Chang T., Zhang H., Guo Z., Guo X. Gao Huajian 2014.04.22

advertisement

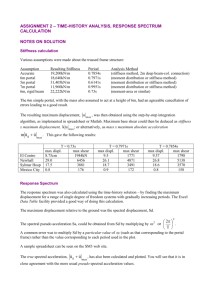

Chang T., Zhang H., Guo Z., Guo X. Gao Huajian 2014.04.22 All pics from internet Provides the most straightforward way for actuation and energy conversion. Water flow Waterwheels Hydroelectric turbines Generally induced by an external source of energy. Lack of intrinsic mechanism similar to downhill flow of water. Thermal Barreiro et al., Science 320, 775 (2008) Electronic Fennimore et al., Nature 424, 408 (2003) Kudernac et al., Nature 479, 208 (2011) kvdW kvdW VvdW V0 kvT kBkvdW kν 2m0 Potential coefficients (eV/atom/K) 0.5kvdW 8 7 e 6 kv 5 i 4 3 0.0 kv 0.5 1.0 1.5 Stiffness coefficient (kvdW) 1 1 zo (ql , qm )2 za (ql , qm )2 dql dqm Guo Z, Chang T, Guo, X, Gao H, J Mech Phys Solids 60, 1676 (2012). 2.0 B C Soft D Hard Displacement (nm) 50 B 25 0 kc = 0.48/4.8/7.7/9.6/12.0/14.4/14.4 nN/nm k = 0.0096/0.096/0.144/0.192/0.24/0.288/0.096 nN/nm 2 A A larger driving force can be generated by a larger stiffness gradient or a smaller local stiffness. Velocity (nm/ns) -25 30 C 15 0 -15 -30 0.0 2.5 5.0 Time (ns) 7.5 10.0 Hard Soft 8 24 6 18 4 12 2 6 0 0.0 0.2 0.4 Time (ns) Superposition Temperature 0.60.0 0.2 0.4 Time (ns) 0 0.6 C 30 30 300K 300K 300K 500K 12 15 6 0 0 -15 -6 -30 -12 0 2 4 6 Time(ns) Accel – Stable – Deaccel Shuttles like a pendulum 8 Displacement(nm) 0.801/2.403 2.403/4.005 0.801/4.005 0.801/4.005 Velocity(nm/ns) 10 36 B A Velocity (nm/ns) Displacement (nm) 12 Nanodurotaxis: Neither active sensing nor wetting Durotaxis was first observed in living cells. Water droplets undergo reverse durotaxis. Wetting Active sensing Lo et al., Biophys J 79, 144 (2000) Discher et al, Science 310, 1139 (2005) Style et al., Proc. Natl. Acad. Sci. U.S.A. (2013) Interlayer Potential (meV/atom) A -48.42 -48.45 -48.48 -48.51 0 3 6 9 12 15 Stiffness (nN/nm) Stiffness gradient induces a bias van der Waals potential 1st/2nd/3rd/4th ring at the rear end Inner part 4th/3rd/2nd/1st ring at the front end B Interlayer Force (pN) 21.23 20 Unbalanced edge force/Net driving force 15 6.29 pN/5.48 pN 1.27 pN/0.93 pN 10 5 13.19 1st/2nd/3rd/4th rings (52 atoms each) on softer side -10 5.995.43 2.371.91 0.63 0 -5 Stiffness jump Stiffness gradient -0.20 -1.72 -3.04 -5.49 -6.79 -0.34 -0.30 -0.66 -0.81 Inner region 1st/2nd/3rd/4th rings (52 atoms each) on harder side -15 Driving force comes mainly from the unbalance edge force -12.02 -12.97 Partly (less) from thermal atomic vibration, as shown by Guo et al, JMPS (2012). Substrate Deformation (nm) Partly (more) from out-of-plane deformation of substrate. 0.020 0.015 Soft Hard 0.801 nN/nm 4.005 nN/nm 0.010 0.005 Contact area 0.000 -0.005 -0.010 Longitudinal position Contributions to edge force from substrate atoms at different position. ~4 pN (320 kPa) Functional graded material ~5 pN (100 kPa) Intrinsically motivated No external power needed ~10 pN (400 kPa) Marerial interface ~2 N (2 kPa) Nanoporous array No biological activity involved Durotaxis! Stiffness Engineering? ? A fundamental law of nanoscale directional motion Mechanism & mechanics General implications *Chang T., Zhang H., Guo Z., Guo X. *Gao Huajian *2014.04.22