THE EFFECT OF FOULING ON PERFORMANCE AND DESIGN ASPECTS OF SYSTEMS

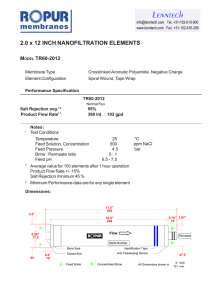

advertisement

THE EFFECT OF FOULING ON PERFORMANCE AND DESIGN ASPECTS OF MULTIPLE EFFECTS DESALINATION SYSTEMS Furqan Tahir Maimoon Atif Mohammed A. Antar CONTENTS Introduction Problem Definition & Objectives Methodology Results & Discussion Conclusion References WHAT IS IT ALL ABOUT OVERVIEW OR CONCLUSION Preheater D1 mf Rejected seawater Feed seawater mcw D4 D2 Down Condenser ms Brine Brine To boiler Brine B1 Seawater in From boiler Brine Product line Flash boxes Rejected brine Features • TBT < 70oC (Steam, waste heat, solar,…..) • PR ~ N • Exists in several layout U and Effect of fouling To ejector Non-condensable gases Rejected seawater From boiler Brine Brine Brine Brine Down Condenser Seawater in Feed seawater Product line To boiler Flash boxes Rejected brine OTHER LAYOUTS!! To ejector Non-condensable gases Rejected seawater From boiler Brine Brine To boiler Brine Brine Down Condenser Product line Flash boxes Rejected brine Seawater in Feed seawater INTRODUCTION Water comprises of more than 70% of our earth but it has unfortunately only 0.3% of usable water. INTRODUCTION The uneven distribution of this asset is very critical especially in the Middle East . To overcome this dwindling resource of fresh water in the Kingdom of Saudi Arabia; Thermal Desalination is a logical & Practical approach. INTRODUCTION Among thermal desalination technologies, Multi Effect Desalination (MED) is getting more attention. Reasons could be: Low energy consumption compared to MSF. Higher overall heat transfer coefficients Less specific Area as compared to MSF Low operating steam temperature, other low grade heat sources can be used to power it. PROBLEM DEFINITION MED-FF ‘n’ effects, ‘n-1’ Flash boxes, ‘n-2’ Pre heaters. OBJECTIVES After comparing the model with other models available in literature. We want: To investigate the effects of Steam temperature, Cooling water temperature, fouling on the design aspects of plant. To analyze the effect of fouling on the performance of the plant METHODOLOGY The jth effect is illustrated for applying mass & Heat balances. METHODOLOGY The parameters to evaluate performance of Plant are: i. Performance ratio (PR) ii. Specific mass flow rate of cooling water iii. Specific Heat Transfer Area (sA) md PR = ms sM cw n ∑A n −1 + ∑ Ap j + Ac ej =j 1 =j 2 sA = mcw = md md METHODOLOGY The Plant is modeled for the following operating parameters: Operation is steady state. The plant is normalized for distillate flow of 1 kg/s. The number of effects vary from 4-8. Steam temperature is taken as Ts=70 oC, Cooling water temperature Tcw=25 oC, Last effect temperature Tn=40 oC and Feed Temperature Tf=35 oC. The intake and rejected salinity of seawater are taken Xf=42,000 ppm and Xn= 70,000 ppm respectively. . RESULTS & DISCUSSION The PR of present model is comparable with the model of El Dessouky et al. The specific areas are in good agreement with Karan et al. and El dessouky’s model. Darwish’s model predicts less specific area due to simplified assumptions. 450 400 8 7 6 Present study 5 El dessouky 4 Karan 3 4 5 6 7 No of effects (n) 8 350 300 250 200 El dessouky 150 Karan Mistry Present study 100 Darwish 3 sA (m2/(kg/s)) Performance Ratio(PR) 9 Darwish 50 9 3 4 5 6 7 No of effects (n) 8 9 RESULTS & DISCUSSION Due to increase in steam temperature, the flashing in Flash boxes and evaporators’ increases, hence improving the PR, however the rise is very little. Also less heat transfer area is required for the same performance. RESULTS & DISCUSSION The seasonal variations cause the temperature of seawater to vary. The cooling water flow rate & Condenser Area will vary in order to keep same performance as the Temperature of seawater/cooling water changes. RESULTS & DISCUSSION The fouling factor has an asymptotic profile, so the resistance will increase sharply in the beginning, and then the rate of increase will be reduced as the time passes RESULTS & DISCUSSION As the time passes the overall heat transfer coefficient decreases due to the fouling and hence specific area required to keep the same performance will increase. RESULTS & DISCUSSION Once the plant is designed and commissioned, its performance won’t be the same as time passes. It is important to predict the performance of the plant over time to decide major overhauling time so that the plant can retain its original performance CONCLUSION MED-FF plant modeling has been carried out and validated. Performance Rating of the plant as well as design considerations have been discussed for different parameters such as steam temperature, cooling water temperature and fouling resistance. CONCLUSION System rating is performed as f(time) such that suggestions for the right overhauling time can be planned. Design parameters such as surface areas are selected based on predicting the overall heat transfer coefficient as a function of time. CONCLUSION Over sizing can be avoided once fouling resistance can be estimated and incorporated into the model and hence time intervals between shutdowns are determined for a given plant size. THANKS