Waste to Energy: Thermochemical Pathways

advertisement

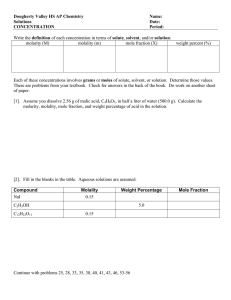

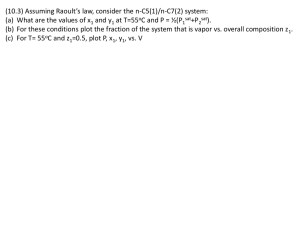

Waste to Energy: Thermochemical Pathways Isam Janajreh, Associate Professor, Mech. & Mat. Engineering Dept. Masdar Institute, Abu Dhabi, UAE Muscat, Oman ijanajreh@masdar.ac.ae 100 5 C/min 10 C/min 15 C/min 20 C/min 95 Weight ( %) 90 Material Characterization: • • • • • • Proximate (TGA) Ultimate (CHNSO-Flash) Chemical Kinetics (TGA) Thermal properties: Bomb Cal/Cp(STA) Impurities (GCMS, ICP, FTIR) Species determination (Drop. Tube) 85 80 75 70 65 60 20 120 220 320 420 520 620 720 820 Temperature (C) Low Temperature Pathways: • Digestion : Hydrolysis, acido, Aceto & Methanogenises • Transesterification • Plastic recycling/remoulding von Mises Strain Min=0.149 0.1 0.25 Max=0.788 0.38 0.52 0.66 0.8 von Mises Stress Min=35.0Mpa 40 High Temperature Pathways: • Incinerations/Combustion • Gasification (GEK) • Pyrolysis (Buchi Reactor) 60 80 Max=165.5Mpa 100 120 140 160 Overview : Country * Bahrain EU-7 India Italy Japan Kuwait Qatar Spain UAE US 2 MSW (Kg/person/day) 1.3 1.4 0.45 0.95 1.12 1.4 1.3 0.88 1.2 2 Advocating zero waste Country Austria Belgium Egypt France Jordan Oman Portugal Tunisia Turkey UK MSW (Kg/person/day) 0.89 0.93 0.81 0.89 0.6 0.7 0.7 0.41 0.95 0.95 Type of Waste (Thousands tons/year) Year Organics Fiber Wood Plastic Paper Glass Metal Others Total 1995 422 41 41 109 178 29 23 11 854 2000 492 47 47 124 203 32 26 13 984 2005 558 53 53 141 231 37 29 15 1,117 2010 662 63 63 167 273 44 35 17 1,324 2015 736 71 71 185 303 49 38 19 1, 472 2020 830 80 80 209 342 55 43 22 *Al-Salem and Lettiere, European Journal of Scientific ResearchISSN 1450-216X Vol.34 No.3 (2009), pp.395-405 1,661 OVERVIEW Provide sustainable routes to maximize resource utilization by converting waste to energy, reduce MENA ‘s emission footprint (CO2, NOX, SOX, CH4, etc), fulfill the emerging stringent environmental regulations, and reduce landfill deposits. Use high temp. conversion: Incineration, gasification and pyrolysis of waste stream into syngas Promote IGCC as the cleanest and most efficient (50%) power generation technology amenable to CO2 capturing and co-firing of MSW Use trans-esterification of waste cooking and algae oil into biodiesel (2nd and 3rd Generation) Use digestion (bioreactor) processes to convert organic waste into bio-fuel/landfill gas and compost MSW (mixed) Combustion Sensible heat Gasification Syngas Heat MSW (Dry) Biomass Homog. Ind. Organic Waste Gas Pyrolysis Algae Culture Waste Classific ation Waste Oil/ Lipid P Oil Trans/esterification o Distillation/Oil Bio-diesel Glycerol Phase-change Material MSW (Wet) Digestion Biogas Compost/Soil Waste Water Industry Sludge Waste Water Treatment Gray Water Clean Water w e r OVERVIEW Cont’d To Gasify, or Not to Gasify? Definition: To convert carbonaceous solid material (CHxOyNzSm) into a mixture of CO and H2 in an O2 deprived environment. CO shift and CO2 removal Gas cleaning CO2 for storage Syngas H2 CO CO2 Gas cooler Sulfur Stage 2: 2 -4 burners O2 CnHmOx CO2,H2O Stage 1: 2 -4 burners Slag Lower: Stoichiometric O2 Ash 1200 1600 Temperature, oC Advantages - Air Syngas upper: Lean O2 H2 Combustor Air Separation Unit O2 Gas turbine Generator Electric Power N2 Gasifier Heat recovery steam generator T=1,000-1,500 C Steam P=20-40bar Flue gas Control over produced energy Coal Capability for carbon capture and storage. Flexibility in feedstock and products. Alternative to “bury or burn” policy. Ash Hydrogen-based energy systems (near zero-CO2 emissions). Small scale gasifiers for distributed generation. Gasific ation v s Combusti on CO C CO2 H2 H H2O N2 N Nox H2S S SOx Steam turbine Pump Condenser Cycle Fuel Temp low (oC) Temp High (oC) Carnot (h) Actual (h) Car(h)/Act(h)% Conventional Steam Power Plant Coal 27 540 63 40 63 Ditto Ultra Super Critical Coal 27 650 67 45 67 IGCC Coal 27 1350 82 46 56 Open Gas Turbine Cycle Gas 27 1210 80 43 54 Combined Cycle Gas 27 1350 82 58 71 Low Speed Marine Diesel (LSMD) Heavy Fuel Oil 27 2000 87 48 55 LSMD with Super Charger Heavy Fuel Oil 27 2000 87 53 61 Generator Electric Power MATERIAL CHARACTERIZATION What does the feedstock compose of? Carbonaceous fuel is a complex collection of organic polymers consisting mainly of aromatic chains. 100 5 C/min 10 C/min 15 C/min 20 C/min Heat flow-10 C/min (W) 95 0.1 85 Event 3 (Boudouard reaction/fixed carbon) 80 75 Event 1 (drying/Moisture release) Heat flow (W) Weight ( %) 90 1 0.01 Event 2 (devolatization) 70 65 60 0 250 500 750 Temperature, C 0.001 200 1000 220 200 420 400 Temperature, Temperature (C) C 620 600 800820 100 Drying 50 Pyrolysis Weight % 75 25 Combustion Gasification Temperature, C 0 0 250 500 750 1000 MATERIAL CHARACTERIZATION CONT’D Proximate Analysis Summary of the proximate analysis Composition Weight (%) DSC/TGA curve of RTC-Coal with respect to time. Moisture 0.3001 Volatiles 37.8147 Fixed Carbon 54.6571 Ash 7.2281 Total 100 Simultaneous DSC/TGA Q600 Proximate analysis is used to calculate the weight percentage of moisture, volatiles, fixed carbon and ash present in the sample. Thursday, August 07, 2014 MATERIAL CHARACTERIZATION CONT’D Ultimate analysis Flash 2000 CHNSO analyzer (TCD) Sample ID Nitrogen Carbon Hydrogen Sulphur Oxygen Ash Balance Wt(%) Wt(%) Wt(%) Wt(%) Wt(%) Wt (%) 1 2.2926 76.5178 5.3233 0.8075 8.1136 6.9452 2 2.1930 73.2217 5.0185 1.0848 7.7913 10.6908 3 2.2319 73.8664 5.0861 1.0148 7.6337 10.1671 4 2.1340 66.7894 4.6437 1.0004 7.8425 17.5901 5 2.1348 71.1166 4.7098 1.0794 7.7338 13.2257 2.1972 72.3024 4.9563 0.9974 7.8230 11.7238 Average Results of ultimate analysis for RTC-coal Ultimate analysis is used to calculate the elemental composition of the sample Thursday, August 07, 2014 Ultimate Wt(%) Wt(%) Molar Carbon analysis Previous New number normalization Nitrogen 2.49 2.50 0.1784 0.0260 Carbon 81.90 82.17 6.8475 1.0000 Hydrogen 5.58 5.60 5.5967 0.8173 Sulfur 1.13 1.13 0.0354 0.0052 Oxygen 8.57 8.60 0.5376 0.0785 Total 99.68 100 Empirical formula of RTC-coal using ultimate analysis C H O N 0.8173 0.0785 0.0260 MATERIAL CHARACTERIZATION CONT’D Calorific value analysis Sample ID Weight (gms ) HHV (MJ/Kg) 1 3.4027 30.2205 2 1.7868 30.8207 3 1.7145 30.4197 4 1.6064 30.2232 Average HHV (MJ/Kg) 30.4210 Higher heating value of RTC-Coal 𝐻𝐻𝑉 𝑀𝐽 = −0.03 𝐴𝑠ℎ − 0.11 𝑀𝑜𝑖𝑠𝑡𝑢𝑟𝑒 + 0.33 𝑉𝑜𝑙𝑎𝑡𝑖𝑙𝑒𝑠 + 0.35 𝐹𝑖𝑥𝑒𝑑 𝐶𝑎𝑟𝑏𝑜𝑛 𝐾𝑔 𝐻𝐻𝑉 𝑀𝐽 = 0.3491 𝐶 + 1.1783 𝐻 + 0.1005 𝑆 − 0.1034 𝑂 − 0.0151 𝑁 − 0.0211 𝐴 𝐾𝑔 Parr 6100 Bomb calorimeter H %Wt O %Wt N %Wt RTC coal 83.36 5.52 7.44 2.53 1.15 1.6 Pine needles 48.58 6.30 43.64 1.48 0.00 1.4 Ply-wood 49.59 6.28 43.74 0.39 0.00 Lignite 66.03 4.65 25.64 2.07 1.62 Feedstock Feedstock RTC coal Pine needles Ply-wood Lignite Empirical formula CH0.7946O0.0670N0.0260 CH1.5550O0.6736N0.0261 CH1.5196O0.6615N0.0067 CH0.8450O0.2912N0.0268 HHV HHV KJ/Kmole MJ/Kg 502928 489784 487566 469939 35.34 19.83 20.14 26.28 Atomic H/C Ratio C %Wt S %Wt 1.8 Biomass Peat Lignite 1.2 1.0 Coal 0.8 0.6 Pine needle & ply-wood Lignite RTC Coal 0.4 0.2 Anthracite 0.0 0 0.2 0.4 Atomic O/C Ratio 0.6 0.8 MODELING: Can a zero dimensional model predict the gasifier performance? Simplest level of modeling. No dimension nor time is variable. Entrained flow gasifiers are amenable to equilibrium. Category Ash condition Typical processes Feed characteristics Size Acceptability of fines Acceptability of caking coal Prefered coal rank Operating characteristics Outlet Gas Temperature Oxidant demand Steam demand Other characteristics Moving Bed Dry Ash Lurgi Slagging BGL 6-50mm Limitted yes (with stirrer) any 6-50mm Better than dry ash yes high Fluid Bed Dry Ash Winnkler, HTW, CFB 6-10mm good possibly low l low (425-650C) low (425-650C) moderate (900-1050C) low low moderate high low moderate hydrocarbone in gas hydrocarbone in gas lower carbon Source: Adapted from Simbeck et al. 1993 Entrained-Flow Agglomerating KRW, U-Gas Slagging Shell, Texaco, E-Gas, Noell, KT 6-10mm better yes any <100 m m unlimitted yes any moderate (900-1050C) moderate moderate lower carbon high (1250-1600C) high low pure gas, high c conversion LOW FIDELITY SIMULATION Equilibrium constant approach Global Gasification reaction 𝐶𝐻𝑥 𝑂𝑦 𝑁𝑧 + 𝑚 𝑂2 + 3.76𝑁2 + 𝑛𝐻2 𝑂 + 𝑝𝐶𝑂2 → 𝑥1 𝐻2 + 𝑥2 𝐶𝑂 + 𝑥3 𝐶𝑂2 + 𝑥4 𝐻2 𝑂 + 𝑥5 𝐶 + •Elemental balance 1) Combustion reactions •Carbon balance •Hydrogen balance •Oxygen balance •Nitrogen balance •Equilibrium constant equation 2) Reduction reactions •For Bouduard reaction: •For CO shift reaction: •For Methanation reaction: •Energy balance between reactant and product 𝑧 + 3.76𝑚 𝑁2 2 K1 x 22 ( Equilibriu m const. for Boudouard reaction ) x3 xtotal K2 x1 x3 ( Equilibriu m const. for CO shift reaction ) x2 x4 •Conversion Metrics K3 𝑥1 283800 + x2 283237.12 + x5 889000 𝐶𝐺𝐸 = 𝐻𝐻𝑉𝑓𝑒𝑒𝑑𝑠𝑡𝑜𝑐𝑘 x5 xtotal ( Equilibriu m const. for Methanatio n reaction ) x12 z xtotal x1 x 2 x3 x 4 x5 ( 3.76m) 2 N n (h i i _ prod1 o hs ) Q Thursday, August 07, 2014 N n (h i i _ react1 o hs ) LOW FIDELITY SIMULATION Results: Equilibrium constant approach H2O Gasification Thursday, August 07, 2014 CO2 Gasification LOW FIDELITY SIMULATION Gibbs energy minimization approach Gibbs Energy minimization using Lagrange : GTt , P g (n1 , n2 ,...., nN ) multiplier 𝑜 Δ𝐺𝑓𝑖 + 𝑅𝑇 ln 𝑛𝑖 𝑛𝑡𝑜𝑡𝑎𝑙 + 𝜆𝑘 𝑎𝑖𝑘 = 0, 𝑖 = 1,2, … , 𝑛 𝑘 List of species considered in the model Species C2 H2 C2 H4 C2 H6 C3 H8 H H2 CO CO2 OH H2 O H2 O2 HCO HO2 N N2 C(g) CH CH2 CH3 CH4 O O2 NCO NH NH2 NH3 N2 O NO NO2 CN HCN HCNO S(g) S2 (g) SO SO2 SO3 COS CS2 HS CS H2 S C(s) S(s) HIGH FIDELITY SIMULATION Reaction kinetics via Arrhenius equation 100 95 ( E / RT ) dX K (1 X ) n ; K A e dt E AR ln(1 X ) ln ln T2 RT E •Direct Arrhenius plot method: Weight ( %) •Integral method: 90 0.1 85 Event 3 (Boudouard reaction/fixed carbon) 80 75 Event 1 (drying/Moisture release) 0.01 Event 2 (devolatization) 70 65 60 1 X T2 X T1 ln T T 1 x 2 1 E 1 A ln R T •Method of approximate temperature integral: d ln P(u ) c b du u 0.001 20 METHODS: Heating Rate 20 K/min 10 K/min 5 K/min Thursday, August 07, 2014 220 420 620 820 Temperature (C) 15 K/min A and E can be used in high Fidelity simulation Heat flow (W) Arrhenius Equation 1 5 C/min 10 C/min 15 C/min 20 C/min Heat flow-10 C/min (W) INTEGRAL METHOD Events E (KJ/mol) Drying 15.9 Devolatization 64.5 Boudouard 152.0 Drying 5.9 Devolatization 65.8 Boudouard 173.8 Drying 5.6 Devolatization 65.3 Boudouard 171.2 Drying 10.9 Devolatization 65.8 Boudouard 168.1 A (sec-1) 2.22E-01 2.19E+02 4.71E+05 4.70E-03 2.13E+02 8.03E+06 2.30E-03 1.73E+02 3.25E+06 5.80E-03 1.17E+02 1.61E+06 DIRECT ARRHENIUS PLOT METHOD E (KJ/mol) 8.3 60.7 172.0 8.0 64.2 182.2 4.7 60.5 145.3 5.0 56.2 122.2 A (sec-1) 3.26E-02 1.51E+02 7.98E+06 1.96E-02 2.16E+02 2.76E+07 3.90E-03 9.66E+01 1.16E+05 1.60E-03 2.62E+01 4.19E+03 APPROX. TEMP. INTEGRAL METHOD E (KJ/mol) 17.0 66.7 155.8 6.9 68.0 177.8 6.6 67.6 175.3 11.9 68.0 172.2 A (sec-1) 3.97E-01 3.02E+02 5.59E+05 1.16E-02 2.92E+02 9.18E+06 5.80E-03 2.38E+02 3.76E+06 1.18E-02 1.60E+02 1.87E+06 HIGH FIDELITY SIMULATION CONT’D Ultimate Analysis Ultimate Analysis (DAF wt. %) Utah Bituminous Coal El-Lajjun Jordanian Oil Shale Tires Carbon Hydrogen Nitrogen Oxygen Sulfur 81.810 5.610 2.490 8.960 1.130 49.373 4.976 1.001 36.438 8.212 80.06 7.57 0.29 10.72 1.36 Proximate Analysis Proximate Analysis (wt. %) Moisture Volatile Fixed Carbon Ash Utah Bituminous Coal 2.304 30.19 57.20 10.306 El-Lajjun Jordanian Oil Shale 1.82 21.21 13.70 63.27 Tires 1.02 67.31 22.93 8.74 Bomb Calorimetry Heating Value (MJ/kg) Utah Bituminous Coal 34.38 El-Lajjun Jordanian Oil Shale 7.66 Tires 29.52 HIGH FIDELITY SIMULATION CONT’D Kinetics of the Gasification Process Heterogeneous Reactions Reaction Activation Energy (𝑬𝒂 ) Pre-Exponential Factor (A) N 1 𝐶 + 𝑂2 → 𝐶𝑂 2 9.23 × 107 2.3 1 𝐶 + 𝐶𝑂2 → 2𝐶𝑂 1.62 × 108 4.4 1 𝐶 + 𝐻2 𝑂 → 𝐶𝑂 + 𝐻2 1.47 × 108 1.33 1 Homogeneous Reactions Reaction Activation Energy (𝑬𝒂 ) Pre-Exponential Factor (A) N 1 𝐶𝐻4 + 𝑂2 → 𝐶𝑂 2 + 2𝐻2 1 𝐻2 + 𝑂2 → 𝐻2 𝑂 2 1.25 × 108 4.4 × 1011 0 1.67 × 108 6.8 × 1015 -1 1 𝐶𝑂 + 𝑂2 → 𝐶𝑂2 2 1.67 × 108 2.24 × 1012 0 𝐶𝐻4 + 𝐻2 𝑂 → 𝐶𝑂 + 3𝐻2 𝐶𝑂 + 𝐻2 𝑂 → 𝐶𝑂2 + 𝐻2 1.25 × 108 3 × 108 0 8.37 × 107 2.75 × 109 0 HIGH FIDELITY SIMULATION CONT’D Mathematical System: Coupled CFD and reaction kinetics 1) Continuity, Momentum, Energy, TKE (k) & TDR (e): ) t xi diffusion ui ) xi xi Time rate advective S source 2) Transportation equation for mi species: mi ) ui mi ) Di ,m mt / Sct ) mi Ri Si t xi xi xi 3) Reaction kinetics: N vi,r Si i 1 k f ,r k b ,r N vi,r Si ; i 1 Ri ,r M i ,r (vi,r vi,r ) k k A e ( E / RT ) h ,*rj C j ,r j 1 N 4) Discrete Lagrangian particle: du P dxP FD u u P ) g P ) P ; up dt dt dm p dt mpc p Ae ( E / RT ) [m p (1 f v0 )m 0p ] dTp dt hAp (T Tp ) dm p dt h fg e p Ap (TR4 Tp4 ) The procedure for the calculation of pulverized feedstock conversion: (a) Solve the continuous phase (b) Introduce and solve for the discrete phase (c) Recalculate the continuous phase flow, using the inter-phase exchange of momentum, heat, and mass determined during the previous particle calculation; (d) Recalculate the discrete phase trajectories in the modified continuous phase flow field; (e) Repeat the previous two steps until a convergence solution HIGH FIDELITY VALIDATION CONT’D Geometry & Mesh Generation Reductor D 13D Top view Diffuser Throat Combustor Inputs 1.6D D/4 D/3 Top view 200t/d two-stage air blown gasifier and nozzle geometry showing blocking topology and the resulted 3D mesh same geometry of Chen et al. and Bockelie et al. The 3D mesh consists of 1,500,000 finite volumes. Fitted within 30 volumes of surface sweep Boundary layer (i.e. y+<20). Captures the exact gasifier topography. HIGH FIDELITY SIMULATION CONT’D Predictive Modeling of the Gasification of Oil Shale in an O2-Blown BYU Atmospheric Gasifier Boundary Conditions Schematic Diagram of the O2Blown BYU Atmospheric Gasifier HIGH FIDELITY SIMULATION CONT’D Predictive Modeling of the Gasification of Oil Shale in an O2-Blown BYU Atmospheric Gasifier 1010 0.05 0.0166 0.0083 700 0.02 0.0000 400 Temperature (oC) 0.00 Mole Fraction of CO 0.0007030 0.0000352 0.0000000 Mole Fraction of H2 Mole Fraction of CO2 HIGH FIDELITY SIMULATION CONT’D Predictive Modeling of the Gasification of Utah Bituminous Coal in an O2-Blown BYU Atmospheric Gasifier 2800 0.3523 0.4913 1600 0.1761 0.2456 400 0.0000 0.0000 Mole Fraction of CO Temperature (oC) Mole Fraction of CO2 0.32 0.16 0.00 Mole Fraction of H2 Mole Fraction of H2 HIGH FIDELITY SIMULATION CONT’D Predictive Modeling of the Gasification of Tire Crumbs in an Air-Blown Drop Tube Reactor 0.1870 0.0934 0.1680 0.0925 0.0000 0.0000 Mole Fraction of CO 0.2300 6.11e-3 0.0104 3.05e-3 0.0000 Schematic Diagram of the DTR at Masdar Institute Mole Fraction of CO2 Mole Fraction of O2 0.0000 Mole Fraction of H2 HIGH FIDELITY SIMULATION CONT’D Comparative Mole Composition of the Product Gases at the Exit and the Cold Gasification Efficiency Mole Fraction\Fuel Coal Oil Shale Tire Hydrogen 0.2832 8.62e-6 4.28e-3 Carbon Monoxide 0.3516 0.0461 0.1523 Carbon dioxide 0.2249 0.0154 0.0836 Cold Gasification Efficiency 69.6 18.5 43.2 Parametric study for the input velocity of oxidizer: Reaction R1 R2 R3 R4 R5 R6 R7 R8 Assembled biomas Gasifier At MI Geometry and mesh Temp. distribution (K) 2 𝐶𝑂 + 𝑂2 → 2 𝐶𝑂2 Kinetic Parameters Aj , Ej [kJ/mol] 𝐴 = 1017.6 [(m3mol-1)-0.75s-1], 𝐸 = 166.28 2 𝐻2 + 𝑂2 → 2 𝐻2 𝑂 𝐶𝑂 + 𝐻2 𝑂 ↔ 𝐶𝑂2 + 𝐻2 𝐶 𝑠 + 𝑂2 → 𝐶𝑂2 𝐶 𝑠 + 𝐶𝑂2 → 2 𝐶𝑂 𝐴 = 1𝑒11 [m3mol-1s-1], 𝐸 = 42 𝐴 = 0.0265, E= 65.8 𝐴 = 5.67𝑒9 [s-1], 𝐸 = 160 𝐴 = 7.92𝑒4 [m3mol-1 s-1], 𝐸 = 218 𝐶 𝑠 + 2 𝐻2 → 𝐶𝐻4 𝐶 𝑆 + 𝐻2 𝑂 → 𝐶𝑂 + 𝐻2 𝐴 = 79.2 [m3mol-1 s-1]𝐸 = 218 𝐴 = 7.92𝑒4 [m3mol-1 s-1],𝐸 = 218 𝐴 = 1𝐸15 [m3mol-1 s-1],𝐸 = 1𝐸8 𝑣𝑜𝑙 + 0.4 𝑂2 → 1.317 𝐶𝑂 + 2.09 𝐻2 + 0.064 𝑁2 Velocity distribution (m/s) What you need to know! • Thermochemical conversions is making a strong comeback as sustainable energy source and efficiency enhancement. • This technology can be deployed as renewable source for million of tons of waste streams disposed of at landfill and risking our ecological system. • High fidelity analyses and simulations are needed at the conceptual level to increase the process efficiency and throughput. HIGH FIDELITY SIMULATION CONT’D Model Boundary and Operating Conditions Selected Model Parameters & Operating Conditions: Feedstock Composition Ultimate (wt%) C O H N S Proximate (wt%) FC V M A HHV (MJ/kg) Gas flow rate (kg/s) Combustor burners 1 Combustor burners 2 Diffuser burners Particle loading (kg/s) Combustor burner 1 Combustor burner 2 Diffuser burner Wall Temperature (K) Combustor Diffuser Reductor Pressure (MPa) Turbulence Model Taiheiyo Bituminous Coal 77.6 13.9 6.5 1.13 0.22 35.8 46.7 5.3 12.1 27.4 4.708 4.708 1.832 0.472 1.112 1.832 1897 1073 873 2.7 K-e Standard Modeled Reactions: Overview : Country * Bahrain EU-7 India Italy Japan Kuwait Qatar Spain UAE US 26 MSW (Kg/person/day) 1.3 1.4 0.45 0.95 1.12 1.4 1.3 0.88 1.2 2 Advocating zero waste Country Austria Belgium Egypt France Jordan Oman Portugal Tunisia Turkey UK MSW (Kg/person/day) 0.89 0.93 0.81 0.89 0.6 0.7 0.7 0.41 0.95 0.95 Type of Waste (Thousands tons/year) Year Organics Fiber Wood Plastic Paper Glass Metal Others Total 1995 422 41 41 109 178 29 23 11 854 2000 492 47 47 124 203 32 26 13 984 2005 558 53 53 141 231 37 29 15 1,117 2010 662 63 63 167 273 44 35 17 1,324 2015 736 71 71 185 303 49 38 19 1, 472 2020 830 80 80 209 342 55 43 22 *Al-Salem and Lettiere, European Journal of Scientific ResearchISSN 1450-216X Vol.34 No.3 (2009), pp.395-405 1,661 To Gasify, or Not to Gasify? Challenges Current needs & technology challenges Physical aspect Modeling implementation Feedstock flexibility •Dynamic and intrinsic behavior •Feedstock and char characterization –proximate&ultimate analysis Accurately models fuel switching and associated reactions Slag blockage/removal •Turbulence-chemistry-radiation interactions •Accurate Slag characterization Accurately models slag flow, composition and temperature distribution and turbulence Downstream fouling and poisoning •Particle dispersion and inhomogeneous distribution •Agglomeration, swelling and fragmentation particle mechanisms •Nitrogen and sulfur production Accurately flow modeling, conversion, ash distribution and pollutant formation Wall/refractory failure •Particle dispersion and inhomogeneous heat distribution •Turbulence-chemistry-radiation interactions •Slag wall build up Accurately model wall interactions, thermal stresses, pressure effects and abrasion Injector failure •Turbulence-chemistry-radiation interactions Accurately model flow and temperature distribution Space efficiency •Particle dispersion •Turbulence-chemistry-radiation interactions Accurately model flow and conversion Cycle Fuel Temp low (oC) Temp High (oC) Carnot (h) Actual (h) Conventional Steam Power Plant Coal 27 540 63 40 Ditto Ultra Super Critical Coal 27 650 67 45 IGCC Coal 27 1350 82 46 Open Gas Turbine Cycle Gas 27 1210 80 43 Combined Cycle Gas 27 1350 82 58 Low Speed Marine Diesel (LSMD) Heavy Fuel Oil 27 2000 87 48 LSMD with Super Charger Heavy Fuel Oil 27 2000 87 53 Car(h)/Act(h)% 63 67 56 54 71 55 61 Model Sample Results A B C Temperature field distribution. (A) Showing complete geometry. (B, C) Closer look at the combustor and diffuser. Average gasifier temperature = 1493 K Model Sample Results a:T (K) d:CO wt fraction b:CO2 wt fraction c:H2O wt fraction Velocity (m/s*100) e:H2 wt fraction f: Oxygen wt fraction g: Volatiles wt fraction h: Char concentration (kg/s)