A haemodialysis system for the treatment of acute renal N.L. Everdell ∗

advertisement

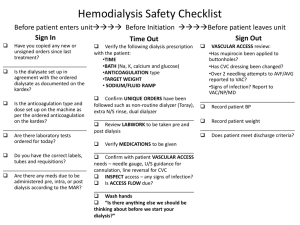

Medical Engineering & Physics 29 (2007) 516–524 A haemodialysis system for the treatment of acute renal failure and metabolic disorders in neonates N.L. Everdell ∗ Department of Medical Physics and Bioengineering, Malet Place Engineering Building, University College London, Gower Street, London WC1E 6BT, United Kingdom Received 2 November 2005; received in revised form 31 May 2006; accepted 20 June 2006 Abstract A prototype dialysis system for the treatment of premature babies has been designed, built and successfully tested. It can be used to treat babies who are suffering from renal failure or metabolic disorders. These patients are difficult or impossible to treat conventionally, due to their very small total blood volume (typically 40 ml) and their intolerance to donated blood. There was a strong case for developing a dialysis system specifically designed for the treatment of such patients. The system is based on a manually operated device that had been previously developed. The method differs from conventional dialysis in several ways. Blood access to the patient is via a single venous catheter. Only a very small amount of blood is needed to prime the extracorporeal circuit—this can be as little as 6.8 ml in the smallest patients. This compares very favourably with the volumes needed in conventional circuits, which are in the range of 15–40 ml. This small priming volume means that donated blood is not needed to prime the circuit, which reduces the risks and complexity of the treatment. The clearance and ultrafiltration rates that can be achieved are independent of the rate that blood can be accessed from the patient, since the same blood passes back and forth through the dialyser several times. In vitro testing covered several areas of operation. The accuracy of the ultrafiltration process was established. The clearance rates that could be achieved were determined. The clearances that have been obtained experimentally with the new system are consistently above 40% of the mean blood flow rate through the system. The largest mean blood flow rate available is 5 ml/min, so the maximum clearance is approximately 2 ml/min. The maximum ultrafiltration rate that can be obtained is 50 ml/h. The amount of damage caused to the blood by the system was found to be well within acceptable clinical limits. In vivo testing established the feasibility of using a computer algorithm to control the withdrawal of blood from the patient. The system has been used successfully to treat seven patients at the time of publication. © 2006 IPEM. Published by Elsevier Ltd. All rights reserved. Keywords: Haemodialysis; Premature; Neonatal; Renal failure; Metabolic disease 1. Introduction In recent years there has been a steady improvement in the survival rates of premature babies. This is because of steady progress in a number of areas of neonatal intensive care. The equipment available has improved as well as the actual methods of treatment. However, these general improvements have exposed one area of weakness, that of the management of acute renal failure (ARF). A study published in 1987 estimated that up to 8% of neonates admitted to intensive care could be ∗ Tel.: +44 207 679 0267. E-mail address: everdell@medphys.ucl.ac.uk. expected to develop renal failure [1]. More recent data [2] suggests that the figure is nearer 1%. Whichever figure is the more accurate, the number of cases is significant. In most of these the renal disease is secondary to some other serious condition. Common amongst these are respiratory distress syndrome (RDS), necrotising enterocolitis and cardiac disease. RDS is the most common complication of preterm birth. For higher birthweight babies, a range of dialysis treatments are available. It is generally accepted [3] that peritoneal dialysis is the preferred treatment for all birthweights. If this is not feasible (e.g. because of abdominal surgery) then either arteriovenous or venovenous extracorporeal circuits can be used. 1350-4533/$ – see front matter © 2006 IPEM. Published by Elsevier Ltd. All rights reserved. doi:10.1016/j.medengphy.2006.06.007 N.L. Everdell / Medical Engineering & Physics 29 (2007) 516–524 However, for babies with birthweights below 1 kg, the treatment options available are much more limited. Necrotising enterocolitis is a common complaint in premature babies—abdominal surgery is usually needed to correct this condition, and this makes peritoneal dialysis very difficult, due to the increased risk of abdominal infection (peritonitis). Continuous arteriovenous filtration requires a minimum mean arterial pressure of 40–50 mmHg [4] to achieve a sufficient extracorporeal blood flow rate. A typical mean pressure for a very low birthweight baby is only 35 mmHg, so this criterion is not met. In theory this limitation could be overcome by using venous access and an externally pumped circuit—in practice it is difficult to achieve adequate blood flow with this technique as well. If the problems of blood access can be overcome there still remains the difficulty of priming the circuit. It must be remembered just how small the total blood volume is in a 1 kg baby. A typical value is 40 ml [5] as compared with 5 litres in an average adult, i.e. just 0.8% of the adult volume. This means that priming even the smallest extracorporeal circuit with donated blood can produce massive, rapid changes in overall blood biochemistry. In very small babies, normal whole blood can never be used to prime the circuit. It contains large amounts of glucose (this keeps the cells alive) and all the calcium is removed from it. The processing it undergoes for preservation renders it very dangerous for babies of this size. These difficulties led to the development of a prototype manual dialysis system designed specifically for the treatment of premature babies [6]. This blood circuit design is unique. There are two other designs that bear superficial resemblance to this circuit [7–9]. Both were designed for use on adults. The new system’s novel design overcame both the problem of vascular access and of blood priming. However, it was not practical as it required the constant attendance of a nurse throughout the whole treatment process. This is in addition to the intensive care nurse who is already required to treat 517 the baby on a one to one basis. Therefore, the manual system was developed further to produce a practical clinical device that could provide both haemofiltration and haemodialysis. The system has also proved very effective for the treatment of some inherited metabolic disorders. It can be used to more effectively reduce the level of toxic chemicals when the kidneys themselves or peritoneal dialysis prove insufficient. Both lactic acidosis and hyperammonaemia have been successfully treated to date. 2. Description of system 2.1. Extracorporeal apparatus The basic layout of the system’s blood circuit is shown in Fig. 1. Fig. 2 is a view of the whole system from above. It is made, for the most part, from standard clinical equipment. The syringes however, are non-standard. They are of a gastight glass type with Teflon bungs (Hamilton Ltd., LA5 9EA, UK). The dialyser is a Miniflow 10 (Gambro Hospal Ltd., PE29 6XX, UK). It has a priming volume of only 3.5 ml and a membrane surface area of 0.042 m2 . The membrane polymer is acrylonitrile sodium methallyl-sulphonate, with a pore size of 2.9 nm. It is sterilised using ethylene oxide. A heparin infusion is delivered via tap 4 using a conventional syringe pump. This is set to deliver continuously. However, due to the cyclic opening and closing of tap 4 during normal operation, the anticoagulant is actually delivered intermittently (see below). The system is different in principle from conventional dialysis equipment because it does not rely on continuous vascular access. Instead, it allows the removal of a fixed quantity of blood from the patient, followed by the repeated cycling of this blood back and forth through a dialyser until the desired amount of haemodialysis and/or ultrafiltration has been achieved. The blood is then returned to the baby. The Fig. 1. Configuration of blood circuit. 518 N.L. Everdell / Medical Engineering & Physics 29 (2007) 516–524 Fig. 2. System viewed from above. total extracorporeal volume of the circuit is very small (as little as 6.8 ml) so priming with donated blood is unnecessary. The operating cycle of the circuit is as follows (refer to Fig. 1). Blood is withdrawn from the patient using syringe B through taps 3 and 4. The amount withdrawn depends on the size of the patient. For the smallest babies this is as little as 3 ml. For the larger babies up to 20 ml may be withdrawn. The rate of blood withdrawal also varies depending on how good the vascular access is. With good access, the rate of withdrawal would be approximately 10 ml/min. The right hand end of the dialyser is closed off during this operation (tap 2 closed), as is the heparin infusion line (by tap 4). When the required amount of blood has been withdrawn, tap 4 is turned so that the heparin infusion can once again flow into the venous line, and the venous line is cut off from the circuit. Tap 2 is turned so that the right hand end of the dialyser is now open. Blood filtration can now begin. The plunger of syringe B is depressed to push the blood through the dialyser into syringe A. This is done at a rate which gives a blood flow of 10 ml/min. A small difference in the rate at which the plungers move provides the transmembrane pressure across the dialyser to allow ultrafiltration to take place. When all the blood is in syringe A, the direction of travel of the plungers is reversed, allowing the blood to flow back into syringe B. The cycle is repeated until the required reduction in blood volume has been achieved.For example, with a working blood volume of 10 ml, the blood would be passed back and forth between the syringes four times during the filtration phase. Each operating cycle would take approximately 6 min. If the required ultrafiltration rate is 10 ml/h, each of these cycles would remove 1 ml of fluid. So on each pass through the dialyser, the blood volume would be reduced by 0.25 ml. With all the blood in syringe B, tap 2 is turned to close off the dialyser, and tap 4 is turned to open access to the venous line. This also closes off the heparin line. The filtered blood is then returned to the patient, again at a 10 ml/min flow rate. The whole cycle can then begin again. Heparin is infused into the apparatus via tap 4, using a standard infusion pump. Other intravenous infusions can also be given via tap 4. At the end of the treatment session, the blood that remains in the dialyser can be flushed back into the patient by replacing it with saline infused via tap 1. Dialysis can be performed in addition to ultrafiltration by passing a suitable dialysate through the outer casing of the dialyser. The mean pressure difference between the blood side and the dialysate side of the membrane is always either positive or zero during all phases of the operating cycle. Therefore, it is not possible for net backfiltration to occur if the dialyser is considered as a whole. However, the pressure gradient along the length of the dialyser means that local backfiltration can still occur where the blood side pressure is lower than that on the dialysate side. This is normal in any dialysis system. 2.2. Syringe actuation The syringe plungers are powered by 1 W stepper motors. The syringes are driven at slightly different rates to provide ultrafiltration. The ‘pushing’ syringe travels faster than the ‘pulling’ syringe, so the volume of the blood in the circuit is gradually reduced, forcing ultrafiltrate through the membrane of the dialyser. A powerful motor is needed to drive the N.L. Everdell / Medical Engineering & Physics 29 (2007) 516–524 syringes because of the effect that blood has on the plunger bung. It greatly increases the coefficient of friction between the plunger and the wall of the syringe. This is thought to be due to lipids from the blood being absorbed into the bearing surfaces of the syringe. Initial trials using ordinary plastic syringes failed because of this problem. The friction increased so much that the rubber bung became detached from the plunger, allowing the blood to leak by. With a standard Becton Dickinson 10 ml syringe this happened after 12 h of operation. Other brands were tried without a significant difference in the time taken or the end result. For this reason 25 ml (Hamilton Ltd., LA5 9EA, UK) gas-tight glass and Teflon syringes were used instead. 2.3. Three-way tap drivers The operating cycle of the system requires that two of the three-way taps are motorised, and each can be turned between two positions 90◦ apart. The torque required to turn these taps is relatively high. A similar process occurs here as with the syringes. Blood seeps into the bearing between the inner and outer body of the tap, greatly increasing the coefficient of friction between these two components. Becton Dickinson Connecta plus 3 three-way taps were tested under this condition of blood contamination, and were found to require a turning torque of 0.38 N m. Therefore, a powerful motor and gearbox are needed. A very large design margin was allowed, and a motor and gearbox combination was chosen that could deliver a torque of 4 N m while still turning the three-way taps at 5 rpm. This is equivalent to a power output of 2 W. The gearbox had a reduction ratio of 500:1. 2.4. Pressure monitoring system To monitor the operation of the system and make sure it operates within safe limits, it is necessary to continuously measure the pressure inside the extracorporeal circuit. This is done in all three phases of the cycle of operation: blood withdrawal, filtration and return. An Abbott Transpac IV monitoring kit is used as a transducer. 2.5. Control hardware and software The whole system is controlled by a standard PC fitted with a National Instruments LAB-PC-1200AI data acquisition card. The control software was written in C using LabWindows/CVI, also a National Instruments product. The system is controlled via a graphical user interface. The software controls several important parameters: ultrafiltration rate, blood sampling volume, withdrawal trigger pressure and pressure limits. Ultrafiltration rate and blood sampling volume were explained earlier. Withdrawal trigger pressure is an important parameter used in the blood withdrawal procedure. The software that controls the withdrawal of blood from the patient needs to be fairly sophisticated 519 to cope with the varying condition and type of the vascular access to the patient. Under good conditions, with good access, blood can be withdrawn at a steady 10 ml/min. However, with poor access, the withdrawal algorithm must monitor the access pressure, and react accordingly—if the pressure drops below a preset limit (the withdrawal trigger pressure) then blood withdrawal is stopped, and the syringe travel is briefly reversed, in an attempt to clear any potential blockage in the venous line. Fig. 3 illustrates a typical blood withdrawal algorithm. Several different algorithms are available—a suitable one is chosen to match the clinical conditions. This type of ‘adaptive’ algorithm is also able to accommodate easily the various different types of vascular access that will be used for dialysis treatment. It has performed equally well with umbilical catheters (both arterial and venous) and central lines. Safety pressure limits can also be set for various conditions of operation. If the pressure in the system reaches these limits, the system will be halted. During normal operation the continuously displayed pressure trace provides a good indication of the condition of the dialyser. As deposits from the blood build up on the inside of the hollow fibres, their resistance to the flow of blood increases. Therefore, the pressure difference between the two ends of the dialyser will also increase. Because the pressure transducer is positioned at one end of the dialyser, this difference will show up as a larger pressure change when the direction of blood flow through the dialyser is reversed. Dialysate flow rate is an important parameter that is not set by the control system. Dialysate is delivered to the outer jacket of the dialyser by a suitable intravenous (IV) pump, and the flow rate is set on the IV pump itself. The system can be initialised using the controls along the bottom of the screen. The operator can enter parameters for working blood volume, ultrafiltration rate and blood withdrawal rate. Alternatively the weight of the baby can be entered into the user interface, and a standard calculation is then performed to determine the operating parameters. The user interface displays several pieces of information as the treatment is progressing: the total treatment time, the cumulative filtrate volume, and the system pressure. If treatment is stopped and restarted, the box at the top right of the screen will display details of each treatment session—the treatment start time, the ultrafiltration rate used, the total volume of ultrafiltrate removed and the time at which treatment was stopped. Fig. 4 illustrates the overall structure of the software control of the system. 2.6. System safety The system is classified as class I equipment by IEC 60601 [10]. It has a direct connection to the patient via the venous line, so this introduces further safety considerations. The entire system is powered through an isolation transformer, which significantly reduces the risk of electric shock. A single fault analysis of the entire system was performed in accordance with IEC 60601 parts 1 and 2 [10,11]. Part 2 520 N.L. Everdell / Medical Engineering & Physics 29 (2007) 516–524 Fig. 3. Withdrawal algorithm flow chart. deals specifically with the safety requirements of dialysis machines. Much of the software and hardware is concerned with providing safe single fault conditions. The system initialisation procedure tests the entire system to ensure that it is functioning correctly. This can be used to prevent a fault being discovered after the system has been connected to the patient. A member of clinical staff is always in attendance while the system is being operated. 3. System evaluation 3.1. Ultrafiltration rate testing The system was extensively tested in vitro to determine its ability to accurately deliver the selected ultrafiltration rate. This is one of the most important treatment parameters in dialysis and must be delivered with an accuracy of ±5%. Fresh whole adult blood was used for these tests. Various combinations of working blood volume and ultrafiltration rate were tested, and each test ran for 1 h. The ultrafiltrate obtained was collected in a burette, and the volume obtained was compared to the required volume. Over 18 tests it was found that the ultrafiltration rate accuracy was within ±4.5%, which is within the specified requirements. This compares well with other published data [12,13]. 3.2. Addition of dialysis—clearance determination The concept of clearance is very important in dialysis. It quantifies the effectiveness of a dialysis treatment. It is defined as the volume of blood plasma that is completely cleared of a given solute per unit time. Dialysis is added to the system because it can provide greater effective clearances than ultrafiltration alone. It involves passing a specially prepared fluid over the outside of the blood carrying semi-permeable tubes. This provides a concentration gradient down which solutes can diffuse. Dialysate is pumped through the outer jacket of the dialyser by a standard intravenous pump. The dialysate is bicarbonate based, a 5 litres bag of Hospal Hemosol BO (Gambro Hospal Ltd., PE29 6XX, UK). The flow rates needed to dialyse a premature baby are very small, of the order of 100 ml/h. So a 5 litres bag could in theory last up to 50 h. In practice the dialysate is only stable for up to 24 h (the bicarbonate starts to precipitate out) so this is the limiting factor. Again, whole blood was used for clearance testing. The purpose of the tests was to determine what the clearance rates were for the system, and also what combination of working blood volume and dialysate flow rates gave the best clearance rates. Dialysate flow rates were chosen based on the mean blood flow rate through the dialyser. This is found by dividing the working blood volume by the time taken for an operating N.L. Everdell / Medical Engineering & Physics 29 (2007) 516–524 521 Fig. 4. System control flow chart. cycle. Two different dialysate flow rates were tested – the first was chosen to be the same as the mean blood flow rate – and the second to be twice as much as this. The ultrafiltration rate was set to zero. The levels of creatinine and urea in the blood were artificially increased so that more accurate measurements could be taken. The levels were increased by a factor of 5, by addition of the purified chemicals to the blood. Blood samples were collected at the inflow and the outflow from the dialyser, and dialysate samples at the outflow. Biochemical assays were then performed on these samples to determine the amount of clearance being achieved. Clearance can be calculated by using concentration values of blood inflow and outflow, or by using blood inflow and dialysate outflow. Combining these methods with data for potassium, urea and creatinine gives six values for each clearance. These were all in fairly good agreement. A mean value was then taken to give the results shown in Figs. 5 and 6. Fig. 5 shows the clearances obtained at the two different dialysate flow rates. This graph shows only a small 522 N.L. Everdell / Medical Engineering & Physics 29 (2007) 516–524 GFR and the clearance are very similar. Above this weight, the GFR increases more rapidly than the available clearance. However, at the maximum weight of 2.35 kg, the clearance is still 46% of the GFR, which is much higher than the clinically acceptable level. 3.3. Haemolysis testing increase in clearance at the higher dialysate flow rate. This indicates that at these blood flow rates, clearance is limited not by dialysate flow, but by the mean blood flow through the system. Fig. 6 compares the achieved clearances with the glomerular filtration rate of the healthy kidneys. The clearance data are related to birthweight via the working blood volume used in the system. A standard formula relates the working blood volume to the birthweight: it is assumed that a baby has 85 ml of blood per kg of body weight. It is also assumed that it is safe to withdraw 6% of the total volume for dialysis. Therefore, the equivalent birthweight in kg is found from the working blood volume by dividing by a factor of 5.1. Clinical continuous haemodialysis aims to achieve a clearance between 10 and 20% of the glomerular filtration rate (GFR) that the healthy kidneys would achieve. So in assessing the performance of the syringe driven system it is necessary to compare the clearances obtained with the GFR that a healthy baby of the same body weight would be producing. Empirical relationships are available which allow the GFR to be estimated [14]. The GFRs for a range of birthweights are included with the clearance data in Fig. 6 (dialysate flow rates were set at twice the effective blood flow rate through the system). It is interesting to note that at weights of 0.8 kg and below the The purpose of this investigation was to determine the amount of cell breakdown (haemolysis) being caused by the action of the dialysis machine itself, over a 12 h period. Haemolysis is caused by mechanical damage to the red blood cells. This will occur particularly at the point where the syringe plunger contacts the inside of the barrel. It is important because it severely affects the ability of the blood to transport oxygen around the body, leading to acute medical problems. Freshly donated adult whole blood was used for the experiment. With the experimental set up being used there are three main sources of haemolysis. The first is the action of the dialysis machine itself. The second is due to the blood in the test reservoirs being agitated by mechanical stirrers. This is necessary so that the formed elements do not settle to the bottom of the blood reservoir. The third comes from the natural breakdown of red cells in the blood samples. To eliminate the last two factors it was necessary to set up a controlled experiment. Therefore, two blood samples were used, a test sample and a control sample. The two were treated identically, apart from the test sample being passed through the dialysis machine, while the control sample was not. The machine was run continuously for 12 h. Every hour a 2.5 ml sample was taken from the test and control reservoirs. The 24 samples were tested for free haemoglobin. The results are shown in Fig. 7. It can be seen that the free haemoglobin level in the control sample does not vary much during the 12 h period. However, the test sample shows a steady increase in free haemoglobin levels during the same period. A calculation can be done using the highest level from this data, the 12 h value of 92.3 mg/dl. A haemolysis level of this size represents a total haemoglobin loss of 0.36%, which is well within safe limits. Fig. 6. Comparison between clearance and glomerular filtration rate. Fig. 7. Haemolysis testing. Fig. 5. Clearances for low and high dialysate flow rates. N.L. Everdell / Medical Engineering & Physics 29 (2007) 516–524 3.4. Testing for blood access In vivo testing was attempted to try to establish the functionality of the blood withdrawal algorithms. Two parameters were varied. The trigger pressure was varied between −100 and −500 mmHg. This is the pressure limit below which blood withdrawal is halted. The lower figure of −500 mmHg was based on clinical experience with the manually operated system. In this system the protocol for blood withdrawal allowed for an extra 0.5 ml of syringe barrel movement (using a standard 10 ml plastic disposable syringe) once blood flow from the access vessel had ceased. This movement obviously generates an excess negative pressure which encourages the flow to restart. This protocol was tested under in vitro conditions and the pressure generated was found to be approximately −500 mmHg. The delay time was varied between 2 and 10 s. This is the time between the cessation of blood withdrawal and its restarting. Blood withdrawal can fail simply because the vein has been ‘sucked dry’ of blood, allowing the venous walls to collapse. This delay allows time for vascular refilling to occur. It was hoped to find out the minimum time that still allowed refilling to occur. Two adult volunteers were used for the experiments. Superficial veins in the wrist were chosen for blood access, as these approximate to the size of the major veins found in a premature baby. The veins were cannulated using 22 gauge catheters. In total four venous access sites were tested. One site occluded too quickly for any testing to be done. The system withdrew blood successfully from the other three sites. Unfortunately the veins used were too large to provide a realistic test of the withdrawal algorithm. However, some useful information was still obtained. 3.5. Clinical use of system At the time of writing, seven patients have been treated with the new system—two with metabolic disease and five with renal failure. The machine has performed as well or better than expected from the in vitro data previously obtained. It has proved to be highly adaptable to the needs of the individual patients. The ages of the babies that have been treated range from 24 to 42 weeks, and their weights from 800 g to 4.8 kg. The first clinical use of the system involved a patient suffering from a mitochondrial cystopathy, a genetic metabolic disorder of the mitochondria. This particular genetic defect disrupts the respiratory pathway and results in excessive production of lactate molecules. High levels of lactate result in a variety of serious medical problems, and if the lactate level is not controlled it is usually a fatal condition. Although the system was designed originally for the treatment of acute renal failure, it is equally applicable to metabolic disorders of this type. The principle of operation is the same. In acute renal failure, metabolites that are normally removed by the kidneys are removed by dialysis. In the 523 same way, unwanted metabolites that result from metabolic disorders can also be removed. Some modification of the system operation was necessary. The baby was not particularly premature (8 months gestation) and it was important to reduce the lactate levels as quickly as possible. In view of these factors it was decided to change the parameters of both blood withdrawal, return and filtration, to increase the clearance of lactate. The maximum rate of blood withdrawal was increased from 10 to 30 ml/min. The same withdrawal rate reduction was used, i.e. steps of 1 ml/min. Blood return was also changed. Before, it was set to always return at 10 ml/min, regardless of the rate of withdrawal. This was changed so that the return rate was always the same as the withdrawal rate. The rate of blood flow through the filter was changed from 10 to 20 ml/min, and the filtration time was reduced from 4 to 2 min. It was thought that since blood access would be good, a reduction in filtration time would result in an overall increase in clearance, because of the increase in effective blood flow rate from the patient. Blood access was initially through an umbilical vein, and later through an umbilical artery. The working blood volume was set initially at 5 ml, and later increased to 10 ml. No ultrafiltration was necessary because it was assumed that the patient’s kidneys were functioning normally. Haemodialysis was achieved with an ordinary cartridge type intravenous pump, attached to a 5 litres bag of Hemosol BO dialysate. The flow rate was set to 400 ml/h. The patient was dialysed for a total of 20 h with no ill effects. The very high initial lactate levels were successfully reduced. The effective blood flow rate through the system was 3.3 ml/min. The lactate clearance was 1.9 ml/min. This figure was used to make a rough calculation of the time taken for the blood lactate level to fall to half of its initial value. It was assumed that the lactate was distributed just in the extracellular fluid and that this compartment constitutes 30% of the baby’s body weight. These approximations give a distribution volume for this baby of 500 ml. Using this value, the lactate half-life was found to be approximately 3 h. This compares favourably with published figures of 7 h [15]. A more detailed review of the clinical use of the system can be found elsewhere [16]. 4. Discussion and conclusion It has been shown that it is feasible to automate syringe driven haemodialysis. A novel prototype system has been developed, extensively tested and proven to perform to the specification originally drawn up. The original aims of the project have been expanded. Initially it was intended only for use in treating premature babies suffering from acute renal failure. Now the scope of its potential application has increased. This now includes heavier babies (up to 5 kg), and babies suffering from a variety of metabolic disorders. Both the ultrafiltration rates and the clearance rates that can be obtained with the new system are more than adequate for clin- 524 N.L. Everdell / Medical Engineering & Physics 29 (2007) 516–524 ical purposes. The haemolysis caused by the system has been tested and found to be well within safe limits. The system directly controls ultrafiltration rate. This represents a significant advantage over most conventional circuits, which can only indirectly control ultrafiltration, with a consequent loss of accuracy. In summary, if peritoneal dialysis is contraindicated, this system is superior to any other method of treatment that is currently available for babies suffering from acute renal failure and metabolic disorders. A second prototype machine is currently being developed by the Medical Physics department of the Freeman Hospital, Newcastle-Upon-Tyne, UK. This will benefit from the knowledge gained in building the first system, and many improvements will be incorporated into its design. Acknowledgements The author would like to thank Dr. Malcolm Coulthard, Jean Crosier and Dr. Michael Kier for their invaluable help with this work. References [1] Stapleton FB. Acute renal failure in neonates: incidence, etiology and outcome. Pediat Nephrol 1987;1:314–20. [2] Haycock GB. Management of acute and chronic renal failure in the newborn. Semin Neonatol 2003;8:325–34. [3] Coulthard MG, Vernon B. Managing acute renal failure in very low birthweight infants. Arch Dis Child 1995;73:187–92. [4] Bunchman TE, Donckerwolcke RA. Continuous arterial–venous diahemofiltration and continuous veno-venous diahemofiltration in infants and children. Pediat Nephrol 1994;8:96–102. [5] Ganong WF. Review of medical physiology. 10th ed Lange Medical Publications; 1981. [6] Coulthard MG, Sharp J. Haemodialysis and ultrafiltration in babies weighing under 1000 g. Arch Dis Child 1995;73:162–5. [7] De Virgiliis G, Vanin M, Buoncristiani U. A new single needle dialysis system. Trans Am Soc Artif Intern Organs 1985;31: 116–8. [8] De Wachter D, Verdonck P, Verhoeven R, Hombrouckx R. Comparison of a new and a standard single-needle dialysis system using a mathematical model. Artif Organs 1993;17:328–38. [9] Hombrouckx R, Bogaert AM, Leroy F, Beelen R, De Vos JY, Van Overmeeren G, Verhoeven R, Verdonck P, Vercruysse V. Limitations of short dialysis are the indications for ultrashort daily auto dialysis. Trans Am Soc Artif Organs 1989;35:503–5. [10] Medical electrical equipment. Part 1. General requirements for safety. IEC 60601-1. London: British Standards Institute; 1990. [11] Medical electrical equipment. Part 2. Particular requirements for the safety of haemodialysis, haemodiafiltration and haemofiltration equipment. IEC 60601-2-16. London: British Standards Institute; 1998. [12] Roberts M, Winney RJ. Errors in fluid balance with pump control of continuous hemodialysis. Int J Artif Organs 1992;15:99– 102. [13] Jenkins R, Harrison H, Chen B, Arnold D, Funk J. Accuracy of intravenous infusion pumps in continuous renal replacement therapies. ASAIO J 1992;38:808–10. [14] Coulthard MG. Maturation of glomerular filtration in preterm and mature babies. Early Hum Dev 1985;11:281–92. [15] Schaefer F, Straube E, Oh J, Mehls O, Mayatepek E. Dialysis in neonates with inborn errors of metabolism. Nephrol Dialysis Transplant 1999;14:910–8. [16] Everdell NL, Coulthard MG, Crosier J, Kier MJ. A machine for haemodialysing very small infants. Pediat Nephrol 2005;20(5): 636–43.