6 The RAND Corporation is a nonprofit om

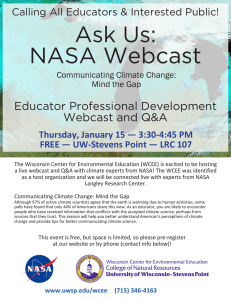

advertisement