DESIGN CONSIDERATIONS FOR MORTISE AND TENON CONNECTIONS Richard J. Schmidt

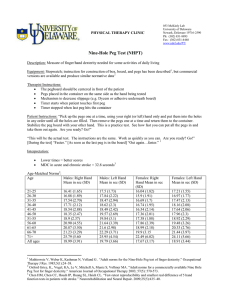

advertisement