Functional capability space and optimum process

advertisement

IIE Transactions (2010) 42, 95–106

C “IIE”

Copyright ISSN: 0740-817X print / 1545-8830 online

DOI: 10.1080/07408170902789027

Functional capability space and optimum process

adjustments for manufacturing processes with in-specs failure

KAMAL MANNAR1 and DAREK CEGLAREK2,3,∗

1

General Electric Healthcare, Waukesha, WI 53188, USA

E-mail: Kamal.Mannar@ge.com

2

The Digital Laboratory, WMG, University of Warwick, Coventry CV4 7AL, UK and 3 Department of Industrial and Systems

Engineering, University of Wisconsin, Madison, WI 53706, USA

E-mail: darek@cae.wisc.edu

Downloaded By: [University of Warwick] At: 09:16 14 December 2009

Received August 2006 and accepted January 2008

This paper introduces a methodology for functional capability analysis and optimal process adjustment for products with failures

that occur when design parameters and process variables are within tolerance limits (in-specs). The proposed methodology defines

a multivariate functional capability space (FC-Space) using a mathematical morphology operation, the Minkowski sum, in order to

represent a unified model with (i) multidimensional design tolerance space; (ii) in-specs failure region(s); and, (iii) non-parametric,

multivariate process measurements represented as Kernel Density Estimates (KDEs). The defined FC-Space allows the determination

of a desired process fallout rate in the case of products with field failures that occur within design tolerances (in-specs). The outlined

process adjustment approach identifies the optimum position of the process mean in order to minimize the overlap between the KDEs

and in-specs failure regions, i.e., achieve the minimum possible process fallout rate for current process variation. The FC-Space-based

process adjustment methodology is illustrated using a case study from the electronics industry where the in-specs failure region is

identified based on warranty information analysis.

Keywords: Warranty analysis, process capability assessment, process adjustment, quality, statistical process control

1. Introduction

A critical concept in the area of statistical process control

is the assessment of manufacturing process capability. Process capability is seen as the ability of the manufacturing

process to consistently produce items within the given specifications of quality characteristics, i.e., within the tolerances

for Design Parameters (DPs) and Process Variables (PVs)

(Polansky, 2001; Ding et al., 2005; Montgomery, 2005).

Therefore, process capability is related to process fallout

rate, which is defined as the probability of DP and PV

measurements to be outside of design tolerances. This definition of process capability is based on the assumption that

any product within design tolerances has satisfactory functional performance, i.e., any product manufactured within

the current tolerance limits is defect free.

With increasing complexity in products, optimal determination of tolerances for DPs and PVs in the design phase

can be challenging (Engelhardt, 2000; Ding et al., 2002a;

Shiu et al., 2003; Ceglarek et al., 2004). Frequently, this

is due to a lack of knowledge during the design phase

∗

Corresponding author

C 2010 “IIE”

0740-817X about the interactions between various DPs and PVs, which

cause product degradation or failure (Khan and Ceglarek,

2000; Ding et al., 2002b; Zhou et al., 2003; Takata et al.,

2004; Chen et al., 2006). Moreover, traditional capability

and adjustments do not take into consideration product

functional assessments that can also contribute to product field failures. Product defects can occur either during

manufacturing inspections or in the field (warranty failures). Therefore, tolerances assigned to DPs and PVs can

include regions that are susceptible to manufacturing or

warranty defects. In such cases, traditional quality control

and inspection in manufacturing based on original design

tolerances cannot detect these defects/failures.

The existence of potential failure regions that occur when

design parameters and process variables are within tolerance units (in-specs) was first proposed by Skinner et al.

(2002) based on their research in semiconductor manufacturing. They identified that the region within the tolerance

of certain PVs is related to low yield and suggested avoiding

these low-yield regions of the tolerance to improve overall process yield. Similarly, Mannar and Ceglarek (2006)

provided an analysis on ways to integrate manufacturing

measurements with warranty information in order to localize warranty failures related to critical DPs and PVs. They

96

Mannar and Ceglarek

identified in-specs fault regions of certain critical DPs and

PVs that are susceptible to specific warranty failures.

1.1. Motivation

Downloaded By: [University of Warwick] At: 09:16 14 December 2009

The existence of in-specs failures serves as motivation to develop a new functional capability analysis and process adjustment methodology. The motivation involves a need for

functional capability analysis, integration of non-normal

process characteristics with in-spec failure regions and determination of an optimum process mean in the presence

of an in-spec failure region, which is described as follows.

1.1.1. Need for functional capability analysis and process

adjustment

In contrast to traditional process capability and adjustment

methods, wherein design tolerances are assumed to be correct, there may exist in-specs failure regions that need to

be incorporated in to the functional capability assessment.

A functional capability assessment provides the following

advantages.

1. Product functional evaluation in global markets: Since

product usage is influenced by numerous factors including geographic markets and customer groups, there can

exist potentially different in-specs failure regions corresponding to each market. Therefore, functional capability assessment and process adjustment must incorporate

these in-specs failure regions separately in order to tailor

product performance to each market.

2. Product functional evaluation in supply chains: Generally,

various suppliers in multiple manufacturing facilities are

involved in producing a product, each having different

variations and distribution characteristics for DPs and

PVs. Functional capability assessment, which incorporates in-specs failures, can help in identifying and evaluating processes and potential suppliers.

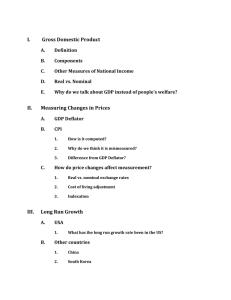

Fig. 1. Multivariate normal process with the mean at design

nominal.

to identify the functional nominal ( X̄f ) that can ensure the

lowest process fallout rate.

Figures 1 to 4 show two-dimensional examples of inspecs fault regions and their effects on process capability and adjustment. Figure 1 illustrates an example of a

multivariate normal process representing a 99.73% confidence interval for the DPs and PVs measured. The process mean is adjusted to be at design nominal ( X̄d ), which

is frequently equivalent to {x̄1 = (USL1 − LSL1 )/2, x̄2 =

(USL2 − LSL2 )/2}, where USL is the Upper Specification

Limit and LSL is the Lower Specification Limit. For the

case of an in-specs failure region, as shown in Fig. 1, this

results in a significantly lower process capability. Therefore,

an optimum process adjustment method requires the determination of the coordinates of the process mean X̄ that minimize the process fallout rate. In other words, it minimizes

the overlap of the corresponding confidence region with

1.1.2. Integration of multivariate non-normal process

measurements and in-specs failure regions

Process capability incorporates both tolerance specifications and distribution characteristics of the measurements

that determine process fallout rate. In addition to in-specs

failure regions, the DPs and PVs may be non-normal.

Therefore, a non-parametric representation of process measurements needs to be incorporated for functional capability analysis and process adjustment.

1.1.3. Determination of optimum process mean for in-specs

fault regions

Traditionally, processes are adjusted to the design nominal

( X̄d ). For cases of in-specs failure regions the adjustment

of the process mean to the design nominal is not optimal and can increase the process fallout rate (Mannar and

Ceglarek, 2006). Therefore, a new methodology is needed

Fig. 2. Multivariate normal process with a mean shift that minimizes the fallout rate of the process.

Process capability, process adjustment, quality

97

Downloaded By: [University of Warwick] At: 09:16 14 December 2009

ing Kernel Density Estimate (KDE)-based confidence regions with the mean set at design nominal. Also, it should

be noted that any variations in the distribution of measurement data will cause a change in optimum process mean

adjustments as can be noted by observing the differences

in Figs 2 and 4.

The proposed methodology addresses the aforementioned issues in the following ways.

Fig. 3. Multivariate non-normal process with the mean at design

nominal.

the failure regions. Figure 2 provides an example of process

adjustment that minimizes the overlap between the in-specs

failure region, process distribution and tolerance limits.

The problem becomes especially challenging when the

process measurements do not follow multivariate normal or

fixed parametric distributions. Such cases require the use of

a flexible non-parametric approach in representing process

measurements. We use a multivariate kernel-density-based

method to determine an estimate of the unknown density

of the process measurements. Kernel density estimation is

a popular technique for smooth estimation of the density,

consisting of a chosen kernel function (such as Gaussian,

Epanechnikov) and bandwidth matrix (width of the kernel

function) to estimate the density (Silverman, 1986; Scott,

1992). This paper follows the approach as implemented by

Polansky (2001) using optimum bandwidth selection based

on research conducted by Wand and Jones (1995). Figure 3

illustrates a case of non-normal process representation us-

Fig. 4. Multivariate non-normal process with a mean location to

avoid failure regions.

1. Determination of Functional Capability Space (FCSpace): Based on the in-specs fault regions and current

process measurements, we define FC-Space to represent

all process mean positions in order to ensure a given

process capability. The FC-Space is part of the process adjustment space that corresponds to the degrees

of freedom allowable for adjusting the process mean.

In this paper, the process adjustment space is based on

homogenous transformation and includes six degrees

of freedom. The overall FC-Space is defined by an inspecs failure region, KDE-based process representation,

tolerance space and process adjustment space. The FCSpace is the subset of adjustment space wherein there is

no overlap of the KDE with the in-specs failure regions.

2. Functional nominal and optimum process adjustment

based on FC-Space: This step determines the optimum

process adjustment necessary to minimize the process

fallout rate. The position of the process mean with minimum process fallout is referred as the functional nominal

( X̄f ) as compared to a fixed design nominal ( X̄d ). The

optimum process adjustment is based on determining

the mean location that is equidistant from the boundaries of the FC-Space. This ensures the least probability

of overlap between the process with different failure and

tolerance regions.

1.2. Related work

A great deal of research exists on monitoring and control

of manufacturing processes (Hawkins, 1991; Ceglarek and

Shi, 1995; Mason and Young, 2001). While recent research

has proposed a number of multivariate process monitoring

and control approaches (see, for example, Montgomery

(2005), there are no methods for process capability studies using non-normal process data and in-specs failures.

A common approach for multivariate process monitoring

is based on the Hotelling T 2 control charts. However, the

required process normality assumption is difficult to satisfy in many multivariate processes, for example, in electrical/electronic assembly processes where parameters are frequently tuned during testing. Recent research has focused

on developing non-parametric approaches to multivariate

process control. Sun and Tsung (2003) developed a kerneldistance-based multivariate control chart using a support

vector-based method for monitoring quality characteristics

that are non-normal. Polansky (2005) proposed another

non-parametric control chart based on estimation of the

Downloaded By: [University of Warwick] At: 09:16 14 December 2009

98

density of the sample subgroup statistic using a kernel density estimator of observed measurements. A comprehensive review of non-parametric control charts is presented

by Chakraborti et al. (2001).

There has also been considerable research on multivariate process capability analysis (Wang et al., 2000).

Generally, a multivariate capability index uses a pdimensional rectangular specification volume and assumes

that the distribution of the process measurements is

known. Multivariate-normal-distribution-based capability

methodologies have been proposed by Taam et al. (1993),

Chen (1994) and Shahriari et al. (1995). Chen (1994) developed a general multivariate capability index that allows both rectangular and elliptical specifications. Wang

et al. (2000) reviewed major multivariate process capability indices under the assumption of normality. Polansky

(2001) proposed a non-parametric, distribution-free estimator to compute multivariate process capability that is

calculated based on the KDE of the probability density

function (p.d.f.). This methodology is also used to estimate

the probability of failures to generate control charts (Polansky, 2005). Foster et al. (2005) proposed cause-related multivariate capability indices based on process-oriented basis

representation.

However, all the aforementioned methodologies assume

that there are no in-specs failure regions, which can often result in miscalculation of process capability and mean

adjustment as illustrated in Figs. 2 to 4. The focus of the

proposed FC-Space approach is to integrate the in-specs

failure regions with non-parametric process measurements

in order to determine process capability as well as optimum

process adjustment to minimize process fallout rate.

1.3. Problem formulation

The FC-Space approach is based on information obtained from design (Tolerance Space), failure analysis (Failure Space) and manufacturing measurements (KDE-based

Process Space). The process adjustment is determined

based on design tolerances, fault region in the space of measurements related to failure and the confidence interval associated with the process measurements used to determine

the capability. These three regions, Tolerance Space, Failure

Space and Process Space are defined as follows (Fig. 5).

1. Tolerance Space Tm (T-Space): Let B represent all DPs

and PVs related to a given field failure which are to be

monitored jointly. B defines an m-dimensional space Rm

(|B| = m) that is of interest for monitoring the selected

field failure. The methodology for identifying B is presented in Mannar and Ceglarek (2006). The tolerance

space, T m , is defined by all design tolerances assigned

to each DP and PV, where ai ∈ B. T m is a subset of Rm

defined by design tolerances.

2. Failure Space F (F-Space): The Failure Space, F is the

failure region in Rm , consists of: (i) an in-specs failure

Mannar and Ceglarek

Fig. 5. Illustration of Tolerance, Failure and Process Spaces

|B| = 3.

region within the T m which is sensitive to warranty failures or cause lower process yield Fin-spec ; and, (ii) an

out-of-tolerance failure region Fout−of−spec = Rm − T m ,

i.e., the region in the m-dimensional space outside of

design tolerance:

F = Fin-spec + Fout-of -spec .

(1)

3. Process Space A (A-Space): The process space A represents measurements obtained for DPs and PVs in B.

The process space A is defined by a specified confidence

region generated based on sample measurements, for

example, 99.73% confidence region. The confidence interval/region can be generated based on parametric or

non-parametric representation of the measurement data

depending on the characteristics of the process. In this

paper, we use a non-parametric approach to generate the

confidence interval for multivariate data based on kernel density estimation for m-dimensional measurements

using n sample manufacturing measurements.

3.1. Adjustment space (Cad j -Space): The adjustment

space corresponds to the possible degrees of freedom associated with the capability to adjust the

process mean, X̄. Since the process region A is

assumed to be constant (no change in shape),

the coordinates of any reference point in A completely define the position of A. Therefore, adjustment space for A can be represented in terms of

mean X̄ = (γ1 , ..., γd ) ∈ Rd , where

m

d =m+

2

is the number of degrees of freedom; (γ1 , . . . , γm )

is the position of the reference point, X̄ and

(γm+1 , . . . , γd ) are the Euler angles specifying the

orientation of X̄. Any adjustment of X̄ in this ddimensional space changes the location or orientation of A. Process space A in a specific position

defined by position of X̄ = x̄ is represented by (A)x̄ .

While Cad j -Space as defined above is generic

enough to incorporate both mean shift and rotation

Process capability, process adjustment, quality

99

of process space A, in this paper we primarily focus on mean-shift-based adjustment of a process.

This assumes that the process space A can only be

adjusted by translational degrees of freedom, i.e.,

Euler angles (γm+1 , . . . , γd ) are constant and only

(γ1 , . . . , γm ) defining the position of the reference

point is considered.

Since the process mean X̄ is used as the reference point for process adjustment, (γ1 , . . . , γm )

are determined based on calculation of the sample

mean for m-dimensions based on n-sample process

measurements.

⎡

⎤

n

n

n

X̄ = ⎣

(x j1 )/n,

(x j2 )/n, . . . ,

(x j m )/n ⎦ .

Downloaded By: [University of Warwick] At: 09:16 14 December 2009

j =1

j =1

j =1

(2)

3.2. Restricted Adjustment Space (COA (F)): The failure

space F is mapped into the Cad j -Space to determine

the coordinates of X̄ for which there is overlap of

A with F:

COA (F) ≡ {x̄ ∈ Rm |(A)x̄ ∩ F = Ø}.

(3)

Based on the above-defined spaces, the functional

capability space, FC-Space, potential capability index F Ĉ p and optimum process adjustment can be

described as follows (illustrated in Fig. 6):

1. Functional capability space (FC-Space): FC-Space is defined as the subset of the Cad j -Space for which there is

no overlap between the failure and process space (F and

A), i.e., {x ∈ Rm |(A)x ∩ F = Ø}. The FC-Space can be

obtained by the Boolean subtraction of CO A(F) from

Cad j -Space:

FC − Space =

{x ∈ Rm |(A)x ∩ F = Ø}. (4)

2. Potential capability index F Ĉ p : This capability index determines the ratio of process dispersion (variation) to

the available tolerance space. The FC-Space determines

the region in the adjustment space that can be used by

the process mean location. This considers both the process dispersion (A) and the failure regions (F). The F Ĉ p

Fig. 6. Illustration of FC-space and COA (F).

index is defined as the volume of the FC-Space corresponding to a 99.73% confidence region; a higher volume indicates better process capability and vice-versa:

F Ĉ p = vol (FC − Space99/73% ).

3. Optimum Process Adjustment: Based on the identified

FC-Space boundaries the next step involves identifying

the functional nominal which is the optimum position

of the mean so as to minimize the process fallout. The

location of the current mean with respect to the functional nominal X̄f determines the functional capability

index FC pk, which is explained below.

3.1. Determination of functional nominal ( X̄f ): The functional nominal corresponds to the position of

the process mean with the lowest possible fallout rate. The functional nominal corresponds to

the optimum process adjustment achieved only

by mean adjustment, i.e., shift of the process

mean without changing the variance or other

distribution characteristics. This involves determining the location of A such that: (i) A ∩

F = Ø, i.e., COA (F) = Ø; and (ii) maximizing

the minimum distance of X̄ to the FC-Space

boundaries.

3.2. Functional capability index (FC pk): The distance of

the current process mean to the functional nominal

determines the mean location index FC pk.

The outline of the proposed approach is shown in Fig. 7.

2. Generation of process space (A)

This section focuses on determining a kernel estimate of

the unknown population p.d.f. f . The confidence intervals obtained from the analysis are shown in Fig. 8. The

methodology for estimating f is based on Polansky (2001)

and consists of the following steps.

Step 1. Select a kernel function K to estimate the p.d.f. fˆ

of a given measurement sample

Step 2. Estimate the optimum bandwidth matrix (H) that

minimizes the mean square error between the estimated fallout rate and the actual fallout rate for

the sample data.

Step 3. Determine of the confidence intervals based on the

estimated p.d.f. fˆ .

The p.d.f. of the measurements fˆ is estimated based on

n random samples with measurements X1 , X2 , . . . , Xn .

Each sample measurement Xi consists of m measurements

Xi = [Xi 1 , . . . , Xi m ].

The kernel function used in the analysis is the multivariate Epanechnikov kernel based on Wand and Jones (1995)

and Polansky (2001), who suggest that Epanechnikov kernels are generally optimal.

Downloaded By: [University of Warwick] At: 09:16 14 December 2009

100

Mannar and Ceglarek

Fig. 7. Outline of the proposed methodology.

The bandwidth matrix H is a symmetric positive definite d × d matrix and defines kernel function K H (x) =

|H|−1/2 K(H−1/2 x). The d-variate kernel-density estimate of

f is given by

fˆ (x; H) = n −1

n

KH (x − Xi ) for all x ∈ Rm .

(5)

i =1

The kernel-based estimate of process fallout p̂(H) is given

by (Polansky, 2001):

p̂(H) = 1 −

f̂ (x; H)d x −

f̂ (x; H)d x

FR

= 1 − n −1

Fig. 8. KDE confidence regions and failure regions.

+

n n i =1 TFR

TFR

KH (x − Xi )d x

i =1 FR

KH (x − Xi )d x.

(6)

Process capability, process adjustment, quality

101

The Mean Squared Error (MSE) of the above estimator is

computed by

MSE[ p̂(H)] = E[ p̂(H) − p]2 .

(7)

The estimation of the optimal bandwidth using Equation

(7) is done using the bootstrap-based approach suggested

by Polansky (2001).

Based on the above mentioned procedure we estimate the

p.d.f. fˆ which is used to determine various confidence intervals of interest (for example, 99.73% confidence interval

corresponding to six-sigma variation). Figure 8 shows an

example of the KDE-based confidence regions.

Downloaded By: [University of Warwick] At: 09:16 14 December 2009

3. Functional process capability space (FC-Space)

This section focuses on the determination of FC-Space and

process capability F Ĉ p index.

The different KDE confidence regions generated are

approximated by the minimum convex polyhedron that

completely surrounds each of these confidence regions. A

separate analysis is conducted for each confidence region

to determine the FC-Space corresponding to the different

confidence regions required. For example, if a 99.73% confidence region is used then the FC-Space corresponding to

this region is obtained.

In general, failure space F can consist of multiple failure

regions: kW defined as number of in-specs failure regions

Fin-spec and kT defined as number of out-of-specs failure

regions Fout-of -spec as shown in Equation (8):

F=

Fin−spec +

j =1

kT

Fout-of -spec .

(−A) ⊕ F j = {x + y|x ∈ (−A), y ∈ F j }.

(12)

The calculation is performed based on the algorithm proposed by Lozano-Perez (1980) which firsts converts any set

A into a convex polygon denoted by Conv(.) and vert(.)

denotes the vertices of the convex polygon generated for F

and A. Lozano-Perez (1980) shows that if A and F j are convex then COA (F j ) is convex and COA (F j ) can be calculated

using Equations (13) and (14):

COA (F j ) = conv(vert(F j ) − vert((A)x̄0 )).

COA (F j ) = F j ⊕ (−(A)x̄0 ).

(13)

(14)

3.2. Determination of FC-Space and capability index F Ĉ p

3.1. Determination of the restricted adjustment space

C OA (F)

kW

V, V is the set of all vertices of A. The calculation of

COA (F j ) involves the sum of F j and −(A)x̄0 which is performed by using the Minkowski sum defined as follows:

(8)

Based on Equation (14) individual COA (F j ) are calculated

to determine COA (F) which is then used to calculate the

FC-Space as:

FC − Space = Cad j Space − COA (F).

(15)

The generated FC-Space is a polygon since it is formed

by the combination of Cad j -Space and COA (F) which are

represented as polygons.

Finally, the volume of the FC-Space corresponding to

99.73% confidence region defines the current process capability, F Ĉ p = vol(FC − Space99/73% ). Figure 9 shows the

FC-Space corresponding to 99.73% confidence region. A

series of FC-Spaces can be generated for different confidence regions as shown in Fig. 10.

j=1

CO A(F) consists of coordinates x̄ in the Cad j -Space wherein

(A)x̄ ∩ Bi = Ø∀Fi ∈ F

COA (Fi ) = {x̄ ∈ Cad j − Space|(A)x̄ ∩ Fi = Ø}.

COA (F) =

KF +KT

∪

j =1

COA (F j ).

(9)

(10)

If c is a given location of A defined by the mean location x̄c ,

then (A)x̄c = x̄c ⊕ (A)x̄0 . The operation ⊕, between any

two objects A and B is defined as

A ⊕ B = {a + b|a ∈ A, b ∈ B} and A B

= A ⊕ (−B), (−B) = {−b|b ∈ B}.

The operations of ⊕ and can be used to identify restricted

adjustment space COA (F j ) as shown in Equation (11):

COA (F j ) = F j (A)x̄0 .

(11)

The equation COA (F j ) = F j (A)x̄0 is equivalent to

COA (F j ) = F j ⊕ (−(A)x̄0 ), where −(A)x̄0 = x̄0 − ai ∀ai ∈

Fig. 9. FC-Space for 99.73% confidence interval corresponding

to MC pm ≥ 1.

102

Mannar and Ceglarek

Downloaded By: [University of Warwick] At: 09:16 14 December 2009

of the point (functional nominal) to the boundaries of FCSpace. This can be considered as part of a max-min location problem (Dasarthy and White, 1980). They show maxmin location problems as to be a non-convex programming

problem with several local optima. Also, as suggested by

Rademacher (2007) an efficient deterministic algorithms to

exactly compute the centroid of a convex body does not exist. Therefore, we adopt a heuristic approach with a “good”

initial estimate of the center of the convex polyhedron and

improve this estimate through local improvement.

Hence, we adopt a two-step approach:

Fig. 10. FC-Space for different confidence interval regions.

4. Process adjustment

4.1. Determination of functional nominal ( X̄ f )

The location of the process mean with respect to the FCSpace can be used to determine the functional nominal X̄f

which is the optimum location of the X̄ with least amount

of overlap between process A and the failure regions. This is

determined based on maximizing the minimum distance of

X̄ with the boundaries of FC-Space. In mean adjustment we

use the boundaries of FC-Space corresponding to a 99.73%

confidence interval to determine the location of X̄ which

maximizes the minimum distance of X̄ from the edges of

the FC-Space.

Let FC-Space (corresponding to a 99.73% process representation) consist of p edges denoted by e j , j = 1, . . . , p,

and let x̄0 be the current coordinate of the mean. For

the sake of simplicity we assume that the mean is adjusted to be on the boundary or inside the FC-Space, i.e.,

x̄0 ∈ FC − Space. For each edge e j let u j,x̄0 be the normal

to e j from the coordinate x̄0 . The orthogonal distance of

x̄0 to each edge (boundary) of FC-Space is therefore given

by |u j,x̄0 |, j = 1 , . . . , p. The optimum position of X̄ which

is the functional nominal, noted as x̄cp ∈ FC − Space, is

obtained by minimizing the maximum distance |u j,x̄k | over

all edges j = 1,. . . , p, that is

Step 1. The initial solution is defined by the Chebyshev

center, which is the center of the largest inscribed

sphere for the convex polygon representing the FCSpace computed via linear programming based on

Section 4.3.1 of Boyd and Vandenberghe (2004).

Step 2. Next a heuristic (genetic algorithm)-based approach is used to determine if an improved estimate

exists which maximizes the minimum distance of

the edges of the FC-Space while within the convex

polygon defining the FC-Space. The fitness function for the Genetic Algorithm (GA) is therefore,

defined by minimizing Equation (17). The GAbased approach is based on the stopping criteria

of iterations = 100 × number of model variables

used in Matlab Direct Search Toolbox.

An illustration of the optimum location satisfying Equation

(16) is provided in Fig. 11.

4.2. Determination of functional capability index (FC pk)

The mean location index determines the location of the

current process mean x̄ to the optimum mean location

Xf = min(|u j,x̄cp |), ∀ j = 1, . . . , p ≥ min(|u j,x̄k |)

(16)

∀ j = 1, . . . , p, ∀x̄k ∈ FC − Space.

This can be achieved by representing it as an optimization

problem as shown in Equation (17):

(x̄k) = max(min(|u j,x̄cp |)),

∀ j = 1, . . . ,p, ∀x̄k ∈ FC − Space.

(17)

The basic objective of Equation (16) is to determine a

point within FC-Space, which will maximize the distance

Fig. 11. Optimum location of mean based on 99.73% C p -Space.

Process capability, process adjustment, quality

103

Table 1. Comparison of traditional and functional capability

analysis

Interpretation

Traditional

capability

analysis

Aggregated capability

MC pm

index

Dispersion capability

Ĉ p

index

Optimum mean location Design

calculation

nominal

1

Process mean location

D̂

index

Functional capability

analysis

FC-Space

Fc p = vol(Fc99.73% )

Functional nominal

FC pk

Distance of process mean

to optimum position

Downloaded By: [University of Warwick] At: 09:16 14 December 2009

Fig. 12. Traditional capability index calculation.

determined by the functional nominal X̄f :

FC pk = dist(x̄, X̄f ).

(18)

5. Relationship of FC-Space to the multivariate

capability index

In this section, we compare the functional capability indices as proposed in this paper to traditional multivariate

capability indices.

In the past few years, researchers have developed several

multivariate capability indices (Cheng, 1991; Taam et al.,

1993; Shariari et al., 1995). A comparison conducted by

Wang et al. (2000) indicate that these capability indices

share a close relationship in calculation and interpretation.

Therefore, for consistency we select definitions proposed

by Taam et al. (1993) to illustrate the relationships between

functional and traditional capability indices.

Table 1 shows the comparison of the traditional capability analysis with the proposed functional capability analysis

based on the FC-Space.

5.1. Traditional capability analysis

The multivariate capability index, MC pm , is defined as follows (Taam et al., 1993):

ˆ pm = Ĉ p .

MC

(19)

D̂

The index can be decomposed into two segments based on

the numerator and denominator.

1. Dispersion capability index Ĉ p : Calculation of Ĉ p is

based on the ratio of the tolerance volume to the process dispersion volume. The calculation is performed

after modification of either the tolerance region or process region to have the same general geometric shape,

i.e., for the case of a normality assumption, either the

tolerance is modified to have an elliptical shape as the

process confidence region, or the process confidence region is modified to be rectangular. Figure 12 illustrates

the modification of tolerance region into elliptical shape

for Ĉ p calculation:

Ĉ p =

vol (Tolerance region)

.

vol (esimated 99.73% process region)

(20)

2. Process mean capability index 1/ D̂: The distance of the

process mean to the design nominal, D̂, can be calculated

as

1/2

n

D̂ = 1 +

( X̄ − µ0 ) S−1 ( X̄ − µ0 )

(21)

n−1

Values of 0 < 1/ D̂ < 1 measure the closeness of the design nominal X̄d to sample mean. The maximum value

of 1/ D̂ = 1 is achieved when the process is centered at

the design nominal X̄d , then the M̂CPM = Ĉ P .

The calculations of the MC pm assume that the design

nominal is the “ideal” process location. However, the current process capability indices do not consider the in-specs

failure region(s) which could result in higher errors when

approximating the same geometric shape.

5.2. Functional capability analysis

The proposed functional capability analysis generalizes the

currently used capability index MC pm by incorporating inspecs failure regions and non-parametric estimates for confidence regions.

Corresponding to the MC pm index we can use the boundaries generated by FC-Space to determine the overall process capability. In traditional capability analysis a value

of MC pm = 1 signifies that 99.73% of the process values

lie within the tolerance region, providing a process fallout

rate of 0.27%. In the functional capability this process fallout rate is guaranteed by the 99.73% boundary for the

104

Mannar and Ceglarek

Downloaded By: [University of Warwick] At: 09:16 14 December 2009

tolerance region and interior fault regions and thus,

MC pm > FC p .

The two parts of the traditional process capability index MC pm , the numerator and denominator in Equation

(19), have a close relationship with the functional capability

indices and can be described as follows:

1. Dispersion functional capability index FC p : The process

functional capability index Fc p = vol(Fc99.73% ) represents the 99.73% volume of the FC-Space. This volume

takes into account the shape and location of the inspecs failure regions, tolerance boundaries and process

spread determined by KDE confidence region. Higher

values for FC p denote a smaller process spread compared to the available tolerance volume, which is similar

to traditional Ĉ p .

However, traditional Ĉ p calculation is based on the

approximation of the process region and tolerance window, which is understood to have the same geometric

shape and thus results in larger errors in the case of

in-specs failure regions and non-parametric confidence

regions.

2. Actual functional capability index (FC pk): Since the location of process mean depends on in-specs failure regions and the KDE confidence region, the functional

nominal is different from the design nominal. Section

4 discusses the determination of the functional nominal. The distance of the optimum functional nominal

from the current mean determines the FCpk which is a

measure of process actual capability index.

6. Case study

The presented methodology of capability adjustment using

FC-Space to monitor manufacturing measurements with

in-specs failure regions is illustrated using an industrial case

study from cell phone manufacturing. The case study analyzes warranty failures of a high-end consumer cell-phone

model from the iDEN phone family introduced in 200l.

Mannar and Ceglarek (2006) identify two critical manufac-

Fig. 13. Scatter plot (869 samples).

Fig. 14. KDE-based confidence regions.

turing measurements related to the failure and one in-specs

fault region.

The analysis is performed using sample of 869 products.

Based on the design tolerances, measurement data and

identified in-specs failure region, we apply the proposed

methodology to determine: (i) the FC-Space corresponding to different confidence intervals; and (ii) the functional

nominal X̄f based on a 99.73% FC-Space.

6.1. Determination of process space A

The process space A is calculated using manufacturing

measurement data. The scatter plot of the measurements

and the corresponding KDE-based confidence regions are

shown in Figs 13 and 14, respectively. The optimal bandwidth values of H for the bivariate data were calculated

based on minimizing the MSE error between the actual

process fallout and estimated process fallout using the p.d.f.

fˆ. The optimal bandwidth values of H = 3.2 for Var1, and

H = 1.156 for Var2.

Fig. 15. Determination of FC-Space.

Process capability, process adjustment, quality

Downloaded By: [University of Warwick] At: 09:16 14 December 2009

Fig. 16. Optimum mean adjustment.

105

process mean to determine regions, that ensure a required

process capability.

The process space consists of confidence regions that are

generated using KDE-based non-parametric estimation of

the distribution of the measurements. A series of FC-Spaces

is generated corresponding to varying confidence intervals

which can be used to determine current process capability.

Based on the FC-Space99.73% generated for 99.73% confidence interval we estimate the potential functional capability

index FC p .

In addition, we determined the optimum process location

defined as the functional nominal which ensures the lowest

process overlap with corresponding tolerance and failure

regions; and actual functional capability index FC pk.

The relationship between functional capability and traditional multivariate process capability is discussed. The proposed methodology is illustrated using a case study from

cell-phone manufacturing.

6.2. Determination of FC-Space

The FC-Space was calculated following the approach described in Section 3. The FC-Space corresponding to the

99.73% confidence region is shown in Fig. 15. Figure 16

shows the FC-Space obtained for varying confidence intervals. Figure 16 also shows the design nominal X̄d = (12.5,

154.5) and the obtained functional nominal X̄f = (10.08,

124.95).

The case study also illustrates the importance of identifying the minimum subset of manufacturing parameters

related to the failure (Mannar and Ceglarek, 2006). This

is important since the proposed methodology is based on

KDE-based process representation and Minkowski sum–

based determination of FC-Space, which are computationally expensive and have estimation bias in higher dimensions. The current state of the art in calculation of the

Minkowski sum for FC-Space calculation (Varadhan and

Manocha, 2006) and KDE estimation (Scott and Sain,

2004) can handle at least three dimensions.

7. Conclusions and future work

This paper focuses on functional process capability analysis and mean adjustment for processes that have in-specs

(within tolerance) failure identified during manufacturing or field phase of the Product Life-cycle Management

(PLM). The consideration of in-specs failures is of critical

importance in integrating design, manufacturing and service engineering in the product PLM paradigm. Current

process capability and adjustment methods lead to incorrect results in the presence of in-specs failure regions.

In order to address this problem, we presented a generic

methodology to handle multiple in-specs failure regions

within the DPs or PVs tolerances (in-specs). The proposed

FC-Space methodology maps the in-specs failure regions

and design tolerance space into the adjustment space of the

Acknowledgements

The authors acknowledge the financial support provided by

a UK STAR Award EP/E044506/1 and Motorola Corp.

The authors would like to acknowledge Ashutosh Katiyar,

ZS Associates, Princeton, NJ, for his initial work on the

paper as well as Dr. Feng Niu and Bassam Bafaraj, Motorola for their discussions related to the warranty issues in

electronic manufacturing.

References

Boyd, S.P. and Vandenberghe, L. (2004) Convex Optimization, Cambridge

University Press, Cambridge, UK.

Ceglarek, D., Huang, W., Zhou, S., Ding, Y., Kumar, R. and Zhou

Y. (2004) Time-based competition in manufacturing: stream-ofvariation analysis (SOVA) methodology-review. International Journal of Flexible Manufacturing Systems, 16(1), 11–44.

Ceglarek, D. and Shi, J. (1995) Dimensional variation reduction

for automotive body assembly. Manufacturing Review, 8(2),

139–154.

Chakraborti, S., Van der Laan, P. and Bakir, S.T. (2001) Nonparametric

control charts: an overview and some results. Journal of Quality

Technology, 3, 304–315.

Chen, H. (1994) A multivariate process capability index over a rectangular

solid zone. Statistica Sinica, 4, 749–758.

Chen, Y., Ding, Y., Jin, J. and Ceglarek, D. (2006) Integration of tolerance

and maintenance design for multi-station manufacturing processes.

IEEE Transactions on Automation Science and Engineering, 3(4),

440–453.

Cheng, S.W., Chang, L.K. and Spiring, F.A. (1991) A multivariate measure of process capability cpm. International Journal of Modeling

and Simulation, 11, 1–6.

Dasarathy, B. and White, L.J. (1980) A maximin location problem. Operations Research, 28(6), 1385–1401.

Ding, Y., Ceglarek, D. and Shi, J. (2002a) Design evaluation of

multi-station assembly processes by using state space approach.

Transactions of ASME, Journal of Mechanical Design, 124(3),

408–418.

Downloaded By: [University of Warwick] At: 09:16 14 December 2009

106

Ding, Y., Ceglarek, D. and Shi, J. (2002b) Fault diagnosis of multistage

manufacturing processes by using state space approach. Transactions of ASME, Journal of Manufacturing Science and Engineering,

124(2), 313–322.

Ding, Y., Jin, J., Ceglarek, D. and Shi, J. (2005) Process-oriented tolerancing for multi-station assembly systems. IIE Transactions on Design

and Manufacturing, 37(6), 493–508.

Droogenbroeck, M.V. and Buckley, M. (2005) Morphological erosions

and openings: fast algorithms based on anchors. Journal of Mathematical Imaging and Vision, 22(2–3), 121–142.

Foster, E.J., Barton, R.R., Gautam, N., Truss, L.T. and Tew, J.D. (2005)

The process-oriented multivariate capability index. International

Journal of Production Research, 43(10), 2135–2148.

Hawkins, D.M. (1991) Multivariate quality control based on regressionadjusted variables. Technometrics, 33, 61–75.

Khan, A. and Ceglarek, D. (2000) Sensor optimization for fault diagnosis

in multi-fixture assembly systems with distributed sensing. Transactions of ASME, Journal of Manufacturing Science and Engineering,

122(1), 215–226.

Lozano-Perez, T. (1980) Spatial planning: a configuration space approach. AI Memo 605, Artificial Intelligence Laboratory, Massachusetts Institute of Technology, Cambridge, MA.

Mannar, K. and Ceglarek, D. (2006) Fault region localization: product

and process improvement based on field performance and manufacturing measurements. IEEE Transactions on Automation Science

and Engineering, 3(4), 423–439.

Mason, R.L. and Young, J.C. (2001) Implementing multivariate statistical

process control using Hotelling’s T2 statistic. Quality Progress, 34(4),

71–73.

Matheron, G. and Serra, J. (1988) Image Analysis and Mathematical Morphology Volume 2: Theoretical Advances, Academic Press, London.

Montgomery, D.C. (2005) Introduction to Statistical Quality Control, fifth

edition, Wiley, New York, NY.

Polansky, A.M. (2001) A smooth nonparametric approach to multivariate process capability. Technometrics, 43(2), 199–211.

Polansky, A.M. (2005) A general framework for constructing control

charts. Quality and Reliability Engineering International, 21(6), 633–

653.

Rademacher, L.A. (2007) Approximating centroid is hard, in Proceedings

of 23rd Annual Symposium on Computational Geometry, pp. 302–

305.

Scott, D.W. (1992) Multivariate Density Estimation: Theory, Practice and

Visualization, Wiley, New York, NY.

Scott, D.W. and Sain, S.R. (2005) Multi-dimensional density estimation,

in Handbook of Statistics, Data Mining and Computational Statistics,

Rao, C.R. and Wegman, E.J. (eds), Elsevier, Amsterdam, pp. 229–

261.

Shahriari, H., Hubele, N.F. and Lawrence, F.P. (1995) A multivariate

process capability vector, in Proceedings of the Fourth Industrial

Engineering Research Conference, pp. 304–309.

Shiu, B.W., Apley, D., Ceglarek, D. and Shi, J. (2003) Tolerance allocation

for sheet metal assembly using beam-based model. IIE Transactions

on, Design and Manufacturing, 35(4), 329–342.

Silverman, B.W. (1986) Density Estimation for Statistics and Data Analysis, Chapman & Hall, London, UK.

Skinner, K.R., Montgomery, D.C., Runger, G.C., Fowler, J.W.,

McCarville, D.R., Rhoads, T.R. and Stanley, J.D. (2002) Multivariate statistical methods for modeling and analysis of wafer probe

test data. IEEE Transaction on Semiconductor Manufacturing, 15(4),

523–530.

Sun, R.X. and Tsung, F. (2003) A kernel-distance-based multivariate

control chart using support vector methods. International Journal

of Production Research, 41(13), 2975–2989.

Taam, W., Subbaiah, P. and Liddy, J.W. (1993) A note on multivariate

capability indices. Journal of Applied Statistics, 20(3), 339–351.

Mannar and Ceglarek

Takata, S., Kimura, F., Van Houten F.J.A.M., Westkamper, E., Shpitalni, M., Ceglarek D. and Lee, J. (2004) Maintenance: changing

role in life cycle management. Annals of the CIRP, 53(2), 643–

655.

Varadhan, G. and Manocha, D. (2006) Accurate Minkowski sum approximation of polyhedral models. Graphical Models, 68(4), 343–355.

Wand, M.P. and Jones M.C. (1995a) Kernel Smoothing, Chapman and

Hall, London, UK.

Wand, M.P. and Jones, M.C. (1995b) Multivariate plug-in bandwidth

selection. Computational Statistics, 9, 97–116.

Wang, F.K., Hubele, N.F., Lawrence, F.P., Miskulin, J.D. and Shahriari, H. (2000) Comparison of three multivariate process capability

indices. Journal of Quality Technology, 32(3), 263–275.

Zhou, S., Ding, Y., Chen, Y. and Shi, J. (2003) Diagnosability study of

multistage manufacturing processes based on linear mixed-effects

models. Technometrics, 45(4), 312–325.

Biographies

Kamal Mannar received his B.Tech. degree in Mechanical Engineering

from the National Institute of Technology Karnataka, India in 2001,

an M.S. degree in Manufacturing Systems Engineering from the University of Wisconsin–Madison in 2005 and a Ph.D. degree in Industrial

and Systems Engineering from the University of Wisconsin-Madison

in 2006. He is currently working as a Knowledge Engine Development

Leader of Global Services Technology, General Electric Health Care,

Pewaukee, Wisconsin. His research interests include methodologies for

diagnosis and prediction of warranty and field failures, remote diagnosis

and prediction for health care equipment and use of field performance as

feedback to design and manufacturing to improve product robustness.

Dariusz (Darek) Ceglarek received his Ph.D. degree in Mechanical Engineering from the University of Michigan–Ann Arbor in 1994. He was

on the research faculty at the University of Michigan-Ann Arbor from

1995 to 2000. In 2000, he accepted an appointment at the University of

Wisconsin–Madison as an Assistant Professor in the Department of Industrial and Systems Engineering where he rose to the ranks of Associate

Professor and Professor in 2003 and 2005, respectively. Since 2006 he is

Professor and EPSRC Research Chair at the University of Warwick, UK.

He is a Fellow of CIRP. He served as Chair of the Quality, Statistics and

Reliability Section of the Institute of Operations Research and Management Sciences (INFORMS); Program Chair for the American Society

of Mechanical Engineers (ASME) Design-for-Manufacturing Life Cycle

(DFMLC) Conferences, Associate Editor of IEEE Transactions (TASE)

and Associate Editor of ASME Transactions, Journal of Manufacturing

Science and Engineering. His research focuses on product life cycle modeling and analysis with emphasis on production and healthcare systems

convertibility, scalability and 6-sigma quality and root cause analysis during design, manufacturing and service phases. He has published widely

in his research areas with more than 60 papers in leading journals. Two

of his paper received Best Paper Awards from the ASME Manufacturing

Engineering Division and ASME Design Engineering Division. He has

received numerous awards including in 2007 a UK EPSRC STAR Award

(granted to an “exceptional senior faculty, recognised international leader

in his/her research field”), US National Science Foundation (NSF) 2003

CAREER Award (NSF’s “most prestigious awards in support of junior

faculty who exemplify the role of teacher-scholars through outstanding

research, excellent education and the integration of education and research”); 1999 Outstanding Research Scientist Award from the College

of Engineering at the University of Michigan; the 1998 Dell K. Allen Outstanding Young Manufacturing Engineer of the Year Award from the Society of Manufacturing Engineers (SME). More information is posted at:

http://digital.warwick.ac.uk/Digital-Product-Lifecycle-Management.