Lithium Ion Battery Safety Monitor

AD8280

Data Sheet

FEATURES

GENERAL DESCRIPTION

Wide supply voltage range: 6.0 V to 30.0 V

Multiple inputs can monitor 3 to 6 cell voltages

and 2 temperatures

Adjustable threshold levels: overvoltage, undervoltage,

overtemperature

Alarm options: separate or shared alarms

Extended temperature range performance

−40°C ≤ TA ≤ +105°C

Can be daisy-chained

Internal reference

Powered from battery stack

LDO available to power isolator

Qualified for automotive applications

Extensive self-test feature aids in meeting ASIL/SIL

requirements

The AD8280 is a hardware-only safety monitor for lithium ion

battery stacks. The part has inputs to monitor six battery cells

and two temperature sensors (either NTC or PTC thermistors).

The part is designed to be daisy-chained with other AD8280

devices to monitor a stack of significantly more than six cells

without the need for numerous isolators. Its output can be configured for an independent or shared alarm state.

The AD8280 functions independently from a primary monitor

and contains its own reference and LDO, both of which are

powered completely from the battery cell stack. The reference, in

conjunction with external resistor dividers, is used to establish

trip points for the overvoltages and undervoltages. Each cell

channel contains programmable deglitching circuitry to prevent

alarms from transient input levels.

The AD8280 also has two digital pins that can be used to select

various combinations of inputs in the case where fewer than six

cells are to be monitored. Most important, it has a self-test feature,

making it suitable for high reliability applications, such as automotive hybrid electric vehicles or higher voltage industrial usage,

such as uninterruptible power supplies. The AD8280 can function

over a temperature range of −40°C to +105°C.

APPLICATIONS

Lithium ion battery backup monitor and threshold detection

Electric and hybrid electric vehicle

Industrial vehicle

Uninterruptible power supply

Wind and solar

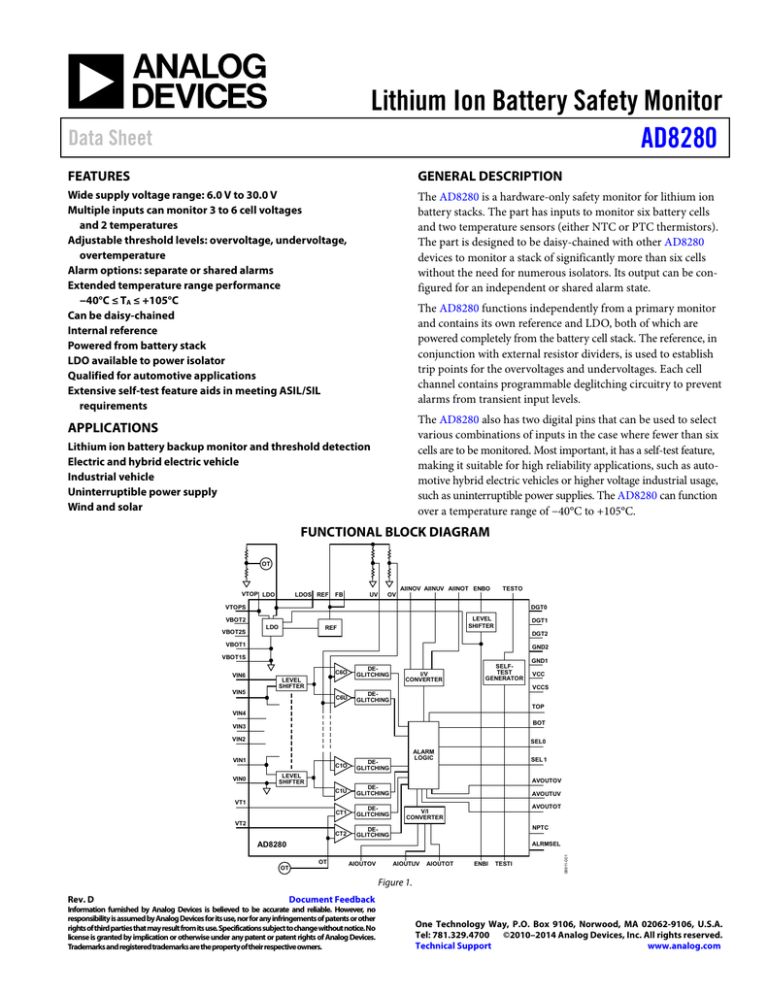

FUNCTIONAL BLOCK DIAGRAM

OT

AIINOV AIINUV AIINOT ENBO

VTOP LDO

LDOS REF

FB

UV

TESTO

OV

DGT0

VTOPS

LEVEL

SHIFTER

VBOT2

VBOT2S

LDO

REF

DGT1

DGT2

VBOT1

GND2

VBOT1S

VIN6

GND1

C6O

DEGLITCHING

C6U

DEGLITCHING

LEVEL

SHIFTER

I/V

CONVERTER

SELFTEST

GENERATOR

VCC

VCCS

VIN5

TOP

VIN4

BOT

VIN3

VIN2

SEL0

VIN1

DEGLITCHING

C1U

DEGLITCHING

CT1

DEGLITCHING

CT2

DEGLITCHING

LEVEL

SHIFTER

SEL 1

AVOUTOV

AVOUTUV

VT1

AVOUTOT

V/I

CONVERTER

VT2

NPTC

AD8280

ALRMSEL

OT

OT

AIOUTOV

AIOUTUV

AIOUTOT

ENBI

TESTI

08911-001

VIN0

C1O

ALARM

LOGIC

Figure 1.

Rev. D

Document Feedback

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Analog Devices for its use, nor for any infringements of patents or other

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Trademarks and registered trademarks are the property of their respective owners.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 ©2010–2014 Analog Devices, Inc. All rights reserved.

Technical Support

www.analog.com

AD8280

Data Sheet

TABLE OF CONTENTS

Features .............................................................................................. 1 Number of Cells Selection......................................................... 17 Applications ....................................................................................... 1 Threshold Inputs ........................................................................ 17 General Description ......................................................................... 1 Top and Bottom Part Designation ........................................... 18 Functional Block Diagram .............................................................. 1 Typical Daisy-Chain Connections ........................................... 18 Revision History ............................................................................... 2 Shared or Separate Alarms ........................................................ 18 Specifications..................................................................................... 3 Deglitching Options ................................................................... 18 Absolute Maximum Ratings............................................................ 5 Enabling and Disabling the AD8280 ....................................... 20 Thermal Resistance ...................................................................... 5 Alarm Output ............................................................................. 20 ESD Caution .................................................................................. 5 Self-Test ....................................................................................... 20 Pin Configuration and Function Descriptions ............................. 6 Protection Components and Pull-Up/Pull-Down Resistors ..... 23 Typical Performance Characteristics ............................................. 8 EMI Considerations ................................................................... 23 Theory of Operation ...................................................................... 15 System Accuracy Calculation ................................................... 23 Applications Information .............................................................. 16 Outline Dimensions ....................................................................... 24 Typical Connections .................................................................. 16 Ordering Guide .......................................................................... 24 Cell Inputs ................................................................................... 16 Automotive Products ................................................................. 24 Temperature Inputs and Thermistor Selection ...................... 16 REVISION HISTORY

8/14—Rev. C to Rev. D

Changes to Table 2 ............................................................................ 5

7/11—Rev. B to Rev. C

Changes to Self-Test Completion Time, tST Parameter and SelfTest Valid Time, tSTV Parameter in Table 1 .................................... 3

6/11—Rev. A to Rev. B

Changes to Table 1, Dynamic Performance, Self-Test

Valid Time, tstv Parameter ................................................................ 4

Change to Figure 36, Figure 37, and Figure 39 ........................... 13

7/10—Rev. 0 to Rev. A

Change to Logic 1 Voltage Input, VIH Parameter in Table 1 ........3

Changes to Temperature Inputs and Thermistor Selection

Section.............................................................................................. 17

Added Figure 46; Renumbered Figures Sequentially ................ 17

Changes to Endnote 1 in Table 6 .................................................. 18

Changes to Ordering Guide .......................................................... 24

4/10—Revision 0: Initial Version

Rev. D | Page 2 of 24

Data Sheet

AD8280

SPECIFICATIONS

VTOP = 7.5 V to 30 V, TA = −40°C to +105°C, unless otherwise noted.

Table 1.

Parameter

TRIP POINT ERRORS

Undervoltage Trip Point Error

Overvoltage Trip Point Error

Overtemperature Trip Point Error

Hysteresis for Overvoltage, Undervoltage,

and Overtemperature Trip Points

CELL INPUTS (VIN0 TO VIN6)

Input Bias Current

Input Offset Current

Input Voltage Range

Input Common-Mode Range

TEMPERATURE INPUTS (VT1, VT2)

Input Bias Current

Input Voltage Range

OVERVOLTAGE THRESHOLD INPUT (OV)

Input Bias Current

Input Voltage Range

UNDERVOLTAGE THRESHOLD INPUT (UV)

Input Bias Current

Input Voltage Range

OVERTEMPERATURE THRESHOLD INPUT (OT)

Input Bias Current

Input Voltage Range

INPUT/OUTPUT CHARACTERISTICS

Logic 1 Current

Logic 0 Current

Logic 1 Voltage Input, VIH

All Pins Except TOP and BOT

TOP and BOT Pins

Logic 0 Voltage Input, VIL

All Pins Except TOP and BOT

TOP and BOT Pins

Logic 1 Voltage Output, VOH

Logic 0 Voltage Output, VOL

Input Bias Current

REFERENCE AND LDO

Reference Voltage

Reference Source Current

LDO Voltage

LDO Source Current

DYNAMIC PERFORMANCE

Fault Detection (Deglitch) Time Range

Fault Detection (Deglitch) Accuracy

Propagation Delay Time

Start-Up Time

Test Conditions/Comments

Min

Typ

Max

Unit

50

+25

+15

+25

60

mV

mV

mV

mV

0

0

0

0

20

20

5

Top of

stack

nA

nA

V

V

−10

0

+10

5

nA

V

0

3.6

20

4.6

nA

V

0

1.4

20

3.3

nA

V

0

1.5

20

4

nA

V

200

50

µA

µA

LDO

V

V

0.8

VBOT

0.2

1

V

V

V

V

µA

5.05

250

5.35

5.0

V

µA

V

mA

12.8

sec

+20

%

µs

ms

−25

−15

−25

40

One cell

AIINxx, AIOUTxx

AIINxx, AIOUTxx

With respect to VBOTx

100

10

150

30

2.0

VTOP

With respect to VBOTx

With respect to VBOTx

With respect to VBOTx

SEL0, SEL1, DGT0, DGT1, DGT2, NPTC, ALRMSEL

4.2

4.95

5.0

0 mA ≤ LDO source current ≤ 10.0 mA

4.85

5.1

Seven settings: 0.0 sec, 0.1 sec, 0.8 sec, 1.6 sec,

3.2 sec, 6.4 sec, and 12.8 sec

0.0

−20

No capacitor on daisy chain

From application enabled to LDO = 90% of

value

Rev. D | Page 3 of 24

4.0

3.0

AD8280

Parameter

Self-Test Completion Time, tST

Self-Test Valid Time, tSTV

Delay Time for Self-Test Start, tRE

Delay Time for Data Valid, tFE

Rise Time for Self-Test Pulse, tR

POWER SUPPLY

Supply Voltage Range

Quiescent Current

Power Supply Enabled

Power Supply Disabled

Data Sheet

Test Conditions/Comments

Deglitch time = 0.0 sec

Deglitch time > 0.0 sec

Min

40

800

0.0

10

4.0

TESTI

VTOP with respect to VBOTx

LDO source current = 10.0 mA

LDO source current = 0.0 mA

Excluding LDO source current

Rev. D | Page 4 of 24

7.5

6.0

Typ

Max

50

1000

3.5

100

5.0

1.0

Unit

ms

ms

µs

ns

µs

ms

30

30

V

V

2.0

1.0

mA

µA

Data Sheet

AD8280

ABSOLUTE MAXIMUM RATINGS

THERMAL RESISTANCE

Table 2.

Parameter

VTOP to VBOTx

VIN0 to VBOTx

VIN1 Through VIN5 Voltage to VBOTx

VIN6 to VBOTx

VIN6 to VTOP

VTx to VBOTx

TESTI, ENBI to GNDx

DGTx, SELx, NPTC to GNDx

AVOUTxx to GNDx

TOP, BOT to VBOTx

Rating

−0.3 V to +33 V

−0.3 V to LDO + 0.3 V

−0.3 V to VTOP + 0.3 V

−0.3 V to VTOP + 1.0 V

−0.3 V to + 1.0 V

−0.3 V to LDO + 0.3 V

−0.3 V to LDO + 0.3 V

−0.3 V to LDO + 0.3 V

−0.3 V to LDO + 0.3 V

−0.3 V to VTOP + 0.3 V

θJA is specified for the worst-case conditions, that is, a device

soldered in a circuit board for surface-mount packages.

Table 3. Thermal Resistance

Package Type

48-Lead LQFP (ST-48)

ESD CAUTION

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

Rev. D | Page 5 of 24

θJA

54

θJC

15

Unit

°C/W

AD8280

Data Sheet

TOP

BOT

TESTO

AIINOV

AIINUV

AIINOT

ENBO

REF

FB

LDOS

LDO

VCCS

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

48

47

46

45

44

43

42

41

40

39

38

37

VBOT2

1

36

VCC

VBOT2S

2

35

GND1

VBOT1S

3

34

GND2

VBOT1

4

33

NPTC

VIN0

5

32

ALRMSEL

VIN1

6

VIN2

7

30

DGT1

VIN3

8

29

SEL0

VIN4

9

28

SEL1

VIN5 10

27

AVOUTOV

VIN6 11

26

AVOUTUV

VTOP 12

25

AVOUTOT

PIN 1

19

20

21

22

23

24

OV

UV

OT

DGT2

VT2

18

ENBI

VT1

17

AIOUTOT

VTOPS

16

AIOUTUV

15

AIOUTOV

14

TESTI

13

08911-002

31 DGT0

AD8280

Figure 2. Pin Configuration

Table 4. Pin Function Descriptions

Pin No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

Mnemonic

VBOT2

VBOT2S

VBOT1S

VBOT1

VIN0

VIN1

VIN2

VIN3

VIN4

VIN5

VIN6

VTOP

VTOPS

VT1

VT2

TESTI

AIOUTOV

AIOUTUV

AIOUTOT

ENBI

OV

UV

OT

DGT2

AVOUTOT

AVOUTUV

AVOUTOV

Description

Lowest Potential of Six-Cell Stack.

Lowest Potential of Six-Cell Stack. Tie to VBOT2.

Lowest Potential of Six-Cell Stack. Tie to VBOT1.

Lowest Potential of Six-Cell Stack.

Input Voltage for Bottom of Cell 1.

Input Voltage for Bottom of Cell 2/Top of Cell 1.

Input Voltage for Bottom of Cell 3/Top of Cell 2.

Input Voltage for Bottom of Cell 4/Top of Cell 3.

Input Voltage for Bottom of Cell 5/Top of Cell 4.

Input Voltage for Bottom of Cell 6/Top of Cell 5.

Input Voltage for Top of Cell 6.

Highest Potential of Six-Cell Stack.

Highest Potential of Six-Cell Stack. Tie to VTOP.

Temperature Input 1.

Temperature Input 2.

Test Input.

Alarm Current Output, Overvoltage. Used in daisy-chain configuration.

Alarm Current Output, Undervoltage. Used in daisy-chain configuration.

Alarm Current Output, Overtemperature. Used in daisy-chain configuration.

Enable Input. When ENBI is logic high, the part is enabled; when ENBI is logic low, the part is disabled.

Overvoltage Trip Point.

Undervoltage Trip Point.

Overtemperature Trip Point.

Digital Select Pin 2. Used with DGT0 and DGT1 to select deglitch time (see Table 7).

Alarm Voltage Output, Overtemperature.

Alarm Voltage Output, Undervoltage.

Alarm Voltage Output, Overvoltage.

Rev. D | Page 6 of 24

Data Sheet

Pin No.

28

29

30

31

32

Mnemonic

SEL1

SEL0

DGT1

DGT0

ALRMSEL

33

NPTC

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

GND2

GND1

VCC

VCCS

LDO

LDOS

FB

REF

ENBO

AIINOT

AIINUV

AIINOV

TESTO

BOT

TOP

AD8280

Description

Digital Select Pin 1. Used with SEL0 to select channels to be used (see Table 5).

Digital Select Pin 0. Used with SEL1 to select channels to be used (see Table 5).

Digital Select Pin 1. Used with DGT0 and DGT2 to select deglitch time (see Table 7).

Digital Select Pin 0. Used with DGT1 and DGT2 to select deglitch time (see Table 7).

Selects three separate alarms or one shared alarm. When ALRMSEL is logic high, three separate alarms are

selected; when ALRMSEL is logic low, one shared alarm is selected.

Selects NTC or PTC thermistor for VTx inputs. When NPTC is tied to logic high (LDO pin), a PTC thermistor is

selected; when NPTC is tied to logic low (VBOTx pin), an NTC thermistor is selected.

Ground. Tie to same potential as VBOT1 and VBOT2.

Ground. Tie to same potential as VBOT1 and VBOT2.

Supply Voltage. Tie to LDO.

Supply Voltage Sense. Tie to LDO.

LDO Output. Tie to VCC, VCCS, and LDOS.

LDO Output Sense. Tie to LDO.

Feedback Pin. Tie to REF.

Reference Output. Tie to FB.

Enable Output.

Alarm Current Input, Overtemperature. Used in daisy-chain configuration.

Alarm Current Input, Undervoltage. Used in daisy-chain configuration.

Alarm Current Input, Overvoltage. Used in daisy-chain configuration.

Test Output.

Used to identify part at lowest potential in daisy chain (see Table 6).

Used to identify part at highest potential in daisy chain (see Table 6).

Rev. D | Page 7 of 24

AD8280

Data Sheet

TYPICAL PERFORMANCE CHARACTERISTICS

SAMPLE SIZE = 2726

SAMPLE SIZE = 2726

1400

1800

UNDERVOLTAGE

OVERVOLTAGE

1200

NUMBER OF HITS

UNDERVOLTAGE

OVERVOLTAGE

1200

900

600

800

600

400

200

08911-003

300

0

–30

1000

–20

–10

0

10

20

0

–30

30

08911-006

NUMBER OF HITS

1500

–20

Figure 3. Overvoltage and Undervoltage Trip Point Error,

Voltage Between VIN0 and VIN1

UNDERVOLTAGE

OVERVOLTAGE

1000

800

600

400

2400

SAMPLE SIZE = 2726

2100

UNDERVOLTAGE

OVERVOLTAGE

1500

1200

900

08911-004

–20

–10

0

10

20

300

0

–30

30

–20

TRIP POINT ERROR (mV)

–10

0

10

20

30

TRIP POINT ERROR (mV)

Figure 4. Overvoltage and Undervoltage Trip Point Error,

Voltage Between VIN1 and VIN2

Figure 7. Overvoltage and Undervoltage Trip Point Error,

Voltage Between VIN4 and VIN5

1800

SAMPLE SIZE = 2726

SAMPLE SIZE = 2726

1800

UNDERVOLTAGE

OVERVOLTAGE

1500

UNDERVOLTAGE

OVERVOLTAGE

NUMBER OF HITS

1500

1200

900

600

1200

900

600

300

–20

–10

0

10

20

0

–30

30

TRIP POINT ERROR (mV)

08911-008

300

08911-005

NUMBER OF HITS

30

600

200

0

–30

20

1800

NUMBER OF HITS

NUMBER OF HITS

1200

0

–30

10

Figure 6. Overvoltage and Undervoltage Trip Point Error,

Voltage Between VIN3 and VIN4

SAMPLE SIZE = 2726

1400

0

08911-007

1600

–10

TRIP POINT ERROR (mV)

TRIP POINT ERROR (mV)

–20

–10

0

10

20

TRIP POINT ERROR (mV)

Figure 5. Overvoltage and Undervoltage Trip Point Error,

Voltage Between VIN2 and VIN3

Figure 8. Overvoltage and Undervoltage Trip Point Error,

Voltage Between VIN5 and VIN6

Rev. D | Page 8 of 24

30

Data Sheet

AD8280

SAMPLE SIZE = 2726

SAMPLE SIZE = 2726

250

180

150

NUMBER OF HITS

NUMBER OF HITS

200

150

100

120

90

60

50

0

–5

–4

–3

–2

–1

08911-012

08911-009

30

0

4.8

0

4.9

5.0

TRIP POINT ERROR (mV)

Figure 9. Overtemperature Trip Point Error

180

300

150

120

90

250

200

150

60

100

30

50

47

48

49

50

0

1.2

51

08911-113

NUMBER OF HITS

350

08911-010

NUMBER OF HITS

5.4

SAMPLE SIZE = 2726

210

1.3

1.4

Figure 10. Overvoltage, Undervoltage, and Overtemperature Hysteresis

1.7

1.8

1.9

0.04

0.05

600

SAMPLE SIZE = 2726

500

400

400

NUMBER OF HITS

500

300

200

100

5.00

5.02

5.04

300

200

0

–0.02

5.06

REFERENCE VOLTAGE (V)

08911-114

100

08911-011

4.98

1.6

Figure 13. Supply Current

SAMPLE SIZE = 2726

4.96

1.5

SUPPLY CURRENT (mA)

HYSTERESIS (mV)

NUMBER OF HITS

5.3

400

SAMPLE SIZE = 2726

0

4.94

5.2

Figure 12. LDO Voltage

240

0

5.1

LDO VOLTAGE (V)

–0.01

0

0.01

0.02

0.03

SHUTDOWN CURRENT (µA)

Figure 14. Supply Current, Power-Down Mode

Figure 11. Reference Voltage

Rev. D | Page 9 of 24

AD8280

Data Sheet

75

25

VOLTAGE BETWEEN

VIN0 AND VIN1

VIN1 AND VIN2

VIN2 AND VIN3

VIN3 AND VIN4

VIN4 AND VIN5

VIN5 AND VIN6

15

10

5

VIN1 TO VIN2 AND VIN5 TO VIN6

0

–5

–10

–15

65

60

55

50

45

40

35

–10

30

10

50

70

90

110

TEMPERATURE (°C)

25

–50

08911-013

–30

50

70

90

110

15

10

VOLTAGE BETWEEN

VIN0 AND VIN1

VIN1 AND VIN2

VIN2 AND VIN3

VIN3 AND VIN4

VIN4 AND VIN5

VIN5 AND VIN6

70

UNDERVOLTAGE HYSTERESIS (mV)

5

0

–5

–10

VIN2 TO VIN3 AND VIN3 TO VIN4

–15

65

60

55

50

45

40

35

–10

30

10

50

70

90

110

TEMPERATURE (°C)

25

–50

08911-014

–30

70

OVERTEMPERATURE HYSTERESIS (mV)

75

8

6

4

2

0

–2

VT2

VT1

–10

10

30

50

TEMPERATURE (°C)

70

90

110

08911-015

–8

–30

10

30

50

70

90

110

Figure 19. Undervoltage Hysteresis vs. Temperature

10

–6

–10

TEMPERATURE (°C)

Figure 16. Undervoltage Error vs. Temperature

–4

–30

08911-017

30

–20

Figure 17. Overtemperature Error vs. Temperature

65

60

55

VT1

50

45

VT2

40

35

30

25

–50

–30

–10

10

30

50

70

90

TEMPERATURE (°C)

Figure 20. Overtemperature Hysteresis vs. Temperature

Rev. D | Page 10 of 24

110

08911-018

UNDERVOLTAGE ERROR (mV)

30

75

VOLTAGE BETWEEN

VIN0 AND VIN1

VIN1 AND VIN2

VIN2 AND VIN3

VIN3 AND VIN4

VIN4 AND VIN5

VIN5 AND VIN6

20

OVERTEMPERATURE ERROR (mV)

10

Figure 18. Overvoltage Hysteresis vs. Temperature

25

–10

–50

–10

TEMPERATURE (°C)

Figure 15. Overvoltage Error vs. Temperature

–25

–50

–30

08911-016

30

–20

–25

–50

VOLTAGE BETWEEN

VIN0 AND VIN1

VIN1 AND VIN2

VIN2 AND VIN3

VIN3 AND VIN4

VIN4 AND VIN5

VIN5 AND VIN6

70

OVERVOLTAGE HYSTERESIS (mV)

OVERVOLTAGE ERROR (mV)

20

AD8280

ENABLED SUPPLY CURRENT (mA)

TRIP POINT ERROR (mV)

10

VOLTAGE BETWEEN

VIN0 AND VIN1

VIN1 AND VIN2

VIN2 AND VIN3

VIN3 AND VIN4

VIN4 AND VIN5

VIN5 AND VIN6

5

0

–5

–15

6

10

14

18

22

26

30

STACK VOLTAGE (V)

2.5

2.0

2.0

1.5

1.0

1.0

DISABLED

0.5

0.5

0

0

6

10

14

18

22

26

30

STACK VOLTAGE (V)

Figure 24. Supply Current vs. Stack Voltage (VIN6 – VIN0)

Figure 21. Overvoltage Trip Point Error vs. Stack Voltage (VIN6 – VIN0)

1.40

5

0

1.35

SUPPLY CURRENT (mA)

TRIP POINT ERROR (mV)

1.5

ENABLED

08911-019

–10

2.5

08911-022

15

DISABLED SUPPLY CURRENT (µA)

Data Sheet

VOLTAGE BETWEEN

VIN0 AND VIN1

VIN1 AND VIN2

VIN2 AND VIN3

VIN3 AND VIN4

VIN4 AND VIN5

VIN5 AND VIN6

–5

–10

–15

1.30

STACK VOLTAGE = 7.5V

STACK VOLTAGE = 18V

STACK VOLTAGE = 29.8V

1.25

1.20

6

10

14

18

22

26

30

STACK VOLTAGE (V)

1.15

–50

08911-020

–25

–10

–30

30

50

10

TEMPERATURE (°C)

70

90

110

08911-023

–20

Figure 25. Enabled Supply Current vs. Temperature

for Various Stack Voltages (VIN6 – VIN0)

Figure 22. Undervoltage Trip Point Error vs. Stack Voltage (VIN6 – VIN0)

10

5.5

8

5.0

6

4.5

LDO

4.0

2

3.5

0

3.0

–2

6

10

14

18

22

26

30

STACK VOLTAGE (V)

2.5

0

5

10

15

20

25

30

SOURCE CURRENT (mA)

Figure 26. LDO and Reference Voltage vs. LDO Source Current,

Stack Voltage = 7.5 V

Figure 23. Input Bias Current vs. Stack Voltage (VIN6 – VIN0)

Rev. D | Page 11 of 24

08911-029

VOLTAGE (V)

4

08911-123

BIAS CURRENT (nA)

REF

AD8280

Data Sheet

5.5

5.08

LDO

5.07

LDO

5.0

5.06

REF

5.05

VOLTAGE (V)

VOLTAGE (V)

4.5

4.0

5.04

5.03

5.02

3.5

5.01

5.00

3.0

REF

4.99

5

15

10

20

25

30

SOURCE CURRENT (mA)

4.98

Figure 27. LDO and Reference Voltage vs. LDO Source Current,

Stack Voltage = 18.0 V

10

6

14

22

18

30

STACK VOLTAGE (V)

Figure 30. LDO and Reference Voltage vs. Stack Voltage (VIN6 – VIN0)

10

35

VIN0

VIN2

VIN4

VIN6

VT1

UV

8

30

LDO

6

25

BIAS CURRENT (nA)

SOURCE CURRENT (mA)

26

08911-033

0

08911-030

2.5

20

15

10

REF

4

VIN1

VIN3

VIN5

VT2

OV

OT

2

0

–2

–4

–6

5

–10

30

10

50

70

90

110

TEMPERATURE (°C)

08911-031

–30

–10

–50

–30

–10

10

30

50

70

90

TEMPERATURE (°C)

Figure 28. LDO and Reference Source Current vs. Temperature

110

08911-034

–8

0

–50

Figure 31. Input Bias Current vs. Temperature

5.11

5.09

LDO

5V/DIV

5.05

5.03

OV

1

5.01

REF

4.99

4.95

–50

–30

–10

10

30

50

70

90

TEMPERATURE (°C)

110

20ns/DIV

Figure 32. Alarm Rise Time

Figure 29. LDO and Reference Voltage vs. Temperature

Rev. D | Page 12 of 24

08911-035

4.97

08911-032

VOLTAGE (V)

5.07

Data Sheet

AD8280

OV

1

5V/DIV

OV

UV

1

2

OT

TESTI

4

Figure 33. Alarm Fall Time

CH1 5V

CH3 5V

M200ms 1.25ks/s

A CH4

2.4V

800µs/pt

Figure 36. TESTI and AVOUTxx, Deglitch Time = 0.1 sec, Self-Test Passes

OV

OV

1

1

UV

2

UV

2

OT

OT

3

TESTI

4

20ms/DIV

08911-024

3

TESTI

4

Figure 34. TESTI and AVOUTxx, Deglitch Time = 0.0 sec, Self-Test Passes

CH1 5V

CH3 5V

CH2 5V

CH4 5V

M200ms 1.25ks/s

A CH4

2.4V

800µs/pt

08911-049

5V/DIV

CH2 5V

CH4 5V

08911-048

20ns/DIV

08911-036

3

Figure 37. TESTI and AVOUTxx, Deglitch Time = 0.1 sec, Self-Test Fails (UV)

OV

OV

1

UV

TESTI

5V/DIV

5V/DIV

1

2

2

OT

20ms/DIV

Figure 35. TESTI and AVOUTxx, Deglitch Time = 0.0 sec, Self-Test Fails (UV)

Rev. D | Page 13 of 24

4µs/DIV

Figure 38. TESTI Edge and AVOUTxx, Self-Test Fails (Enlarged)

08911-038

TESTI

4

08911-025

3

AD8280

Data Sheet

OV

OV

1

5V/DIV

1

UV

2

CELL

ALARM

TRIPPED

2

OT

CH1 5V

CH3 5V

CH2 5V

CH4 5V

M400ms 625s/s

A CH4

2.4V

1.6ms/pt

200ms/DIV

Figure 39. Alarm Condition Entering Self-Test, Part Passes Self-Test

08911-139

TESTI

4

08911-050

3

Figure 42. Cell Voltage Change to Trip Alarm, Deglitch Time = 800 ms

TESTI

4

OV

5V/DIV

5V/DIV

1

OV

1

CELL

2

ALARM

TRIPPED

UV

OT

3

1sec/DIV

4µs/DIV

Figure 40. Alarm Condition Entering Self-Test, Part Passes Self-Test

(Enlarged)

Figure 43. Cell Voltage Change to Trip Alarm, Deglitch Time = 3.2 sec

1

ENBI

OV

5V/DIV

2

REF

3

TESTI

08911-028

4

1ms/DIV

08911-140

08911-143

2

Figure 41. Start-Up Time

Rev. D | Page 14 of 24

Data Sheet

AD8280

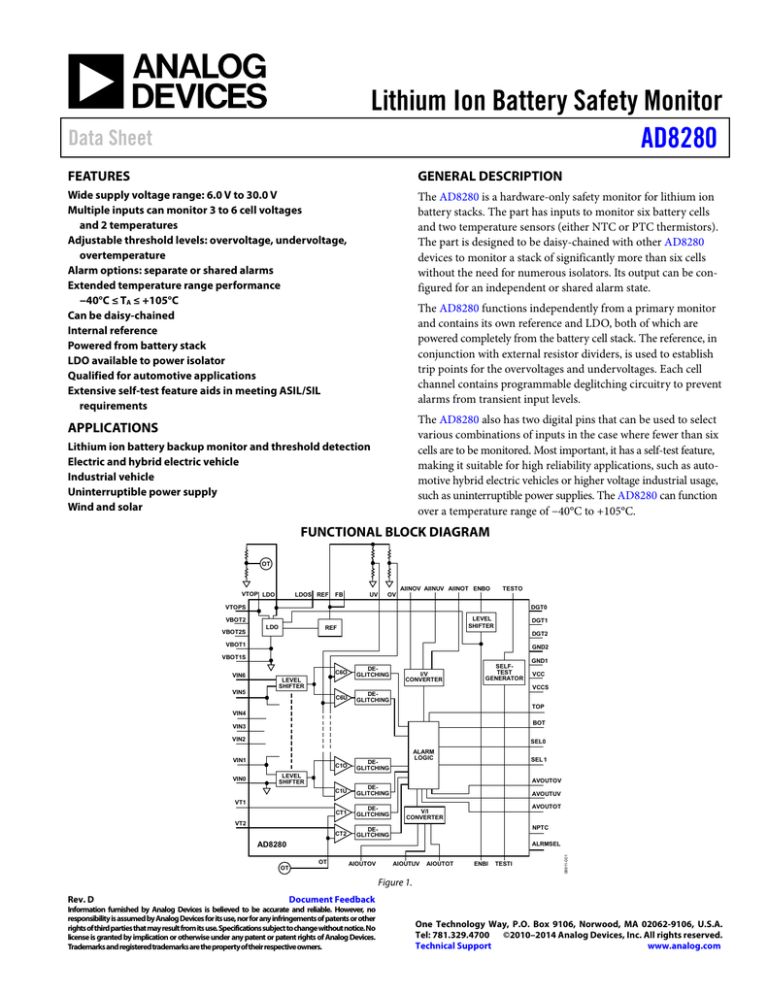

THEORY OF OPERATION

Figure 44 shows a block diagram of the AD8280. The AD8280

is a threshold monitor that can be used to monitor up to six cell

voltages and two temperature voltages. The part can also be used

in a daisy-chain configuration to monitor as many cells as required.

The benefit of the daisy-chain configuration is that isolation is

required to bring the alarm signal away from the high voltage

environment on only the bottom part of the chain, reducing

system cost and minimizing the board space required.

The part also contains its own LDO and reference. The LDO

can be used to drive external components such as thermistors

or isolators, whereas the reference can be used with the voltage

dividers to establish the trip points.

The cell and temperature voltage inputs are connected to the part

using the VIN0 through VIN6 inputs and the VT1 and VT2 inputs,

respectively. Because the six-cell stack voltage can be up to 30 V,

the input voltages are level-shifted and referenced to the lowest

potential (part ground or VBOTx) of the AD8280. These voltages

are then input into window comparators and compared to trip

points set by external resistor dividers.

The AD8280 has the following unique features and capabilities:

Three, four, five, or six cells can be monitored.

Negative or positive temperature coefficient thermistors

can be used.

Multiple parts can be configured in a daisy chain to monitor

hundreds of cells. Information about the status of the alarms

on the entire daisy chain, as well as input signals that enable

the part and initiate self-test, are all communicated via the

bottom, or master, part in the chain.

Alarm outputs for overvoltage, undervoltage, and overtemperature status can be shared, with each output indicating

the same status for any of the occurring alarm conditions,

or the alarm outputs can function as separate entities with

each indicating the status of the specific condition.

An extensive self-test feature ensures that the internal

components are functioning correctly. The self-test is

initiated upon request to the TESTI pin.

If the cell or temperature voltage inputs exceed or fall below the

selected trip points, an alarm, in the form of a digital voltage level,

changes state at the voltage output (AVOUTxx) of the part. The

alarm state also exists in the form of a current output (AIOUTxx)

used to communicate to the other devices when multiple parts

are used in a daisy-chain configuration.

The part contains programmable deglitching circuitry to ensure

that transient voltages appearing at the cell inputs are ignored.

OT

LDOS REF

VTOP LDO

FB

UV

OV

AIINOV AIINUV AIINOT ENBO

TESTO

DGT0

VTOPS

LEVEL

SHIFTER

VBOT2

VBOT2S

LDO

REF

DGT1

DGT2

VBOT1

GND2

VBOT1S

VIN6

VIN5

C6O

DEGLITCHING

C6U

DEGLITCHING

LEVEL

SHIFTER

I/V

CONVERTER

SELFTEST

GENERATOR

GND1

VCC

VCCS

TOP

VIN4

BOT

VIN3

VIN2

SEL0

VIN1

DEGLITCHING

C1U

DEGLITCHING

CT1

DEGLITCHING

CT2

DEGLITCHING

LEVEL

SHIFTER

SEL 1

AVOUTOV

VT1

VT2

AVOUTUV

AVOUTOT

V/I

CONVERTER

NPTC

AD8280

OT

ALRMSEL

OT

AIOUTOV

AIOUTUV

AIOUTOT

Figure 44. Functional Block Diagram

Rev. D | Page 15 of 24

ENBI

TESTI

08911-039

VIN0

C1O

ALARM

LOGIC

AD8280

Data Sheet

APPLICATIONS INFORMATION

TYPICAL CONNECTIONS

TEMPERATURE INPUTS AND THERMISTOR

SELECTION

Figure 45 is a block diagram of the AD8280 typical connections.

VT1 and VT2 are voltage inputs and are designed to work with

thermistors that are configured as resistor dividers, as shown

in Figure 45. The voltage at the top of the thermistor divider

should be the +5 V output of the LDO. The LDO pin can source

more current than the REF pin and is better suited to drive the

thermistor dividers.

CELL INPUTS

The battery stack of six cells should be connected to VIN0 through

VIN6, with the highest potential connected to VIN6 and the lowest

to VIN0. The connections should be made through a low-pass filter

consisting of a 10 kΩ resistor and a 10 nF capacitor, as shown in

Figure 45. The lowest potential of the six-cell stack should also be

connected to VBOT1, VBOT1S, VBOT2, and VBOT2S as well,

whereas the highest potential should be connected through a

diode to VTOP and VTOPS. It is recommended that decoupling

capacitors of 0.1 μF and 10 μF be used at the VTOP pin.

If a voltage source other than that of the AD8280 LDO is used

to drive the thermistor bridge (VTH), it is important that the

VT1 and VT2 voltages be brought to 0 V when the AD8280 is

disabled or powered down because the VT1 and VT2 inputs

must be at 0 V when the LDO is also at 0 V.

100nF

Z1

10µF

0.1µF

PART

GROUND

VTOP VTOPS AIINOV

AIINUV

AIINOT ENBO TESTO UV OV OT

FB

REF

VCC

VCCS

0.1µF

10kΩ 10nF

+

+

+

+

+

+

LDO

AVOUTOV

LDOS

AVOUTUV

UV

REF

OV

REF

OT

REF

2.2µF

AVOUTOT

VIN6

VIN5

0.1µF

VIN4

VIN3

AD8280

TOP

BOT

VIN2

ALRMSEL

VIN1

DGT2

VIN0

DGT1

VT1

VT2

DGT0

VBOT2S

NPTC

VBOT2

SEL0

VBOT1S

SEL1

VBOT1

AIOUTOV AIOUTUV AIOUTOT ENBI

TESTI GND1 GND2

22pF

PART

GROUND

08911-040

NOTES

1. PART IS CONFIGURED AS FOLLOWS:

MIDDLE PART IN DAISY CHAIN

ALARMS ARE SHARED

DEGLITCH TIME SET TO 0.0 SECONDS

NTC THERMISTOR INPUTS

6 CELL INPUTS

Figure 45. Typical Connections of the AD8280

Rev. D | Page 16 of 24

Data Sheet

AD8280

Also, if the resistor (RTOP) used in the top of the thermistor

bridge circuit is less than 10 kΩ, another resistor (RIN) must be

added in series to the input to the VTx pin (see Figure 46). The

two resistors together must be greater than 10 kΩ (RTOP + RIN >

10 kΩ). This configuration is required only if VTH is not the

AD8280 LDO.

+

VIN5

+

VIN4

+

VIN3

+

VIN2

VTH

VIN1

VIN0

RIN

AD8280

VTx

THERMISTOR

08911-042

RTOP

VIN6

Figure 48. Four-Cell Connections for the AD8280

08911-047

AD8280

VIN6

Figure 46. Input Configuration for VTx When Not Using the LDO for VTH

VIN5

The part can work with both negative temperature coefficient

(NTC) and positive temperature coefficient (PTC) thermistors.

For NTC, the NPTC pin should be tied to logic low (VBOTx

pin); for PTC, the NPTC pin should be tied to logic high (LDO

pin). If the part is set to NTC mode, the OT alarm is tripped

when the voltages at VT1 and VT2 drop below the trip point.

If the part is set to PTC mode, the OT alarm is tripped when

the voltages at VT1 and VT2 rise above the trip point.

NUMBER OF CELLS SELECTION

The part can be configured to work with three, four, five, or six

cells. Table 5 describes how to program the SEL0 and SEL1 pins

to determine the number of cells being monitored. A logic low

represents VBOTx, and a logic high represents the LDO output

voltage. Figure 47 through Figure 49 show how to connect the

cells to the part in a five-cell, four-cell, or three-cell application.

Table 5. SELx Pin Programming

Number of Cells Used

6 cells

5 cells (VIN5 shorted)

4 cells (VIN4 and VIN5 shorted)

3 cells (VIN3, VIN4, and VIN5 shorted)

+

+

SEL0

0

0

1

1

SEL1

0

1

0

1

VIN6

VIN5

VIN4

VIN3

+

VIN2

AD8280

08911-041

VIN1

VIN0

+

VIN3

VIN2

+

AD8280

08911-043

VIN1

VIN0

Figure 49. Three-Cell Connections for the AD8280

THRESHOLD INPUTS

The thresholds (or trip points) are set externally with a voltage

divider providing maximum flexibility. The desired trip point

voltage is connected to the following pins: OV (overvoltage trip

point), UV (undervoltage trip point), and OT (overtemperature

trip point). The +5 V output of either the reference (REF) or the

LDO can be used as the top voltage of the divider. However,

because the reference output is more accurate than the LDO output, the reference output is better suited to power the trip point

setting dividers. If the thermistor dividers used for temperature

sensing are driven from the LDO output, it is recommended that

the LDO be used to drive the OT trip point divider as well for

better temperature drift performance.

Decoupling capacitors (0.1 µF) should be used with the bottom

leg of each divider in addition to a 2.2 µF capacitor at the REF

output, as shown in Figure 45.

+

+

VIN4

+

The REF pin should be loaded with no more than 25 kΩ of

resistance. Therefore, when using REF to drive three voltage

dividers (OV, UV, and OT), it is recommended that the resistance of each divider total at least 75 kΩ. If driving only two

dividers (OV and UV) with the reference, each divider should

total no less than 50 kΩ.

Figure 47. Five-Cell Connections for the AD8280

Rev. D | Page 17 of 24

AD8280

Data Sheet

TOP AND BOTTOM PART DESIGNATION

When configured in a daisy chain, the AD8280 operates differently, depending on where it is in the chain: top part (highest

potential), middle part, or bottom part (lowest potential). The

TOP and BOT pins are used to designate the location of each

part in the daisy chain. Table 6 is the logic table for identifying

the location of the part in the daisy chain or, when not used in

a daisy chain, identifying it as a single (standalone) part.

The logic high and logic low for the TOP and BOT pins are

different from those of the other logic pins of the AD8280.

The TOP and BOT pins are referenced to VTOP (logic high)

and VBOTx (logic low), respectively.

Table 6. Designation of the AD8280 in Daisy-Chain and

Standalone Configurations

Desired Condition

Middle part (middle potential part)

Bottom part (lowest potential part)

Top part (highest potential part)

Single part (highest and lowest potential part)

1

TOP1

0

0

1

1

BOT1

0

1

0

1

For the TOP and BOT pins only, Logic 1 is VTOP and Logic 0 is VBOTx.

Bottom Part in Daisy-Chain Configuration

The bottom part in a daisy-chain configuration is the master

part and accepts voltage inputs into the ENBI and TESTI pins.

The AIINOV, AIINUV, and AIINOT pins of the bottom part

are connected to the AIOUTOV, AIOUTUV, and AIOUTOT

pins, respectively, of the next higher potential part in the daisy

chain. The AIOUTOV, AIOUTUV, and AIOUTOT pins of the

bottom part can be left floating, or they can be tied to part

ground (VBOTx).

Middle Part in Daisy-Chain Configuration

When the AD8280 is designated as a middle part, the AIINOV,

AIINUV, AIINOT, ENBO, and TESTO pins are connected to

the AIOUTOV, AIOUTUV, AIOUTOT, ENBI, and TESTI pins,

respectively, of the AD8280 above it.

Top Part in Daisy-Chain Configuration

When the AD8280 is designated as a top part, the AIINOV,

AIINUV, AIINOT, ENBO, and TESTO pins can be left floating,

or they can be tied to VTOP.

Standalone Part

When the AD8280 is designated as a single part (used as a standalone part), the AIOUTOV, AIOUTUV, and AIOUTOT pins

can be left floating, or they can be tied to part ground (VBOTx).

The AIINOV, AIINUV, AIINOT, ENBO, and TESTO pins can

be left floating or tied to VTOP. The AD8280 accepts voltage

inputs into the ENBI and TESTI pins.

Alarm Signals in Daisy-Chain Configuration

Regardless of the part designation, the alarm signals are

available as voltage outputs on any part in the chain on the

AVOUTOV, AVOUTUV, and AVOUTOT pins. These signals

indicate the status of the part where the voltage alarms are

monitored, as well as the status of the parts above it in the daisy

chain. Make sure to use isolators to bring those signals outside

the high voltage battery environment.

TYPICAL DAISY-CHAIN CONNECTIONS

Figure 50 shows the typical connections for configuring the part

in a daisy chain.

SHARED OR SEPARATE ALARMS

The AD8280 can be configured for three separate alarms or for

one shared alarm. Tying the ALRMSEL pin to a 5 V logic high

forces the part into separate alarm mode. In this mode, each

alarm trips only for its designated monitoring function. That is,

the OV alarm trips only if an overvoltage condition exists at any

of the cell inputs, the UV alarm trips only if an undervoltage

condition exists at any of the cell inputs, and the OT alarm trips

only if an overtemperature condition exists at either of the

temperature inputs.

In shared alarm mode, any of the three conditions—overvoltage,

undervoltage, or overtemperature—trips the alarm on all three

signal chains. In shared mode, it is necessary to monitor only

one alarm because all three contain the same signal.

DEGLITCHING OPTIONS

The deglitching circuitry is available so that the part is immune

to transients occurring at the cell inputs. If a transient voltage of

a high or low enough level to trip an alarm occurs at the input

to the part, the alarm state does not occur if the transient

voltage is present for less than the selected deglitch time.

The DGT0, DGT1, and DGT2 pins are used to establish the

deglitch time. Table 7 shows the options available and the

corresponding logic levels to use when setting the deglitch

time with the DGT0, DGT1, and DGT2 pins.

Table 7. Fault Detection Time Pin Programming

Deglitch Time

0.0 sec

0.1 sec

0.8 sec

1.6 sec

3.2 sec

6.4 sec

12.8 sec

DGT0

0

0

0

0

1

1

1

DGT1

0

0

1

1

0

0

1

DGT2

0

1

0

1

0

1

0

Do not tie all three deglitching pins (DGT0, DGT1, and DGT2)

to logic high (111); this setting is used only during the testing of

the part at the factory.

Setting the deglitch time to 0.0 sec (000) allows the use of an

external deglitching circuit, if desired. Additionally, when the

deglitch time is set to 0.0 sec, the time required to ensure that

the part has completed its self-test is significantly reduced (see

the Self-Test section). The DGTx pins should be tied to a fixed

logic level and not toggled or changed during operation of the

AD8280.

Rev. D | Page 18 of 24

Data Sheet

AD8280

100nF

10µF 0.1µF

T1/T2

VTOPx UV OV OT TESTO AIINxx ENBO

T1

NTC

T2

10kΩ

10nF

+

VIN6

+

VIN5

+

VIN4

+

VIN3

+

VIN2

SEL1

VIN1

BOT

VIN0

TOP

+

1.0µF

VCCx

LDOx

UV

REF

REF/FB

10kΩ

DGT0

OV

REF

OT

REF

2.2µF

DGT1

AD8280

SEL0

100nF

ALRMSEL/

AVOUTxx

VT1

DGT2/

VT2 VBOTx NPTC TESTI AIOUTxx ENBI GNDx

22pF

VTOPx UV OV OT TESTO AIINxx ENBO

T3

+

VIN6

+

VIN5

+

VIN4

+

+

T4

+

VIN3

T3/T4

VCCx

LDOx

UV

REF

REF/FB

OV

REF

OT

REF

DGT0

DGT1

AD8280

SEL0

VIN2

SEL1

VIN1

BOT

VIN0

VT1

TOP

ALRMSEL/

AVOUTxx

DGT2/

VT2 VBOTx NPTC TESTI AIOUTxx ENBI GNDx

VTOPx UV OV OT TESTO AIINxx ENBO

T5

+

VIN6

+

VIN5

+

VIN4

T6

+

+

VIN3

REF/FB

DGT0

UV

OV

OT

REF

REF

REF

DGT1

AD8280

SEL0

VIN2

SEL1

VIN1

BOT

TOP

ALRMSEL/

AVOUTxx

DGT2/

VT2 VBOTx NPTC TESTI AIOUTxx ENBI GNDx

VIN0

VT1

VOUT

ENBI

TEST

Figure 50. Typical Daisy-Chain Connections

Rev. D | Page 19 of 24

08911-044

+

T5/T6

VCCx

LDOx

AD8280

Data Sheet

ENABLING AND DISABLING THE AD8280

The AD8280 can be disabled or put into a standby mode by

bringing the ENBI pin to logic low, lowering the quiescent

current of the AD8280 from a maximum of 2.0 mA to 1.0 µA

and dropping the LDO and reference output to 0 V. Bringing

the ENBI pin to a logic high takes the part out of standby mode

and enables it.

When the AD8280 is used in a daisy-chain configuration, the

enable/disable signal is a voltage logic level that is sent to the

part designated as the bottom part (the bottom part monitors

the lowest voltage cells). The bottom part transfers the enable/

disable signal up the daisy chain via a current out of the ENBO

pin and into the ENBI pin of the next higher part in the daisy

chain. All the parts in the daisy chain are enabled by sending a

logic high to the ENBI pin of the bottom, or master, part. All

the parts in the daisy chain are disabled by sending a logic low

to the ENBI pin of the bottom part.

ALARM OUTPUT

The alarm status of the AD8280 appears as a voltage logic level

at the AVOUTOV, AVOUTUV, and AVOUTOT pins. When the

AD8280 is in a daisy-chain configuration, the alarm status is

passed from the AIOUTxx pins of one part to the AIINxx pins

of the next lower potential part in the daisy chain. Figure 51

shows the output state when the part is in an unalarmed (logic

low) or alarmed (logic high) state.

If the AD8280 is configured for the shared alarm mode, the status

of all three voltage output pins (AVOUTxx) is the same. In shared

alarm mode, the unused pins can be left floating, they can be tied

to ground through a high resistance to limit the current draw,

or they can be tied together.

SELF-TEST

The AD8280 has the unique capability of extensively testing

its internal components to ensure that they are functioning

correctly. This feature is very important to the designer who is

concerned with meeting the difficult safety integrity level guidelines of IEC 61508 or ISO 26262.

The part produces internal fault conditions and compares the

results to what is expected. The status of the alarm signals is

interrupted during the self-test, and the pass/fail status of the

self-test is communicated via the alarm status signal pins

(AVOUTxx and AIOUTxx).

Because the AD8280 uses an internal reference to perform its

self-test, the self-test detects open circuits and short circuits at

the threshold pins, as well.

See Figure 51 for a timing diagram and Figure 52 for timing

definitions related to the self-test feature.

To initiate a self-test, the TESTI pin is prompted with a rising

edge from a 5 V logic level pulse (test pulse). The pulse applied

at TESTI must stay high for a minimum time (tST min). Following the rising edge of the pulse to initiate the self-test, the alarm

status for any AVOUTxx or AIOUTxx pin goes into a logic high

status while the part performs its internal self-test. After sufficient

time to perform the test has elapsed and assuming that the part

passes self-test, the alarm status reverts to the unalarmed state,

a logic low. If the part fails self-test, the alarm remains in a logic

high state when the falling edge of the test pulse applied at

TESTI occurs.

The minimum tST is dependent on the status of the DGTx pins.

If all three DGTx pins are tied to a logic low, the self-test ignores

the deglitch function of the part and completes the self-test in a

shorter time (50 ms max). When at least one DGTx pin is set to

logic high, the AD8280 defaults to the minimum deglitch time of

100 ms during the self-test. Because the self-test includes multiple

layers and passes, this minimum time is specified as 700 ms.

Therefore, if a faster self-test is required, the user should set the

internal deglitch time to 0.0 sec and use an external deglitch

circuit if deglitch is required.

Self-Test in Daisy-Chain Configuration

The self-test can also be used when multiple AD8280 parts

are configured in a daisy chain. The test pulse is applied to the

TESTI pin of the bottom part as a voltage and then travels up

the chain as a current. The self-test for each part is started as

soon as the part sees the rising edge of the test pulse, virtually

simultaneously. When the highest part in the chain passes its

self-test, it sends that information to the next lower part in the

daisy chain. Even if that part has already completed its self-test,

it cannot pass its own result on to the next part in the daisy

chain until it receives the pass signal from the part above it.

This process continues with each part lower down the chain.

Therefore, when a pass signal appears at the bottom part in the

daisy chain, it indicates that every part in the daisy chain passed

the self-test. If any part in the chain fails the self-test, the part

below the failing part never receives a pass signal, and, subsequently, the bottom part never receives a pass signal either.

Therefore, regardless of whether the bottom part passes self-test,

the AVOUTxx signals at the bottom part never change state from

the logic high that occurred when the self-test was initiated, and

the user will know that there is a failed part in the chain.

Rev. D | Page 20 of 24

Data Sheet

AD8280

NORMAL OPERATION

UNALARMED

AIOUTxx/AVOUTxx

ALARMED

AIOUTxx/AVOUTxx

DURING SELF-TEST MODE

TESTI

AIOUTxx/AVOUTxx

TEST OK

AIOUTxx/AVOUTxx

TEST FAILS

HIGH AT FALLING EDGE OF TESTI:

PART FAILS SELF-TEST

LOW AT FALLING EDGE OF TESTI:

PART PASSES SELF-TEST

08911-045

AIOUTxx/AVOUTxx

ALARMED

TEST OK

Figure 51. Timing Diagram for Alarms at AIOUTxx and AVOUTxx

Self-Test and Alarm Conditions

Self-Test Timing and Monitoring Strategy

If an alarm occurs just prior to or just after the self-test pulse is

initiated, the alarm causes the self-test to fail. The time span for

this condition depends on the deglitch time.

When monitoring the signals for self-test on the AD8280, note

the following items:

Deglitch time = 0.0 sec. The part fails self-test if an alarm

occurs in the time period from 20 ms before the leading

edge of the self-test pulse to 20 ms after the leading edge

of the self-test pulse.

Deglitch time > 0.0 sec. The part fails self-test if an alarm

occurs in the time period from 120 ms before the leading

edge of the self-test pulse to 120 ms after the leading edge

of the self-test pulse.

Therefore, in the unusual circumstance that the part fails selftest and there is an alarm condition state after the self-test, it

is recommended that the user retest the part to ensure that

an alarm did not occur just prior to or just after initiating the

self-test.

The self-test works when the part is in the shared alarm mode

or in the separate alarm mode. When the part is in the separate

alarm mode, the self-test status on an output pertains only to

that portion of the internal circuit relevant to the condition being

monitored: overvoltage, undervoltage, or overtemperature.

Rev. D | Page 21 of 24

After initiating a self-test of the AD8280 with a rising edge

on the TESTI pin, the alarm appearing at the AVOUTxx

pin remains valid up to tRE max.

When the rising edge of the TESTI pulse occurs, the user

should monitor the AVOUTxx pin to make sure that it is

in the high state after the tRE max time has elapsed.

After the tST max time has elapsed, the user can verify that

the AVOUTxx pin has changed to the low state, indicating

that the part or parts passed the self-test. The user must

also ensure that the minimum length of the TESTI pulse

is greater than tST max. The status of the self-test on the

AVOUTxx pin is valid until tSTV min after the trailing edge

of the TESTI pulse.

The alarm state is valid again tFE max after the trailing edge

of the pulse.

AD8280

Data Sheet

NO ALARM WHEN SELF-TEST IS INITIATED

1

TESTI

0

1

AVOUTxx

SELF-TEST PASS

0

tSTV

1

AVOUTxx

SELF-TEST FAIL

0

tFE

tRE

tST

ALARM WHEN SELF-TEST IS INITIATED

1

TESTI

0

1

AVOUTxx

SELF-TEST PASS

0

tSTV

1

AVOUTxx

SELF-TEST FAIL

tRE

0

tST

NOTES

1. tRE IS THE TIME FROM THE RISING EDGE OF THE TEST PULSE (TESTI) TO THE START OF THE SELF-TEST.

2. tST IS THE TIME FROM THE RISING EDGE OF THE TEST PULSE UNTIL THE PART COMPLETES ITS SELF-TEST (TEST PULSE MUST BE

LONGER THAN tST MAX).

3. tSTV IS THE TIME FROM THE FALLING EDGE OF THE TEST PULSE THAT THE SELF-TEST INDICATION REMAINS VALID (LOW = PASS, HIGH = FAIL).

4. tFE IS THE TIME FROM THE FALLING EDGE OF THE TEST PULSE UNTIL THE SELF-TEST DATA IS CLEARED AND THE ALARM DATA IS AGAIN VALID.

Figure 52. Timing Definitions

Rev. D | Page 22 of 24

08911-046

tFE

Data Sheet

AD8280

Sample Calculation

PROTECTION COMPONENTS AND PULL-UP/

PULL-DOWN RESISTORS

As shown in Figure 45, several devices are added to provide

protection in a high voltage environment. Zener Diode Z1

ensures that the six-cell stack voltage does not significantly

exceed the maximum 30 V across the part. It is recommended

that a 33 V rated Zener diode be used for Z1.

The user can also use diodes in the daisy-chain lines (anode to

cathode from higher potential to lower potential) to protect the

parts in the event that an open circuit appears on the battery

connections, causing a high reverse voltage across the AD8280

(these diodes are not shown in Figure 45). The diodes should

have a reverse voltage rating comparable to the highest voltage

of the battery system.

If diodes are used in the daisy chain, it is also recommended that

a diode be used between the top cell in the stack (anode) and

VTOP (cathode) of the top part, as well as between VBOTx

(anode) of each part and VTOP (cathode) of the next lowest

potential part in the daisy chain.

Because there are no pull-up or pull-down resistors internal to

the part, the user may want to pull down the TESTI pin of the

bottom part through a 10 kΩ resistor to VBOTx (part ground).

The addition of this resistor ensures that the part is not locked

in self-test mode if the line opens. Also, the user may want to pull

up the ENBI pin on the bottom part of a daisy chain so that if the

line opens, the chain stays in the enabled (powered up) mode.

EMI CONSIDERATIONS

To increase immunity to electromagnetic interference (EMI), use

the following components and layout schemes (see Figure 50).

Use a 22 pF capacitor on each of the daisy-chain lines.

Route the daisy-chain lines on an inner PCB layer.

Use ground planes (connected to VBOTx from the higher

potential part) both over and under the daisy-chain lines to

shield them.

Route the connections from VBOTx to VTOP to best

ensure a low impedance connection between them.

Use ferrite beads on the VTOP lines as shown in Figure 50.

Use 100 nF capacitors across each of the six-cell battery stacks.

Place the AD8280 parts as close together as possible on the

board to minimize the length of the daisy-chain lines.

SYSTEM ACCURACY CALCULATION

When calculating system accuracy, there are four error sources

to consider:

Trip point error (see Table 1)

Reference voltage error (see Table 1)

Resistor tolerance

Resistor temperature coefficient

Following is a sample calculation for overvoltage accuracy. In

this calculation, the following conditions are assumed:

Resistors used in the external resistor divider to set the trip

points are ±1%, 100 ppm/°C resistors.

Temperature range is −40°C to +85°C.

Desired overvoltage trip point is 4.0 V (resistor values

selected should be 15 kΩ and 60 kΩ).

The resulting sources of error are described in this section.

Maximum Trip Point Error

The maximum trip point error is ±15 mV.

Maximum Reference Error

The maximum reference error is as follows:

(60/(60 + 15)) × ±50 mV = ±40 mV

Maximum Resistor Tolerance Error

The maximum resistor tolerance error depends on the values

of the resistors. If one resistor is high and the other is low, the

worst-case error is as follows:

(60.6/(60.6 + 14.85)) × 5.00 V = 4.016 V (error of +16 mV)

(59.4/(59.4 + 15.15)) × 5.00 V = 3.984 V (error of −16 mV)

In this sample calculation, the maximum resistor tolerance

error is ±16 mV.

Maximum Temperature Coefficient Error

If one resistor drifts high and the other resistor drifts low, the

worst-case error is as follows:

60 kΩ + (100 ppm/°C × (25°C − (−40°C)) × 60 kΩ) = 60.39 kΩ

15 kΩ − (100 ppm/°C × (25°C − (−40°C)) × 15 kΩ) = 14.9 kΩ

(60.39/(60.39 + 14.90)) × 5.00 V = 4.010 V (error of +10 mV)

or

60 kΩ − (100 ppm/°C × (25°C − (−40°C)) × 60 kΩ) = 59.61 kΩ

15 kΩ + (100 ppm/°C × (25°C − (−40°C)) × 15 kΩ) = 15.1 kΩ

(59.61/(59.61 + 15.10)) × 5.00 V = 3.990 V (error of −10 mV)

In this sample calculation, the maximum temperature coefficient

error is ±10 mV.

Total System Accuracy

The system accuracy, or the sum of all the errors, is ±81 mV. If

the resistor pair coefficients are matched so that drift is in the

same direction, that portion of the error can be ignored, and the

total system accuracy would be ±71 mV.

Rev. D | Page 23 of 24

AD8280

Data Sheet

OUTLINE DIMENSIONS

0.75

0.60

0.45

9.20

9.00 SQ

8.80

1.60

MAX

37

48

36

1

PIN 1

7.20

7.00 SQ

6.80

TOP VIEW

0.15

0.05

SEATING

PLANE

0.20

0.09

7°

3.5°

0°

0.08

COPLANARITY

(PINS DOWN)

25

12

13

VIEW A

0.50

BSC

LEAD PITCH

VIEW A

24

0.27

0.22

0.17

ROTATED 90° CCW

COMPLIANT TO JEDEC STANDARDS MS-026-BBC

051706-A

1.45

1.40

1.35

Figure 53. 48-Lead Low Profile Quad Flat Package [LQFP]

(ST-48)

Dimensions shown in millimeters

ORDERING GUIDE

Model 1, 2

AD8280WASTZ

AD8280WASTZ-RL

AD8280-EVALZ

1

2

Temperature Range

−40°C to +105°C

−40°C to +105°C

Package Description

48-Lead Low Profile Quad Flat Package [LQFP]

48-Lead Low Profile Quad Flat Package [LQFP]

Evaluation Board with Two AD8280WASTZ Devices

Package Option

ST-48

ST-48

Z = RoHS Compliant Part.

W = Qualified for Automotive Applications.

AUTOMOTIVE PRODUCTS

The AD8280W models are available with controlled manufacturing to support the quality and reliability requirements of automotive

applications. Note that these automotive models may have specifications that differ from the commercial models; therefore, designers

should review the Specifications section of this data sheet carefully. Only the automotive grade products shown are available for use in

automotive applications. Contact your local Analog Devices account representative for specific product ordering information and to

obtain the specific Automotive Reliability reports for these models.

©2010–2014 Analog Devices, Inc. All rights reserved. Trademarks and

registered trademarks are the property of their respective owners.

D08911-0-8/14(D)

Rev. D | Page 24 of 24