Health Physics Society Radiation Safety for X-ray Diffraction and Fluorescence Analysis

advertisement

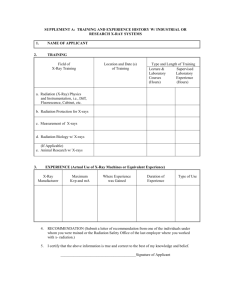

ANSI/HPS N43.2-2001 Health Physics Society An American National Standard Radiation Safety for X-ray Diffraction and Fluorescence Analysis Equipment ANSI/HPS N43.2-2001 An American National Standard - Radiation Safety for X-ray Diffraction and Fluorescence Analysis Equipment Approved: July 31, 2001 American National Standards Institute, Inc. Forward (This forward is not part of ANSI/HPS N43.2-2001, Radiation Safety for X-ray Diffraction and Fluorescence Analysis Equipment.) The problem of radiation hazards connected with the operation of x-ray diffraction and fluorescence analysis equipment has been a continuing one since the advent of such equipment. While many improvements have been made in safety since the last release of this standard, many pieces of older and custom-built equipment are still in use today. In addition, new uses have been found in areas like surface and thin film analysis that were not addressed in the original standard. This revision is meant to modernize the past recommendations (many of which are still valid, however) and to provide guidance for x-ray use in new technologies. Historically, the American Standards Association (ASA), Sectional Committee Z54, in 1946 issued American War Standard Z54.1 “Safety Code for the Industrial Use of X-rays” which included a section on x-ray diffraction. In 1967, the ASA was superseded by the USA Standard Institute, and Sectional Committee Z54 was replaced by Committee N43 under the sponsorship of the National Bureau of Standards (NBS). Responsibility for the development of the original standard was assigned to Subcommittee N43-1. American National Standard N43.2-1971 “Radiation Safety for X-ray Diffraction and Fluorescence Analysis Equipment” was approved on October 6, 1971, published as NBS Handbook 111, and then reaffirmed with minor revisions in 1976. In 1985, the Health Physics Society replaced the National Bureau of Standards as the Secretariat for the N43 Committee. In 1988 Subcommittee N43.2 reformed to begin updating process and had the standard reaffirmed in March 1989. Revision work was completed in December 1998 and the draft received N43 Committee approval April 23, 1999. Suggestions for improvement gained in the use of this standard will be welcome. They should be sent to HPS Standards Program Director, Health Physics Society, 1313 Dolley Madison Blvd., Suite 402, McLean, VA 22101, USA. iv Below is the list of Members of Subcommittee N43.2 which had the responsibility for the development of ANSI/HPS 43.2-2001: Jeffrey Leavey, Chair (IBM Corporation) David Allard (Pennsylvania Bureau of Radiation Protection) Mike Byrnes (Lucent Technologies) Ted de Castro (Lawrence Berkeley Laboratory) Mark Depp (formerly with Bruker AxS) Len DeRoche (formerly with Rigaku USA) Wes Dunn (formerly with International Isotopes, Inc.) Reed Durham (Lockheed Martin Energy Systems) William Morris (Dept. of the Navy) Robert Westerdale (EDAX, Inc.) iii This standard was consensus balloted and approved by the ANSI-Accredited HPS N43 Committee on April 23, 1999. At that time, the N43 Standards Committee had the following membership: Chair Vice Chair ABB Industrial Systems Inc. Alliance of American Insurers American Automobile Manufacturers Association American Conference of Governmental Industrial Hygienists American Crystallographic Association American Insurance Services Group American Iron and Steel Institute American Public Health Assoc., Inc. American Society for Nondestructive Testing, Inc. American Society for Testing and Materials Atomic Energy Control Board Conference of Radiation Control Program Directors Health Physics Society National Institute of Standards and Technology Underwriters' Laboratories, Inc. Univ. of California (Los Alamos Nat'l Lab) U. S. Dept of the Air Force, Office of the Surgeon General U. S. Dept of the Army, Office of the Surgeon General U.S. Department of Energy U. S. Department of the Navy U. S. Dept of Health and Human Services - Public Health Individual Members iv John C. Taschner Gordon M. Lodde John R. Dukes Thomas F. Bresnahan Donald A. Greschaw William Watt (alt.) David A. Felinski (alt.) Gordon M. Lodde Camden Hubbard Stewart M. Fastman Anthony LaMastra Peter A. Hernandez (alt.) Jesse Lieberman K. Dieter Markert Marvin M. Turkanis R. E. Irwin Mike Henry Bart Lago (alt.) Jack Fix David Lee (alt.) Douglas M. Eagleson James W. Tracy (alt.) Peter Boden David Dini (alt.) John C. Taschner Don Jordan Harris Edge Gregory R. Komp (alt.) Peter O'Connell Joel Rabovsky (alt.) David E. Farrand William Morris (alt.) Steven Doremus (alt.) H. Thompson Heaton Frank Cerra (alt.) John H. Weiler Contents 1. Introduction ............................................................................................................................................... 1 2. Scope ........................................................................................................................................................ 1 3. Definitions ................................................................................................................................................. 1 4. Types of Injuries........................................................................................................................................ 3 5. Dose Limits ............................................................................................................................................... 3 6. Installation and Equipment Requirements ................................................................................................ 3 6.1 Installation requirements .............................................................................................................. 3 6.2 X-ray System Classification and Requirements........................................................................... 5 7. Operating Procedure Requirements ......................................................................................................... 7 7.1 Federal, State and Local regulations and Procedures................................................................. 7 7.2 Radiation Protection Surveys and Inspection .............................................................................. 7 7.3 Normal Opertion ........................................................................................................................... 8 7.4 Repair and Alignment................................................................................................................... 8 7.5 Use of Nonstandard Accessories................................................................................................. 8 7.6 X-ray Use in Vacuum Systems .................................................................................................... 8 8. Personnel Requirements .......................................................................................................................... 9 8.1 Responsibility ............................................................................................................................... 9 8.2 Health Surveillance ...................................................................................................................... 9 8.3 Personnel Monitoring ................................................................................................................... 9 9. References.............................................................................................................................................. 10 Figures Figure 1. Area Designations ......................................................................................................................... 4 Tables Table 1. NCRP External Ionizing Radiation Dose Recommendations ....................................................... 13 Table 2. Transmission Through Lead of X-rays Generated at Constant Potential..................................... 13 Table 3. Thickness of lead (mm) required for a primary beam barrier located 5 cm from focal spot......... 13 Appendix A. Detection and Measurement of Radiation from X-ray Diffraction and Fluorescence Analysis Equipment 14 v AMERCIAN NATIONAL STANDARD ANSI/HPS N43.2-2001 Radiation Safety for X-ray Diffraction and Fluorescence Analysis Equipment 1. Introduction This standard reviews the types of injuries resulting from accidental exposure to ionizing radiation resulting from the operation of analytical x-ray diffraction and fluorescence equipment, establishes equipment design criteria, sets up requirements for approved operating procedures, and recommends the establishment of health surveillance, and personnel monitoring programs. The circumstances under which operation of equipment must be limited to specially designated areas equipped with radiation barriers and warning signs are provided. Dose limits recommended by the National Council on Radiation Protection and Measurements are provided for reference. A list of references to selected articles on various aspects of radiation safety is given, and notes on the detection and measurement of radiation from x-ray diffraction and fluorescence analysis equipment are included in an appendix. 2. Scope This standard provides guidelines specific to the radiation safety aspects of the design and operation of x-ray diffraction and fluorescence analysis equipment. It does not include electrical safety guidelines or other safety considerations outside the realm of radiation safety. 3. Definitions The definitions and terms contained in this standard, or in other American National Standards referred to in this document, are not intended to embrace all legitimate meanings of the terms. They are applicable only to the subject treated in this standard. ALARA. As Low As Reasonably Achievable making every reasonable effort to maintain exposures to radiation as far below the dose limits as practical, taking into account the state of the technology, the economics of the improvements in relation to the benefits, and other societal or socioeconomic considerations. Analytical X-ray Equipment. Laboratory equipment utilizing x-ray radiation to analyze or obtain information about material properties (e.g. surface characteristics, elemental composition, material structure, etc.) using diffraction or fluorescence techniques. Controlled Area. A specified area to which access is managed in order to protect personnel from radiation. Dose, Absorbed. The energy imparted to matter in a volume element by ionizing radiation divided by the mass of irradiated material in that volume element. The unit is the Gray (Gy) and the special unit of absorbed dose is the rad. One Gy = 1 J/kg and one rad equals 100 ergs per gram. (1 Gy = 100 rad.) Dose Equivalent (H). The product of absorbed dose, radiation weighting factor, and other modifying factors necessary to express on a common scale, for all ionizing radiation, the dose incurred by exposed persons. The unit is the Sievert (Sv) and the special unit of dose equivalent is the rem. (1 Sv = 100 rem.) Dose Rate, Absorbed. The absorbed dose per unit time. Exposure. A measure of the ionization produced in air by x- or gamma-radiation. This unit is considered obsolete. It is the sum of the electrical charges on all of the ions of one sign produced in air when all electrons liberated by photons in a volume element of air are completely stopped in the air, divided by the mass of the air in the volume element. The special unit of exposure is the roentgen (R) which = 2.58x10-4 Coulomb/kg. Exposure Rate. The exposure per unit time. Fail-safe Design. A design in which all realistically anticipated failures of indicators or 1 ANSI/HPS N43.2-2001 safety components result in a condition in which personnel are safe from exposure to radiation. For example: if a light indicating "X-RAY ON" fails, the production of x-rays shall be prevented, or if a shutter status indicator fails, the shutter shall close. High Radiation Area. Any area accessible to individuals, in which radiation could result in an individual receiving a deep dose equivalent in excess of 1.0 mSv (100 mrem) in any one hour at 30 cm (1 foot) from the source or from any surface that the radiation penetrates. Note: other definitions of high radiation area may exist, see Section 7.1. Installation. A room or other space with defined boundaries where analytical x-ray equipment is located. Installation Enclosure. That portion of an installation which clearly defines the transition from an uncontrolled to a controlled area, and provides such shielding as may be required to limit the dose rate in the uncontrolled area during normal operation. For example, the walls of a room containing an x-ray unit may be the installation enclosure. Normal Operation. Operation under conditions suitable for collecting data as recommended by a manufacturer of the x-ray system. Recommended shielding and barriers shall be in place. Primary Beam. Ionizing radiation from an x-ray tube anode or secondary target which is allowed to pass by a direct path through an aperture in the radiation source housing for use in conducting x-ray measurements. Primary Radiation. Ionizing radiation coming by direct path from the x-ray tube anode and/or secondary target. Qualified Expert. A person having the knowledge and training necessary to measure ionizing radiation, analyze the significance of and evaluate the potential for health effects, and advise regarding radiation protection as it pertains to x-ray diffraction and fluorescence analysis x-ray equipment. (Where guidance is needed as to the competence of an individual to discharge the responsibilities of a qualified expert, it may be obtained from a national 2 certifying board or through local, state, or other regulatory agencies.) Qualified Operator. A person involved with the routine operation of analytical x-ray equipment who has had adequate instruction and training in the operation and safety as required by the relevant regulations, person in charge, or supervisor of the equipment. Quality Factor. An energy dependent dimensionless factor by which absorbed dose is to be multiplied by to obtain, for radiation protection purposes, a quantity that expresses on a common scale for all ionizing radiation, the magnitude of radiation effects likely to be incurred by exposed persons. The quality factor (Q) for x-rays is 1.0. This term has been superseded by the radiation weighting factor (WR). Radiation Area. Any area accessible to individuals, in which radiation could result in an individual receiving a deep dose equivalent in excess of 0.05 mSv (5 mrem) in any one hour at 30 cm (1 foot) from the source or from any surface that the radiation penetrates. Note: other definitions of radiation area may exist, see Section 7.1. Radiation Safety (or Protection) Officer. One who has the knowledge and responsibility to apply appropriate radiation protection regulations. He or she may be the owner or the person in charge of the controlled area, a qualified expert, or a technically competent person appointed by the person in charge. Radiation Source. An apparatus or a material emitting or capable of emitting ionizing radiation. Radiation Source (or X-ray Tube) Housing. That portion of an x-ray system which contains the x-ray tube and/or secondary target. Often the housing contains radiation shielding material or inherently provides shielding. Radiation Survey. An evaluation of the radiation hazard in and around an installation. It customarily includes a physical survey of the arrangement and use of the equipment and measurement of the exposure rates under the full range of expected and “worst case” operating conditions. ANSI/HPS N43.2-2001 Radiation Weighting Factor (WR). A linearenergy-transfer dependent factor by which absorbed doses are to be multiplied in computing the dose equivalent. (Note: this term was formerly known as the Quality Factor Q.) Shall. Where "shall" is used for a provision specified herein, that provision is intended to be a requirement. In cases of accidental exposure, severe burns affecting the upper extremities of the body (e.g. hands and fingers) are the most frequently reported types of injury [1]. Amputation of one or more fingers is sometimes required [2]. Exposure of the lens of the eye to large doses can result in cataracts and other opacities [3]. Sometimes the damage does not become apparent until years later. Should, is Recommended. "Should" or "is recommended" is used to indicate provisions which are not required but which are here recommended as good practices for many facilities. Section 9 provides extensive references about health effects. System Barrier. That portion of an x-ray installation which clearly defines the transition from a controlled area to a radiation area and provides such shielding as may be required to limit the dose rate in the controlled area during normal operation. For example, an interlocked enclosure immediately around the x-ray unit could be a system barrier. Recommendations for permissible doses of ionizing radiation are established by the National Council on Radiation Protection and Measurements (NCRP), and by the International Commission on Radiological Protection (ICRP). Regulatory limits are established by the Environmental Protection Agency (EPA) and implemented by Nuclear Regulatory Commission (NRC) (for radioisotope sources), Occupational Safety and Health Administration (OSHA) (for machine produced radiation), Department of Energy (DOE), and/or States. The current NRCP recommended limits are summarized in Table 1. Be sure to consult the regulations governing the x-ray installation (federal, state, local, and/or others) for dose limits and other requirements. Uncontrolled Area. Any area to which access is not controlled for purposes of radiation protection (see 6.1.3). X-ray Accessory Apparatus. Any portion of an x-ray installation which is external to the radiation source housing and into which an x-ray beam is directed making x-ray measurements or for other uses. X-ray Generator. That portion of an x-ray system which provides the accelerating (high) voltage and current for the x-ray tube. X-ray Installation. One or more x-ray systems, the surrounding room or controlled area, and the installation enclosure. X-ray System. Apparatus for generating and using ionizing radiation, including all x-ray accessory apparatus. 4. Types of Injuries Analytical x-ray diffraction and fluorescence analysis equipment have the potential to generate high intensity ionizing radiation literature 5. Dose Limits The problem of correctly evaluating doses due to intense small-area beams of low energy x-ray photons is not trivial and results can easily be in error by an order of magnitude. Appendix A, Detection and Measurement of Radiation from x-ray Diffraction and Fluorescence Analysis Equipment, has been prepared as an aid in avoiding some of the pitfalls. 6. Installation and Equipment Requirements 6.1 Installation Requirements Three types of areas within installations are recognized in this standard: radiation area, controlled area, and non-controlled area. The areas, as well as the dose limits and barriers required, are schematically illustrated in Figure 1. 3 ANSI/HPS N43.2-2001 Installation Enclosure (See 6.1.2.2) CONTROLLED AREA Dose equivalent greater than uncontrolled area, but less than a radiation area. System Barrier (See 6.1.1.3) RADIATION AREA Dose equivalent > 0.05 mSv (5 mrem) in any one hour at 30 cm, but < 0.05 Sv (5000 mrem) in a year (see 6.1.1.1) UNCONTROLLED AREA Dose equivalent < 0.02 mSv (2 mrem) in any one hour and < 1 mSv (100 mrem) in a year (see 6.1.3.1) Fig. 1. Area Designations Note that the establishment at all times of three physically separate areas may not be required. In other words, it may be possible to set up an installation utilizing modern X-ray equipment with enclosures so that the temporary radiation area within the controlled area can be the same physical space. Radiation area requirements would have to be met when such areas temporarily exist (e.g. enclosures open and interlocks bypassed), and controlled area requirements would have to be met other times. For example, the implementation of a "temporary radiation area" for a modern, enclosed diffractometer during alignment might require only a simple rope boundary with the appropriate sign within the controlled area, and continuous operator presence for supervision during the period of time the radiation area 4 exists outside the confines of the enclosure. The establishment of controlled areas must therefore include the provision or plan for the establishment of radiation areas when and where they are needed. 6.1.1 Radiation Area 6.1.1.1 Designation of a radiation area. Any area accessible to personnel in which there exists radiation at such levels that the individual could receive in excess of 0.05 mSv (5 mrem) in any one hour at 30 cm (1 foot) from the source or any surface that the radiation penetrates, and less than 0.05 Sv (5000 mrem) in a year. 6.1.1.2 Occupancy. The occupancy in a radiation area shall be limited so that the ANSI/HPS N43.2-2001 accumulated dose received does not exceed applicable regulatory limits. 6.1.1.3 System barrier. Each radiation area shall be surrounded by a system barrier with sufficient inherent shielding so that the dose equivalent received by individuals in the surrounding controlled area does not exceed 0.05 mSv (5 mrem) in any one hour at 30 cm (1 foot) from the source or any surface that the radiation penetrates. 6.1.1.4 Caution sign. Each radiation area shall be conspicuously posted with a sign or signs bearing the trefoil radiation symbol and the words: CAUTION: RADIATION AREA The standard colors for signs are a magenta trefoil and wording on a yellow background. Additional wording may be included such as “When the Equipment Is Energized”. 6.1.1.5 Supervision. Each radiation area shall be under the general supervision of a Radiation Safety Officer and under continuous supervision by an operator during operation. Note that continuous supervision may not require continuous personnel presence, but control over access to the radiation area is to be maintained. For example, continuous supervision may involve personnel presence, door locks, entry monitors, or other engineered solutions. 6.1.2.3 Identifying sign. Each controlled area shall be identified by an appropriate and easily recognizable warning sign posted at each entrance. For example, a black and yellow sign with the following words could be used: Warning: X-rays In Use Contact ______________ For Access 6.1.2.4 Supervision. Each controlled area shall be under the general supervision of a Radiation Safety Officer, an operator, or the person in charge of the area. 6.1.3 Uncontrolled areas 6.1.3.1 Dose equivalent limit. The dose equivalent received by individuals in uncontrolled areas shall not exceed 1 mSv (100 mrem) in any year and less than 0.02 mSv (2 mrem) in any one hour. 6.2 X-ray System Classification and Requirements 6.2.1 Classification. 6.2.1.1 General. X-ray systems for certain specific applications can be designed so all possible x-ray beam paths are fully enclosed. However, operational requirements such as: (a) 6.1.2 Controlled Area (b) 6.1.2.1 Designation of a controlled area. Any area in which the dose equivalent received by individuals may exceed 1 mSv (100 mrem) in any year, but does not exceed the levels that would require it to be designated a radiation area (see 6.1.1.1), shall be designated a controlled area. Access to controlled areas is managed in order to protect personnel from occupational radiation exposure. (c) 6.1.2.2 Installation enclosure. Each controlled area shall be visibly separated from adjacent uncontrolled areas by an installation enclosure so that the dose equivalent received by individuals in the uncontrolled areas does not exceed 1 mSv (100 mrem) in any year. This may be accomplished by the use of shielding, distance, or other means. frequent changes of attachments and configuration; a need for making adjustments with the x-ray beam on; and motion of specimen and detector over wide angular limits; occasionally, but not necessarily, make the use of a fully enclosed system during normal operation impractical. For the purpose of this standard two classes of x-ray systems are recognized. They are designated Enclosed Beam X-ray Systems and Open Beam X-ray Systems. 6.2.1.2 Enclosed beam x-ray system. An enclosed beam x-ray system is one in which all possible x-ray paths are fully enclosed according to the requirements of section 6.2.2.3. For example, the use of interlocked beam pipes or tubes or an interlocked enclosure around the whole x-ray system may qualify the system as 5 ANSI/HPS N43.2-2001 an enclosed beam system. However, enclosed beam systems become open beam systems during the period when interlocks are defeated. 6.2.1.3 Open beam x-ray system. An x-ray system that does not comply with all of the requirements of section 6.2.2.3 shall be classified as an open beam x-ray system. 6.2.2.1.4 Each shutter shall be provided with a “shutter open” indication (e.g. warning light or device) of fail-safe design. The indicator shall activate when the “shutter open” signal is initiated. (Consideration should be given to the use of materials other than lead for shutters (e.g. tantalum, tungsten, etc.) to avoid corrosion that high radiation levels can produce and may cause shutter operation to fail.) 6.2.2 Requirements 6.2.2.1 General requirements for all x-ray systems covered by this standard. 6.2.2.1.1 The dose due to unwanted, stray, or anticipated accidental scatter and leakage radiation from components such as high voltage rectifiers shall not exceed 0.1 mSv (10 mrem) in a week in any accessible region 5 cm from the outside surface of the generator cabinet. Assuming that an individual may be in the vicinity of the equipment while it is operating for as long as 40 hours per week, the dose rate should not exceed 0.0025 mSv/hr (0.25 mrem/hr). (Note: the applicable regulations may vary, see Section 7.1.) 6.2.2.1.2 The x-ray accessory apparatus shall include a beam stop, trap or other barrier with sufficient shielding so that the dose rate due to the transmitted primary beam does not exceed 0.0025 mSv/hr (0.25 mrem/hr) under normal operating conditions. Shielding information for lead is presented in Table 2, which can be used in determining the amount of shielding required. Table 3 presents lead shielding information found in the first edition of this standard (minimum lead thickness for the tube maximum rated anode current and potential). 6.2.2.1.3 Warning lights or devices of failsafe design labeled with the words "X-RAYS ON", or other words having similar meaning, shall be located: 6.2.2.1.5 A label bearing the conventional radiation symbol and the words, CAUTION: THIS EQUIPMENT PRODUCES X-RAYS WHEN ENERGIZED, or other words having similar meaning, shall be attached near any switch which energizes an x-ray tube. Additional wording should include: TO BE OPERATED ONLY BY QUALIFIED PERSONNEL. 6.2.2.1.6 Systems that contain an x-ray tube shall be equipped with an interlock that shuts off the high voltage to the tube if the tube is removed from the radiation source housing or if the housing is disassembled. 6.2.2.1.7 Normal operating and alignment procedures shall be documented by the manufacturer of the x-ray system. If the radiation source housing and/or x-ray accessory apparatus are not compatible (i.e. nonstandard) components supplied by the same manufacturer, procedures shall be documented by the person in charge of the use of the system and reviewed by the Radiation Safety Officer. 6.2.2.1.8 Normal operating procedures shall be such that a qualified operator following instructions will not receive in any one hour a dose equivalent in excess of 0.25 mSv (25 mrem) to the extremities or 0.025 mSv (2.5 mrem) to the whole body. near any switch which activates the high voltage to energize an x-ray tube; in a conspicuous location near the radiation source housing and radiation beam(s) and visible from all instrument access areas. 6.2.2.1.9 Alignment procedures should be such that a qualified worker aware of the radiation hazards will not receive in any one hour a dose equivalent in excess of 0.25 mSv (25 mrem) to the extremities or 0.025 mSv (2.5 mrem) to the whole body while following these instructions. If either of these dose rates is likely to be exceeded, a warning shall be included in the alignment instructions. Such lights or devices shall activate when the xray tube is energized. 6.2.2.1.10 The use of an area radiation monitor is discussed in Section 7.2.2. (a) (b) 6 ANSI/HPS N43.2-2001 6.2.2.2 Requirements for an open beam x-ray system in addition to general requirements in 6.2.2.1. 6.2.2.2.1 Radiation levels external to the x-ray tube housing with all shutters closed shall not exceed 0.025 mSv/hr (2.5 mrem/hr) as measured at 5 cm from the surface of the housing within which an x-ray tube is operating at full rated power at maximum rated accelerating potential. 6.2.2.2.2 Each port of the radiation source housing shall be provided with a beam shutter interlocked with the x-ray accessory apparatus coupling, or collimator, in such a way that the port will be open only when the collimator or coupling is in place. Shutters at unused ports shall be secured to prevent casual opening. 6.2.2.2.3 It is strongly recommended that a guard (e.g. beam tubes) or interlock which prevents entry of any part of the body into the primary beam path should be utilized when practical. 6.2.2.2.4 Radiation dose levels in the vicinity of controls and adjustments of the x-ray accessory apparatus used during normal operation shall not exceed 0.25 mSv/hr (25 mrem/hr) to the extremities or 0.025 mSv/hr (2.5 mrem/hr) to the whole body. 6.2.2.2.5 A system barrier shall be provided to meet the requirements of 6.1.1.3. 6.2.2.3 Requirements for an enclosed beam x-ray system in addition to general requirements in 6.2.2.1. 6.2.2.3.1 The radiation source, beam paths, sample, detector and/or other devices (e.g. analyzing crystal, filters, etc.) shall be enclosed in a chamber, coupled chambers, beam pipes, whole system enclosure, etc. that cannot be entered by any part of the body during normal operation. 6.2.2.3.2 The inherent shielding of the chamber/enclosure walls shall be sufficient to limit the dose rate in all regions 5 cm from its outer surface to 0.0025 mSv/hr (0.25 mrem/hr) during normal operation. 6.2.2.3.3 The system enclosure, sample chamber, etc. closure shall be interlocked with the x-ray tube high voltage supply and/or a shutter in the primary beam so that no x-ray beam can enter the sample chamber while it is open unless the interlock has been consciously and deliberately defeated. 6.2.2.3.4 The interlock required by section 6.2.2.3.3 shall be of fail-safe design. 6.2.2.3.5 If there is more than one port in the radiation source housing or more than one radiation source, all requirements under 6.2.2.3 must satisfied for each port in every source housing associated with the system. 7. Operating Procedure Requirements 7.1 Federal, State, and Local Regulations and Procedures 7.1.1 Installations may be subject to federal, state and local regulations that are different than those provided here, and may involve registration, licensing, and compliance with specific rules. Some other topics of regulatory interest may include: licensing or registration, operator training, radiation area definition, posting and labeling requirements, reporting, etc. In addition, the institution, installation supervisor or operator may impose administrative requirements. The Radiation Safety Officer, person in charge of the installation, and all equipment operators shall be familiar with applicable operating procedures and regulations governing the x-ray installation. 7.2 Radiation Protection Surveys and Inspection 7.2.1 A radiation survey and inspection and test of protective devices shall be made before a new installation is placed in routine operation, and whenever changes are made that could adversely affect radiation protection (e.g. maintenance, relocation of equipment, radiation shielding modifications, etc.) In addition, periodic surveys should be performed at least once every 12 months. Guidance for performing surveys can be found in: American National Standard for General Radiation Safety Installations Using Non-Medical X-ray and 7 ANSI/HPS N43.2-2001 Sealed Gamma-Ray Sources, Energies up to 10 MeV (ANSI N43.3-1993)[4]. 7.2.2 The need for active or passive fail-safe radiation area monitors should be evaluated on a case by case basis. The proper placement of detectors and integration into the equipment interlock circuitry can provide enhanced safety. When appropriate, the use of these devices is highly recommended and should be implemented. 7.4.6 If an alignment procedure results in increasing the dose rate in any area so that the usual designation of that area no longer applies, the person in charge shall erect temporary barriers and warning signs as required to create a new controlled area and shall keep the area under surveillance until normal operation has been restored. 7.3 Normal Operation 7.4.7 Repairs should be carried out on an uncluttered surface so that any pieces left out during reassembly will be conspicuous. 7.3.1 Only those procedures specified by the manufacturer of the x-ray system should be used, unless an alternate procedure has been documented by the person in charge and approved by the Radiation Safety Officer. Variations from approved radiation safety and operating procedures shall be reviewed and approved by the person in charge and the Radiation Safety Officer. 7.4.8 After reassembly, the x-ray system shall be checked by the Radiation Safety Officer or other person in charge. Particular attention should be given to the alignment of shielding, shutters and collimators. Lead parts should be inspected for damage, distortion, or corrosion which could result in radiation leakage and should be mounted in such a way that they will not cold-flow because of their own weight. 7.4 Repair and Alignment 7.5 Use of Nonstandard Accessories 7.4.1 Most severe injuries have occurred during non-routine operations such as repair and alignment [5]. It is recommended that the Radiation Safety Officer, or other person in charge of an x-ray installation be advised when these operations are to be undertaken. 7.5.1 Any device for use with an x-ray tube shall be regarded as a nonstandard accessory unless it is a compatible component manufactured specifically to fit the radiation source housing used. It is recommended that no new accessory be aligned or operated until the manufacturer’s procedures have been reviewed by the operator(s) and the person in charge (e.g. supervisor), and a radiation survey has been carried out. 7.4.2 No operation involving removal of cover shielding materials or tube housings or modifications to shutters, collimators or beam stops shall be performed without ascertaining that the tube is off and will remain off until safe conditions have be restored. The x-ray source power switch, rather than safety interlocks, shall be used for routine shutdown in preparation for repairs. 7.4.3 No x-ray tube shall be operated without a suitably shielded housing to restrict the primary or secondary radiation to a well defined beam. 7.5.2 Nonstandard accessories shall not be aligned or operated by the equipment users until procedures have been approved and a radiation survey carried out. Manufacturer's personnel performing work on nonstandard accessories (e.g. installation, maintenance, etc.) shall follow safety procedures specific to this type of operation. 7.6 X-ray Use in Vacuum Systems 7.4.4 Alignment procedures recommended by manufacturer of the x-ray system shall be used when available. 7.4.5 Special alignment procedures shall not be used unless approved by the Radiation Safety Officer and the person in charge of the analytical x-ray installation. 8 7.6.1 Certain types of x-ray surface analysis (e.g. XPS or x-ray photospectrometry) must be performed in a vacuum. Typically an x-ray tube is installed into one or more penetrations of the vacuum system and can be adjusted for sourceto-sample distance. The vacuum system also typically contains multiple view ports with high vacuum windows for observing the sample visually. ANSI/HPS N43.2-2001 7.6.2 The location of x-ray tubes in relation to windows shall be considered carefully. Any window within the radiation emission cone of the source may create a local radiation or high radiation area. If the x-ray source is adjustable, efforts shall be taken to ensure safe operation over the full range of adjustment. 7.6.3 If windows cannot be positioned to prevent radiation emission because of technical or operational reasons, lead glass covers or similar material may be used to reduce radiation levels. Covers shall be affixed so they cannot be accidentally knocked aside. A survey shall be performed to verify the effectiveness of the covers under all anticipated operating conditions. 7.6.4 If the entire system, including x-ray tube, is under one contiguous vacuum, and radiation leakage is less than 0.0025 mSv/hr (0.25 mrem/hr) at 5 cm, and a change in any part of the system will not increase the radiation level, then the system shall be considered to be an enclosed beam system. control. They shall also be responsible for carrying out all specified instructions and maintaining prescribed operating conditions. Lastly, they should ensure that adequate medical surveillance and radiation monitoring of personnel are carried out. 8.1.2 Each worker shall, upon the instruction of a qualified expert or responsible supervisor, follow the recommendations and instructions that have been drawn up in the interest of radiation protection. 8.1.3 Each worker shall use the protective devices and radiation dosimetry provided. 8.1.4 Each worker shall bring to the attention of those in charge any defect or deficiency in radiation protection devices and procedures. 8.1.5 Female radiation workers who become pregnant should refer to the applicable regulations concerning declaration of pregnancy. 8.2 Health Surveillance 8. Personnel Requirements It should be stressed that recommendations and radiation safety procedures with respect to the installation and operation of the equipment are not in themselves sufficient to guarantee adequate protection. Such protection depends largely on the expert knowledge of the staff and on their cooperation in carrying out the instructions prepared by their supervisor in the interests of radiation protection. All personnel involved with operation of equipment shall have adequate instruction and safety training as required by the regulations, person in charge, or supervisor of the installation. Two videotapes that may assist in radiation safety training are cited in Section 9.2. 8.1 Responsibility 8.1.1 The owner or the person in charge of a controlled area shall be responsible for the evaluation of needs and the formation of policy with respect to radiation protection. They shall be responsible for the working conditions and for the instruction of all persons working in the area regarding radiation hazards and methods of 8.2.1 The need for periodic medical examination shall be determined by the equipment operator's management, the Radiation Safety Officer and the operator's medical personnel. If performed, the exam should pay particular attention to the eyes and to the skin of the hands and the face. 8.3 Personnel Monitoring 8.3.1 Doses to personnel received as a result of occupational exposures should be systematically evaluated with appropriate radiation measuring instruments (see Appendix A) to ensure that regulatory limits are not exceeded. 8.3.2 The deficiencies of personnel monitoring devices at low x-ray energy and their use are well known. However, according to a report [6] on seventeen cases of accidental exposure, the personnel dosimeter gave the first indication that an accident had occurred in five of the cases. The use of suitable personnel monitoring devices is recommended provided the response of the personnel dosimeter to low energy x-rays is known and documented. Whole body and extremity dosimetry should be used by any operator who uses open beam systems, performs alignments with x-ray beam on, or 9 ANSI/HPS N43.2-2001 otherwise bypasses an interlock with the x-ray tube energized. The operator's management and Radiation Safety Officer shall determine the need for personnel radiation monitoring based on regulatory requirements and exposure potential. 9. References 9.1 The following publications are referred to in this standard and the appendix. Although some may be hard to locate, they are included here as sources of information from the original standard. Additional references are listed in Section 9.2. 1. Howley, J.R. and Robbins, C., Radiation hazards from x-ray diffraction equipment. Radiological Health Data and Reports vol. 8, no. 5, (May 1967), pp. 245-249. 2. A Summary of Industrial Accidents in USAEC Facilities, 1965-1966. United States Atomic Energy Commission, Division of Technical Information, Oak Ridge, TN 37830, (TID-5360-Supplement 6), pp. 4 and 6. 3. Merriam, G.R. and Focht, E.F., Clinical study of radiation cataracts and relationship to dose. The American Journal of Roentgenology, Radium Therapy and Nuclear Medicine, vol. 77, May 1957, pp. 759-785. 4. American National Standard for General Radiation Safety - Installations Using NonMedical X-ray and Sealed Gamma-Ray Sources, Energies Up To 10 MeV, American National Standard N43.3-1993. 5. Kaelble, E.F. (Editor), Handbook of X-rays. New York: McGraw-Hill Book Co., (1967). 6. Conference on Detection and Measurements of X-Radiation from Color Television Receivers. United States Department of Health, Education and Welfare; and Electronic Industries Association; Bureau of Radiological Health, Washington, D.C. 20850, March 28-29, 1968 (Technical Papers). 7. Clark, G.L. (Editor), The Encyclopedia of Xrays and Gamma Rays. New York: Reinhold Publishing Corporation, 1963. 9.2 The following publications are not cited in this standard, but are included as additional sources of information. 10 1. Video: Double Edged Sword, National Audiovisual Center (GSA), Washington, D.C. 2. Video: The Invisible Partner, International Center for Diffraction Data, 12 Campus Blvd., Newton Square, PA, 19073-3273, (610) 325-9814, Catalog Number ALCOA-VHS. 3. Computer-based training: Working Safely with X-rays, International Center for Diffraction Data, 12 Campus Blvd., Newton Square, PA, 19073-3273, (610) 325-9814, Catalog Number ALCOACBT. A printed workbook version of the computer course is also available as Catalog Number ALCOA-SWB. 4. Basic Radiation Protection Criteria. National Council on Radiation Protection and Measurements. P.O. Box 30175, Washington, D.C. 20014, 1971 (NCRP Report 39). 5. Lindell, B. Occupational hazards in x-ray analytical work. Health Physics, vol. 15, no. 6, December 1968, pp. 481-486. 6. Lubenau, J.O., Davis, J.S., McDonald, D.J., and Gerusky, T.M., Analytical x-ray hazards: a continuing problem. Health Physics, vol. 16, June 1969, pp. 739746. 7. Attix, F.H. and Roesch, W.C. (Editors). Radiation Dosimetry, vol. 1 - 1968 (Fundamentals), vol. 2 - 1966 (Instrumentation) and vol. 3 - 1969 (Sources, Fields, Measurements and Applications). New York: Academic Press. 8. Accident Prevention Manual for Industrial Operations. Chicago: National Safety Council, 1964, (5th Edition), Ch. 42, pp. 33-35. 9. Beu, K.E. (Chairman). Safety Considerations in the Design of X-ray Tube and Collimator Couplings on X-ray Diffraction Equipment. American Crystallographic Association, Polycrystal Book Service, P.O. Box 11567, Pittsburgh, PA, 15238, 1962, (Apparatus and Standards Committee Report No. 1). 10. Report of Committee III on Protection Against X-rays Up to Energies of 3 MeV and Beta- and Gamma-Rays from Sealed Sources. London: Pergamon Press (for the International Commission on Radiological Protection), 1960, (ICRP Publication 3), pp. 12-13. ANSI/HPS N43.2-2001 11. Cook, J.E. and Oosterkamp, W.J. Protection against radiation injury. International Tables for X-ray Crystallography, Birmingham, England: The Kenosha Press, 1962, (vol. III, section 6), pp. 333-338. 12. Radiation hazards associated with x-ray diffraction techniques. Acta Crystallographica, vol. 16, 1963, pp. 324-328. 13. Klug, H.P. and Alexander, L.E., X-ray Diffraction Procedures for Polycrystalline and Amorphous Materials. New York: John Wiley & Sons, 1974, 2nd edition, pp. 58-60, 861862. 14. Rudman, R. X-ray diffraction analysis, part one - safety and generators. Journal of Chemical Education, vol. 44, January 1967, (pp. A7-A43). 15. Radiation Safety in X-ray Diffraction and Spectroscopy. Proceedings of a conference held January 6-7, 1970 at the University of Pennsylvania, Philadelphia, PA. United States Department of Health, Education and Welfare, Bureau of Radiological Health, Rockville, MD 20852 (DHEW Publication No. FDA 72-8009 BRH/DEP 72-3. 16. Radiological Protection in the Use of Xray Crystallographic and Spectrometric Equipment. Department of Employment and Productivity, Advisory and Information Unit, Baynards House, 1 Chepstow Place, London, W.2.,1969. 17. Radiation Protection in Educational Institutions. National Council on Radiation Protection and Measurements, 7910 Woodmont Ave., Suite 1016, Washington, D.C., 20014, 1966, (NCRP Report 32). 18. Jenkins, R. and Haas, D.J., Hazards in the Use of X-ray Analytical Instrumentation. X-ray Spectrometry, vol. 2, 1973, pp. 135-141. 19. Jenkins, R. and Haas, D.J., Incidence Detection and Monitoring of Radiation from X-ray Analytical Instrumentation. Xray Spectrometry, vol. 4, 1975, pp. 3-42. 20. A Guide to Radiation Protection in the Use of X-ray Optics Equipment, Monograph No. 15, Science Reviews Ltd., ISSN 0141-7568, ISBN 0-90692752-4. 21. Martin, E.B.M, A Guide to the Safe Use of X-ray Diffraction and Spectrometry Equipment, Monograph No. 8, Occupational Hygiene, 1983, ISSN 0141-7568;8, ISBN 0-905927-11-7. 22. Zhao, S., Kramer, M., and Hohlfeld, K. The yield from x-ray tubes in terms of ambient dose equivalent. Radiation Protection Dosimetry, vol. 51, no. 4, 1994, pp. 297-300. 23. Hughes, W., An installation to avoid direct radiation hazards in x-ray analysis. Journal of Scientific Instruments, vol. 39, 1962, pp. 564-565. 24. Hughes, W., Simple shutter-closing device for x-ray tubes. Journal of Scientific Instruments, vol. 39, 1962. 25. Hughes, W. and Taylor, C.A., Safe universal mounting and alignment system for x-ray goniometers. Journal of Scientific Instruments, vol. 38, 1961. 26. Hallewell, V.A., Murphy, R.J., Pauling, P.J. and Robertson, G.B., A comprehensive safety shutter and collimator coupling for the Philips x-ray tube shield PW 1016. Journal of Scientific Instruments, vol. 42, 1965. 27. Kennard, O., Martin, A.J.P., and Woodget, L., Labyrinth radiation trap for use with standard x-ray diffraction equipment. Journal of Scientific Instruments, vol. 36, 1959. 28. Lee, J.D. and Oldham, G., Safety device for x-ray tubes and goniometers. Journal of Scientific Instruments, vol. 43, 1966. 29. Sutherland, H.H., Design of a safety system for x-ray generators, Journal of Scientific Instruments, vol. 44, 1967. 30. Abrahams, S.C. and Blackmore, W.R., A shielding device for x-ray diffraction cameras. Review of Scientific Instruments, vol. 24, 1953, p. 885. 31. Trout, E.D., A suggestion for radiation safety in the use of x-ray diffraction equipment. Health Physics, vol. 22, 1972, p. 94. 32. Krizek, T.J. and Ariyan, S., Severe acute radiation injuries of the hands. Plastic and Reconstructive Surgery, vol. 51, 1973, pp. 14-21. 33. Weigensburg, I.J., Asbury, C.W., and Feldman, A., Injury due to accidental exposure to x-rays from an x-ray fluorescence spectrometer. Health Physics, vol. 39, 1980, p. 237-241. 11 ANSI/HPS N43.2-2001 34. Weeks, J.L., Radiation exposure in the laboratory. Journal of the Society of Occupational Medicine, vol. 26, 1976, pp. 9-12. 35. McLaughlin, J.E. and Blatz, H., Potential radiation hazards in the use of x-ray diffraction equipment. American Industrial Hygiene Association Quarterly, vol. 16, 1955, pp. 108-112. 36. Burdick, K.G. and Miraldi, F., Radiodermatitis due to exposure in industry. Journal of the American Medical Association, vol. 188, no. 6, 1964, pp. 235-236. 37. Berger, M.E., Hurtado, R., Dunlap, J., Mutchinick, O., Velasco, M.G., Tostado, R.A., Valenzuela, J., and Ricks, R.C., Accidental radiation injury to the hand: anatomical and physiological considerations. Health Physics, vol. 72, no. 3, 1997, pp. 343-347. 38. Leenhouts, H.P., Another failure of a commercial x-ray shutter system. Health Physics, vol. 22, 1972, pp. 413-414. 39. LaMastra, A. and McDonald, D.J., Report of a failure of a commercial x-ray diffraction shutter status system. Health Physics, vol. 20, 1971, pp. 639-640. 40. Watrous, R.M., Hodges, H.W., and McAndrew, M.J., Radiation burns from diffraction apparatus simulating infections. Journal of the American Medical Association, vol. 152, no. 6, 1953, pp. 513-514. 41. Steidley, K.D., Stabile, R.J., and Sanfilippo, L.J., A case history of severe radiation burns from 50 kVC x-rays. Health Physics, vol. 40, 1981, pp. 399405. 42. Robertson, J.K., Radiation hazards from x-ray diffraction equipment. New Zealand Journal of Science, vol. 11, 1968, pp. 433-439. 43. Bain, J.T.B., MacCabe, J.E., X-ray burns in industry. British Medical Journal, vol. 1, 1962, pp. 1476-1477. 44. Acute accidental superficial x-ray burns. British Journal of Dermatology, vol. 74, 1962, pp. 392-402. 45. Day, F.H., Thimble chamber calibration on soft x-rays. U.S. Department of Commerce, National Bureau of Standards, research paper RP1926, vol. 41, October 1948. 46. Taylor, L.S. and Stoneburner, C.F., The measurement of low-voltage x-ray 12 47. 48. 49. 50. 51. 52. 53. 54. 55. 56. intensities. Bureau of Standards Journal of Research, vol. 9, no. 1, 1932, pp. 769-780. Quimby, E.H. and Focht, E.F., Dosage measurements in contact roentgen therapy. American Journal of Roentgenology and Radium Therapy, vol. 50, no. 5, 1943, pp. 653-668. Desjardins, A.U., Action of roentgen rays and radium on the gastrointestinal tract. American Journal of Roentgenology and Radium Therapy, vol. XXVI, 1931, pp. 151-190. Victoreen, J.A., Atlee, Z.J., and Trout, E.D., The behavior of thimble chambers when used for the measurement of very soft radiation. American Journal of Roentgenology and Radium Therapy, vol. 53, no. 4, 1945, pp. 391-394. McBride, W.W. and Lieben, J., Radiodermatitis from diffraction apparatus. Archives of Environmental Health, vol. 4, 1962, pp. 73-77. Burgess, P.H., The development and testing of a new technique for the measurement of dose rates in the main beam of crystallographic x-ray equipment. Radiation Protection Dosimetry, vol. 16, no. 3, 1986, pp. 247251. Conference of Radiation Control Program Directors (CRCPD), Suggested State Regulations for Control of Radiation - Part H - Radiation Safety Requirements for Analytical X-ray Equipment. CRCPD, Inc., 205 Capital Ave., Frankfort, KY 40601. (http://www.crcpd.org/) Dax, M., X-ray film thickness measurements. Semiconductor International, August 1996, pp. 91-100. Benzel, W. and Wallace, P. (editors), Xray safety workshop, 43rd Annual Denver X-ray Conference, August 1-5, 1994, Steamboat Springs, CO., University of Denver Department of Engineering and International Center for Diffraction Data. Zhao, Y., Che, R., Tang, E., and Xian, D., High pressure x-ray diffraction station at the Beijing synchrotron radiation facility. High Pressure Research, vol. 8, 1992, pp. 711-713. Maharaj, H.P., Safety considerations and recommendations for analytical xray devices from a review of survey ANSI/HPS N43.2-2001 57. 58. 59. 60. 61. 62. 63. data. Health Physics, vol. 66, no. 4, 1994, pp. 463-471. Olsher, R., The Los Alamos Scientific Laboratory X-ray Survey Manual, Doc. No. LA-8246-M, 1983. Angilello, J. and Linnartz, H., X-ray diffraction safety improvements at IBM Research Lab, Report RC-5505, IBM Thomas J. Watson Research Center, Yorktown Heights, NY, 10598, 1975. Masse, F.X., Coutu-Reilly, J., Galanek, M., and Ducatman, A., The need for additional warning in x-ray diffraction equipment: a shutter failure incident. Health Physics, vol. 58, no. 2, 1990, p. 219. Blatz, H., Laboratory support for an xray inspection program. Health Physics, vol. 10, 1964, pp. 643-649. Moore, M.J. and Sorensen, D.B., Radiation alarm system for scattered radiation. Health Physics, vol. 15, 1968, pp. 362-363. Murphy, E.G. and Stewart, H.F., Warning chimes for experimental x-ray machine. Health Physics, vol. 14, 1968, pp. 517-518. Pipes, E.W., A voltage-sensing device for monitoring x-rays. Health Physics, vol. 13, 1967, pp. 1351-1352. 13 ANSI/HPS N43.2-2001 Table 1. NCRP External Ionizing Radiation Dose Recommendations Whole body (head, trunk of body, gonads) 0.05 Sv/yr (5 rem/yr) Lens of the eye 0.15 Sv/yr (15 rem/yr) Extremities (hands / forearms, feet / ankles) 0.5 Sv/yr (50 rem/yr) Skin of whole body 0.5 Sv/yr (50 rem/yr) Embryo / fetus of “declared” pregnant worker 0.005 Sv (0.5 rem) for the entire gestation period; 0.0005 Sv (0.05 rem) per month Non-occupational* 0.001 Sv/yr (0.1 rem/yr) *Dose received by members of the public. Consult the applicable regulations for a more complete definition. Table 2. Transmission Through Lead of X-rays Generated at Constant Potential* Thickness Transmission at: (mm) 20 kV 30 kV 40 kV 50 kV 75 kV 100 kV 0.0635 5.18E-05 3.88E-04 2.74E-03 0.127 1.78E-07 6.05E-06 2.64E-04 0.1905 4.52E-07 4.52E-05 0.25 2.70E-03 3.20E-02 7.60E-02 0.254 3.17E-07 1.06E-05 0.5 9.00E-05 5.30E-03 2.40E-02 1 ~ 1 E-6 3.30E-04 4.10E-03 2 ~ 1 E-11 5.70E-06 2.30E-04 3 1.70E-05 4 1.40E-06 *Source: Martin, E.B.M., A Guide to the Safe Use of X-ray Diffraction and Spectrometry Equipment, Monograph No. 8, Occupational Hygiene, 1983, ISSN 0141-7568;8, ISBN 0-905927-11-7, pg.57. Table 3. Thickness of lead (mm) required for a primary beam barrier located 5 cm from focal spot* Anode Current High Voltage mA 50 kVp 70 kVp 100 kVp 20 1.5 5.6 7.7 40 1.6 5.8 7.9 80 1.6 5.9 ---160 1.7 ------*Source: ANSI N43.2-1977. 14 ANSI/HPS N43.2-2001 Appendix A Detection and Measurement of Radiation from X-ray Diffraction and Fluorescence Analysis Equipment (This Appendix is not a part of this standard, but is included for information purposes only.) A.l Nature of the Radiation A.1.1 Typical acceleration potentials are 25 to 50 kVp for diffraction tubes and 25 to 100 kVp for those used in fluorescent analysis ([7], p. 1096). The upper limit for the energy of x-ray photons is, therefore, 50 or 100 keV. There is no theoretical lower limit to the energy of the photons in the radiation spectrum, but the intensity below about 5 keV is low and the x-rays are readily attenuated. The spectrum can be assumed to extend from 5 to 100 keV with an intensity maximum in the range 20 to 30 keV depending on the accelerating potential. A.1.2 Superimposed on this spectrum are the lines of the characteristic x-ray photons of the anode. These constitute less than half of the output in the case of tubes used for diffraction but may be the bulk of the fluorescence x-rays when secondary targets are employed. The energies involved are generally in the range 5.4 to 17.5 keV for diffraction. A.1.3 In order to measure the dose from both the bremsstrahlung spectrum and the characteristic spectrum, a radiation survey device with known energy absorption characteristics throughout the 5 to 100 keV energy range should be used. A.2 Sources of Radiation A.2.1 Hazardous radiation may come from the following sources ([6], p. 6-2): 1. 2. 3. 4. 5. 6. The primary beam. Leakage or scatter of the primary beam through cracks in ill fitting or defective equipment. Penetration of the primary beam through the tube housing, shutters or diffraction apparatus. Secondary scatter emission from the sample or other material exposed to the primary beam. Diffracted or fluorescence x-rays. Radiation generated by vacuum tube rectifiers in the high voltage power supply. A.2.2 The primary beam is most hazardous because of the extremely high dose rates. Exposure rates of 4x103 Gy/min (4x105 rad/min) at the port have been reported for ordinary diffraction tubes [1]. A.2.3 The leakage or scatter of the primary beam through apertures in ill fitting or defective equipment can produce very high intensity beams of possibly small and irregular cross section. A.2.4 Diffracted beams also tend to be small and irregular in shape. They may be directed at almost any angle with respect to the main beam, and occasionally involve dose rates of the order of 0.8 Gy/hr (80 rad/hr). A.2.5 The hazard resulting from penetration of the useful beam through shutters or the x-ray tube housing is slight in well designed equipment. Adequate shielding is easily attained at the energies commonly used for diffraction and fluorescence analysis. 15 ANSI/HPS N43.2-2001 A.2.6 Adventitious (i.e. incidental) radiation from the high voltage power supply may result from malfunctioning vacuum tube rectifiers. The effective potential is twice the potential applied to the x-ray tube, and the radiation is very penetrating. This condition can arise at any time and the only effective countermeasure is to shield the assembly that contains the rectifiers and check at least twice a year for radiation leakage. A.2.7 In addition to the six sources of radiation listed above, large quantities of primary radiation may be accidentally released as the result of removal of parts of the system or the improper installation of accessories. Immediate detection of the condition is the only effective way to reduce the exposure of personnel. In installations where disassembly of shielding components and changes of accessories occur frequently, consideration should be given to the use of an area monitor having audible and visible indicators that are actuated when a preselected radiation level has been exceeded. A.3 Choosing a Radiation Survey Method A.3.1 One of the major problems in carrying out a radiation survey program is to obtain a detector with good energy independence at very low photon energies ([7], p. 105-127). The type of instrument generally recommended for accurate measurements of dose rates at low x-ray energies is an ionization chamber with a thin window (e.g. ~1.0 mg/cm2 plastic or low atomic number material). Special calibration corrections may be required at low x-ray photon energies (< 20 keV), and these energies are an important part of the spectrum when iron, chromium, or copper anodes, targets, or filters are used. A.3.2 In general, for the accuracy required in radiation protection surveys, calibration corrections may not be necessary so long as the whole sensitive area of the detector is uniformly irradiated. In this connection, the relatively large size of many ionization chambers (3.5 inch diameter for a typical survey instrument) must be listed as a disadvantage of this type of instrument because of the resulting low sensitivity when used in searching for beams of small cross section. A.3.3 Instruments which detect x-ray photons (e.g. thin window Geiger-Muller (GM) detectors, thin NaI scintillation detectors, Si(Li), plastic scintillators with thin windows, and other solid-state detectors like TLDs, etc.) offer high sensitivity in a small cross section, and are generally superior to ionization chambers for detecting beams of small cross section. However, the response is generally very energy dependent and the readings must be interpreted with care. Readings obtained with a GM counter in the low energy x-ray range are particularly unreliable without knowing the detector’s energy response or having actual calibration data. On the other hand, thin window GM detectors are very useful in locating small beams so they may be mechanically eliminated by adding shields or correcting unsatisfactory assemblies. The use of these simpler counters for this purpose is acceptable. Modern plastic scintillators, TLDs, and other detectors can also offer high sensitivity, small diameters, and good response linearity. However, special consideration is needed with regard to proper calibration and detector placement. A.4 Evaluating the Dose Rate Due to Small Beams A.4.1 Generally, knowledge of the dose rate from a direct X-ray beam (e.g. primary, diffracted, or fluorescence beam) is not needed. One case where such information is needed is in accident investigations. The techniques described here should not be construed as part of any normal operating or survey procedure. 16 ANSI/HPS N43.2-2001 A.4.2 Instrumental methods. An instrument which is calibrated for radiation that uniformly exposes the entire active detector volume will give an erroneously low reading when exposed to a beam having dimensions smaller than the detector ([7], p. 155-162), and the reading must be multiplied by a scaling factor (f): f= Detector Cross Section Area Beam Cross Section Area Beams as small as 0.01 cm2 are commonly encountered around single crystal diffraction apparatus and correction factors of 6000 or more may be required for a 3.5-inch diameter ionization chamber. In such cases, it becomes difficult to detect beams in which the dose rate may be hundreds of times greater than permissible. A.4.3 To resolve this difficulty in connection with the detection and measurement of X-rays from color television receivers, the NCRP has allowed for the fact that the smaller the beam the less is the likelihood that the same area of an individual will be repeatedly or continuously exposed. The standard for some television receivers permits the dose rate to be averaged over an area of 10 cm2. The same practice is acceptable for surveys around x-ray generator cabinets and system barriers, but in the vicinity of x-ray tube housings, beam ports, collimators, and specimen chambers where small, intense beams are likely to be encountered, it is recommended that the area over which the dose rate is averaged be limited to 1 cm2. A.4.4 On this basis it may be assumed that the largest correction factor that will need to be applied will be numerically equal to the sensitive area of the detector in square centimeters. In general, . . X = X scale for A beam > A detector . . A X = detector x X scale A beam f or 1 cm 2 < A beam < A detector . . A X = detect2or x X scale 1 cm f o r A b e a m < 1 cm 2 . . X X A is is the corrected exposure (or dose) rate, scale is the survey meter face reading, and where the area of the beam or detector as appropriate. A.4.5 Film methods. X-ray film in a low absorption optically opaque envelope is a useful adjunct to the survey meter in searching for radiation leaks. This method often gives recognizable shadows of features of the x-ray equipment that may effectively locate the leak. An estimate of the cross section of the beam can be obtained for use in correcting readings of a survey meter, or the film method itself can be made to give a semi-quantitative estimate of the dose if calibration data are available ([7], pp. 185-212). An additional advantage of the film is its suitability for integrating over a long period in order to detect very weak beams and to give an indication of the dose averaged over a period of time that includes all the steps of a given procedure. The latter sometimes leads to the detection of a possibly hazardous transient situation. A.4.6 Of special interest to those checking equipment in the field where darkroom facilities may not be available, is the use of instant film packs of the type used to take photomicrographs from microscopes. These have the developer built into the film pack and the photograph can be viewed generally in less than a minute. A.4.7 Fluorescent screen method. Fluorescent screens are occasionally useful, but their low sensitivity generally limits their effectiveness to cases involving a direct beam. This being the case, the screen 17 ANSI/HPS N43.2-2001 should be mounted on a long handle to minimize any risk of exposing the hands. It should be viewed through a lead-glass shield. The sensitivity can be improved by darkening the room completely and allowing 20 minutes or longer for the eyes to become dark adapted; however, the hazard of working in a darkened environment must also be assessed. A.5 Calibration A.5.1 The accuracy of any radiation detector is only as good as its calibration. All radiation survey meters shall be calibrated as required by regulations or in accordance with ANSI standard 323A-1997 Radiation Protection Instrumentation Test and Calibration, Portable Survey Instruments. A recommended calibration interval is at least annually. A.6 The Use of a Check Source A.6.1 As a means of detecting abrupt changes in calibration resulting from component deterioration or hidden damage, a check source should be provided. Iron-55, which decays by electron capture directly to the stable isotope manganese-55 is suggested for this application. It emits the 5.9 keV x-ray characteristic of manganese-55. This radiation represents the extreme low energy range of the spectrum encountered in survey work and provides an excellent test of an instrument's capabilities in this most difficult range. A 1.85 MBq (50 µCi) source is sufficient to provide a dose of approximately 0.1 mSv/hr (10 mrem/hr), and its half-life (2.7 years) is long enough to insure a reasonably long useful life. The source should be mounted in a jig that will insure fixed geometry and used on a regular basis. If possible, the source dose rate should be established when the survey instrument has been recently calibrated. Thereafter it is only necessary to correct the source dose rate for radioactive decay and, possibly, variations in air absorption due to changes in barometric pressure and relative humidity. The simplicity of the spectrum facilitates making such corrections. A.6.2 Another function of the check source is in determining the stability of survey instruments over time. A source of higher energy photons (or beta particles) and longer half-life might be preferred for this application to avoid complications from air absorption and decay corrections. 18