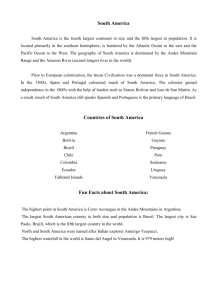

Enabling Trade: Increasing the Potential of Trade Reforms

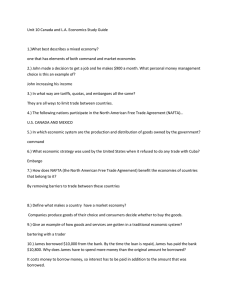

advertisement