Lec. No. 2 Processing of glass fibers

advertisement

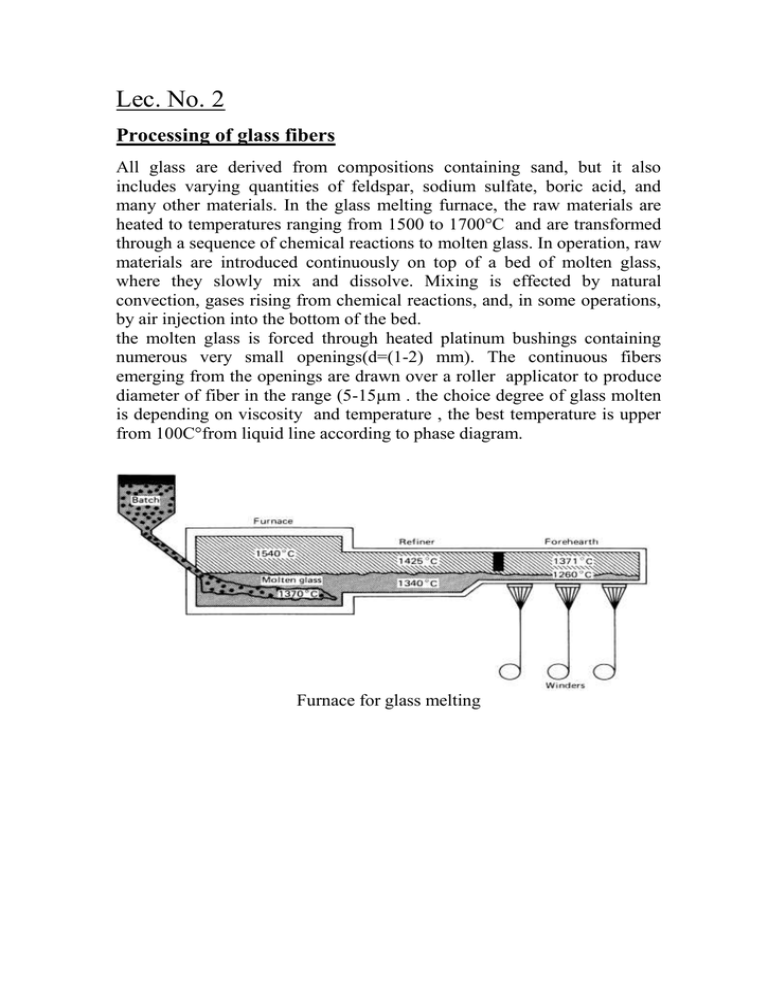

Lec. No. 2 Processing of glass fibers All glass are derived from compositions containing sand, but it also includes varying quantities of feldspar, sodium sulfate, boric acid, and many other materials. In the glass melting furnace, the raw materials are heated to temperatures ranging from 1500 to 1700°C and are transformed through a sequence of chemical reactions to molten glass. In operation, raw materials are introduced continuously on top of a bed of molten glass, where they slowly mix and dissolve. Mixing is effected by natural convection, gases rising from chemical reactions, and, in some operations, by air injection into the bottom of the bed. the molten glass is forced through heated platinum bushings containing numerous very small openings(d=(1-2) mm). The continuous fibers emerging from the openings are drawn over a roller applicator to produce diameter of fiber in the range (5-15µm . the choice degree of glass molten is depending on viscosity and temperature , the best temperature is upper from 100C°from liquid line according to phase diagram. Furnace for glass melting Lec . No . 3 Oxide fibers Ceramic oxide fibers, both continuous and discontinuous, have been commercially available since the 1970s, and processing and microstructure control are very important in obtaining the desired properties. Among the desirable characteristics in any ceramic fiber for structural applications are: 1) 2 ) Small grain size for low-temperature applications 3 ) Large grain size for high-temperature applications 4) High purity. 1)Alumina fibers Alumina fibers have γ, δ and α α -Alumina is the thermodynamically stable form. In practice, it is very difficult to control the time and temperature conditions to proceed from γ α . At low firing, the fibers will give a smaller grain size and therefore an unacceptable level of porosity. At higher processing temperatures, porosity can be eliminated but excessive grain growth will result. This dilemma can be avoided by introducing a second phase that restricts grain boundary mobility while the porosity is removed at high temperature. It is possible to select the type and amount of the second phase that inhibits the grain growth at the service temperature. Lec. No.4 Whiskers Whiskers are normally obtained by vapor phase growth. They are monocrystalline, short fibers with extremely high strength because of their high aspect ratio (50 to 10 000). They have a diameter of a few microns, but they do not have uniform dimensions and properties. ceramic Whiskers produce from oxides : Al2O3 , MgO , MgO- Al2O3 , BeO , NiO , ZnO , Cr2O3. ceramic Whiskers are produced from molten metal at air or wet hydrogen inert gas then pull and crystal growth at one direction . more Whiskers are used (Al2O3 , SiC). table : properties of oxide whiskers Material Al2O3 BeO B2O3 MgO S.G 3.9 1.8 2.5 3.6 Melting point 2082 2549 2449 2799 T.S(Gpa) 14-28 14-21 7 7-14 E(Gpa) 550 700 450 310 Nano oxide fibers An emerging technology is the production of fibers of very small diameter, of the order of 50nm. These fibers are produced by the spinning of a precursor organic fiber from a pipette to a collecting plate. A high voltage (tens of kilovolts) is passed between the pipette and the plate and the polymer is drawn from the pipette to the plate. The fibers are generally collected on the plate to form a random array although work is proceeding to align the fibers. Lec. No.5 Non-oxide fibers Commercially available non-oxide ceramic reinforcements are in three categories: continuous, discontinuous, and whiskers. non-oxide fibers are used in different application at high and low temperature . Silicon carbide fiber is a major development in the field of ceramic reinforcements. 1. Silicon carbide Continuous SiC fibers were produced by thermal degradation of a polymer precursor such as a polycarbosilane . to from a continuous fiber is made by melt-spinning. The fiber is then converted by pyrolysis at 1300°C into a fiber consisting mainly of( β-SiC) of about 15µm diameter. Methods of manufacturing SiC fibers 1) SiC fibers via polymers 2) SiC fibers via CVD 2)boron carbide and boron nitride There are other promising ceramic fibers, e.g. boron carbide and boron nitride. Boron nitride fiber has the same density (2.2 g /cm3) as carbon fiber, but has a greater oxidation resistance and excellent dielectric properties .Boron carbide fiber is a very light and strong material. Lec. No.6 Fibrous monolithic ceramics (FMs) Fibrous monolithic ceramics (FMs) consist of a hexagonal arrangement of submillimeter ‘cells’ of strong polycrystalline ceramic and a network of crack-deflecting weak ‘cell boundaries’. These composites are sintered or hot-pressed monolithic ceramics with a distinct fibrous texture. This unique architecture opened new avenues for ceramic composites, in which they fail in a nonbrittle manner because of crack interactions with weak cell boundaries such as crack deflection or crack delamination . This approach provides simple and versatile method for manufacturing nonbrittle ceramic composites from a variety of different material combinations that include oxide ceramicsAl2O3/Al2O3–ZrO2 and nonoxide ceramics (SiC/graphite), (SiC/ BN ) and( Si3N4/BN). three processing methods for producing fibrous monolithic ceramics, i.e. coextrusion , microfabrication by coextrusion , and hybrid extrusion and dip-coating . Lec. No.7 Structures of Fibrous monolithic ceramics Various material combinations Fibrous monolithic ceramics consist of dense cells separated by a continuous cell boundary, in which the cells provide most of the strength of the FM and the cell boundary provides the toughness by isolating the cells from each other and promoting dissipation of fracture energy by mechanisms such as pullout of the cells or deflection of a crack through the cell boundary . The cell boundaries must be either weak themselves or poorly bonded to the cells to dissipate fracture energy and exhibit minimal or no reaction with the cells for long-term use at elevated temperatures. To date, many kinds of structural ceramics have been examined for a strong cell phase. They are in the forms of either oxides (Al2O3, ZrO2 and ZrSiO4 ) or nonoxides( SiC , Si3N4 , and borides ). Oxides have the advantage of stability in oxidizing environments, while non-oxides have the advantage of substantially higher strength and superior creep resistance. In all-oxide FMs, porous cell boundaries are generally employed because Lec. No.8 SiC/SiC Composites CMCs exhibit high mechanical properties at high or very high temperatures (400– 3000°C), and in severe environments. They were developed initially for military and aerospace applications. Now they are being introduced into new fields and their range of applications will grow when their cost is lowered drastically. CMCs can be fabricated by different processing techniques, using either liquid or gaseous precursors. The CVI SiC/SiC composites consist of a SiC-based matrix reinforced by SiC fibers. They are produced by Chemical Vapour Infiltration (CVI). This technique derives directly from Chemical Vapour Deposition. In very simple terms, the SiC-based matrix is deposited from gaseous reactants on to a heated substrate of fibrous preforms (SiC). CVI is a slow process, and the obtained composite materials possess some residual porosity and density gradients. Despite these drawbacks, the CVI process presents a few advantages: (i) the strength of reinforcing fibers is not affected during composite manufacture. (ii) the nature of the deposited material can be changed easily, simply by introducing the appropriate gaseous precursors into the infiltration chamber. (iii) a large number of components. (iv) large complex shapes can be produced in a near net shape. Lec. No.9 Interface properties – influence on the mechanical behavior The fiber-matrix interfacial domain is a critical part of composites because load transfers from the matrix to the fiber and occur through the interface. Most authors promote the concept of weak interfaces to increase fracture toughness. The major contribution to toughness is attributed to crack bridging and fiber pull-out. Weak interfaces are detrimental to composite strength. A high strength requires efficient load transfers from fibers to the matrix. This is obtained with strong interfaces. These latter requirements, to be met for strong composites, are therefore incompatible with the former ones for tough composites, if toughening is based solely upon the above mentioned weak interface-based mechanisms. Fiber/matrix interfaces exert a profound influence on the mechanical behavior and the lifetime of composites. Efforts have been directed towards optimization of interface properties. ( FIGURE. Schematic diagram showing crack deflection when the fiber coating/interface is strong (a) or weak (b)) Lec. No.10 Silicon Melt Infiltrated Ceramic Composites(MI-CMCs) Silicon melt infiltrated, SiC-based ceramic matrix composites (MI-CMCs) have been developed for use in gas turbine engines. These materials are particularly suited to use in gas turbines due to their: 1) low porosity. 2) high thermal conductivity. 3) low thermal expansion. 4) high toughness. 5)high matrix cracking stress. PROCESSING of (MI-CMC) the term “melt infiltrated ceramic matrix composite” (MI-CMC) will refer only to continuous fiber composites whose matrices are formed by molten silicon (or silicon alloy) infiltration into a porous SiC- and/or C-containing preform. The process of (MI-CMC) includes : 1) As with most other ceramic composite systems, a coating is applied to the fibers to serve as the fiber-matrix interphase. 2) fibrous perform a) In the prepreg process b)In the slurry cast process Some important thermal properties of Prepreg and Slurry Cast measured at room temperature and at 1200°C, are listed in Table 3. Overall, the thermal properties Table 3 Lec. No.11 Fracture Strength The in-plane tensile fracture response of materials are typically characterized by a stress-strain curve as shown in Figure 2 when measured in a simple displacement controlled method. In general, the curve can be divided into four sections (shown by the dotted lines in Figure 2), with the first section representing the simple linear elastic loading of the composite. FIGURE 2. Typical in-plane tensile stress-strain behavior for a continuous fiber reinforced ceramic composite. Lec. No.12 Carbon Fiber Reinforced Silicon Carbide Composites (C/SiC, C/C-SiC) Ceramic matrix composites (CMC), based on reinforcements of carbon fibers and matrices of silicon carbide (called C/SiC or C/C-SiC composites) represent a relatively new class of structural materials. In the last few years new manufacturing processes and materials have been developed. PROCESSING of (C/SiC, C/C-SiC) Three different techniques are currently used in an industrial scale for the production of C/SiC and C/C-SiC composites, each of them leading to specific microstructures and properties : 1)Chemical Vapour Infiltration (CVI). 2)Liquid Polymer Infiltration (LPI) or Polymer Infiltration and Pyrolysis (PIP). 3)Liquid Silicon Infiltration (LSI). Lec. No.13 Carbon fiber / carbon matrix composite (c/c composite) Carbon fiber-reinforced carbon is a composite material consisting of carbon fiber reinforcement in a matrix of graphite . Carbon–carbon is wellsuited to structural applications at high temperatures, or where thermal shock resistance and/or a low coefficient of thermal expansion is needed. While it is less brittle than many other ceramics, it lacks impact resistance .carbon/Carbon (C/C) is a lightweight, high-strength composite material capable of withstanding temperatures over 3000°C in many environments. Processing of (c/c composite) The material is made in three stages: First, material is laid up in its intended final shape, with carbon filament and/or cloth surrounded by an organic binder such as plastic. Often, coke or some other fine carbon aggregate is added to the binder mixture. Second, the lay-up is heated, so that pyrolysis transforms the binder to relatively pure carbon. Third, the voids are gradually filled by forcing a carbon-forming gas such as acetylene through the material at a high temperature, over the course of several days.