Optimized Behavioral Interventions: What Does Control Systems Engineering Have to Offer?

advertisement

Optimized Behavioral Interventions:

What Does Control Systems Engineering

Have to Offer?

Daniel E. Rivera

Control Systems Engineering Laboratory

School for Engineering of Matter, Transport, and Energy (SEMTE)

Ira A. Fulton Schools of Engineering

Arizona State University

http://csel.asu.edu

daniel.rivera@asu.edu

CSEL

Joint Prevention and Methodology Seminar

Penn State University

October 6, 2010

CSEL

About this talk

Control Systems Engineering Laboratory

Control Systems Engineering Laboratory

•

Goal is to discuss how control systems engineering can

inform the design and implementation of time-varying

adaptive behavioral interventions.

•

Talk will have some tutorial flavor, but will not be a

comprehensive survey.

•

Emphasis will be given to the connections between behavioral

health, methodology, and engineering, and the opportunities

(and challenges) that these present to the behavioral

scientist, the methodologist, and the engineer.

2

CSEL

Control Systems Engineering Laboratory

Outline

•

What is meant by control systems engineering?

•

How can these concepts improve behavioral interventions?

- Hypothetical time-varying adaptive intervention (inspired by

the Fast Track program) as a control system problem.

- Description and application of Model Predictive Control.

•

Relating theory to control engineering modeling:

Theory of Planned Behavior in a weight loss intervention.

•

Summary and conclusions; looking to the future.

3

CSEL

Control Systems Engineering Laboratory

Current Projects in Behavioral Health

•

K25DA021173*, “Control engineering approaches to adaptive

interventions for fighting drug abuse,” Mentors: L.M. Collins

(Penn State) and S.A. Murphy (Michigan).

•

R21DA024266*, “Dynamical systems and related engineering

approaches to improving behavioral interventions,” NIH

Roadmap Initiative Award on Facilitating Interdisciplinary Research Via

Methodological and Technological Innovation in the Behavioral and

Social Sciences, with L.M. Collins, Penn State, co-PI.

*Funding received from NIDA (National Institute on Drug Abuse) and OBSSR

(Office of Behavioral and Social Sciences Research) is gratefully acknowledged.

4

CSEL

Control Systems Engineering Laboratory

Our Logo (in more detail)...

http://csel.asu.edu/health

5

CSEL

Control Systems Engineering Laboratory

•

Similarities Between Behavioral

Scientists and Control Engineers

Behavioral scientists are interested in developing and delivering

effective interventions that:

- demonstrate high levels of adherence.

- display uniformity and reproducibility despite heterogeneity of

the target population, and inherent variability associated with

delivery of the intervention,

- are cost-effective in nature.

All these goals are compatible with the objectives of

control systems engineering...

6

CSEL

Control Systems Engineering Laboratory

Control Systems Engineering

•

The field that relies on dynamical models to develop algorithms

for adjusting system variables so that their behavior over time is

transformed from undesirable to desirable.

•

Control engineering plays an important part in many everyday life

activities. Some examples of control systems engineering

applications include:

-

Cruise control and climate control in automobiles,

-

The “sensor reheat” feature in microwave ovens,

-

Home heating and cooling,

-

The insulin pump for Type-I diabetics,

-

“Fly-by-wire” systems in high-performance aircraft,

-

Homeostasis,

-

Many, many, more...

7

CSEL

Control Systems Engineering Laboratory

Control Systems Engineering

(Continued)

Control systems engineers strive to improve system operation by

“closing the loop”:

•

Open-loop: refers to system behavior without a controller or

decision rules (i.e., MANUAL operation).

•

Closed-loop: refers to system behavior once a controller or

decision rule is implemented (i.e., AUTOmatic operation).

A well-tuned control system will effectively transfer variability from

an expensive system resource to a less expensive one.

8

From Open-Loop Operation to

Closed-Loop Control (Stochastic Viewpoint)

Controlled

Variable Deviation

(e.g., Temperature)

Open-Loop

(Before Control)

Closed-Loop

Control

Manipulated

Variable Deviation

(e.g., Flowrate)

The transfer of variance from an expensive resource to a cheaper one is one of

the major benefits of control systems engineering

CSEL

9

Control Systems Engineering Laboratory

Control Engineering Concepts Are Not New to

Psychology...

• Carver C.S. and M.F. Scheier. On the self-regulation of behavior. New York:

Cambridge University Press; 1998.

• Hyland, M.E., “Control theory interpretation of psychological mechanisms

of depression: comparison and integration of several theories,” Psychological

Bulletin, Vol. 102, No. 1, pgs. 109-121, 1987.

• Molenaar, P.C.M., “Dynamic assessment and adaptive optimization of the

psychotherapeutic process,” Behavioral Assessment, Vol. 9, pgs. 389-416, 1987.

• Molenaar, P.C.M., “Note on optimization of individual psychotherapeutic

processes,” Journal of Mathematical Psychology, Vol. 54, pgs. 208-213, 2010.

CSEL

Control Systems Engineering Laboratory

10

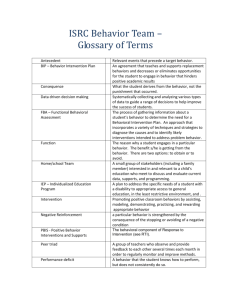

Basic Components of Adaptive Interventions

(Collins, Murphy, and Bierman, Prevention Science, 5, No. 3, 2004)

• The assignment of a particular dosage and/or type of treatment is

based on the individual’s values on variables that are expected to

moderate the effect of the treatment component; these are known

as tailoring variables.

• In a time-varying adaptive intervention, the tailoring variable is

assessed periodically, so the intervention is adjusted on an on-going

basis.

• Decision rules translate current and previous values of tailoring

variables into choice(s) of treatment and their appropriate dosage.

CSEL

Control Systems Engineering Laboratory

11

Adaptive Intervention Simulation

(inspired by the Fast Track Program, Conduct Problems Prevention Research Group)

•

A multi-year program designed to prevent conduct disorder in at-risk children.

•

Frequency of home-based counseling visits assigned quarterly to families over a

three-year period, based on an assessed level of parental functioning.

•

Parental function (the tailoring variable) is used to determine the frequency of

home visits (the intervention dosage) according to the following decision rules:

- If parental function is “very poor” then the intervention dosage should correspond to

-

weekly home visits,

If parental function is “poor” then the intervention dosage should correspond to

bi-weekly home visits,

If parental function is “below threshold” then the intervention dosage should correspond

to monthly home visits,

If parental function is “at threshold” then the intervention dosage should correspond to

no home visits.

CSEL

Control Systems Engineering Laboratory

12

Parental Function Feedback Loop Block Diagram*

(to decide on home visits for families with at-risk children)

(Open-Loop)

(Closed-Loop

System)

From Rivera, D.E., M.D. Pew, and L.M. Collins, “Using engineering control principles to inform the design

of adaptive interventions: a conceptual introduction,” Drug and Alcohol Dependence, Special Issue on

Adaptive Treatment Strategies, Vol. 88, Supplement 2, May 2007, Pages S31-S40.

CSEL

13

Control Systems Engineering Laboratory

Parental Function - Home Visits Adaptive Intervention as a

Production-Inventory Control System

(Rivera, Pew, and Collins, “Using engineering control principles to inform the design of adaptive interventions,”

Drug and Alcohol Dependence, Vol. 88, Suppl. 2, May 2007, Pages S31-S40)

Controller/

Decision

Rules

Intervention

Dosage

(Manipulated

Variable)

Parental Function Target

(Setpoint Signal)

r(t)

u(t)

θ

KI

( Delay Time) (Gain)

Exogenous

Depletion

Effects

(Disturbance

Variable)

Inflow

ym (t)

LT

Measured Parental

Function

(Feedback Signal)

Parental Function

(Controlled

Variable)

y(t)

d(t)

Outflow

y(t + 1) = y(t) + KI u(t − θ) − d(t)

Parental function y(t) is built up by providing an intervention u(t) (frequency of home visits), that is

potentially subject to delay, and is depleted by potentially multiple disturbances (adding up to d(t)).

CSEL

Control Systems Engineering Laboratory

14

E-.,+F,-.45-0G5<*9,<

)*+,-.*/012-3.45-0678

Parental Function - Counselor Home Visits Adaptive Intervention

Single Participant Family Illustration

0

#""

)*+,-.*/012-3.45)*+,-.*/012-3.45-095*/

("

"

0

!!

"

!

"

!

#$

#%

$&

'"

'!

$&

'"

'!

A,,B/?

@4!A,,B/?

=5-.>/?

:50;4<4.

!!

#$

#%

C4D,06D5-.>8

• The assigned dosage (frequency of counseling visits) decreases as the tailoring

variable (parental function) increases, as prescribed by the decision rules.

CSEL

15

Control Systems Engineering Laboratory

Simple “IF-THEN” Rules May Not Be Optimal

456,1)57-891:)*01-.;3

High Depletion (d(t) = 5)

-

#""

456,1)57-891:)*01

456,1)57-891:)*01-F057

("

"!!

"

!

#$

#%

)*+,-./01)23

$&

'"

'!

C1),6D,1)*01-E0>5F,>

C1),6D,1)*01-E0>5F,>

456,1)57-891:)*01-.;3

No Depletion (d(t) = 0)

A,,B7?

@*!A,,B7?

/01)27?

<0-=*>*)>

!!

"

!

#$

#%

)*+,-./01)23

$&

'"

'!

-

#""

456,1)57-891:)*01

456,1)57-891:)*01-F057

("

"!!

} offset!

"

!

#$

#%

)*+,-./01)23

$&

'"

'!

"

!

#$

#%

)*+,-./01)23

$&

'"

'!

A,,B7?

@*!A,,B7?

/01)27?

<0-=*>*)>

!!

Single participant family scenario. Offset (where parental function fails

to reach a desired goal at the end of the intervention) occurs when

high depletion (representing a large magnitude disturbance) is present.

CSEL

Control Systems Engineering Laboratory

16

Model Predictive Control (MPC)

• Control engineering technology widely used in many industrial applications

(from chemical mfg to automotive and aerospace).

• As an optimization technology, MPC can minimize (or maximize) an objective

function that represents a suitable metric of intervention performance.

• As a control system, MPC accomplishes feedback (and feedforward action)

in the presence of model error, measurement unreliability, and disturbances

that may affect the intervention.

• Three major steps in MPC:

– Prediction of intervention outcomes at time instants in the future (i.e.,

the prediction horizon) based on a model,

– Optimization of a sequence of future dosage decisions through

minimizing (or maximizing) an objective function,

– Receding horizon strategy.

CSEL

17

CSEL

Model Predictive Control

Conceptual Representation

Control Systems Engineering Laboratory

Future

Prior

Tailoring

Variable

Assessments

Tailoring Variable Goal

(Setpoint r(t+i))

Predicted

Tailoring

Variable

!(t+i)

Prediction Horizon

Prior

Depletion

Controlled

Variable

Past

Forecasted Depletion dF(t+i)

(if available)

Disturb.

Variable

Control Systems Engineering Laboratory

Umax

Manipulated

Variable

Prior

Dosages

Future Dosages u(t+i)

Umin

Move Horizon

t

min

∆u(t)...∆u(t+m−1)

t+1

t+m

t+p

Take Tailoring Variables to Goal Penalize Changes in the Intervention Dosages

!

"#

$

!

"#

$

p

m

%

%

2

Qe (i)(ŷ(t + i) − r(t + i)) +

Q∆u (i)(∆u(t + i − 1))2

J=

i=1

i=1

18

CSEL

Model Predictive Control

Flowchart

Control Systems Engineering Laboratory

Offline

Online

Supply a dynamical

model to the control

system.

Assess tailoring variables

(i.e., measure controlled

variables)

Compute an error projection utilizing the

model, previous measurements and

decisions, and disturbance forecasts

(if available).

Specify controller parameters

to meet desired performance

and robustness.

Solve a mixed-integer quadratic program

(MIQP) which calculates the optimal sequence

of future dosages that minimize the objective

function subject to constraints.

Implement the

first dosage decision

(i.e., move)

Wait until the

next review

period.

19

Controller/Decision Rule Comparison, Scenario 1

High Depletion Rate (d(t) = 5)

Model Predictive Control

(Qe = 1, Qdu = 0.05, p = 30, m = 10)

456,1)57-891:)*01-.;3

-

#""

456,1)57-891:)*01

456,1)57-891:)*01-F057

("

"!!

} offset!

"

!

#$

#%

)*+,-./01)23

$&

'"

'!

C1),6D,1)*01-E0>5F,>

C1),6D,1)*01-E0>5F,>

456,1)57-891:)*01-.;3

“IF-THEN” rules

A,,B7?

@*!A,,B7?

/01)27?

<0-=*>*)>

!!

"

!

#$

#%

)*+,-./01)23

$&

'"

-

#""

456,1)57-891:)*01

456,1)57-891:)*01-F057

("

"!!

"

!

#$

#%

)*+,-./01)23

$&

'"

'!

-

A,,B7?

@*!A,,B7?

'!

/01)27?

<0-=*>*)> !!

"

!

#$

#%

)*+,-./01)23

$&

'"

'!

36 month intervention reviewed at quarterly intervals. Offset problem is eliminated in the MPC

controller through judicious assignment of intervention dosages during the course of the intervention.

CSEL

Control Systems Engineering Laboratory

20

CSEL

IF-THEN vs. MPC Comparison

(Robustness Analysis)

Control Systems Engineering Laboratory

• The system response of five participant families, each characterized by its own dynamical

model, is evaluated using a controller tuned on the basis of an average (“nominal”) effect.

MPC Control

(Qe = 1, Qdu = 0.05, p = 30, m = 10)

#""

("

"

(

&

'

$

456)*7*851)-91:,;

#

!! "

!

4<-.=3

4<-.=3

“IF-THEN” Decision Rules

'!

$& '"

#$ #%

#""

("

"

(

&

)*+,-./01)23

'

$

D,,EAB

C*!D,,EAB

/01)2AB

>0-?*@*)@

(

&

'

456)*7*851)-91:,;

$

#

!! "

!

'!

$& '"

#$ #%

91),6F,1)*01

91),6F,1)*01

456)*7*851)-91:,;

D,,EAB

C*!D,,EAB

/01)2AB

>0-?*@*)@

(

&

)*+,-./01)23

'

$

456)*7*851)-91:,;

#

!! "

!

#

!! "

!

'!

$& '"

#$ #%

)*+,-./01)23

'!

$& '"

#$ #%

)*+,-./01)23

• The MPC controller individually assigns the proper intervention dosages to each

participant family, leading to no offset and more consistent outcomes. This is

achieved at the expense of greater variability in the intervention dosages.

21

Simulation Cases

• Scenario 1: Comparison with simple “IF-THEN” rules.

• Scenario 2: Constrained, augmented operation.

Total number of counseling visits constrained to an upper limit; group

counseling may be offered when in-home visit limit is reached.

– Scenario 2(a):

» Unlimited counseling visits, no group meeting available.

– Scenario 2(b) :

» Overall dosage limited to a maximum of 48 in-home counseling visits;

» no group meeting available.

– Scenario 2(c):

» Overall dosage limited to a maximum of 48 in-home counseling visits;

» Group counseling available when in-home visit limitation is reached.

CSEL

Control Systems Engineering Laboratory

22

Scenario 2(a)

()*+,-.)/012,304-5313*1

0

#""

)*+,-.*/012-3.45)*+,-.*/012-3.45-095*/

("

"0

!!

"

!

#$

#%

$&

'"

!"

&"

$"

"

'!

!!

A,,B/?

9:)/;-822*304

E52-<,/4-90F4<4.<

)*+,-.*/012-3.45-0678

(No limit on number of counseling visits; no group meeting offered)

@4!A,,B/?

=5-.>/?

:50;4<4.

"

!

#$

"

!

#$

#%

$&

'"

'!

#%

$&

'"

'!

721

6)

!!

"

!

#$

#%

$&

'"

'!

!!

C4D,

(382

• 69 total counseling visits required in this unconstrained

scenario to achieve the parental function goal without offset.

CSEL

23

Control Systems Engineering Laboratory

Scenario 2(b)

)*+,-.*/012-3.45)*+,-.*/012-3.45-095*/

("

"0

!!

"

!

#$

#%

$&

'"

()*+,-.)/012,304-5313*1

0

#""

&"

$"

"

!!

A,,B/?

@4!A,,B/?

=5-.>/?

:50;4<4.

!!

!"

'!

9:)/;-822*304

E52-<,/4-90F4<4.<

)*+,-.*/012-3.45-0678

(Counseling visits limited to 48 (total); no group meeting offered)

"

!

#$

"

!

#$

#%

$&

'"

'!

#%

$&

'"

'!

721

6)

"

!

#$

#%

$&

'"

'!

!!

C4D,

(382

• The dosage constraint places a fundamental limit on the effectiveness

of the intervention. The controller does “the best it can” (for the

given objective function parameters), within these restrictions.

CSEL

Control Systems Engineering Laboratory

24

Scenario 2(c)

)*+,-.*/012-3.45)*+,-.*/012-3.45-095*/

("

"0

!!

"

!

#$

#%

$&

'"

()*+,-.)/012,304-5313*1

0

#""

'!

A,,B/?

@4!A,,B/?

=5-.>/?

:50;4<4.

!!

!"

&"

$"

"

!!

9:)/;-822*304

E52-<,/4-90F4<4.<

)*+,-.*/012-3.45-0678

(Counseling visits limited to 48 (total); group meeting available)

"

!

#$

"

!

#$

#%

$&

'"

'!

#%

$&

'"

'!

721

6)

"

!

#$

#%

$&

'"

'!

!!

C4D,

(382

• MPC adapts the intervention to meet the outcome goal,

properly sequencing the additional intervention component

(once the counseling visits limit is reached).

CSEL

25

Control Systems Engineering Laboratory

Some Challenges

• Dynamic modeling from intensive longitudinal data using ideas from

system identification (engineering) and functional data analysis (statistics).

• Developing novel (and practical) experimental designs within the vast,

challenging domain of behavioral health.

• Issues with controller tuning (which impact modeling); resolving the

nomothetic versus idiographic debate.

• Application areas (with L.M. Collins, R21 Roadmap Project):

– Low-dose naltrexone for fibromyalgia (Jarred Younger, Stanford University).

– Weight loss interventions; prevention of excessive gestational weight gain

(D. Downs, J. Savage and L. Birch, Penn State; D. Thomas, Montclair State)

– Dynamical systems modeling of smoking behavior and cessation (with M. Piper, T.

Baker, M. Fiore, UW-Center for Tobacco Research and Intervention)

CSEL

Control Systems Engineering Laboratory

26

CSEL

Intervention acts upon

Control Systems Engineering Laboratory

{

Attitude toward

the behavior

Subjective norm

Perceived

behavioral control

Conceptual Model for

Weight Change Interventions

Energy

Balance

Model

Diet

Behavioral

Model

Physical Activity

Fat-free mass

Fat mass

The dynamical model consists of a system of integrated

differential equations describing:

• Physiology (energy balance),

• Behavior change (Theory of Planned Behavior).

Navarro-Barrientos, J.E., D.E. Rivera, and L.M. Collins, “A dynamical systems model for

understanding behavioral interventions for weight loss,” 2010 International Conference on

Social Computing, Behavioral Modeling, and Prediction (SBP 2010), Springer.

27

CSEL

Control Systems Engineering Laboratory

Behavioral

belief ×

evaluation

of outcome

Path Diagram for the

Theory of Planned Behavior

γ11

ζ1

Attitude

Toward the

Behavior

(η1 )

(ξ1 = b1 × e1 )

β41

ζ5

ζ4

Normative

belief ×

motivation

to comply

ζ2

γ22

(ξ2 = n1 × m1 )

Subjective

Norm

(η2 )

β42

Intention

β54

(η4 )

Behavior

(η5 )

β43

β53

Control

belief ×

power of

control belief

γ33

(ξ3 = c1 × p1 )

η1

η2

η3

η4

η5

η

=

=

Bη+Γξ+ζ

0

0

0

0

0

0

0

0

0

β41 β42 β43

0

0 β53

Perceived

Behavioral

Control

(η3 )

0

0

0

0

β54

ζ3

0

0

0

0

0

η1

η2

η3

η4

η5

28

+

γ11

0

0

0

0

0

γ22

0

0

0

0

0

γ33

0

0

ξ1

ξ2 +

ξ3

ζ1

ζ2

ζ3

ζ4

ζ5

CSEL

Fluid Analogy for the

Theory of Planned Behavior

Control Systems Engineering Laboratory

ξ2 (t)

γ22 ξ2 (t − θ2 )

ζ2 (t)

3##4

ξ1 (t)

5/67&8%',&

9(-:

γ11 ξ1 (t − θ1 )

ζ1 (t)

3##4

.%%'%/0&

(η1 )

#4

(1 − β41 )η1

(η2 )

#4

β42 η2 (t − θ5 )

γ33 ξ3 (t − θ3 )

ζ3 (t)

3##4

(1 − β42 )η2

1)2

ζ4 (t)

β43 η3 (t − θ6 )

β41 η1 (t − θ4 )

(η3 )

3##4

β53 η3 (t − θ8 )

!$%&$%'($

#4

(η!"#4 )

(1 − β54 )η4

β54 η4 (t − θ7 )

#4

(1 − β43 − β53 )η3

ζ5 (t)

3##4

)&*+,'(-

(η5 )

#4

η5 (t)

29

CSEL

Control Systems Engineering Laboratory

Dynamic TPB Model

The conservation principle (Accumulation = Inflow − Outflow) leads to the

following system of differential equations:

dη1

dt

dη2

τ2

dt

dη3

τ3

dt

dη4

τ4

dt

dη5

τ5

dt

τ1

= γ11 ξ1 (t − θ1 ) − η1 (t) + ζ1 (t)

= γ22 ξ2 (t − θ2 ) − η2 (t) + ζ2 (t)

= γ33 ξ3 (t − θ3 ) − η3 (t) + ζ3 (t)

= β41 η1 (t − θ4 ) + β42 η2 (t − θ5 ) + β43 η3 (t − θ6 ) − η4 (t) + ζ4 (t)

= β54 η4 (t − θ7 ) + β53 η3 (t − θ8 ) − η5 (t) + ζ5 (t),

where:

τ1 , · · · , τ5 are time constants,

η1 , · · · , η5 are the inventories,

ξ1 (t) = b1 (t)e1 (t), ξ2 (t) = n1 (t)m1 (t), ξ3 (t) = c1 (t)p1 (t),

γ11 , · · · , γ33 are the inflow resistances,

β41 , · · · , β54 are the outflow resistances,

θ1 , · · · , θ7 are time delays and ζ1 , · · · , ζ5 are disturbances.

30

ξ3 (t)

CSEL

Dynamic TPB Model:

simulation results

Control Systems Engineering Laboratory

System response for various step change increases in strength of beliefs to attitude:

Input ("1)

100

50

Attitude (!1)

0

100

50

Intention (!4)

0

80

60

40

20

Behavior (!5)

0

50

40

b1=8, e1=8, 2nd order

30

b1=6, e1=6, 1st order

20

b1=4, e1=4

10

0

0

5

10

15

20

25

30

35

t

Model parameters:

θ1 = · · · θ3 = 0, θ4 = · · · θ7 = 2

τ1 = · · · τ3 = 1, τ4 = 2, τ5 = 4

γij = 1, βij = 0.5, ζi = 0

ξ1 = b1 × e1 :

(solid) b1 = 4, e1 = 4

(dashed) b1 = 6, e1 = 6

(dot-dashed) b1 = 8, e1 = 8

31

CSEL

Control Systems Engineering Laboratory

Dynamical TPB Model Summary

•

At steady-state, the dynamical model corresponds exactly

to the TPB structural equation model (SEM),

•

Additional model parameters (time constants, delays, and

damping coefficients) represent transient behavior in a

manner fully consistent with dynamical systems theory,

•

Parameter estimation from data can be accomplished by:

- system identification (engineering)

- functional data analysis (statistics).

32

CSEL

Conceptual Model for Gestational

Weight Gain Interventions

Intervention acts upon

Intervention acts upon

Control Systems Engineering Laboratory

{

Subjective norm

Perceived

behavioral control

{

b1

Attitude toward

the behavior

Energy

Intake

TPB

Model

e1

n1

m1

c1

p1

Fetal

Energy

Balance

Model

FFMf

FMf

Fetal

energy

intake

b1

Attitude toward

the behavior

Physical

Activity

TPB

Model

e1

n1

Subjective norm

m1

c1

Perceived

behavioral control

p1

Diet

Physical

Activity

Placental

Volume

Maternal

Energy

Balance

Model

FFMm

FMm

Energy Balance Model

Behavioral Model

33

CSEL

Fluid Analogy for Mediation Analysis

Control Systems Engineering Laboratory

Path Diagram:

aT (t − θ1 )

T (t)

e1 (t)

$##%

e1

e2 (t)

M

b

a

T

!

c

e2

c! T (t − θ2 )

bM (t − θ3 )

$##%

Y (t)

Y

#%

M (t)

#%

bM (t)

(1 − b)M (t)

,(-%

!"#

&%'(')"*+%

Y (t)

!"#$%

dM

τ1

= a T (t − θ1 ) − M (t) + e1 (t)

dt

dY

τ2

= c! T (t − θ2 ) + b M (t − θ3 ) − Y (t) + e2 (t).

dt

Time constant (!) and delay (!) variables are essential features in this

dynamic model representation for mediation. Aspects of moderation and

confounding phenomena can also be explained through a fluid analogy.

34

CSEL

Control Systems Engineering Laboratory

Smoking Cessation Intervention:

Group Averages

30

Negative Affect

Craving

25

20

15

10

5

•

0

5

10

15

20

25

Time (days)

30

35

40

45

Following the quit date (day 15), dynamic responses are observed in craving

(blue) and negative affect (red) for treatment group receiving drug and

counseling.

35

Summary and Conclusions

• Adaptive behavioral interventions constitute dynamical systems that can be

optimized by applying a control engineering perspective.

• Applying a control engineering requires intensive measurement and a

recognition of the input/output nature of phenomena associated with

behavioral interventions.

• A hypothetical adaptive intervention based on Fast Track has been evaluated

using simple “IF-THEN” decision rules vs. an engineering-based Model

Predictive Control decision algorithm.

• Fluid analogies from supply chain management have been useful as the basis

for modeling adaptive interventions, and relating theory and SEM models to

engineering control systems.

• A plethora of opportunities exist in applying systems approaches to

behavioral interventions which include novel experimental design,

formulation of optimal decision policies, and simulation.

CSEL

Control Systems Engineering Laboratory

36

CSEL

Control Systems Engineering Laboratory

Looking to the Future

We have considered the importance of establishing connections between

prevention/behavioral health, methodology, and engineering. Some

implications of this work (not an exhaustive list):

• Behavioral scientist: willingness to collect and work with intensive

longitudinal data, reconfigure interventions to enable adaptation (i.e.,

systematically assess tailoring variables and allow dosage changes through

the course of the intervention).

• Methodologist: develop expertise and familiarity with differential

equations, dynamical input/output system models, and control theory.

• Control engineer: work with data sets that may be irregularly sampled,

have missing entries, and involve multiple human participants. Understand

experimental designs meaningful to problems in behavioral health. Examine

and understand the nomothetic vs. idiographic methods debate.

37

CSEL

Control Systems Engineering Laboratory

Acknowledgments

• Linda M. Collins, Ph.D., The Methodology Center and Dept. of

Human Development and Family Studies, Penn State University.

• Susan D. Murphy, Ph.D., Department of Statistics, Department of

Psychiatry, and Institute for Social Research, Univ. of Michigan.

• R21 Roadmap Initiative Grant Project Team (N. Nandola, J.E.

Navarro, S. Deshpande, ASU; J. Johnson and I. Shani, PSU)

Support from NIH-NIDA (National Institute on Drug Abuse) and

NIH-OBSSR (Office of Behavioral and Social Sciences Research) through

Grants K25DA021173 and R21DA024266

38

CSEL

Control Systems Engineering Laboratory

Primary References

• Collins, L.M., S.A. Murphy, and K.L. Bierman, “A conceptual framework for adaptive preventive

interventions,” Prevention Science, 5, No. 3, pgs. 185-196, Sept., 2004.

• Rivera, D.E., M.D. Pew, and L.M. Collins, “Using engineering control principles to inform the

design of adaptive interventions: a conceptual introduction,” Drug and Alcohol Dependence,

Special Issue on Adaptive Treatment Strategies, Vol. 88, Supplement 2, May 2007, Pages S31-S40.

• Rivera, D.E., M.D. Pew, L.M. Collins, and S.A. Murphy, “Engineering control approaches for the

design and analysis of adaptive, time-varying interventions,” Technical Report 05-73, The

Methodology Center, Penn State University;

• Nandola, N. and D.E. Rivera, “A novel model predictive control formulation for hybrid systems

with application to adaptive behavioral interventions,” Proceedings of the 2010 American Control

Conference, Baltimore, MD, June 30 - July 2, 2010.

• Navarro-Barrientos, J.E., D.E. Rivera, and L.M. Collins, "A dynamical systems model for

understanding behavioral interventions for weight loss," !2010 International Conference on Social

Computing, Behavioral Modeling, and Prediction (SBP 2010), March 29 - April 1, 2010; extended

version in press to Mathematical and Computer Modelling of Dynamical Systems.

39

CSEL

Control Systems Engineering Laboratory

•

•

Additional References

Some additional tutorial presentations that may be of interest:

•

Rivera, D.E., “Engineering control theory: can it impact adaptive interventions?”

tutorial presentation at 2010 Society for Prevention Research workshop, June 1, 2010.

Can be downloaded from http://csel.asu.edu/adaptiveintervention (select item 10).

•

Rivera, D.E., “A brief introduction to system identification,”

Penn State Methodology Center Brown Bag presentation, March 20, 2008.

Can be downloaded from http://csel.asu.edu/controleducation (select item 10).

•

Rivera, D.E., “An introduction to mechanistic models and control theory,” tutorial

presentation at the SAMSI Summer 2007 Program on Challenges in Dynamic Treatment

Regimes and Multistage Decision-Making, June 18 - 29, 2007.

Can be downloaded from http://csel.asu.edu/controleducation (select item 9).

A free web-based reference, written by two distinguished control engineers:

•

Åström, K. J. and R. M. Murray. Feedback systems: an introduction for

scientists and engineers,” http://www.cds.caltech.edu/~murray/amwiki.

40