INSTALLATION INSTRUCTIONS CM12, CA12, CA16, CAF12 and CAF16 IMPORTANT SAFETY INSTRUCTIONS:

advertisement

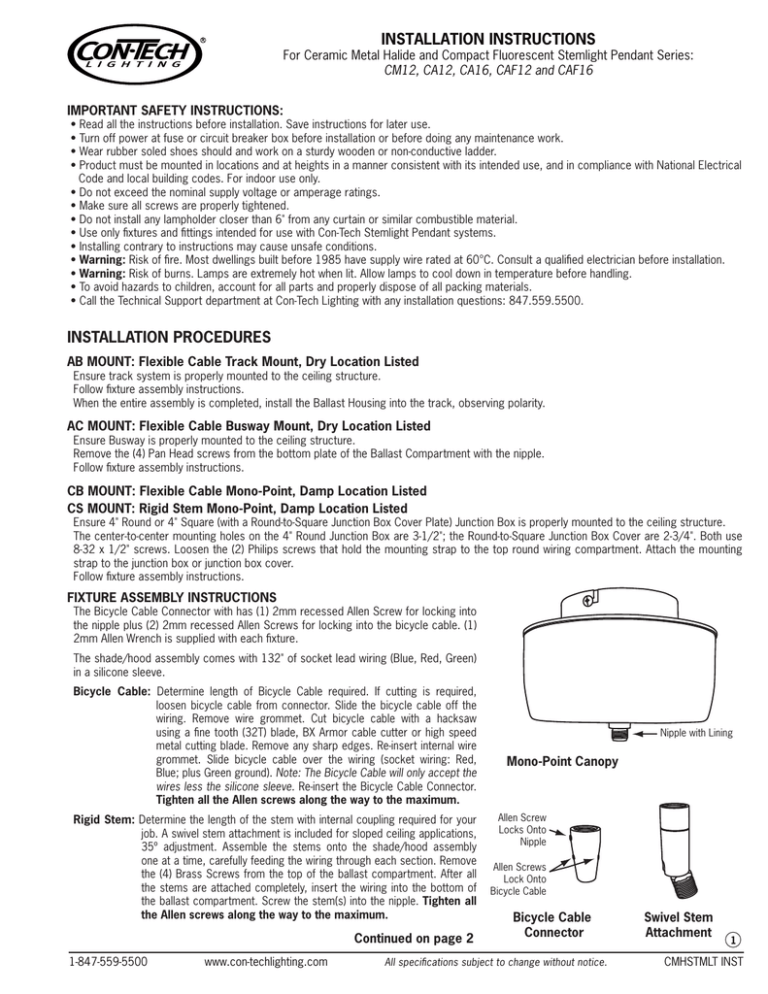

INSTALLATION INSTRUCTIONS For Ceramic Metal Halide and Compact Fluorescent Stemlight Pendant Series: CM12, CA12, CA16, CAF12 and CAF16 IMPORTANT SAFETY INSTRUCTIONS: • Read all the instructions before installation. Save instructions for later use. • Turn off power at fuse or circuit breaker box before installation or before doing any maintenance work. • Wear rubber soled shoes should and work on a sturdy wooden or non-conductive ladder. • Product must be mounted in locations and at heights in a manner consistent with its intended use, and in compliance with National Electrical Code and local building codes. For indoor use only. • Do not exceed the nominal supply voltage or amperage ratings. • Make sure all screws are properly tightened. • Do not install any lampholder closer than 6" from any curtain or similar combustible material. • Use only fixtures and fittings intended for use with Con-Tech Stemlight Pendant systems. • Installing contrary to instructions may cause unsafe conditions. • Warning: Risk of fire. Most dwellings built before 1985 have supply wire rated at 60°C. Consult a qualified electrician before installation. • Warning: Risk of burns. Lamps are extremely hot when lit. Allow lamps to cool down in temperature before handling. • To avoid hazards to children, account for all parts and properly dispose of all packing materials. • Call the Technical Support department at Con-Tech Lighting with any installation questions: 847.559.5500. INSTALLATION PROCEDURES AB MOUNT: Flexible Cable Track Mount, Dry Location Listed Ensure track system is properly mounted to the ceiling structure. Follow fixture assembly instructions. When the entire assembly is completed, install the Ballast Housing into the track, observing polarity. AC MOUNT: Flexible Cable Busway Mount, Dry Location Listed Ensure Busway is properly mounted to the ceiling structure. Remove the (4) Pan Head screws from the bottom plate of the Ballast Compartment with the nipple. Follow fixture assembly instructions. CB MOUNT: Flexible Cable Mono-Point, Damp Location Listed CS MOUNT: Rigid Stem Mono-Point, Damp Location Listed Ensure 4" Round or 4" Square (with a Round-to-Square Junction Box Cover Plate) Junction Box is properly mounted to the ceiling structure. The center-to-center mounting holes on the 4" Round Junction Box are 3-1/2"; the Round-to-Square Junction Box Cover are 2-3/4". Both use 8-32 x 1/2" screws. Loosen the (2) Philips screws that hold the mounting strap to the top round wiring compartment. Attach the mounting strap to the junction box or junction box cover. Follow fixture assembly instructions. FIXTURE ASSEMBLY INSTRUCTIONS The Bicycle Cable Connector with has (1) 2mm recessed Allen Screw for locking into the nipple plus (2) 2mm recessed Allen Screws for locking into the bicycle cable. (1) 2mm Allen Wrench is supplied with each fixture. The shade/hood assembly comes with 132" of socket lead wiring (Blue, Red, Green) in a silicone sleeve. Bicycle Cable: Determine length of Bicycle Cable required. If cutting is required, loosen bicycle cable from connector. Slide the bicycle cable off the wiring. Remove wire grommet. Cut bicycle cable with a hacksaw using a fine tooth (32T) blade, BX Armor cable cutter or high speed metal cutting blade. Remove any sharp edges. Re-insert internal wire grommet. Slide bicycle cable over the wiring (socket wiring: Red, Blue; plus Green ground). Note: The Bicycle Cable will only accept the wires less the silicone sleeve. Re-insert the Bicycle Cable Connector. Tighten all the Allen screws along the way to the maximum. Rigid Stem: Determine the length of the stem with internal coupling required for your job. A swivel stem attachment is included for sloped ceiling applications, 35º adjustment. Assemble the stems onto the shade/hood assembly one at a time, carefully feeding the wiring through each section. Remove the (4) Brass Screws from the top of the ballast compartment. After all the stems are attached completely, insert the wiring into the bottom of the ballast compartment. Screw the stem(s) into the nipple. Tighten all the Allen screws along the way to the maximum. Continued on page 2 1-847-559-5500 www.con-techlighting.com Nipple with Lining Mono-Point Canopy Allen Screw Locks Onto Nipple Allen Screws Lock Onto Bicycle Cable Bicycle Cable Connector All specifications subject to change without notice. Swivel Stem Attachment 1 CMHSTMLT INST INSTALLATION INSTRUCTIONS For Ceramic Metal Halide and Compact Fluorescent Stemlight Pendant Series: CM12, CA12, CA16, CAF12 and CAF16 WIRING INSTRUCTIONS Track Mount: Connect the socket leads (Blue-to-Blue, Red-to-Red) to the ballast compartment socket leads; cap the green lead. Push the wire connectors into the ballast housing. Tighten all Allen Screws to the maximum. Line up the mounting slots, turn the bicycle cable connector clockwise until it locks into place. A turning tool is supplied with the fixture. Mono-Point Mount: Connect the socket leads (Blue-to-Blue, Red-to-Red) and the Green Ground Lead. Connect the primary leads (Black-to-Black, Whiteto-White, Green-to-Green). Take the ballast plate and attach the (4) Brass Screws through the slots into the threaded brackets. Connect the primary leads from the junction box to the primary leads of the fixture (Black-to-Black, White-to-White, Green-toGreen). Attach the top round wiring compartment to the junction box and tighten the (2) Philips/Straight Blade screws. SHADE ASSEMBLY INSTRUCTIONS Metal Shade: Open the bottom lens assembly by loosening the (3) thumb screws. Insert the proper wattage lamp into the E26 Medium Base Socket. Close the bottom lens assembly and tighten the (3) thumb screws. Brass Screws on Ballast Plate Mounting Plate Top of Canopy Acrylic Shade: Remove the reflector assembly from the shade/hood/socket assembly by removing the (3) brass screws attached to the metal housing plate. Place the acrylic shade onto the housing so it sits on the metal housing plate. From the inside of the acrylic shade, place the white shade retaining plate onto the metal housing plate. Align the (3) three holes in the white shade retaining plate with the metal housing plate, and tighten the plates together with the (3) three screws. When tightened, this will secure the acrylic shade to the fixture housing. Insert the proper wattage lamp into the E26 Medium Base socket. The socket is adjustable vertically, however, the lamp position from the factory is in the proper wide distribution setting. 2 1-847-559-5500 www.con-techlighting.com All specifications subject to change without notice. CMHSTMLT INST