PCMM Portable, Continuous, Miniature and Modular Technology Rick Mitzner

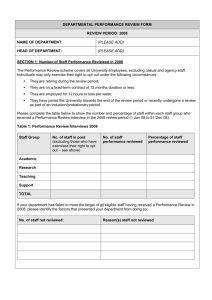

advertisement

PCMM Portable, Continuous, Miniature and Modular Technology Rick Mitzner Senior Director, Engineering Technology Pfizer Global Engineering Pfizer Inc Sept 30, 2015 Portable, Continuous, Miniature & Modular A vision to transform SOD Product Development and Manufacturing A standardized SOD technology platform used for development and commercial production. The system uses continuous processing, with state-of-the-art technologies, enabling flexible batch size providing production-on-demand. The complete ‘containerized’ POD-based facility is pre-engineered and assembled in the field for fast deployment. 2 PCMM Development Approach • Open Innovation: platform available to the industry • Leverage commercially available technologies • Collaborate with key business partners – Pfizer – Equipment Supplier (GEA) – Portable Facility Supplier (G-Con) • Phase 2 collaboration planned 3 PCMM OSD: A Factory in a POD Continuous Processing Platform Technology for Solid Oral Dosage Forms HSWG and CDC Skids Pre-fabricated in Belgium FAT in Belgium Shipped to Groton Building 90 Mock-up Integrated into a ‘Portable’ cGMP POD 6 Modules Pre-fabricated in College Station Texas FAT in Texas Shipped to Groton … and re-assembled into a grey space warehouse in Groton, CT PCMM Videos G-Con Video GEA Video 5 PCMM OSD Prototype Processing Equipment Feeders CMT Mixer CMT Mixer Feeders Granule Conditioning Unit HSWG Wet Granulation Tablet Press Dryer Continuous Mixing & Direct Compression ConsiGmaTM WG Raw Material Dispensing Total Elevation ~14.5 ft PCMM PAT and Product Diversion Diversion 1 Post Fluid Bed Drying PAT 1 (NIR) Post CMT Potency & Blend Uniformity PAT 2 (NIR) Post TSWG Granule Formation PAT 3 (NIR) PAT 5 (NIR) Post Granule Sizing Potency & Granule Uniformity, Moisture Feed Frame Potency & Blend/Granule Uniformity Diversion 3 Mixing Continuous Tablet Eject Compression Chute & Direct PAT 4 (FBRM) Post Granule Sizing PSD Diversion 2 Post Granule TM ConsiGma WG Sizing Batch to Continuous for OSD: Key Enablers & Differences • Loss-in-weight feeders – Low variability and high accuracy required • Integration/automation across unit operations – Balanced mass flow through entire processing system • Product tracking/diversion – In-line monitoring from beginning-of-run to end-of-run requiring – Proper mechanical access/sampling point design – Control strategy/logic to manage process deviations and interruptions 8 PCMM Assembled POD Corridor/Entrance POD Processing POD Raw Materials POD Technical Space 9 PCM&M POD Layout Raw Materials Corridor/Entrance POD cGMP Space Airlock & Cleaning Tech Space 10 Current State Batch Process Transfer of Technology Current State (dry granulation / roller compaction) Drug Product Quantities Phase IIB Clinical Supplies <10 kg Transfer of Technology Experiments Engineering Models Tech Transfer & Process Scale Up Phase III Clinical Supplies <100 kg Tech Transfer & Process Scale Up Process Analytical Technology Advanced Process Control Commercial Supplies 100 to 1000 kg │ 11 Future State PCM&M Platform Technology Current State (dry granulation / roller compaction) Drug Product Quantities Future State (dry blend / direct compaction) Phase IIB Clinical Supplies x <1 hour <10 kg Tech Transfer & Process Scale Up time Phase III Clinical Supplies x several hours <100 kg Tech Transfer & Process Scale Up time Commercial Supplies Flexible 100 to 1000 kg time │ 12 An Integrated Approach to a Platform Technology An opportunity to transform the Development to Manufacture Paradigm Integrated System World-class Material Science, Formulation & Development Practices Equipment Design Advanced Process Control Process Analytical Technology Engineering Models │ 13 World-class Commercial Manufacturing ~500 MM tab/year 24/5 operation, 30% downtime PCMM Business Benefits • Same continuous process for product development, clinical trials & commercial production • Eliminates scale-up, minimizes API consumption, reduces tech transfer risk • Production-on-Demand lowers inventory and reduces risk of product expiration • Portable POD minimizes market entry investment with recoverable assets • PAT and APC provide robust, adaptable process control and CPV • Modular technology includes direct compression and wet granulation tablets • Additional unit operations can be added (dry granulation, coating, encapsulation, packaging, etc.) 14 PCMM Videos G-Con Video GEA Video 15