IV: SAWN LUMBER PART

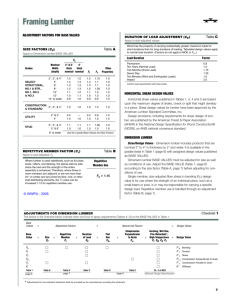

advertisement