Annual Program Review Update

advertisement

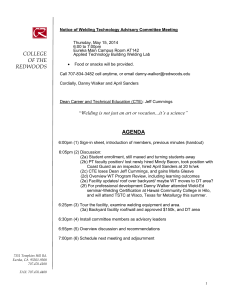

Program/Discipline: APPLIED TECHNOLOGY/ WELDING Annual Program Review Update Instructions The Annual Update is conducted district-wide by each program/discipline and consists of a) analysis of general changes, staffing, resources, facilities, equipment and other needs, as well as b) reporting of curricular changes and outcomes assessment. The questions on the subsequent pages are intended to assist you in planning for your program or area. Input should be sought from all campuses. It should be submitted or renewed every year by the designated date in anticipation of budget planning for the next fiscal year. Institutional data used to document program/discipline statistics and trends will be provided by Institutional Research. Please include pertinent documents such as student learning outcomes assessment reports and data analysis to support any requests for new faculty, facilities, equipment, etc. Retain this information for your discipline’s use, Submit an electronic copy of your Annual Update Document and supporting data to the Program Review Committee. Also submit a copy of these documents to your Division Chair, Director, or Campus Lead Faculty. Annual Program Review Update* Be sure to include information from all three campuses. Note: Eureka campus is currently the only welding program offered. RevisedAnnUpdateS08 1 12/31/2008 Page 1 of 17 Program/Discipline: APPLIED TECHNOLOGY/ WELDING Submitted by (names): Danny Walker Contact Information (phone and email): 707-834-3482/ 476-4622/ danny-walker@redwoods.edu Date: 11-03-2008 1. Program/Discipline Changes Has there been any change in the status of your program or area since your last Annual Update? (Have you shifted departments? Have new degrees or certificates been created by your program? Have activities in other programs impacted your area or program? For example, a new nursing program could cause greater demand for life-science courses.) Note: curricular changes should be addressed under 12 (Curriculum). No (go to next question) Yes Describe the changes below: 2. Program/Discipline Trends Refer to the data provided (data link is located at http://inside.redwoods.edu/Assessment/ProgRev/InstructionalProgramReviewData.as p) and describe the trends in enrollment, retention, success rates, and student demographics. If applicable, describe how changes in these areas are impacting your discipline and describe efforts within your area to address these impacts. Welding Technology Data-EKA SEC_CRS_NAME 2003-4 WT-80 (previously180) 10 WT40 1 WT53 28 WT54 24 WT56 0 WT90 21 WT91 0 Total End of Term Enrollment 84 Course Retention 94% Completers EA&OAW 0 Completers MIG&TIG 0 Success A-C or Credit N/A FTES N/A 2004-5 0 3 30 12 2 28 3 78 96% 0 0 87% 11.05 2005-6 19 1 39 17 7 16 0 99 89% 1 1 78% 14.47 2006-7 18 6 74 19 0 22 0 139 91% 1 1 79% 16.72 2007-8 18 3 57 45 0 22 0 145 94% 0 0 74% 20.37 Fall 08 0 2 21 19 0 22 0 64 N/A 0 0 N/A 9.41 Grand Total 65 16 249 136 9 131 3 609 93% 2 2 80% 72.02 The program has been functioning at a part-time level for several years and with one part-time instructor. The long term full-time instructor (Allen Johnson) came out of retirement twice to aide survival of the welding program and finally fully retired in1991. We currently offer three sections as evening courses which all show full enrollment and waiting lists. The demand for RevisedAnnUpdateS08 2 12/31/2008 Page 2 of 17 these courses indicates a need for more courses offered and added daytime offerings. The lack of offering courses in the WT certificates and degree (such as IT-tech math, CET10electronics, and MT52-metallurgy) negatively affects the student success rate. Local employers are asking for students with skills taught in these courses. This information is found with the data from an employer/ employee survey done in 2006 with our IR department (Adrian Chevraux-Fitzhugh) and 2008 Welding Advisory Committee survey results (See attachment #1-Advisory Minutes). A proposal is being forwarded from the Business and Technology Division to add a full-time instructor and find a math course to replace the existing IT-math course. CR Institutional Research data shows Retention rates are high with an average of 93% and success rates with an average of 80% over the past few years. Another measure of success is the student entering the workforce before completing academic goals. This is our ultimate goal and difficult to obtain data once the student leaves school. However, we have seen many students enter the workforce locally. 3. Labor Market Review (for occupational programs) Occupational programs must review their labor market data. Links to various reports and information, as well as instructions on how to create program-specific reports, can be found at http://www.redwoods.edu/District/IR/Reports/LaborMarket.asp. Institutional Research (IR) is available to help with surveys and reviews. All survey data (whether collected by your program or the institution) should be sent to IR to be kept on record. a. Meets a documented labor market demand, b. Does not represent duplication of other training programs (in the region), and c. Is of demonstrated effectiveness as measured by the employment and completion success of its students. STUDY SHOWS OPEN-SHOP WAGES ARE RISING Open-shop wages are steadily rising to meet demand in sectors of the construction industry, soaring 5.1 percent in 2007, according to a Sept. 29 article in Engineering News-Record (ENR). The article was based on a survey conducted by the Personnel Administration Services in Saline, Mich., which also predicted that wages could rise another 4.8 percent in 2008.According to the article, although some sectors have dwindled, the need to staff petrochemical and power projects is the driving force for wage increases. Southern states have been the most affected, seeing a 5.4 percent increase in 2007 and are on track for another rise of 5.2 percent in 2008, according to ENR. Many companies and contractors are experiencing an absence of skilled craftspeople such as electricians, pipe fitters and boilermakers, which are the highest paid journeymen in the Gulf Coast region, the article noted. In addition, the article cited a study by the Carnegie Mellon University Electricity Industry Center that reports about half of the power industry's 400,000 workers are eligible for retirement during the next 10 years. For more details on this article go to http://www.abc.org Workforce Investment Board Data Description 2006 Regional Jobs % Regional Jobs 2006 State Jobs % State Jobs Construction 9,181 7.1% 1,263,047 6.2% Manufacturing 7,984 6.2% 1,572,105 7.7% [The above data from WIB (Workforce Investment Board) shows increasing trend of jobs]. RevisedAnnUpdateS08 3 12/31/2008 Page 3 of 17 News article from State of the Industry- Sunday May 13, 2007 Rex Bohn (senior resource manager at Evergreen Pulp): “And the biggest hurdle of all will be staffing our mill. The problem we face with an experienced work force is the constant retirement of long-term employees. Finding a skilled employee to replace retiring employees with special skill sets is daunting. College of the Redwoods Vocational Tech classes and skilled displaced timber workers has been a source for these positions. “ Job Market Outlook. State of California Humboldt County Occupations with Most Job Openings - Shortterm # of projected job openings 700 welders 5 welders STATE OF CALIFORNIA SHORT TERM DATA Employment Employment Change Occupational Title 2007 2009 Numerical Percent Welders, Cutters, Solderers, and Brazers 30,600 30,800 200 0.7 STATE OF CALIFORNIA LONG TERM DATA Annual Average Occupational Employment Employment Change Title 2006 2016 Numerical Percent Welders, Cutters, Solderers, and Brazers 31,200 35,400 HUMBOLDT COUNTY DATA Annual Average Occupational Employment Title 2004 2014 Welders, Cutters, Solderers, and Brazers RevisedAnnUpdateS08 130 140 4,200 13.5 Employment Change Numerical Percent 10 7.7 4 Occupations with Most Job Openings - Longterm # of projected job openings 10,080 welders 50 welders Average Annual Job Openings New Jobs Net Replacements [1] Total [2] 100 600 700 Average Annual Job Openings New Jobs Net Replacements [1] Total [2] 420 660 1,080 Average Annual Job Openings New Jobs Net Replacements [1] Total [2] 1 4 5 12/31/2008 Page 4 of 17 4. Budget Resources List your area’s budget for the following categories in the table below. Restricted funds have a sponsor/grantor/donor (federal, state, local government, etc). The funds are restricted by the sponsor/grantor/donor. Everything else is unrestricted. Category Unrestricted Funds Supply and 0 printing budget Equipment replacement and 0 repair budget Professional 0 Development Work-study 0 funding Additional SAM (student material) 2008 F+Sp annual Budget Items fees = WT40F/Sp(2+1)+WT53F/Sp(21+19)+ WT54F/Sp(19+21)+WT90/Sp(22)+ WT80Sp(19) = 124students x $30=$3720 Restricted Funds $100. $1038.53 (See attachment #2-Budget). 0 0 Alumni Grant = $476.71 We receive material donations from local industries FREE without associated dollar amount. Yes No Is the funding for these areas adequate? If not, describe the impact of unaddressed needs on your discipline or program. The majority of facility equipment was installed in 1964 when the program started. Funding for repair, maintenance, or replacement of existing equipment is needed. The addition of new equipment currently used in industry would enhance student learning and increase FTES with additional curriculum that would be created. Some of the equipment should be upgraded to be current with industry. In a couple of cases, it may be money better spent to replace the old equipment and save the repair cost towards the purchase of new equipment. Additionally, some floor space was lost due to expansion of the Machine Shop. This area was also used for the instruction in Sheet Metal and the Foundry Area (neither is taught at this time). The Foundry Area was totally removed and the Sheet Metal equipment was put into the Welding Shop area. Although the sheet metal equipment is used in the welding program, it cuts down on the floor space used for welding larger projects. The return to the original floor space or even an increased area would be a benefit for student projects. Not only do we need to repair our current equipment and add floor space, we need to expand the instruction and equipment to include CNC Plasma and Torch Cutting process. This equipment is commonly used in industry and the student would be better prepared in the workforce with this operational skill. (Details on this equipment are listed in 10. Equipment section of this review). The funding from SAM fees is only to purchase consumable items and materials that the student might take home with them. Other expenditures for maintenance and equipment repair have been done with grant funding and donations. This funding is limited and not routinely available. The chart (following) shows a typical budget in the Applied Technology Department. Programs of AT, CT, DT have similar budgets and the WT program should be included with a budget RevisedAnnUpdateS08 12/31/2008 5 Page 5 of 17 accordingly. As funding is set up now, the MT and WT programs share and negotiate a budget at a lower value (Please see attachment #2). The following chart shows a budget proposal. WT-welding PRC budget proposal 55610 Equipment Repair 55922 Printing 54730 Miscellaneous. Supplies. 54300 Instructional Supplies 54650 Maintenance Supplies 400.00 200.00 1,400.00 100.00 300.00 0.00 0.00 0.00 0.00 0.00 400.00 200.00 1,400.00 100.00 300.00 $2,400.00 5. Learning Resource Center Resources Is the level of resources provided by the Academic Support Center and Library (Learning Resource Center) adequate? Yes No If not, explain. 6. Student Services Resources Complete the following grid concerning Student Services Areas. Student Services Does the area satisfy the needs of your discipline? Area There is a connection to this discipline/program and YES the student services area does satisfy the needs of the discipline. There is a connection to this discipline/program and NO the student services area does not satisfy the needs of the discipline. Uncertain about the student service area provided or how it connects to this discipline/program Admissions and Records Counseling Financial Aid Career Services Disabled Student Programs and Services (DSPS) Extended Opportunities Programs and Services (EOPS) CalWorks Residence Halls Upward Bound Student Conduct RevisedAnnUpdateS08 6 12/31/2008 Page 6 of 17 If a lack of support was indicated in the table above, describe your program/discipline need. N/A 7. Faculty Resource Needs Complete the Faculty Employment Grids below (data link is provided at http://www.redwoods.edu/District/IR/Reports/EnrollmentFTES.asp). Faculty Load Distribution in the Program Discipline Name (e.g., Math, English, Accounting) Total Teaching Load for fall 2007 term Welding 13.5TLU 0 WT53 WT54 WT90 % of Total Teaching Load by Full-Time Faculty % of Total Teaching Load Taught by Part-Time Faculty % Change from fall 2006 % Change from fall 2005 Explanations and Additional Information (e.g., retirement, reassignment, etc.) 100 33% 33% 9.0 TLU +(1)wt40 6.0 TLU 4.5 TLU for WT542005 WT53-2006 Both also done in summers. Faculty Load Distribution in the Program Discipline Name (e.g., Math, English, Accounting) Total Teaching Load for spring 2008 term Welding 13.5TLU 0 +(1)WT40 % of Total Teaching Load by Full-Time Faculty % of Total Teaching Load Taught by Part-Time Faculty % Change from spring 2007 100 0% 33% 13.5 TLU 9.0 TLU +(1)WT40 +(1)WT40 100% PTF % Change from spring 2006 100%PTF Explanations and Additional Information (e.g., retirement, reassignment, etc.) 4.5 TLU WT53-07 WT53-08 Also did summers. a. Describe the status of any approved, but unfilled full-time positions. N/A b. If you are requesting a Full-Time Faculty position develop an attachment to this report that addresses the following criteria (as listed in AR 305.03) • The ratio of full-time to associate faculty • Current availability of associate faculty • Relation to program review recommendations • Effect on diversity of the faculty • Effect on academic offerings and ability to serve students and the community • Effect on the vitality and future direction of a program and/or the college • Effect on student learning (Please see attachment #3 – FT faculty request). RevisedAnnUpdateS08 7 12/31/2008 Page 7 of 17 c. If your Associate Faculty needs are not being met, describe your efforts to recruit Associate faculty and/or describe barriers or limitations that prevent retaining or recruiting Associate Faculty The program has the potential to grow and the student enrollment suggests that more courses could be offered. This could be accomplished with a full-time instructor. The full time instructor retired several years ago (1991) and courses have been maintained since then by one parttime faculty. The number of courses offered has been lower since the fulltime instructor retired. We have been offering three courses with a 2 unit value and 13.5 TLU (60 student capacity) versus the one 4 unit course and 10.5 TLU (20 student capacity). This has been done to allow a higher number of students entrance in to the Welding Program and is the maximum (60% of FT) that a part-time faculty is allowed to teach. The current instructor is teaching at an Associate Faculty level and at a maximum level allowed at 13.5 TLUs. The enrollment data indicates that more courses could run if offered. 8. Staff Resources Complete the Classified Staff Employment Grid below (please list full- and part-time staff). This does not include faculty, managers, or administration positions. If a staff position is shared with other areas/disciplines, estimate the fraction of their workload dedicated to your area. Staff Employed in the Program Assignment Full-time Part-time staff (e.g., Math, (classified) staff (give number) English) (give number) Gains over Prior Year Welding None None None Losses over Prior Year (give reason: retirement, reassignment, health, etc.) None yes no Do you need more full-time of part-time classified staff? If yes, explain why. It would be beneficial to incorporate a classified person into the program to aide faculty with maintaining equipment, material collection and storage. If the program is allowed to grow, the addition of a staff person may be warranted. The time requested is two (2) hours a week per section. This requested time may be increased with the addition of more course sections. 9. Facilities, and Classroom Technology Are teaching facilities adequate for achieving the educational outcomes of this Yes No Please see attachment #4- Facilities discipline/program? If No was checked, complete and attach Facility Form (facilities.form) for each instructional space that does not meet the needs of this discipline/program: RevisedAnnUpdateS08 8 12/31/2008 Page 8 of 17 10. Equipment Is the available equipment (other than classroom specific equipment described in the facilities section) adequate to achieve the educational outcomes of your program/discipline? Yes No If No was checked, complete the following grid for each piece of equipment being requested for this area/discipline: Equipment One TIG welding machine (to replace Airco TIG machine) One CNC plasma machine (installation not included) One Miter Band Saw Approximate Price Number of students using equipment each semester $4,189.00 30 $8,000.00 Describe how the equipment allows achievement of program/discipline educational outcomes The welding lab currently has four TIG welding machines which are shared between many students. This temperamental machine could be replaced. 20 The addition would add student industry standard equipment and learning operation would enhance student success in the job market. 60 Our current saw does not function (motor burned up) and is used by many students when operational. $2,629.95 Equipment Repair Is the equipment used for your discipline/program in need of repair, which is outside your current budget allotment? This does not include classroom specific equipment repair described in the facilities section. Yes No If Yes was checked, provide the following information to justify a budget allotment request: Equipment requiring repair (1) One set (14) of replacement OAW welding hoses (@$16.99) (2) Repair one Airco 400A machine (new contacts) RevisedAnnUpdateS08 Repair Cost / Annual maintenance cost (1) One time cost of $237.86 (2) One time cost of $400.00 Number of Describe how the equipment allows students using achievement of program/discipline equipment each educational outcomes semester (1) Sixty (60+) (1) The OAW process is used by all beginning students and most hoses are just plain old and brittle. (2) Twenty (20) (2) This machine is highly used in WT80 and often by students of other WT courses. (3) This will outfit all OAW stations 9 12/31/2008 Page 9 of 17 (3) One set (14) Safety Flashback Arrestors (@$41.89) (3) One time cost of $586.46 with safety devices which should be currently installed. (3) Forty (40+) NOTE: (ALL the above rationale will allow program educational outcomes of welding). 11. Learning Outcomes Assessment Update. List all expected program-level outcomes, whether you have completed the assessment loop (use of results) or not. For each outcome, identify the means of assessment and the criteria for success. Summarize the data that have been collected in the ‘Assessment Results’ column. If no data have been collected and analyzed for a particular outcome, use the ‘Assessment Results’ column to clarify when these data will be collected and analyzed. In the fourth column, indicate how the assessment results are being used to improve the program. Program Outcomes (Not all disciplines have program-level outcomes) Means of Assessment and Performance Criteria Assessment Results Summary Use of Results Effective Communication. Read, listen, test, evaluates welds with comprehension. Demonstrate problem solving skills Student grade reports show an average in Spring and Fall of 91% Student grade reports show an average in Spring and Fall of 78% Student responsibility of attendance is good with exception of those who should have dropped. Continue process Critical thinking Personal responsibility Integrate knowledge skills into daily life Continue process and encourage more study time. Encourage increased student responsibility during the first weeks of class. List all course-level student learning outcomes for which some assessment activity (assessment, analysis, or use of results) has taken place since the most recent program review, and complete the table below as appropriate Student Learning Outcomes (course-level) RevisedAnnUpdateS08 Means of Assessment and Performance Criteria Assessment Results Summary 10 Use of Results 12/31/2008 Page 10 of 17 Two written WT53 - Spring 08 exams/ weld 1. Demonstrate proficiency shop safety and exercise safe welding practices. 2. Setup and operate oxyacetylene (OAW) and electric arc welding equipment (SMAW). 3. Manipulate materials, tools, and equipment for OAW and SMAW welding. 4. Adjust equipment with correct pressures and amperages for specific welds and cuts. 5. Describe, produce, and evaluate basic weld joints and preparation. 6. Weld mild steel with OAW and SMAW processes to industry standards. 7. Identify and explain particular welds, techniques, procedures and processes. WT54 - Spring 08 Two written 1. Demonstrate shop exams/ weld safety and exercise proficiency safe welding practices. 2. Setup and operate oxy-acetylene (OAW), air-acetylene (AAW), air-propane (APW), and electric arc welding equipment (SMAW). 3. Demonstrate RevisedAnnUpdateS08 Data with F students : Exam Average = 69% Weld Average = 73% Data without F students: 15 student Exam Average =84% / Weld Average = 94% Data with F students: Exam Average = 63% Weld Average = 70% Data without F students: 14 student Exam Average = 79% / Weld Av = 87% 11 The averages are low due to five (5) failed students who did not drop after the census date. Encourage student responsibility The averages are low due to six (6) failed students who did not drop after the census date. Encourage student responsibility 12/31/2008 Page 11 of 17 manipulative skills in OAW, SMAW, OABW, AAW welding and soldering. 4. Adjust equipment with correct pressures and amperages for specific welds and cuts. 5. Describe, produce, and evaluate basic weld joints and preparation. 6. Weld mild steel with OAW and SMAW processes to industry standards. 7. Braze mild steel with OABW and solder copper pipe with AAW or APW. 8. Identify and explain particular welds, techniques, procedures and processes. WT180 - Spring 08 1. Demonstrate shop safety and exercise safe welding practices. 2. Adjust, and operate electric arc (SMAW)metal inert gas (MAG)welding equipment. 3. Demonstrate manipulative skills in basic MAG and SMAW welding. 4. Set-up equipment with correct pressures and amperages for specific welds. 5. Describe, produce and evaluate basic weld joints and preparation. 6. Set up and operate oxyacetylene RevisedAnnUpdateS08 Two written exams/ weld proficiency Data with F students: Exam Average = 64% Weld Average = 63% Data without F students: 13 student Exam Average = 87% / Weld Av = 93% 12 The averages are low due to six (6) failed students who did not drop after the census date. Encourage student responsibility. 12/31/2008 Page 12 of 17 handheld and pattern burning torch machine. 7. Weld and cut mild structural steel materials. 8. Comprehend weld symbols, welding symbols, and print nomenclature. Discuss the extent to which part-time faculty (if applicable) have been involved in the dialogue about assessing student learning outcomes: Associate faculty has been involved 100% in assessing SLO's. 12. Curriculum Update Identify curricular revisions and innovations undertaken a. in the last year. All current course outlines have been updated to CCCCO standard and approved by Curriculum Committee. b. planned for the coming year. Updating current Certificates (3) and Degree (1) are in progress. Complete the grid below. The course outline status report can be located at: http://www.redwoods.edu/District/IR/Reports/Curriculum/Curriculum_Course_Outlines.htm Course WT53 WT54 WT56 WT67 WT80 (number change only from 180 to 80) WT90 WT91 WT60 WT61 WT63 WT64 WT180 (deleted) Year Course Outline Year Next Update Last Updated Expected 2008 all WT courses updated in the last year. 2013 is the next scheduled course update. If the proposed course outlines updates from last year’s annual update (or comprehensive review) were not completed, please explain why. All proposed course outlines were updated in the last year of 2007-08. RevisedAnnUpdateS08 13 12/31/2008 Page 13 of 17 13. Communication Are the current lines of administrative, faculty, and staff communication adequate to meet the needs of this discipline/program? Describe representative example of effective or ineffective communication. The current communication line from faculty to Division Chair to Dean to President to Board appears to work now that "shared governance” and “collegial consultation” and “participatory governance" is being employed. 14. Action Plans List any action plans submitted since your last annual update. Describe the status of the plans. If they were approved, describe how they have improved your area. No action plans have been submitted to date…11.06.2008 15. Goals and Plans If you have recently undergone a comprehensive review, attach your Quality Improvement Plan (QIP) if applicable. QIP Attached If you do not have a QIP, refer to the goals and plans from your previous annual update. For each goal and/or plan, comment on the current status. List any new goals and plans your area has for the coming year, and indicate how they are aligned with the goals/objectives in CR’s Strategic Plan. (CR’s strategic plan is located on the web at http://inside.redwoods.edu/StrategicPlanning/strategicplan.asp). Goals and Plans (from last years (2007-2008)Program Review Document: *Recommendation 1: Recruit 1 Full-Time faculty, with the goal of supplying projected demand with Full-Time faculty. Planned Implementation Date: Begin recruitment early in 2008. Estimated Completion Date: Beginning of Fall 2008 semester. Action/Tasks: • Secure administrative approval for recruitment. • Publicize opening to ensure maximum possible pool of qualified applicants • Form hiring committee • Process first round applications • Contact applicants for interviews • Determine whether any applicants are suitable and rank their suitability • Contact desired applicants with offers Measure of Success/Desired Outcome: Successful recruitment qualified applicant to meet a small majority of projected TLU needs while keeping the Welding Program a net financial benefit to the rest of the college. Estimated Cost(s): • Gross costs of $80,000/year in salary and benefits for new Full-Time faculty. • With 1 FT faculty, we can add welding Fabrication and Metallurgy so that students could complete a certificate and/or degree in Welding. Who is Responsible: Helen Edwards Consequences if not funded: RevisedAnnUpdateS08 14 12/31/2008 Page 14 of 17 • Inability of the expected students to finish their certificates in a timely manner, due to the lack of faculty available to teach required courses. • Damage to the reputation of the Welding program as students discover they cannot complete their certificates in a timely manner. • Losses of enrollment at CR both directly due to lack of Welding sections and indirectly, as students avoid CR due to inability to complete their certificate and/or degree. • Inability to improve articulation due to lack of full-time faculty with the long-term interests of the program at heart. *Recommendation 2: Replace and upgrade some of the existing equipment Planned Implementation Date: Spring 2008 Estimated Completion Date: Beginning of Fall 2008 semester. Action/Tasks: • Write VTEA proposal for new equipment • Work with appropriate departments and Division Chair to formulate budget for maintenance Measure of Success/Desired Outcome: Student and employer satisfaction surveys will reveal improvement in placements. Estimated Cost(s): • Budget for priority items needs to be researched Who is Responsible: Helen Edwards Consequences if not funded: • Inability of the students to finish their certificates or degrees with the skills required by employers. • Loss of students to other educational facilities that have industry current equipment. • Loss of enrollment of new students wanting the skills required by employers. *Recommendation 3: Continue with advisory committee meetings but record minutes of the meeting for data. Planned Implementation Date: Current year 2007-2008 Estimated Completion Date: Current year 2007-2008 Action/Tasks: Delegate a person to record meeting minutes. Measure of Success/Desired Outcome: Maintain documents of the minutes. Estimated Cost(s): None Who is Responsible: Danny Walker Consequences if not funded: n/a COMMENTS on last years recommendations: Recommendation 1 has been addressed and a Full-time faculty member is being formally requested. This has been proposed/approved at department and division level and will be forwarded with proper documentation and forms in late November. RevisedAnnUpdateS08 15 12/31/2008 Page 15 of 17 Email from Division Chair: Colleagues: Please see Keith’s email below regarding the process for faculty position requests. As a reminder, our division ranked the following positions for Fall 2009 hire: 1. BUS / ECON 2. Welding 3. CIS 4. DHET The Solar / Electrical and HRC positions are pending further discussion with the administration. If you are responsible for any of the above areas, please forward your position requests to me by Nov. 28th. Thanks, Chris Gaines Division Chair, Business and Technology Professor, Business 7351 Tompkins Hill Road, Eureka, CA 95501-9300 Phone: 707.476.4564 | Fax: 707.476.4484 Recommendation 2 did not get addressed. The VETA grant funding was not followed up on by the part-time instructor due to the lack of time and input. The instructors’ time was spent on updating curriculum and course outlines for state Chancellor Office approval. The retirement of current division chair also negatively affected the VETA grant request process. However, recent development of a block grant may aide in equipment upgrades and purchases. Recommendation 3 was successful with an Advisory Committee meeting in January 2008 to discuss community and employer needs from the Welding Program. Minutes were recorded and surveys given to obtain data for future curriculum in the welding program. NEW GOALS AND PLANS FOR 2009 1) Continue the process of obtaining a Full-time position in the Welding Program. If completed, the program will be able to function with an increase in course offerings and curriculum. This will allow a larger number of students to enroll in classes and complete certificates and degree in a timely manner. 2) Pursue means of updating equipment by replacement or repair. This would include an Iron Worker machine recommended by the Welding Advisory Committee in 2008. 3) Maintain contact with local community and employers by holding at least one annual Advisory Committee meeting which is currently held near the first of the academic year in the month of January. 4) Ask for the existing method of combining the Machine Tool Program and Welding Program budget be split. This way we know what finances are available for each program and budgeting can be planned appropriately. RevisedAnnUpdateS08 16 12/31/2008 Page 16 of 17 RevisedAnnUpdateS08 17 12/31/2008 Page 17 of 17 Applied Tech $14,155 Fall 2008 SP09 Beginning Budget Description BEGIN 54650 54720 54730 55520 55610 55620 55922 3,050.00 Maint. Supp. Tools <200 Misc. Supp. Laundry Equip Repair Equip Rental Printing 200.00 122.94 1,477.06 450.00 400.00 200.00 200.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 200.00 122.94 1,477.06 450.00 400.00 200.00 200.00 3,050.00 WT- 0956.5 breakout 54650 54720 54730 55520 55610 55620 55922 Maint. Supp. Tools <200 Misc. Supp. Laundry Equip Repair Equip Rental Printing 100.00 0.00 738.53 0.00 200.00 0.00 100.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 100.00 0.00 738.53 0.00 200.00 0.00 100.00 1,138.53 MT- 0956.3 breakout 54650 54720 54730 55520 55610 55620 55922 Maint. Supp. Tools <200 Misc. Supp. Laundry Equip Repair Equip Rental Printing 100.00 122.94 738.53 450.00 200.00 200.00 100.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 100.00 122.94 738.53 450.00 200.00 200.00 100.00 1,911.47 3,050.00 Object Code MT WT 0956 Total funds for MT and WT 12/31/2008 EXPENSES BALANCE cls/BudgetReports/Budget Sheet AT FA08SP09cls.xls Wednesday, January 23, 2008 Welding Advisory Committee Minutes 01.22.2008 Attached Agenda on page 2. Members present: Danny Walker (CR vocational instructor), Art Cardoza (Eureka City Schools), Jim Collins (Eureka Oxygen Supply), John McBeth (O and M Industries), Kevin Williams (O and M Industries), Gary Morris (Eureka High School Instructor), Kurt Kernen (Kernen Construction), Helen Edwards (CR Business and Technology Division Chair), Bill DeFouri (sub by Jack Skinner-Eureka Humboldt Fire Extinguisher), Guest and caterer: Lesley Sundberg. Members Absent: Aaron Libow (self employed welder), Tim Clausen (Fortuna Iron retired owner), Mark Wright (Fortuna Iron). Meeting started at 6:01pm with introductions of all members. Danny Walker explained the purpose of the advisory committee meeting and the need for the members input on what they thought the Welding program needed, did not need, what could be improved or deleted with respect to curriculum, facilities, equipment, student needs and employer needs. A worksheet that member input could be written on was distributed to all members early so members’ thoughts could be recorded. A tour of the welding shop and yard was done with discussion of equipment needs, repairs that are needed, equipment that could be deleted. Donated materials and donators were acknowledged and thanked. The current $30 class fee was discussed as adequate at this time due to the donations that are made. Jim Collins makes the point that the program is good and the way to improve a good thing is to offer more of it. Danny read two emails of students who wanted to enroll but could not with full classes and the classes and waiting lists full. Another section could be offered now but not allowed with the 60% faculty limit. Helen Edwards explained the Measure Q bond money failure to cover our vocational area and the need for members to attend Thursday’s Board meeting with support for the money to be spent where the voters approved it. She also supports the need of full time faculty in the welding program. Art Cardoza asked about our certificate programs and articulation. Danny explained the three certificates and AS degree in CR welding and what is being done with the State Chancellor Office. He agreed to the need for articulation and suggested further work needs to be done with safety and required entrance safety test in mind. A curriculum weld worksheet was given to members and discussed. Discussion of meeting again annually in January or before will be decided after Danny sends out an update of program status by email after the current semester ends. Meeting adjourned at 7:04-pm The members’ responses on worksheet shows: 1. You have all the basic equipment needed. 2. Teach stick welding, basic math, simple layout, basic print reading. 3. Need to add CNC plasma. 4. There is plenty of SMAW equipment, teach math-combining fractions and decimal equivalents. 5. Teach more SSFCAW = E71-T1. 6. Teach hydraulic punch skills, layout skills with respect to triangles. 7. CR has a clean learning environment/ good for learning, need articulation with High Schools. 8. Teach by application and incorporate function with math skills. 9. In house AWS certification needs to be continued, CR has been helpful to many in the past years. 10. There is a need for more course offerings; students are frustrated without being able to enroll. 11. Add new inverter weld power sources, this equipment has benefits over other power sources. 12. Teach gas welding for the easy transfer of manipulative skills into TIG welding and comprehension of fusion. 1 COLLEGE OF THE REDWOODS Notice of Advisory Committee Meeting Dear Advisory Members: The spring 2008 meeting will take place Tuesday, January 22, 6:00pm to 7:00pm--- CR Eureka Main Campus in the Applied Technology Building Welding Technology Lab—Room AT142. Please R.S.V.P. Danny Walker at 476-4622 or 834-3482cell or email dannywalker@redwoods.edu to confirm your planned attendance. Sincerely, Danny Walker NOTE: Liquids and solids will be provided (electric shock upon request). “Welding is not just an art or vocation…it’s a science” AGENDA Advisory Members: Mike Backman, Arthur Cardoza, Tim Clausen, Jim Collins, Bill DeFouri, Dennis Hake, Kurt Kernen, Aaron Libow, John McBeth, Gary Morris, Kevin Williams, Mark Wright. Division Chair Business and Technology: Helen Edwards Tuesday January 22, 6:00p.m. CR Applied Technology Building; Welding Shop—Room AT142 6:00pm 6:05pm 6:10pm 6:30pm 6:35pm 6:55pm 7:00pm 1. 2. 3. 4. 5. 6. Introduction of members. Purpose of the Advisory Committee. Facilities tour of welding equipment and area. Overview of recent Program Review. Recommendations. Schedule Next Meeting. 7. Adjournment. 7351 Tompkins Hill Rd. Eureka, CA 95501-9300 707.476.4100 FAX: 707.476.4400 2 3 Facilities and Classroom Technology Form Program/Disciplines: Welding Year: 2008 Submitted by: Danny Walker List classroom or instructional space name/number: AT142 Check if any of the following are not adequate: Ventilation / room temp ADA access Number of seats / work stations Other (briefly describe): Technology (computers, projectors, internet) The Welding Program lost floor space due to the expansion of the Machine Shop area. This area was also used for the instruction in Sheet Metal and the Foundry Area (neither is taught at this time). The Foundry Area was totally removed and the Sheet Metal equipment was put into the Welding Shop Area. Although the sheet metal equipment is used in the welding program, it cuts down on the floor space for welding. The return to the original floor space or even an increased area would be a benefit for student projects. Describe the specific action and estimated cost (if available) to make this space adequate for your instructional needs: A possible solution to returning floor space would be to extend the building in a northern direction which is currently an open, outside, metal fence perimeter storage space and work area. Although this addition would give needed weatherproof work area, it would decrease some of the needed outside workspace. Measure Q bond money was to aide our Career Technical Programs which included facilities. As of today, the Welding Program has not benefited from the bond. The cost of increasing building space is expensive and no $ amount has been finalized. This will require a consultant with faculty and Division input. Our plans have not been addressed as expected. No cost can be offered at this time. List the average number of discipline/program sections scheduled in this room each semester, and the total number of students enrolled in these sections. Sections: Currently three (3) Students: Currently sixty (60+) Facility, Classroom Technology Form 12/31/2008 Page 1 of 1