary conditions (5.28) and we get

b(a)

g (a)

a

dr

( rr )

r

b(a)

a

R 2 W ( r ) 2 W

2

2

R

( s r ) RR

dr

,

r

(5.29)

where b(a) a 2 ( B 2 A2 ) /( s) .

Equation (5.29) presents the pressure-radius (g-a) relationship, which we examine

below. Before doing that, however, we introduce dimensionless variables as follows

g

Mechanics of Soft Materials

g

W

r

R

a

b

; W ; r ; R

a ; b ,

c

c

A

A

A

A

52

(5.30)

Volokh 2010

where c is the shear modulus.

Substituting (5.30) in (5.29) we get

b (a )

g (a )

a

R 2 W ( r ) 2 W

2

R 2

( s r ) RR

dr

,

r

(5.31)

where

b (a ) a 2 (( B / A) 2 1) /( s) ,

(5.32)

R 2 s (r 2 a 2 ) 1 .

(5.33)

The dimensionless multiplier p p / c is obtained from (5.27) and (5.28)1 by

integration

r

R ( ) 2 W

d

R (r ) 2 W

( ) 2 W

,

p (r )

(

r

)

g

(

a

)

(

)

(

)

a ( s )2 RR

( s r ) 2 RR

R ( ) 2

(5.34)

and normalized stresses take the form

rr

R 2 W

p

rr

c

( sr ) 2 RR

(r ) 2 W

p

.

c

R 2

2 W

zz zz p s

c

ZZ

(5.35)

We use the Fung model (5.20) to numerically generate the pressure-radius curves and

stresses. Firstly, we set an unprestressed state with 0 and the internal and external

reference radii A 0.71 mm and B 1.10 mm accordingly. The pressure-radius and stress

distribution curves are calculated with the help of Mathematica presented in figure below. We

show stresses for dimensionless pressure

g 0.5 , which corresponds to pressure

g 13.47 KPa for the shear modulus c 26.95 KPa .

Mechanics of Soft Materials

53

Volokh 2010

Secondly, we set a prestressed state with 160 and the internal and external

reference radii A 1.43 mm and B 1.82 mm accordingly. The pressure-radius and stress

distribution curves are presented in figure below. We again show stresses for dimensionless

pressure g 0.5 , which corresponds to pressure g 13.47 KPa for the shear modulus

c 26.95 KPa .

5.5 Homework

1. Is C3 : (m 0 m 0 ) the independent invariant? Hint: Use the Caley-Hamilton formula

(1.39).

2. Prove (5.4).

3. Prove (5.5).

4. Derive (5.7) from (5.6).

5. Prove (5.15).

6. Derive (5.23)1 from the condition of constant volume.

Mechanics of Soft Materials

54

Volokh 2010

6 Viscoelasticity

Rubberlike materials and soft biological tissues can exhibit a time-delayed response.

For example, stresses can decrease under the constant strains – stress relaxation – or strains

can increase under the constant stresses – creep. Such phenomena are usually related to

viscosity, which is a fluid-like property of solids.

6.1 Rheological model

To describe viscosity we start with a simple one-dimensional model, also called

rheological. Rheological models are prototypes for general three-dimensional constitutitive

theories. For example, the spring model is a prototype for hyperelasticity theories. To account

for viscoelasticity we will use the device shown in the figure below.

E

q

E

This rheological model represents the so-called ‘standard solid’, which includes the

classical elasticity due to the top linear spring with the Young modulus E and viscosity due

to the chain of the linear spring with Young modulus E and the linear dashpot with the

viscosity coefficient . The dashpot provides the time delay in the mechanical response of

the device.

We assume, for the sake of simplicity, that the device has a unit length and a unit area

and, consequently, strains and stresses are equal to elongations and forces. The resulting

stress is composed of stresses acting on the top and bottom elements of the device

E

q ,

(6.1)

where E is the stress in the top spring; is the strain of the whole device; and q is

the ‘viscous’ stress in the bottom element.

The viscous stress can be calculated considering the dashpot with the linear

proportionality between the stress and strain rate in as in the case of Newtonian fluids

Mechanics of Soft Materials

55

Volokh 2010

q ,

(6.2)

where is a dashpot strain.

On the other hand, the viscous stress is also equivalent to the stress in the bottom

spring

q E ( ) .

(6.3)

Differentiating (6.3) with respect to time and substituting from (6.2) we get the

evolution equation for the viscous stress

q

q

,

(6.4)

where

(6.5)

E

is the relaxation time and

E

E

(6.6)

is a relative spring stiffness and

q(t ) 0 .

(6.7)

is the initial condition.

Equations (6.1) and (6.4) represent the constitutive description of the model of

‘standard solid’.