Science and Risk-based Validation: Using Practical Approaches

advertisement

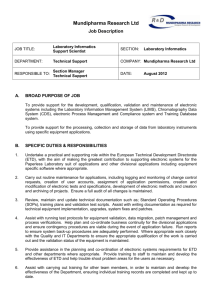

Event: Session: WASHINGTON 2010 CONFERENCE Dates: Location: Wednesday-Thursday 9-10 June 2010 Washington, D.C. Science and Risk-based Validation: Using Practical Approaches Across projects to Break Down Implementation Silos Session Leader: Mark Hannon, Nick Haycocks Wednesday, 9 June Start End Time Presentation Title Time Speaker (Leader/Speaker Breakfast 7:00) Breakfast Welcome and Introductions 7:30 9:00 9:00 9:15 9:15 10:00 10:00 10:30 10:30 11:15 Networking Break Brunelle Science and Risk-Based Validation: Amgen’s Approach to Implementation for Equipment Qualification Amgen has been developing and implementing a risk-based approach to equipment qualification designed to simplify the process utilizing the ASTM 2500 framework and other guidance. The Amgen model utilizes a crossfunctional risk assessment process supported by Good Engineering Practices. This allows Quality to focus validation efforts around critical aspects, verifying that appropriate risk control measures are in place and functioning correctly. This presentation will introduce the process, show how the program developed, and provide examples of actual practice. Challenges encountered and benefits realized will be included. A Risked-Based Approach to Validating Aseptic Processing and Process Bowen Validation Lunch Selby Validation: Is Risk Management Religion or Remedy? Risk management is promoted as the tool to focus the efforts of the pharmaceutical industry to where it adds most value whilst at the same time protecting the patient. Nowhere is this more valuable than in validation activities. This presentation, will offer an overview of risk management as it is currently practiced and use examples to illustrate how it can be applied in validation activities to both the advantage and the disadvantage of the patient and the company. A Science and Risk-Based Approach to Establishing a Calibration Program Foss 11:15 12:00 12:00 13:00 13:00 14:00 14:00 15:00 15:00 15:30 16:15 15:30 16:15 17:00 17:00 Hannon Haycocks Watler Implementing a Risk-Based Approach for Process Validation In this discussion we will explore how to implement the FDA’s Guidance on Quality Risk Management (ICH Q9) and PDA’s Technical Report 42 concepts to identify high risk factors. FMEA will be used to identify critical parameters which then streamline the validation effort across stages 1, 2 and 3 of the new FDA process validation guidance. The risk analysis will identify high risk elements to be mitigated during stage 1 through Quality by Design practices such as mechanistic and DOE techniques. As validation advances, the risk analysis will become an integral part in justifying parameters to study during the intensive commercial qualification stage. Finally, the risk analysis coupled with statistical process control techniques such as “short-run” SPC, will be used to develop and streamline the ongoing process monitoring program. Networking Break Risk-Based Approach to the Qualification of a Purified Water System Zoccolante Hannon Internal Audits for Risk-Based Approaches to Qualification Risk-based approaches are applied to many new process and systems validations. Companies perform internal quality audits to evaluate commissioning and qualification in advance of regulatory inspections, such as PAI, and gauge the conformance to company quality policies. Although not a regulatory requirement, companies are adopting Pharmaceutical Quality Systems utilizing Quality Risk Management to both facilitate regulatory inspections and improve Quality Systems. We will examine the roles for audits described in ICH Q9 and Q10, and what auditors may look for in evaluating qualification packages. Discussion is based upon the principles pioneered in the ISPE Commissioning and Qualification Baseline Guide and currently being furthered developed by the ASTM E 2500 Standard Guide. Additional, topics include Good Engineering Practice, requirements for commissioning, use of vendor testing (FAT), evaluating risk assessments, design verification, reviewing validation records, and capturing the output of validation into living systems, such as Risk Control Strategies. Attendees will be familiarized with role of internal qualification audits for risk based approaches then, review practical applications of audit principles and identify potential pitfalls. Seminar Adjourns, Reception Thursday, 10 June Start End Time Presentation Title Time Speaker 7:00 8:00 8:00 9:00 Breakfast Quality Risk Management – Driving Focus, Controlling Risks, Improving the Howard Process Lambert Acosta 9:00 10:00 10:00 10:30 10:30 11:15 Managing the Risk of Cross-Contamination: ISPE’s Risk-MaPP Baseline Wilkins Guide Networking Break A Case Study in Master Soils: Risk Based Approaches for Developing Klewer Robust and Efficient Cleaning Processes An important strategy for successful cleaning validation is the development of robust cleaning cycles. A major obstacle in implementing this strategy is that manufacturing equipment and process soils are often not readily available for cycle development, resources which are especially scarce when a new product is being launched. The above obstacles can be overcome through the use of bench-scale cleanability studies and Formulated Master Soilants (FMS). The criteria for selecting a suitable FMS and a methodology for designing, optimizing, and validating cleaning cycles will be discussed. A case study will be presented to illustrate the implementation of a formulated master soil. 11:15 12:00 Wozniak Quality Risk Management (QRM) -- Its Application to a Biopharmaceutical It is time to apply QRM effectively and efficiently. This presentation will lead us on a journey on how to establish, initiate and formalize your QRM efforts through a case study. Included will be the importance of management commitment, documentation and formation of teams as well as compliance with ICH Q9, and Annex 20 of the PIC/SGMP code of GMP. The implementation of mitigation measures will demonstrate how QRM will focus attention on the most critical quality aspects and the sense of success that implementation of these measure can realize in many workplaces. The FMEA approach will also be discussed, including the pros and cons of this methodology for the case study presented. 12:00 13:00 13:00 13:45 Lunch Butterell Continuous Quality Verification: An Approach to Process Validation This presentation will provide an overview of Continuous Quality Verification (CQV) as an approach to process validation and the circumstances under which CQV may be used. It will show the primary elements of this approach as applied to the implementation of continuous processing for an existing product. How CQV links to real-time release and the expected impact of p p p CQV on regulatory filing content will also be discussed. 13:45 15:00 Gooen, FDA FDA Guidance Overview What is the FDA seeing as companies apply Risk-based approaches, where Godwin, FDA is the industry compared to expectations. Some generic descriptions, progress to date, sticky wickets, Q&A 15:00 15:30 15:30 16:15 Networking Break Modular Approach to Risk Based Qualification - Knowledge management across an enterprise - Tools you can use Seminar Adjourns 16:15 **Please Note that Agendas are Subject to Change** Veverka Waters