Lecture#8 Dr.Haydar Al-Ethari

advertisement

Lecture#8

- Strain Gages

- Electrical Resistance Strain Gages

- Strain Gage Rosettes

- transformation matrix

Dr.Haydar Al-Ethari

References:

1- James Doyle, 2004, Modern Experimental Stress Analysis: completing

the solution of partially specified problems. John Wiley & Sons, Ltd.

2- Dieter G.E., (1986), Mechanical Metallurgy, McGraw-Hill.

3- Hearn E. J., (2000), Mechanics of Materials, vol. 1&2., Butterworth &

Heinemann.

Strain Gages:

A transducer is a device that transforms one type of energy into another.

These are of great importance in measurement because, generally, it happens

that the original quantity (strain, say) to be measured is too small to handle

in its original form and instead an intermediate quantity is used. In modern

measurements, the most common intermediate quantity is the electric

voltage.

Electrical Resistance Strain Gages:

Probably the most reliable of all the tools of experimental stress analysis is

the electrical resistance strain gauge. The principle of its action is that the

electrical resistance of a conductor changes proportionally to any strain

applied to it. Thus, if a short length of wire were bonded to the structure in

such a way that it experiences the same deformation as the structure, then by

measuring the change in resistance, the strain can be obtained.

Basic Theory

Consider a conducting wire of length L and area A as shown. Its resistance

(neglecting temperature effects) is proportional to its length but inversely

proportional to the area, that is,

R = L/A

where is a constant of proportionality, called the specific resistivity and is

essentially inversely proportional to the number of mobile electrons per unit

volume (N/V).

1

where K is a proportionality factor, the resistance is written as:

Suppose this wire is stretched; there will be a small change in resistance

given by:

or

The number of mobile electrons is generally proportional to stress (and

hence strain = L/L), that is:

and

It follows that any change in length, and hence sectional area, will result in a

change of resistance. Thus measurement of this resistance change enables a

direct reading of linear strain to be obtained. This is made possible by the

relationship which exists for a number of alloys over a considerable strain

range between change of resistance and strain which may be expressed as

follows:

∆R

∆L

= Sm

R

L

where R and L are the changes in resistance and length respectively and

Sm is termed the material sensitivity or gauge factor.

Typical values of Sm for most conventional gauges lie in the region of 2 to

2.2, and most strain-gauge instruments allow the value of Sm to be set

accordingly, thus enabling strain values to be recorded directly.

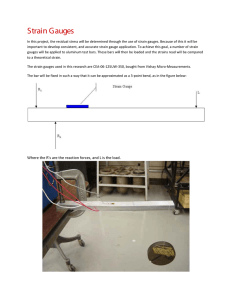

An actual gauge is not a straight length of wire but is in the form of a grid as

shown in the figure. The original wire gauges were wound back and forth

over a paper former so as to maintain a large resistance but small size.

2

The gauge sensitivity or gauge factor is measured in a uniaxial stress field

and this will give rise to an error when the gauge is used in other than the

calibrated situation. This is known as the transverse sensitivity error. In

general, this error is not very large and therefore the extension in the gage

direction (even in multiaxial strain fields) is assumed to be given by

ε =

∆R / R

Sm

Strain gauge measures only extension, that is, the normal component of

strain. It does not measure shear strain directly—this must be obtained by

deduction from a number of extension measurements.

Strain Gage Rosettes

At a particular point on the surface of a deformed structure, there are, in

general, three unknown strains; either ( xx, yy, xy) or 1, 2, ). Therefore,

three independent pieces of experimental data must be recorded if the strain

state is to be specified. Since one strain gauge cannot measure shear directly,

three gauges must be arranged to give three independent extension

measurements and the transformation equations used to determine the shear

component. This combination of three (sometimes four) gauges is called a

strain gage rosette. In practice, rosettes are usually mounted with respect to

a reference axis (not necessarily the principal strain axes).

The majority of rosette gauges are either rectangular rosettes with

and 900 or delta rosettes with = 00, 600 and 1200.

3

= 00, 450

Transformation matrix

The values of the principal strains associated with the three strain readings

taken from a

strain gauge rosette may be found by calculation using the following

transformation eqn.:

This equation can be applied three times for the three values of

of the

rosette gauges. Thus with three known values of for three known values of

, three simultaneous equations will give the unknown strains x, y, xy or

you can use the following transformation matrix:

Or in general:

{

data }

= [ C ]{

coord}.

The principal strains ( and the principal stresses) can then be determined

using the known for you procedure (See Lect.#1).

4