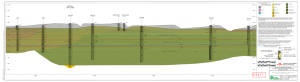

Golder Associates Ltd. REPORT ON GEOTECHNICAL / HYDROGEOLOGICAL ASSESSMENT

advertisement