RLW Navigator From design to production: simulation and

advertisement

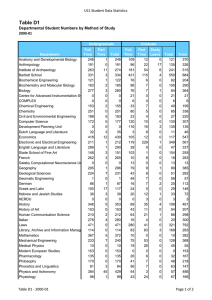

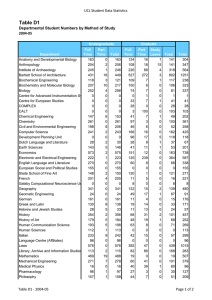

RLW Navigator Remote Laser Welding System Navigator for Eco & Resilient Automotive Factories From design to production: simulation and optimisation of the Body in White joining process Warwick Manufacturing Group 9th December 2014 1 Live web feed via URL (emailed to all attendees) Live twitter link @rlwnavigator #rlwnav14 RLW Navigator Remote Laser Welding System Navigator for Eco & Resilient Automotive Factories Audience Survey RLW Navigator Symposium Survey 4 RLW Navigator Remote Laser Welding System Navigator for Eco & Resilient Automotive Factories Welcome & Symposium Introduction Prof. Darek Ceglarek, WMG, University of Warwick, UK RLW Navigator Symposium Agenda 9.30 – 9.35 9.35 – 9.50 9.50 – 10.20 Welcome and Symposium Introduction Overview of HVM Catapult program Laser Processing for the Automotive Prof. Darek Ceglarek, WMG, Univ. of Warwick Dr Alan Curtis, HVM Catapult, Univ. of Warwick Prof. Richard Dashwood , WMG Academic Director Dr Andrei Andreev ,Trumpf GmBH 10.20 – 10.35 RLW Navigator Project Introduction 10.35 – 11.00 Coffee and Contacts 11.00 – 11.20 RLW System Configurator 11.20 – 11.40 11.40 – 12.00 12.00 – 12.20 RLW Workstation Design & OLP RLW Process Optimiser RLW Process Control 12.20 – 13.00 Lunch 13.00 – 13.15 13.15 – 13.35 RLW Eco Advisor RLW Navigator NPI Workflow Prof. Ian Anthony Stroud, EPFL Charles Marine, Stadco Group 13.35 – 14.20 14.20 – 15.00 15.00– 16.00 WMG Facility Tour Round Table & Panel Discussion Summary & Conclusion Prof. Darek Ceglarek, WMG, Univ. of Warwick Break & Live Demonstrations Prof. Darek Ceglarek, WMG, University of Warwick Antonio Taurisano, EnginSoft S.p.A Dr. Marcello Colledani, Polimi Prof. Joszef Vancza, SZTAKI Dr. Pasquale Franciosa, WMG, Univ. of Warwick Markus Kogel-Hollacher, Ph.D., Precitec GmBH, Dr. Pasquale Franciosa, WMG, Univ. of Warwick RLW Navigator Remote Laser Welding System Navigator for Eco & Resilient Automotive Factories Overview of HVM Catapult Dr. Alan Curtis, Chief Executive – WMG Centre HVM Catapult, University of Warwick, UK Prof. Richard Dashwood - WMG Academic Director, University of Warwick, UK RLW Navigator Remote Laser Welding System Navigator for Eco & Resilient Automotive Factories Laser Processing for the Automotive Industry Dr Andrei Andreev, Industry Management AutomotiveRemote Applications, Trumpf GmBH, DE RLW Navigator Remote Laser Welding System Navigator for Eco & Resilient Automotive Factories Introduction Prof. Darek Ceglarek, WMG, University of Warwick, UK RLW Navigator Symposium Remote Laser Welding •It is a single sided joining process for steel •It is 5 times faster than Spot Welding •It is structurally comparable to current processes •It offers product design opportunities CHALLENGES OPPORTUNITIES • • • • • • • Faster Processing Speed Flexible Manufacturing Fast model changeover Reduced Floor Space Lower Investment Costs Lower Operating Costs Improved Product Design • • • • • • • Process Feasibility Workstation design Robot Programming & OLP Part fit up Process Monitoring Process Control Energy Efficiency 10 RLW Navigator Symposium RLW Navigator Project Definition The RLW Navigator Project will provide a software toolkit to facilitate the process planning, design, implementation and optimisation in the application of Remote Laser Welding technology in Body In White sheet metal joining 11 RLW Navigator Symposium RLW Navigator Project Content The Path to “First-Time-Right” 12 RLW Navigator Symposium RLW Navigator Project Development Exploitation Industry Ready Demonstrator Analytical Experiments Concept Development TRL 7-9 TRL 5-6 TRL 3-4 TRL 1-2 13 RLW Navigator Symposium RLW Navigator Demonstrator The main purpose of the Demonstrator is to provide a industry compatible platform to verify and validate the experimental methods and tools to current industrial standards and to apply these methods and tools to the Pilot Build of an existing industrial case study and demonstrate Application Readiness (TRL 6) TRL 1-2 TRL 3-4 TRL 5-6 TRL 7-9 14 RLW Navigator Symposium RLW Navigator Demonstrator 15 RLW Navigator Symposium RLW Navigator Demonstrator Comau SmartLaser IPG 4kW Fibre Laser Inspection Fixtures PRIMES Power/Focus Meter Metrology PRECITEC Process Monitoring Metallography Strength Testing Welding Fixture Dimpling Fixture 16 RLW Navigator Symposium RLW Navigator Project Benefits GUI based Process Estimator R & M based Process Simulator Reduced time to deliver Process Concept Early Process and Robot Path Planning Feasibility OLP for Remote Laser Welding Workstation Layout Robot/Fixture Calibration Reduced Robot Programming in Commissioning/Launch phase Virtual “walk-through” of process based on fixture and robot optimisation Energy Consumption based on actual Robot Path and Process content Process Monitoring for Comau SmartLaser Process Monitoring software to predict weld performance Laser Parameter Optimiser to improve Weld Quality Reduced Weld Quality Loops in Commissioning/Launch phase Early interaction with Product Design to generate feasible stitch matrix and 3D clamp design Laser Parameter Process Window for all stack-ups related to weld performance Reduced fixture clamp adjustment in Commissioning/Launch phase The Path to “First-Time-Right” 17 RLW Navigator NPI Process RLW NAV Workflow Process Feasibility System & Workstation Design System Configurator Workstation Planner & OLP System Configurator Process Control Workstation Planner & OLP Process Optimiser Eco-Advisor Process Optimiser Digital Visualisation Process Feasibility System & Workstation Design Process Control Process Control 18 RLW Navigator Symposium RLW Navigator Project Content RLW System Configurator Antonio Taurisano, EnginSoft S.p.a, IT Dr. Marcello Colledani, POLIMI, IT 19 RLW System Configurator Assembly Layout and Process Estimator What is it? • Integrated environment based on a GUI for fast evaluation of layout feasibility What does it do? • • • • Quick design and editing of Assembly Layouts Automatic generation of Task Sequencing table Fast evaluation of main design KPIs Displays layout, task sequencing and KPIs at a glance Benefits • • • • • • • Strong reduction of time for line feasibility analysis Improved feseability evaluation Easier management of all data needed for line design within the same GUI Faster real time evaluation of design KPIs Fully customizable resources and costs database Easy management of design constraints Functionalities for faster reporting 20 Assembly Layout and Process Estimator Verification & Validation JLR door test case has been implemented in order to verify the reliability of the tool in terms of GUI stability and results accuracy 20 entities, 57 operations and 9 stations have been defined in order to study the test case • Time to design the line ≈ 4h • Time for station definition ≈ 0.5h STATION 1 • Results Components 100 R1 Handling+Welding robot TurnTable Safety light OP1-Operator Components Smart Laser-Lase welding robot TurnTable STATION 4 Clamping Fixture Complex-AUTO FIXTURE_AUTO CLAMPS (RLW) Power Motor 100R1-Handling+Welding robot Laser Source REFERENCE VALUES FROM INDUSTRIAL CASE LAYER 0 RESULTS DELTA ERROR [%] WeightingFactor p with W.F. r WeightingFactor p with W.F. r WeightingFactor p with W.F. 0.216 0.0002233944 0.2557544757 0.232 0.0002389758 0.2557544757 7.4 7.0 0.080 0.0000200978 0.2508340231 0.080 0.0000200777 0.2508340231 0.0 -0.1 1.000 0.0000491639 0.4637076783 1.000 0.0000491587 0.4637076784 0.0 0.0 0.688 0.0017286432 1.0000000000 0.668 0.0017243108 1 -2.9 -0.3 r 0.0 0.0 0.0 0.0 WeightingFactor 0.757 0.090 0.072 1.000 0.072 1.000 r 0.0 0.0 0.0 0.0 0.0 0.0 p with W.F. 0.0020539980 0.0000226326 0.0000647030 0.0001176987 0.0000745393 0.0027027027 r WeightingFactor 0.2853585713 0.766 0.2508340231 0.090 0.3338695284 0.072 0.4523977350 1.000 0.2557544757 0.072 0.2000000000 1.000 p with W.F. 0.0020588673 0.0000226100 0.0000645295 0.0001176681 0.0000742391 0.0026666667 r WeightingFactor 0.2853585713 1.2 0.2508340231 0.0 0.3338695284 0.0 0.4523977350 0.0 0.2557544757 0.0 0.2000000000 0.0 p with W.F. 0.2 -0.1 -0.3 0.0 -0.4 -1.3 21 Assembly Layout and Process Estimator Software Demonstration 22 RLW System Configurator Configuration Optimiser What is it? • System-level configuration optimiser, integrated with performance evaluation modules What does it do? • • • • • Precise calculation of system performance, considering resource reliability and buffers. Multi-objective optimisation on: Production and inventory costs. Line actual productivity (i.e., OEE and JPH). Energy consumption. Cycle times. Generation of a set of optimised candidate solutions (Pareto frontier) Robustness and sensitivity analysis Discrete Event Simulation for candidate solutions SUMMARY OF CONFIGURATIONS Benefits • • • • • Fast configuration evaluation, to study more potential configuration in less time Actual and detailed line OEE and JPH estimation Connection with reliability databases Detailed and customizable output visualiser Robustness levels for each optimal configuration PRODUCTIVITY JLR TH [PART/MIN] 0,455 ABL(TOT) [PARTS] 3,309 WIP[PARTS] 7,407 JPH[PARTS/HOUR] 27,300 ENERGY N SPOTS 95 N STICH 0 E PART 427500 E HOUR 11678445 WELDING COST CW PART [EU/PART] 1,188 CW HOUR [EU/HOUR] 32,440 INVENTORY COST Ci [EU/HOUR] 0,059 ENERGY COST Ce [EU/HOUR] 0,648 TOTAL COST [EU/HOUR] 33,148 TOTAL COST [EU/part] 1,213 N° ROBOTS 28 REC 1 REV 1 0,4567 1,4897 5,6 27,402 REC 1 REV 2 0,4555 1,4005 5,5 27,33 0,455 1,505 5,6 27,3 REC 3 REV 1 0,457 1,487 5,6 27,42 REC 3 REV 2 0,4563 1,3833 5,49 27,378 0,4606 3,2862 7,4316 27,636 13 59 176500 4836453 13 59 176500 4823745 13 59 176500 4818450 13 59 176500 4839630 13 59 176500 4832217 14 56 175000 4836300 0,863 23,651 0,861 23,531 0,858 23,418 0,858 23,521 0,858 23,485 0,835 23,075 0,0448 0,044 0,045 0,045 0,044 0,0594528 0,268 23,965 0,875 17 0,268 23,843 0,872 16 0,267 23,731 0,869 19 0,269 23,835 0,869 17 0,268 23,797 0,869 16 0,268 23,403 0,847 17 REC 2 REC 4 23 RLW System Configurator System-Level Configurator • What does it do? • • • • • Component database Reliability database Early-stage design of assembly systems in a designoriented Graphical User Interface Integrated definition of task sequencing and layout Precise calculation of system performance over a large number of alternative configurations Multi-objective optimisation on costs, productivity and number of resources Robustness analysis and Discrete Event Simulation for candidate solutions Transfer functions Optimal system configuration Integrated platform for system concept generation and configuration optimisation Assembly Layout and Concept Generator User input GUI What is it? Design input: o Product information o Basic features o Basic KPIs o Resources Stations modelling Configuration optimiser Benefits • • • • • Faster and integrated system design procedure Fast configuration evaluation to study more potential configuration in less time (1000 configurations, 30 minutes) Actual and detailed line OEE and JPH estimation Connection with reliability and component databases Detailed and customizable output visualiser 24 RLW System Configurator Verification & Validation Validation on JLR industry case System Configurator has been used for the optimization of JLR industry case, consisting in 4 different reconfigurations with hybrid RSW+RLW technologies: Process speed (+400%) Overall costs (-30%) Energy (-60%) Floor space (-50%) Number of robots (-40%) Comparison between analytical and DES Simulation Provide an estimation of the error incurred by the designer when using the analytical method Maximum error on throughput: 0,4% Maximum error on WIP: 1,6% Validation on other industrial cases Test System Configurator to be tailored on specific application and layout: Case 1: machining and assembly of vehicle engines Case 2: body-in-white assembly Number of stations Group of operations Intermediate buffers Failure modes Configurations Computational time Case 1 23 23 22 147 1500 3 hours Case 2 3 24 2 18 100 7 minutes Process Simulator Software Demonstration 26 RLW Navigator NPI Process RLW NAV Workflow Process Feasibility System & Workstation Design System Configurator Workstation Planner & OLP System Configurator Process Control Workstation Planner & OLP Process Optimiser Eco-Advisor Process Optimiser Digital Visualisation Process Feasibility System & Workstation Design Process Control Process Control 27 RLW Navigator Symposium RLW Navigator Project Content RLW Workstation Design & OLP Prof. Joszef Vancza, Institute for Computer Sciences and Control (SZTAKI) , HU 28 RLW Workstation Design & OLP Workstation Planning & OLP What is it? • A software toolbox that supports the detailed configuration, optimization, automated off-line programming and simulation of RLW workstations. What does it do? • • • • • • Accessibility analysis, feedback to fixture and product design Integrated welding task sequencing and robot path planning for minimizing cycle-time Collision detection and avoidance Detailed workstation design Automated off-line robot code generation Simulation of the RLW workstation Benefits • • • • Significantly reduced robot programming effort and time First-time-right implementation due to complete calibrated digital model Shortened ramp-up process and accelerated time-to-market Increased throughput and reduced energy demand 29 Workstation Planning & OLP Verification & Validation Computational tests • • • Real product (LR door) and robot (Comau C4G) ~90 problem instances Benchmarking against single published method Test results • • Cycle-time improvement up to 200% No zig-zaging Successful physical tests at WMG 1. 2. 3. 4. 5. 6. Building the model of the workcell Placement of the fixtures Calibration Simulation Automatic OLP generation Code execution and measurements 30 RLW Workstation Design & OLP Software Demonstration 31 RLW Navigator NPI Process RLW NAV Workflow Process Feasibility System & Workstation Design System Configurator Workstation Planner & OLP System Configurator Process Control Workstation Planner & OLP Process Optimiser Eco-Advisor Process Optimiser Digital Visualisation Process Feasibility System & Workstation Design Process Control Process Control 32 RLW Navigator Symposium RLW Navigator Project Content RLW Process Optimiser Dr. Pasquale Franciosa, WMG, University of Warwick, UK 33 RLW Process Optimiser Process Integration Concept PRODUCT & PROCESS DATA DATA LIBRARY OPTIMISED RLW PROCESS OPTIMUM CLAMP LAYOUT PROCESS UNFEASIBLE MODIFY PRODUCT OPTIMUM STITCH LAYOUT OPTIMUM LASER PARAMETERS 34 RLW Process Optimiser Part Variation Modeller What is it? • Software package for virtual modelling of deformation patterns of sheet-metal part/assembly What does it do? • • • Generates virtual part or assembly based on part CAD and/or measurement data Variation Simulation Analysis for deformable parts Statistical Process Control (SPC) for surface measurements (cloud of points data) used in stamping process or/and assembly Benefits • • • Facilitates design optimisation for improved part and assembly performance Provides an analysis tool for surface measurements (cloud of points data) used in stamping process or/and assembly Facilitates root cause analysis in stamping and assembly processes Deviation [mm] Deviation [mm] Deviation [mm] 35 RLW Process Optimiser Fixture Layout Analyser & Optimiser What is it? • Determine clamp location to optimise part to part fit-up geometry What does it do? • • • Definition and application of design locator strategy Optimisation of clamp position to satisfy joint fitup geometry Optimisation of clamp position to satisfy assembly dimensional quality • • • • • • Improved interaction between product and process engineering Reduced engineering implementation cost Reduced fixture design time and engineering design changes Reduction of fixture content and complexity Reduction of installation, commissioning and launch time Improved assembly quality Gap [m m ] Benefits Sam pling point 36 RLW Process Optimiser Laser Process Parameter Optimiser What is it? • Determine optimum parameter selection laser welding/dimpling What does it do? Definition of optimum process parameters (i.e., power, speed), based on defined output criteria: • • Maximum joint quality Minimum cycle time Minimum power demand Automatic identification of feasible process windows Allow process optimisation loop with robot simulation and path planning Gap [mm] 0.05 0.1 0.2 0.3 1.0 2.0 3.0 4.0 Gap [m m ] • • • Speed [m/min] • Sam pling point Benefits • • • • • Improved joint quality Facilitate parameter selection based on process performance Reduced engineering implementation cost Reduced number of process parameter adjustements Reduction of installation, commissiong and launch time 37 RLW Process Optimiser RLW Navigator Test Case Verification & Validation Tool Result % Measurable result Fixture Layout Analyser & Optimiser Laser Process Parameter Optimiser Coupon trials Door assembly NA (65/72) - 90% (245/250) - 98% (61/72) - 85% Percentage of stitches* with satisfactory gap (based on predicted clamp location) Coupon trials: percentage of welding trials* with predicted error below 10% Door assembly: percentage of satisfactory stitches** (based on predicted parameters) *Number of coupon trials = 250 - **Total number of stitches on door assembly = 72 Stack-up 1 1.40 1.20 1.20 1.00 1.00 0.80 0.60 0.40 0.40 0.20 0.00 TC BC Penetration B-width Stack-up 2 Predicted KPI Predicted KPI 1.20 KPI value [mm] KPI value [mm] 1.40 1.00 0.80 0.60 0.40 0.20 0.00 S-value TC S-value TC BC B-width Stack-up 4 Experimental KPI (average) 1.60 Penetration Stack-up 3 0.60 0.00 S-value Experimental KPI (average) 0.80 0.20 Penetration Stack-up 1 Stack-up 3 Predicted KPI Experimental KPI (average) KPI value [mm] KPI value [mm] Predicted KPI BC B-width Experimental KPI (average) 1.60 1.40 1.20 1.00 0.80 0.60 0.40 0.20 0.00 Stack-up 4 Penetration S-value TC BC B-width Stack-up 2 38 RLW Process Optimiser Software Demonstration 39 RLW Process Optimiser Process Integration Concept PRODUCT & PROCESS DATA DATA LIBRARY OPTIMISED RLW PROCESS OPTIMUM CLAMP LAYOUT PROCESS UNFEASIBLE MODIFY PRODUCT OPTIMUM STITCH LAYOUT OPTIMUM LASER PARAMETERS 40 RLW Navigator NPI Process RLW NAV Workflow Process Feasibility System & Workstation Design System Configurator Workstation Planner & OLP System Configurator Process Control Workstation Planner & OLP Process Optimiser Eco-Advisor Process Optimiser Digital Visualisation Process Feasibility System & Workstation Design Process Control Process Control 41 RLW Navigator Symposium RLW Navigator Project Content RLW Process Control Markus Kogel-Hollacher Ph.D., Precitec Optronik GmBH, DE Dr. Pasquale Franciosa, WMG, University of Warwick, UK 42 RLW Process Control Process Monitoring Concept Design What is it? • Sensor hardware integrated into the Comau SmartLaser robot as first in-axis solution What does it do? • • Integrates state-of-the-art sensor technology into the Comau SmartLaser robot Enables the in-process and in-situ acquisition of the desired quality information to evaluate the current quality status Installation Benefits • • • The current system can be used at the commissioning and production stage of NPI for statistical process control, Root cause analysis (RCA), and process adjustment Retrofit of all existing Comau SmartLaser robots Fully implemented sensor technology for Process monitoring/ control enables continuous compliance to the specific quality standards and improve decision making processes Back reflection Plasma Temperature 43 RLW Process Control Weld Quality Performance Evaluator Data Monitoring What is it? • Software package for estimation of joint performance (i.e., penetration and s-value) using in-line process monitoring data What does it do? • • • It takes the most relevant KPIs in remote laser welding and relates them with the signals extracted from the processing area Direct output of weld quality reduces operator’s interpretation errors Closed-loop process adjustment based directly on weld quality is achievable Welding process parameters can be optimised for a specific performance output Model Development Rep. 1 Gap [mm] 0.05 0.1 0.15 0.2 0.25 0.3 0.4 1.0 Speed [m/min] • 2.0 3.0 4.0 No WELD Benefits • • • • In-process weld analysis reduces NDT and destructive testing Use of analytical mathematical model automatically linking monitoring data to joint performance Facilitate Statistical Process Control and root cause of joint failure Capability for in-line closed loop process control and adjustment 44 RLW Process Controller Verification & Validation Tool Measurable Result % Process Monitoring Installation of in-axis monitoring system for COMAU SmartLaser Installed & Tested Weld Quality Performance Evaluator Percentage of welding trials* with predicted error below 10% (56/60) - 93% *Total number of welding trials = 60 Main achievements • • Predicted S-value (Average) Good agreement between predicted and measured KPIs S-value has high correlation to signal data (plasma, temperature and back-radiation) Measured S-value (Average) 16.00% 2.2 speed=2m/min speed=3m/min 14.00% speed=4m/min 12.00% 1.8 1.6 1.4 speed=1m/min Error [%] KPI value [mm] 2 10.00% 8.00% 6.00% 4.00% 2.00% 1.2 1 0.00% 45 RLW Process Controller Software Demonstration 46 RLW Navigator NPI Process RLW NAV Workflow Process Feasibility System & Workstation Design System Configurator Workstation Planner & OLP System Configurator Process Control Workstation Planner & OLP Process Optimiser Eco-Advisor Process Optimiser Digital Visualisation Process Feasibility System & Workstation Design Process Control Process Control 47 RLW Navigator Symposium RLW Navigator Project Content RLW Eco – Advisor Prof. Ian Anthony Stroud, EPFL, CH 48 RLW Eco Advisor Eco-advisor Software What is it? • Welding eco-effects calculator What does it do? • • • Estimates energy used for welding Animates given path to show robot movements Calculates energy for robot movement calibrated by experiments • Calculates energy for laser based on stitch data • Calculates energy for auxiliary equipment based on • overall time Benefits • • • • • Ability to foresee effects of different welding strategies Quantification of effects based on theory and experiments Component for factory planning Theoretically and experimentally based Separation of contributing factors for more complete understanding 49 RLW Eco Advisor Verification & Validation Verification and validation • • • Experiments to measure laser power in welding Experiments to measure real welding path for comparison with theoretical power use Calculation of power loss in motors as a multiplication factor for software Comparison of power consumed by Mechanical Movement Sl. No Power consumption in KWh Experimental Computational Description 1 0.02 0.02 71 Stitches 2 0.007 0.006 Stitches 1 - 23 3 0.0074 0.007 Stitches 24 - 45 4 0.0077 0.007 Stitches 46 - 71 50 RLW Eco Advisor Software Demonstration 51 RLW Navigator Symposium RLW Navigator Project Content RLW Navigator NPI Concept Charles Marine, Stadco Group, UK 52 RLW Navigator NPI Process Traditional BIW NPI Process Order Acquisition Engineering Concept 3D Design Installation & Commissioning Manufacture & Assembly Launch Production 2D Design Robot Simulation Release Release to Engineering • • • • • Proposal Development Estimating Submission Nomination Project Handover Process Feasibility to Manufacture • • • • • Concept Feasibility 3D Design 2D Design Robot Simulation System Layout OK to Ship • • • • Manufacture Build Inspection Validation System & Workstation Design Ready for Launch • • • • Site Preparation Installation Commissioning Preliminary Acceptance Ready for Job1 • • • • • • Quality Loops Weld Quality Dimensional Quality Cycle Time Process Capability Final Acceptance • Process Monitoring Process Control 53 RLW Navigator NPI Process RLW NAV NPI Process Concept Commercial • RFQ • Product Data • Prod’ Data Design • Product • Build • Locators • Tolerances Concept 3D Design System Configurator Process Feasibility Stamped Parts Q Loop Process Optimiser Process Optimiser Workstation Planner & OLP Workstation Planner & OLP Process Control Process Control Stamped Parts Production 2D Design System Configurator Order Acquisition Stamped Parts Q Loop Process Optimiser Process Optimiser Workstation Planner & OLP Workstation Planner & OLP Eco-Advisor Digital Visualisation Engineering System & Workstation Design Workstation Manufacture & Assembly Manufacture & Assembly Installation & Commissioning Launch Process Control Process Control Production 54 RLW Navigator NPI Process RLW NAV NPI Process Concept Commercial • RFQ • Product Data • Prod’ Data Design • Product • Build • Locators • Tolerances 3D Design Concept Stamped Parts Q Loop Stamped Parts Q Loop Stamped Parts Production 2D Design System Configurator System Configurator Process Estimator Process Estimator Process Concept Process Cost Process Simulation Robot Clamp Simulation Feasibility Process Parameters Process Feasibility Robot Access Robot Clamp Simulation Feasibility Process Parameters Robot OLP Workstation Manufacture & Assembly Stitch Matrix Clamp Matrix Workstation Placement Laser Parameter Matrix Robot Simulation Stitch Matrix 3D Clamp Matrix DESIGN FEASIBILITY LOOP Weld KPI’s Laser Parameter Matrix Robot Simulation/OLP Robot Clamp Simulation Feasibility Robot Access Process Parameters Weld Quality Cycle Time Robot OLP Weld Quality Weld KPI’s Weld KPI’s Workstation Placement Process Parameters Robot Clamp Simulation Feasibility Process Parameters Order Acquisition Robot Calibration QUALITY FEASIBILITY LOOP Cycle Time Weld Quality Cycle Time System Simulation Engineering System & Workstation Design Manufacture & Assembly Installation & Commissioning Launch Process Control Production 55 RLW Navigator NPI Process NPI Feasibility Process Comparison Engineering Manufacture & Assembly Installation & Commissioning Launch Production Feasibility Order Acquisition Order Acquisition Engineering Manufacture & Assembly Installation & Commissioning Launch Production Current RLW Process RLW NAV Process 56 RLW Navigator NPI Process NPI Feasibility Process Comparison Current RLW Process RLW NAV Process Engineering Manufacture & Assembly Installation & Commissioning Launch Production Feasibility Order Acquisition Manufacture & Assembly Installation & Commissioning Order Acquisition Engineering Launch Detailed Process Concept Reduced Design Time Reduced Fixture Adjustment Optimised Process Reduced Weld Optimisation Production Reduced Robot Programming Predictive Weld Quality Monitoring 57 RLW Navigator Remote Laser Welding System Navigator for Eco & Resilient Automotive Factories WMG Tour RLW Navigator Remote Laser Welding System Navigator for Eco & Resilient Automotive Factories Audience Survey RLW Navigator Symposium Survey 60 RLW Navigator Remote Laser Welding System Navigator for Eco & Resilient Automotive Factories Round Table and Panel Discussion RLW Navigator Remote Laser Welding System Navigator for Eco & Resilient Automotive Factories Summary & Conclusion RLW Navigator Remote Laser Welding System Navigator for Eco & Resilient Automotive Factories Live Demos