MECH201P - Manufacturing and Design

advertisement

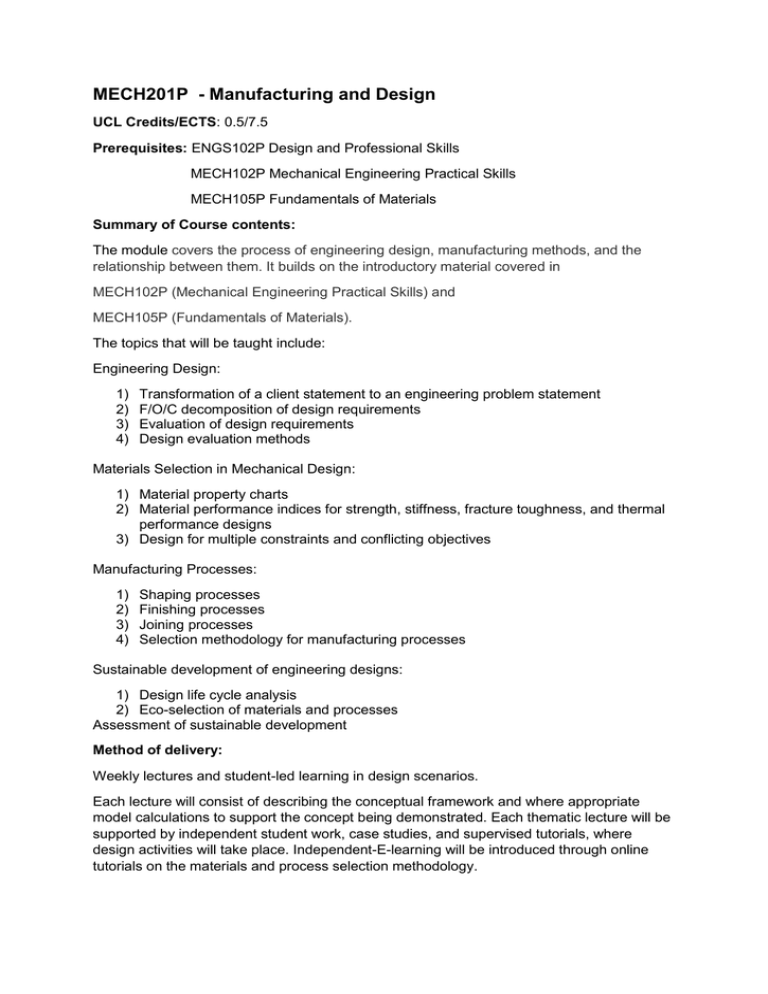

MECH201P - Manufacturing and Design UCL Credits/ECTS: 0.5/7.5 Prerequisites: ENGS102P Design and Professional Skills MECH102P Mechanical Engineering Practical Skills MECH105P Fundamentals of Materials Summary of Course contents: The module covers the process of engineering design, manufacturing methods, and the relationship between them. It builds on the introductory material covered in MECH102P (Mechanical Engineering Practical Skills) and MECH105P (Fundamentals of Materials). The topics that will be taught include: Engineering Design: 1) 2) 3) 4) Transformation of a client statement to an engineering problem statement F/O/C decomposition of design requirements Evaluation of design requirements Design evaluation methods Materials Selection in Mechanical Design: 1) Material property charts 2) Material performance indices for strength, stiffness, fracture toughness, and thermal performance designs 3) Design for multiple constraints and conflicting objectives Manufacturing Processes: 1) 2) 3) 4) Shaping processes Finishing processes Joining processes Selection methodology for manufacturing processes Sustainable development of engineering designs: 1) Design life cycle analysis 2) Eco-selection of materials and processes Assessment of sustainable development Method of delivery: Weekly lectures and student-led learning in design scenarios. Each lecture will consist of describing the conceptual framework and where appropriate model calculations to support the concept being demonstrated. Each thematic lecture will be supported by independent student work, case studies, and supervised tutorials, where design activities will take place. Independent-E-learning will be introduced through online tutorials on the materials and process selection methodology. Assessment: Assessment will be based on the following coursework A logbook, in the format of a design report, containing: problem statement and design FOC, alternative designs, model calculations and drawings for the detailed design, materials selection, process selection, and justification of design sustainability. Testing of prototype against constraints and calculations A presentation to an academic/industry panel presenting and justifying design choices. Module aims: The module covers the process of engineering design, manufacturing methods, and the relationship between them. It builds on the introductory material covered in MECH102P (Mechanical Engineering Practical Skills) and MECH105P (Fundamentals of Materials). 1. To train students in the methodology of all stages of engineering design: from the analysis of the client statement to the manufacturing of the design. 2. To develop the practical, theoretical, and computational engineering skills relevant to the design process 3. To develop an appreciation of sustainability in engineering design, and an understanding of how design decisions can affect the environmental and economic costs of the design and product. Intended learning outcomes: Upon completion of this module students should be able to: Demonstrate knowledge of design methodologies Apply the materials selection methodology in designs for strength, stiffness, weight savings, fracture resistance, and thermal applications Obtain a working knowledge of computational materials/process selection tools and deepen existing knowledge on CAD tools. Understand the environmental & economic costs of making products and recycling them. Assessment: The course will have the following assessment components: Logbook / design report (50%) Testing of design prototype (20%) Final presentation (30%) To pass this course students must: Obtain an overall pass mark of 40% for all sections combined. PLEASE NOTE: This information is given in good faith but accuracy cannot be guaranteed.