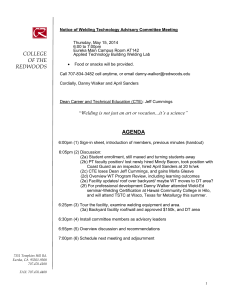

Jeff A. Cummings Instructional Program Review Update 2012/13

advertisement

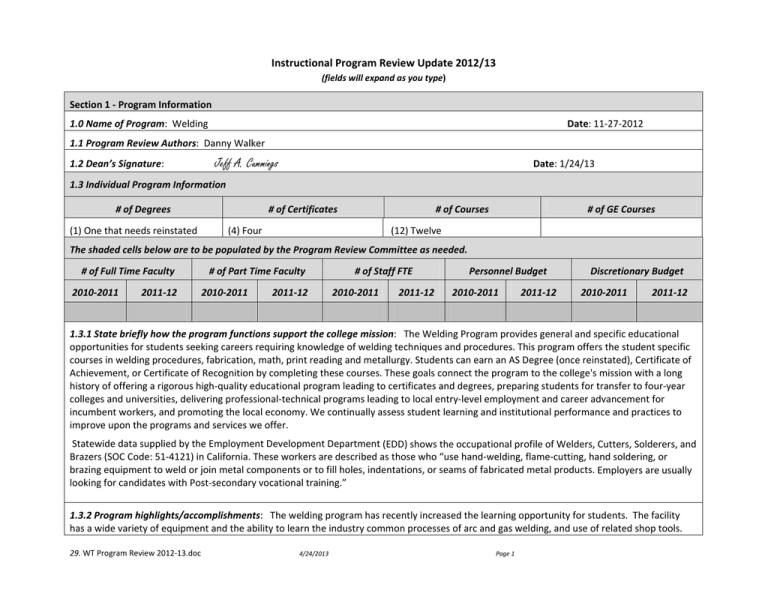

Instructional Program Review Update 2012/13 (fields will expand as you type) Section 1 ‐ Program Information 1.0 Name of Program: Welding Date: 11‐27‐2012 1.1 Program Review Authors: Danny Walker 1.2 Dean’s Signature: Jeff A. Cummings Date: 1/24/13 1.3 Individual Program Information # of Degrees # of Certificates (1) One that needs reinstated # of Courses (4) Four # of GE Courses (12) Twelve The shaded cells below are to be populated by the Program Review Committee as needed. # of Full Time Faculty 2010‐2011 # of Part Time Faculty 2011‐12 2010‐2011 # of Staff FTE 2011‐12 2010‐2011 2011‐12 Personnel Budget 2010‐2011 Discretionary Budget 2011‐12 2010‐2011 2011‐12 1.3.1 State briefly how the program functions support the college mission: The Welding Program provides general and specific educational opportunities for students seeking careers requiring knowledge of welding techniques and procedures. This program offers the student specific courses in welding procedures, fabrication, math, print reading and metallurgy. Students can earn an AS Degree (once reinstated), Certificate of Achievement, or Certificate of Recognition by completing these courses. These goals connect the program to the college's mission with a long history of offering a rigorous high‐quality educational program leading to certificates and degrees, preparing students for transfer to four‐year colleges and universities, delivering professional‐technical programs leading to local entry‐level employment and career advancement for incumbent workers, and promoting the local economy. We continually assess student learning and institutional performance and practices to improve upon the programs and services we offer. Statewide data supplied by the Employment Development Department (EDD) shows the occupational profile of Welders, Cutters, Solderers, and Brazers (SOC Code: 51‐4121) in California. These workers are described as those who “use hand‐welding, flame‐cutting, hand soldering, or brazing equipment to weld or join metal components or to fill holes, indentations, or seams of fabricated metal products. Employers are usually looking for candidates with Post‐secondary vocational training.” 1.3.2 Program highlights/accomplishments: The welding program has recently increased the learning opportunity for students. The facility has a wide variety of equipment and the ability to learn the industry common processes of arc and gas welding, and use of related shop tools. 29. WT Program Review 2012‐13.doc 4/24/2013 Page 1 The program is project oriented and students have opportunity to create, fabricate, and repair. Students learn operation of welders, torches, plasma cutter, shears, saw, brakes, drill press, iron‐worker, punches and notcher, grinders, and hand tools. And now, new up‐to‐date digitally controlled arc welders and Computer Numerically Controlled (CNC) plasma cutting has been installed in the welding lab. Students who learn the operation of this equipment will be better prepared to enter the workforce, staying current with the newest technology (this aligns with our Educational Master Plan goal #4). The welding program has successfully put many students to work locally, interstate, and overseas. Section 2 ‐ Data Analysis 2.1 Enrollment & Fill Rate Review and interpret data by clicking here or going to: http://www.redwoods.edu/District/IR/Program_Select.asp Select your program and click on: Enrollments & fill rates Enrollment ☐ Comment if checked: Noting a less than 10% change, a district wide drop of only 6% from 201 to 189 students (welding) is shown in the data. The eleven sections of enrollment for 2010‐11 included courses at Del Norte, Mendocino, and Eureka sites. A low enrolled WT54 course at Del Norte of twelve students which has a cap of twenty students is noted. Low enrollment in WT53 at Mendocino/Garberville is also noted. However, over‐enrolled courses at the Eureka campus still maintained a high overall enrollment number. Fill Rate ☐ Comment if checked: The same number of eleven sections was offered in each year of 2010‐11 and 2011‐12. The typical section enrollment cap is set at twenty students. However, it should be noted that the cap for Garberville was set at 12 students and the reason for a fair 77% fill rate, even with the low number of enrolled students. The eleven sections of courses for 2011‐12 had high fill rate but was under cap with a lower number of 189 (versus201) students. The main reason for the lower 89% versus 99% fill rate ( or ‐ 10%) were the courses of WT56, WT67, and WT80 at the Humboldt site having a lower number of students when compared to an over capped fill rate of the previous year. 2.2 Success & Retention Review and interpret data by clicking here or going to: http://www.redwoods.edu/District/IR/Program_Select.asp Select your program and click on: Success & Retention Success ☐ Comment if checked: The same good number of 84% success rate is shown similar to both years. The largest number of students enrolled at the Humboldt site is making the largest effect of the overall program success. This program percentage of success is higher than the district wide 69% also similar to both years. Retention ☐ Comment if checked: The same excellent number of 93% retention is shown similar in both years 2010‐11 and 2011‐12. The largest number of students enrolled at the Humboldt site is affecting the overall program retention. This program percentage is 4% higher than the district wide 89% similar to both years. 2.3 Persistence Review and interpret data by clicking here or going to: http://www.redwoods.edu/District/IR/Program_Select.asp Select your program and click on: Persistence ☐ Comment: The district wide persistence showed a drop of 11% from 2010‐11 to 2011‐12. This being said, the welding persistence is even 29. WT Program Review 2012‐13.doc 4/24/2013 Page 2 lower from 27% in 2010‐11 to 13% in 2011‐12. This equates to a drop of 14%. The number of students applying for certificates is low. In the future, faculty will try to persuade students to persist and complete certificates. 2.4 Completions Review and interpret data by clicking here or going to: http://www.redwoods.edu/District/IR/Program_Select.asp Select your program and click on: Completions & Transfers ☐ Comment: Many students in the welding program find work/employment before completion of an educational goal as defined by their student education plan (if they have filed a plan), or completion of a certificate (if they have filed for one). Many students’ educational goals are not at the certificate or degree level. In my opinion, the individual who obtains employment is successful and has reached their educational goal. We need to find a way to consider this as success, to measure and track these students. However and ironically, the state with respect to the community colleges does not accept these students successful at this time. Success is only tied to “completers” of academic programs. We in Career Technical Education might train students with as little as one course to improve a job skill to maintain current employment, or even enter the workforce with a new job. This program helps the community by providing a skilled workforce as defined by our college mission goal number five. “CR puts student success first by providing outstanding developmental, career technical, and transfer education. The College partners with the community to contribute to the economic vitality and lifelong learning needs of its service area” Student Equity Group Data 2.5 Enrollments Review and interpret data by clicking here or going to: http://www.redwoods.edu/District/IR/Program_Select.asp by group Select your program and click on ~ by Student Equity Group next to Enrollments & fill rates Comment: Interestingly, the district shows about half of the students split by gender. However when looking at the Del Norte and Mendocino campus, the enrollment shows about two thirds the students are female. The enrollment in the welding program, which includes Humboldt (Eureka), Del Norte (Crescent City), and Mendocino (Garberville), shows 90% of the students are male. An interesting note for the Mendocino site, even though the student number (8) is low (under 15), 38% were female and many of the eight were over 50 years of age. Welding is typically a profession entered by men versus women, even though women make excellent welders. So, 90% male in the CR welding program is not unexpected. The majority of welding students, like district wide enrollment, is Caucasian and under 24 years of age. Also number comparison with respect to DSPS and BSI show similar percentages between welding program and district numbers. 2.6 Success & Retention Review and interpret data by clicking here or going to: http://www.redwoods.edu/District/IR/Program_Select.asp by group Select your program and click on ~ by Student Equity Group next to success & retention Comment: The success and retention percentages were similar for gender, both for the welding program and the district. This indicates that neither gender is performing lesser or better than the other. As it turns out, both genders of welding student are performing above the district percentages. The success (87%) for welding students was higher than the district wide (68%) for both gender. The retention was also higher (96%) for welding students than the district average (89%) for both genders. 2.7 Persistence Review and interpret data by clicking here or going to: http://www.redwoods.edu/District/IR/Program_Select.asp 29. WT Program Review 2012‐13.doc 4/24/2013 Page 3 by group Select your program and click on ~ by Student Equity Group next to persistence Comment: N/A with fewer than twenty students in a cohort. Additional Indicators 2.8 Faculty Information Review and interpret data by clicking here or going to: http://www.redwoods.edu/District/IR/Program_Select.asp Select your program and click on: Faculty (FT/PT) & FTES/FTEF Comment: Not much has changed with respect to faculty in the years from 2010‐11 to current. The previous Del Norte (DN) and Garberville (SF) welding sites are not being offered in the last year and to date. The prospect of teaching welding at these two sites is not likely. The Del Norte sight was actually held on the DN High School grounds. That facility is no longer available at a reasonable cost, and the faculty retired. The SF site is not showing much student interest and therefore faculty is not needed. The one full time faculty has maintained the Eureka facility. During the EKA faculty evaluation, the evaluators expressed that the program would benefit from additional faculty or even a class assistant. The welding program has contacted a potential instructor for future increase of offered courses. The future faculty has offered to teach a Summer 2013 course. 2.9 Labor Market Data (CTE/Occupational programs only) Refer to the California Employment Development Division: http://www.edd.ca.gov/ www.labormarketinfo.edd.ca.gov Provide a narrative that addresses the following: a. Documentation of labor market demand b. Non‐duplication of other training programs in the region c. Effectiveness as measured by student employment and program completions. Narrative: The EDD reports occupational wages in the first quarter of 2012 show an hourly mean of $19.59 with further data showing the 25th percentile at $14.21, mean at $18.09, and 75th percentile at $23.08, and mean annual earning at $39,684 National data from O*Net on Wages and Employment Trends shows detail report for 51‐4121.00 Welders, Cutters, Solderers, and Brazers as workers who use hand‐welding, flame‐cutting, hand soldering, or brazing equipment to weld or join metal components or to fill holes, indentations, or seams of fabricated metal products. The number of workers employed in 2010 to be 337,000 employees. The median wages in 2011 were $17.27 hourly or $35,920 annually. The projected growth from 2010 to 2020 to increase (+10% to 19%), with the number of projected job openings +140,700. The Department of Labor Statistics (DLS) and the American Welding Society (AWS) expect 200,000 welders to retire nationwide in 2012. DLS states: welders, cutters, solderers, and brazers may work outdoors, often in inclement weather, or indoors, sometimes in a confined area. They may work on a scaffold high off the ground, and they occasionally must lift heavy objects and work in awkward positions. Most work full time and overtime is common in this occupation. The EDD occupational projections of employment, which may be called “outlook” or “demand”, were estimated in 2010. The data shows 29. WT Program Review 2012‐13.doc 4/24/2013 Page 4 an increase of welding jobs in California from 21,700 to 24,100 which are 11% more jobs by 2020. Even with our current slow economy, they project 820 annual job openings to the year 2020. These jobs may be attributed to retiring “baby boomers” and not a sign of a growing economy. If the economy were to improve, it would be expected that the number of welding jobs would also increase. In order to fill these jobs with qualified workers, there is a need to prepare new and trained workers. EDD reports “employers are usually looking for candidates with post‐secondary vocational training”. This is a task that community colleges such as College of the Redwoods can and does provide. EDD describes education or training needed to prepare a welder as: “Welding Technology/Welder: A program that prepares individuals to apply technical knowledge and skills to join or cut metal surfaces. Includes instruction in arc welding, resistance welding, brazing and soldering, cutting, high‐ energy beam welding and cutting, solid state welding, ferrous and non‐ferrous materials, oxidation‐reduction reactions, welding metallurgy, welding processes and heat treating, structural design, safety, and applicable codes and standards.” We are the only training facility in the region and found on the EDD list of approved training facilities with the following: “College of the Redwoods Welding Technology/Welder” Data which tracks students once leaving CR is not readily available at this time. However, the measurement of student success is shown with welding students finding employment with local industry such as Humboldt Bay Water District, O and M Industry, Amulet Manufacturing, Sierra Pacific, California Acquisition Company (Simpson Timber Co.), Johnson Industry, U‐Haul, and Fortuna Iron Works. Some students employed by Amulet Manufacturing followed the employer which relocated from Humboldt County to Idaho. One student currently works in Florida and continues to maintain contact. Another local residing student continued from the CR welding program to an underwater welding school, he now welds all over the world. Still other students have started their own businesses, such as Ironsides Metal Works in Arcata and Work Horse Welding in Southern Humboldt. Overall, what has been the impact of the change in indicators on student achievement and learning: After review of overall data, no major differences show any concerns. The data shows consistency throughout the last several years. Provide narrative on the factors that may have contributed to the improvement or decline in the identified population:N/A Section 3 – Critical Reflection of Assessment Activities Curriculum & Assessment Data Are all courses on track for complete assessment of all outcomes in two years? Y/N Note: The timeline was a five‐year plan and changed to a two‐year plan. 29. WT Program Review 2012‐13.doc 4/24/2013 Yes and there are plans to redo all course learning outcomes to make assessment more sustainable. This work may be completed before Page 5 What courses, if any, are not on track with regard to assessment? Explain. # of PLOs Assessed and Reported during the 2011‐2012 academic year. % of Course Outlines of Record updated If there is no plan for updating outdated curriculum, when will you inactivate? View curriculum status: click here or go to: http://www.redwoods.edu/District/IR/Program_Select.asp Select your program and click on: Curriculum Status Assessment Reporting completed? Y/N Program Advisory Committee Met? Y/N reinstatement of the AS degree. N/A None: The PLO’s have been changed and are newly listed in the CR catalog. These new outcomes are being assessed in the current cycle. 100% are current from (April 11, 2008) and will need update within one year. Plans have been made to start this work within the next two weeks, with Erik Kramer assisting. Yes (February 08, 2012) Yes (May 8, 2012) 3.0 How has assessment of course level SLO’s led to improvement in student learning (top three): (1) The past welding math component, course IT161/IT62 (CTE math course) is being looked at with the Math Department. The discussion/assessment is leading to change in the offered math courses. Some thoughts have been to reinstate IT62, offer practical application in current math courses, or to even create a new math course appropriate for Career Technical (CTE) students. Math120 is currently listed in certificates of welding. After discussion with math faculty and CTE peers, this course will likely be removed from the certificate level. Assessment of outcomes was a concern as well as the lack of application of math skills. In the future and if math courses with application relevant to CTE students are created or reinstated, they may be added to certificates. The Math120 course will still be listed as a general education (GE) requirement in Area D3 for the AS degree. (2) Evaluating SLO’s has led to a need to restate the current learning outcomes in a simpler language. The actual learning outcomes will not change, but the language which describes the SLO should change. This will allow better assessment. (3) The assessment has indicated an improvement in syllabi is needed. This has already started with Spring 2013 syllabi. Students will be more in tune with class expectations and requirements. 3.1 How has assessment of program level outcomes led to degree/certificate improvement (top three): (1) The improvement in scheduling what courses are offered or expected may change for the degree (once reinstated) and certificates. These curriculum changes are being discussed. At a minimum, courses are offered on a two year rotation. So, a fulltime student can complete their academic goal in four semesters. (2) As mentioned in 3.0 (1), The math component of the program is being discussed with the Math Department (MD). The concern from the CTE side is that students need a course of math which is appropriate to the learning outcomes with respect to practical application. The concern 29. WT Program Review 2012‐13.doc 4/24/2013 Page 6 from the MD is that the courses have rigor and content. We (CTE and MD) are working together to find a solution with benefit to the student in mind. A few sessions have taken place where collaborative discussion has been positive. Future discussions will take place with the intent to find a solution to improve offered math courses. 3.2 (Optional) Describe unusual assessment findings/observations that may require further research or institutional support: See 3.0 item (1) Section – 4 Evaluation of Previous Plans 4.1 Describe plans/actions identified in the last program review and their current status. What measurable outcomes were achieved due to actions completed? Actions Current Status Outcomes Ventilation system repair (medium level) Some repairs made by maintenance crew Safer air quality for students in lab Emergency lighting system (high level) Still needed Safe work environment if power goes out Increased floor space* (high level) Still needed Provide work space for student projects Lincoln arc welding machines (low level) Still needed (repair) Provide fully functional equipment Crescent spot weld machine (medium level) Repaired as a class project by students Allow the use and SLO of spot welding Projection screen (low level) New screen and projector provided Ability for students to view films and slides *Provide roof over backyard concrete slab On hold due to financial state of the college None at this time 4.2 (If applicable) Describe how funds provided in support of the plan(s) contributed to program improvement: Section – 5 Planning 5.0 Program Plans (2012/2013) Based on data analysis, student learning outcomes and program indicators, assessment and review, and your critical reflections, describe the program’s Action Plan for the 2012/13 academic year. If more than one plan, add rows. Include necessary resources. (Only a list of resources is needed here. Provide detailed line item budgets, supporting data or other justifications in the Resource Request). 29. WT Program Review 2012‐13.doc 4/24/2013 Page 7 5.1 Program Plans Action to be taken: 1) Pursue installation of the roof covering backyard concrete slab 2) Hire another faculty member This also aligns with our Educational Master Plan goal #1 <‐ 3) Reinstate the AS Degree 29. WT Program Review 2012‐13.doc Expected Impact on Program/Student Learning Students will be able to Increased workspace will This relates to our institutional plan goal complete projects in a provide students with less competition for work shorter time frame, number 2.1+2.3, and thus allowing more is connected to 4.1+ area and increased projects 4.2 learning time Institutional plan goals Having another faculty Students will have more opportunity to complete 3.3 and 4.1 will be will provide certificates and degree in represented with an conversation to take a shorter time. As it is additional faculty. place between each Another faculty will other and assessment now, all courses are promote student discussion offered on a two year number and FTES, cycle for a full time which will add to our student. Many of our funding. An additional students cannot afford benefit to the program time or finances to be full would be acceptance time. of being an American Welding Society approved facility. The AWS requires that a minimum of two faculties be on site for acceptance. The degree is needed The GE component will This will improve the ability for students to for those students who add learning outcomes achieve their learning transfer to a four year institution. Those outcomes as our students may be institutional goal looking for a career in 3.2+3.4 and 4.2 engineering, business, Our Educational or teaching. Assessing Master Plan goal #2 this cohort of students Relationship to Institutional Plans 4/24/2013 Relationship to Assessment Page 8 Resources Needed Board has already approved by bond measure Q funding of $150,000‐ which is on hold Yes None 4) Safety emergency lighting installed reflects this need Not needed 5) Hire a class assistant or lab tech The addition aligns with institutional goals 3.2+3.3+3.4. This also aligns with Educational Master Plan Goal #1.4 6) Assess and revise the course level outcomes from last year overall. Work has already started on this plan. This aligns with institutional goals 3.1+3.2 and Educational Master Plan goal #3.3 will be renewed. N/A other than provision of a safe work place This will allow better and easier assessment N/A Yes A class assistant will improve student learning by allowing faculty more time actually teaching without spending time maintaining lab equipment Learning will continue at the current level and not affect student level of outcome Yes No 5.2 Provide any additional information, brief definitions, descriptions, comments, or explanations, if necessary. The safety issue of having lights when the power goes out is a serious concern. The lack of this safety issue has been mentioned in the last couple of Program Reviews. The adjoining room of AT133 has received a system which works and AT142 could use a similar setup. We actually lost power a semester ago and being night courses found the students in the dark. No injuries were reported. Section 6 – Resource Requests 6.0 Planning Related, Operational, and Personnel Resource Requests. Requests must be submitted with rationale, plan linkage and estimated costs. Check One Amount Recurring Rationale Request $ Cost Y/N Linkage Plannin Operation Personnel g al Faculty hire X Unknow Maybe/Yes (See area 5.1 #2) n Safety lights X Unknow No (See area 5.1 #4) n Class assistant hire X Unknow Maybe/Yes (See area 5.1 #5) n 29. WT Program Review 2012‐13.doc 4/24/2013 Page 9 Section 7‐ PRC Response by section (completed by PRC after reviewing the program review) 7.0 The response will be forwarded to the author and the supervising Director and Vice President: S.1. Program Information: Satisfactory S.2. Data Analysis: A slight drop of enrollments district‐wide. The narrative on the fill rate numbers and cap was a little confusing. Success and retention are higher than district, with a drop in persistence district‐wide. Certificate applications are low and the narrative noted that many students aren’t completers, but enhancing labor market skills and being employed. Equity numbers are not unexpected (male vs. female) and success and persistence are higher than district wide in equity. Labor market data good; CR is the only training facility in the region, but demand is minimal. Data has been consistent throughout last few years. Summary: There is interest for students taking courses, but this is not a program where students need a degree or certificate; overall numbers are strong. S.3. Critical Reflection of Assessment Activities: Course outlines need to be updated; assessment reporting is good; SLO and PLO assessment has led to evaluation, discussion and likely revision of the math component to more accurately reflect the needs of the student. On track. S.4. Evaluation of Previous Plans: Some incomplete, some completed S.5. Planning: Good references to institutional plan goals/objectives; Safety lighting, requested and not completed in Section 4 previous plans, was listed in section 5 as not needed‐an explanation should be included. Because course outlines are due, it should be noted in the planning section (is noted in assessment, but should also be included here.) S.6. Resource Requests: Rational reflects back to section five linkages. 29. WT Program Review 2012‐13.doc 4/24/2013 Page 10