Continuous Flow Multi-Step Organic Synthesis Please share

advertisement

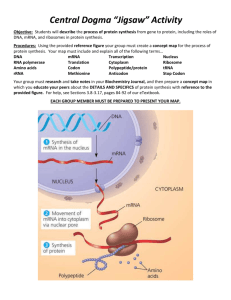

Continuous Flow Multi-Step Organic Synthesis The MIT Faculty has made this article openly available. Please share how this access benefits you. Your story matters. Citation Webb, Damien, and Timothy F. Jamison. “Continuous Flow Multi-step Organic Synthesis.” Chemical Science 1.6 (2010): 675. As Published http://dx.doi.org/10.1039/C0SC00381F Publisher Royal Society of Chemistry, The Version Author's final manuscript Accessed Thu May 26 11:22:56 EDT 2016 Citable Link http://hdl.handle.net/1721.1/76348 Terms of Use Creative Commons Attribution-Noncommercial-Share Alike 3.0 Detailed Terms http://creativecommons.org/licenses/by-nc-sa/3.0/ CREATED USING THE RSC ARTICLE TEMPLATE (VER. 3.1) - SEE WWW.RSC.ORG/ELECTRONICFILES FOR DETAILS ARTICLE TYPE www.rsc.org/xxxxxx | XXXXXXXX Continuous Flow Multi-Step Organic Synthesis Damien Webb, Timothy F. Jamison 5 Received (in XXX, XXX) Xth XXXXXXXXX 200X, Accepted Xth XXXXXXXXX 200X First published on the web Xth XXXXXXXXX 200X DOI: 10.1039/b000000x A recently developed strategy for multi-step synthesis is the use of continuous flow techniques to combine multiple synthetic steps into a single continuous operation. In this mini-review we discuss the current state of the art in this field. Introduction 10 15 20 25 30 The multi-step synthesis of complex organic compounds from simpler precursors is one of the outstanding accomplishments of synthetic organic chemistry. Through the development and invention of synthesis strategies, methods and technologies, increasingly complex molecules can be assembled with designed structures and functions for a variety of medicinal, agrochemical and materials applications. However, despite significant advances, organic synthesis is still largely considered an inefficient and unsustainable practice that is highly labour- and resource-intensive.1 The traditional pathway for multi-step synthesis proceeds by the batchwise and iterative step-by-step transformation of starting materials into desired products (Figure 1(a)). Typically, after the completion of each synthetic step (A+B→C, C→D and D→E), products are isolated from the reaction mixture and purified to remove any undesired components that might interfere with the subsequent synthetic transformations. Although this approach is the foundation on which modern synthesis has been built, such an approach is time-consuming, often wasteful and in stark contrast to the single-cell multi-step biosynthetic pathways found in nature.2 (a) traditional approach A + B reaction 1 40 45 reaction 2 D reaction 3 50 55 E step-by-step batch synthesis intermediates C and D isolated and purified 65 (b) 'ideal' synthesis E A Multi-Step Flow Synthesis Solution-based approaches 60 C streamlining multi-step syntheses is the use of continuous flow techniques5 to combine multiple synthetic steps into a single continuous reactor network, thereby circumventing the need to isolate intermediate products (Figure 1(c)). In this mini-review we detail some recent developments in the field of multi-step continuous flow synthesis6 and discuss select contemporary examples of this emerging technology. one-step to E economic synthesis (c) continuous flow multi-step synthesis Synthetic chemists have long known that telescoping can be an effective tactic for truncating a multi-step synthesis.7 Telescoping reaction sequences typically involves the consecutive addition of reagents and/or catalysts to a reactor in order to initiate further transformations of intermediate products or to achieve in situ quenching of reactive species. This strategy is well suited to flow chemistry and a number of reports employing solution-based systems have been disclosed. The Yoshida group has published several examples outlining the use of highly reactive and unstable organolithium compounds for multi-step synthesis under continuous flow conditions.8 For example, o-dibromobenzene could be effectively coupled with two different electrophiles via sequential halogen–lithium exchange reactions in an extremely fast yet controlled manner (Scheme 1).9 The authors used flow reactors constructed from stainless steel micromixers and tubes, whilst the reagent streams were driven by syringe pump devices. The success of these protocols is attributed to effective temperature and residence time10 (tR) control that allows the unstable intermediates to be rapidly transferred to the next stage of the reactor before decomposition can occur. 70 A C D Br E B Br C and D not isolated multiple steps in 1 operation Figure 1 Synthesis strategies. 35 Currently, the ideal laboratory synthesis3 (Figure 1(b)) is unlikely to be achieved in practice, although a number of innovative strategies have been developed to increase synthetic efficiency.4 A recently introduced method for This journal is © The Royal Society of Chemistry [year] in THF PhCHO n-BuLi TMSCl in THF in hexane in THF tR = 0.82 s tR = 6.93 s tR = 0.49 s tR = 1.57 s –78 °C –78 °C 0 °C 0 °C n-BuLi in hexane TMS OH Ph 74% = the introduction of an input stream to the reactor network tR = residence time in the reactor (see ref. 10) Scheme 1 Generation and reaction of o-bromophenyllithium species using flow chemistry (Yoshida). Journal Name, [year], [vol], 00–00 | 1 5 Recently, the McQuade group reported a synthesis of the nonsteroidal anti-inflammatory drug ibuprofen using continuous flow methods (Scheme 2).11 The three-step synthesis (Friedel– Crafts acylation, 1,2-migration and ester hydrolysis) was linked into a single continuous system and provided ibuprofen in 51% isolated yield following off-line workup and crystallisation of the exiting flow stream. O 20 eq. KOH in MeOH in MeOH/H2O H2O 1 eq. RT tR = 5 min tR = 2 min 150 °C TfOH 5 eq. 45 tR = 3 min 50 °C O 65 °C 51% after recrystallization 0 °C 50 10 Scheme 2 Continuous flow synthesis of ibuprofen (McQuade). 15 20 The ability to perform multi-step reactions in an uninterrupted continuous fashion may also be beneficial for medicinal chemistry applications.12 Cosford recently described a continuous two-step synthesis of a focused 13-membered library of imidazo[1,2-a]pyridine-2-carboxamides (Scheme 3).13 No isolation of the carboxylic acid intermediate was required and a final off-line purification of the crude reaction mixture provided the targets. For their work the authors used the commercially available Syrris AFRICA flow system.14 O HO tR = 15 min 100 °C 75 °C Br O N N CO2Me HN 65 HN 1.2 eq. in DMF 25 Scheme 3 Synthesis of a Mur ligase inhibitor using multi-step continuous flow synthesis (Cosford). 70 Continuous separation and distillation 30 35 40 Although the telescoping processes described above are effective, they are not without limitations. A significant drawback is that excess reagents are often required, whilst the requirement for careful route design to ensure downstream reagent compatibility is an added challenge. The integration of solution-based quenching with subsequent phase separation operations into flow systems would therefore greatly expand the utility of this new technology. The Jensen group reported the integration of microfluidic biphasic extraction systems with microreactors for the multistep synthesis of carbamates (Scheme 4).15 A microseparator incorporating a hydrophobic membrane was designed and used to successfully remove the aqueous stream and thus any water-soluble components.16 2 | Journal Name, [year], [vol], 00–00 HCl (aq.) triflate formation DMF and N2 in DMF liquid-liquid separation microdistillation aqueous extract N2 + CH2Cl2 Heck reaction On-Bu t-Bu Scheme 5 Continuous synthesis of an enol-ether involving liquid–liquid separation and continuous solvent exchange (Jensen and Buchwald). O 46% N2 Tf2O in CH2Cl1 55 2 eq. in DMF HOBt, EDC (1.2 eq. in DMF) tR = 20 min OH DIPEA DIPEA N OR' The Jensen group added a further instrument to the flow toolbox with the development of a microfluidic distillation unit capable of performing an in-line solvent switch. Working in conjunction with the Buchwald laboratory, a two-step flow sequence to prepare enol ethers was developed (Scheme 5).17 A bespoke silicon device was employed to carry out a continuous distillation of a binary solvent mixture (dichloromethane/DMF).18 in CH2Cl2 OH 1 eq. in DMF RT N H Scheme 4 Continuous carbamate synthesis involving multiple reactions and separations (Jensen). t-Bu 60 NH2 R On-Bu N H OH O gas-liquid separation Pd(OAc)2, dppp, NEt3 MeO2C H2N Curtius liquid-liquid rearrangement separation 105 °C aqueous extract OH 1 eq. acyl azide formation 1.1 eq. NaN3 (aq.) 1 eq. PhI(OAc)2 4 eq. HC(OMe)3 O R'OH R Cl 1 eq. in toluene 75 Solid-supported multi-step flow synthesis The use of supported reagents, catalysts and scavengers in synthesis is well documented and has proven to be an extremely advantageous technology in the modern laboratory.19 The combination of immobilized reagents with flow reactors20 has great potential for revolutionising the synthesis process.21 The Ley group has pioneered the use of solid-supported reagents, catalysts and scavengers to facilitate organic synthesis and has an expanding portfolio of work in the area of continuous flow multi-step synthesis.22 Indeed, the group’s 2006 synthesis of the complex natural product oxomaritidine is currently the most elaborate example of continuous flow multi-step synthesis to date (Scheme 6).23 Employing a variety of supported reagents and catalysts, including the commercially available H-Cube hydrogenator,24 seven synthetic steps were orchestrated into a single reactor network to afford the target in excellent yield (>40%) and purity (>90%). This journal is © The Royal Society of Chemistry [year] HO HO Br PS-NMe3N3 PS-PhP(n-Bu)2 70 °C RT then 55 °C in 1:1 MeCN/THF P(O)(OMe)2 Me H-Cube! N2 N H OH MeO PS-TPAP OMe MeO O OMe in THF 4:1 MeOH/H2O O MeO PS-NMe3OH H MeO 1.2 eq. KOtBu in MeOH O F3C solvent switch to CH2Cl2 F Ph 55% 80 °C Me Me oxomaritidine Me N H OC(O)CF3 Si 35 Scheme 6 Continuous flow synthesis of oxomaritidine (Ley). PS = polymer supported. 5 10 NH2 QP-TU QP-TU NH2 Si-amine PS-PIFA NH2 Me PS-TEMPO I F S SO3 O N N H PS-SO3H 2 eq. all in MeCN PS-PIFA OC(O)CF3 PS-NMe2 N 35 °C N QP-BZA N N Ph CF3 QP-TU 70 °C OH 2 eq. 5 eq. in CH2Cl2 Si-amine N3 PS-NMe2•CuI 100 °C 60 °C O O tR = 48 min PS-TEMPO 1 eq. The development of catalytic process is integral to the future of synthesis25 and so the use of solid-supported catalysts for muliple steps in flow systems is particularly attractive. Using an electroosmotic flow-driven miniaturized flow reactor, Watts recently reported the use of two solid-supported catalysts in series for the two-step synthesis of analytically pure α,β-unsaturated compounds (Scheme 7).26 40 45 Scheme 8 Three-step continuous flow synthesis of a triazole employing a variety of immobilized reagents and scavengers (Ley). The Lectka group has described the use of sequentially linked jacketed glass columns for catalytic and enantioselective multi-step flow synthesis and reported a continuous route to the metalloproteinase inhibitor BMS-275291 (Scheme 9).30 The use of scavenger columns eliminated the need for batch purification of the eluting flow stream. In their approach the flow streams were purely gravity-driven and Celite® was employed to control the column residence times. Remarkably impressive yields and selectivities were observed. OMe S OMe O2N N PS-SO3H N O Si-piperazine s-Bu OEt O S 1:1 in MeCN O NO2 OEt 1.05 eq. in THF Me >99% yield >99% purity Me 20 25 30 Scheme 7 Continuous two-step synthesis of α,β-unsaturated compounds using supported catalysts (Watts). In many instances, such as the synthesis of pharmaceuticals, the quality of the final product of a synthetic route must meet stringent purity standards. An effective method for achieving in-line purification in flow-mode is the integration of solidsupported scavengers to selectively remove unwanted components of the flow stream. The Ley group recently reported on the multi-step synthesis of triazoles27 using the commercially available flow system from Vapourtec28 (Scheme 8). Following three chemical transformations (oxidation, homologation and ‘click’ triazole formation) the flowing solution was subsequently pumped through a variety of strategically positioned solid-supported scavengers to sequester any fouling components. This effectively provided the desired product in excellent purity and without recourse to traditional column chromatography.29 Me N H t-Bu 1 eq. in THF PS-CDI PS-trisamine Cl 2.25 eq. in THF celite! PS-organocat. PS-NMe3SH PS-piperazine O Cl Cl O s-Bu Cl HS Cl N H Cl 2.25 eq. in THF N O Me N t-Bu N H Me BMS-275291 O Me O H N O Cl 34% dr 91.5:8.5 OMe • N H2N H N PS-CDI 50 60 NH2 N N 55 This journal is © The Royal Society of Chemistry [year] O N O H2N O N Me 15 O OH FMocHN N PS-trisamine O H N O PS-organocat. Scheme 9 Synthesis of BMS-275291 using a column-based system incorporating resin-bound reagents and scavengers (Lectka). In a further example of a multiphase continuous flow system, Ulven reported the preparation of a 15-membered library of potential chemokine receptor ligands (Scheme 10).31 Three separate building blocks were combined in three distinct reaction steps, whilst two scavenger resins were employed to remove any unreacted substrates. Semi-automatic purification of the crude products allowed a high compound throughput, further underscoring the potential of continuous flow multiJournal Name, [year], [vol], 00–00 | 3 step synthesis as a tool for the drug discovery process. References 1 R' CbzN 35 Br 2 1.5 eq. in DMF NH 1 eq. in DMF tR = 7 min tR = 6 min H-cube! PS-trisamine PS-NMM 75 °C R N C 75 °C O 40 3 PS-trisamine 75 °C 1.5 eq. in DMF N R' H N N 11-96% after semiautomatic flash chromatography R 4 O 45 N O PS-NMM 50 5 Scheme 10 Three-step continuous flow synthesis of receptor ligands (Ulven). 10 Finally, immobilized enzymes have also been integrated into continuous flow systems. Ley and co-workers reported the preparation of the natural product grossamide using a continuous flow reactor system (Scheme 11).32 An initial peptide coupling protocol,33 was followed by a peroxidase catalysed dimerization to deliver the neolignan natural product. 55 5 60 15 O MeO HO 65 H2O2•urea, pH 4.5 buffer OH PS-HOBt PS-SO3H PS-enzyme 6 PyBroP DIPEA in DMF 70 NH2 OH HN O HO OH O in THF 7 N H HO 8 O MeO grossamide 75 9 10 OH N N N PS-HOBt 80 11 12 Scheme 11 A multi-step continuous synthesis of grossamide using an immobilised horseradish peroxidase (Ley). 85 20 25 30 Summary and Outlook In this mini-review we hope to have demonstrated that the use of continuous flow methods for multi-step organic synthesis is a burgeoning and exciting area of research that has the potential to greatly simplify and improve the synthesis process. Indeed, with the promise of economic and safety benefits, pharmaceutical manufacturers have begun to investigate and implement continuous manufacturing as a viable alternative to the traditional batchwise synthesis of API’s.32 Although many challenges remain, continuous flow multi-step synthesis may be a key breakthrough technology for enabling the efficient preparation of complex substances. 4 | Journal Name, [year], [vol], 00–00 13 14 15 90 95 16 17 18 100 For relevant discussions see: (a) B. M. Trost, Science, 1991, 254, 1471; (b) P. T. Anastas and M. M. Kirchoff, Acc. Chem. Res., 2002, 35, 686; (c) T. Hudlicky, Chem. Rev., 1996, 96 , 3. P. M. Dewick, Medicinal Natural Products: A Biosynthetic Approach, Wiley, Chichester, 2009. For a recent review on biosynthetic approaches to total synthesis see: P. G. Bulger, S. K. Bagal and R. Marquez, Nat. Prod. Rep., 2008, 25, 254. P. A. Wender and B. L. Miller in Connectivity Analysis and Multibond-Forming processes in Organic Synthesis: Theory and Application (ed. T Hudlicky), JAI Press, Greenwich, 1993. For a review on cascade reactions in total synthesis see: K. C. Nicolaou, D. J. Edmonds and P. G. Bulger, Angew. Chem., Int. Ed., 2006, 45, 7134; for C–H functionalisation methods see the thematic issue: Chem. Rev., 2010, 110, 575; for a review on enantioselective cascade catalysis see: A. M. Walji and D. W. C. MacMillan, Synlett, 2007, 10, 1477; for protecting-group-free synthesis see: R. W. Hoffmann, Synthesis, 2006, 21, 3531; for a discussion of one-pot synthesis see: S. J. Broadwater, S. L. Roth, K. E. Price, M. Kobaslija and D. T. McQuade, Org. Biomol. Chem., 2005, 3, 2899; for multicomponent strategies see: B. B. Tour and D. G. Hall, Chem. Rev., 2009, 109, 4439; for an excellent example of efficiency in synthesis see: K. B. Hansen et al., J. Am. Chem. Soc., 2009, 131, 8798. For recent reviews on flow chemistry see: (a) T. Wirth, Microreactors in organic synthesis and catalysis, Wiley-VCH, Weinheim, 2008; (b) R. L. Hartman and K. F. Jensen, Lab Chip, 2009, 9, 2495; (c) B. P. Mason, K. E. Price, J. L. Steinbacher, A. R. Bogdan and D. T. McQuade, Chem. Rev., 2007, 107, 2300; (d) K. Geyer, T. Gustafsson and P. H. Seeberger, Synlett, 2009, 15, 2382 (e) A. Kirschning, W. Solodenko and K. Mennecke, Chem. Eur. J., 2006, 12, 5972; (f) C. Wiles and P. Watts, Eur. J. Org. Chem., 2008, 10, 1655; (g) S. V. Ley and I. R. Baxendale in Proceedings of Bosen Symposium, Systems Chemistry, 2008, 65; (h) K. Jähnisch, V. Hessel, H. Löwe, M. Baerns, Angew. Chem., Int. Ed., 2004, 43, 406. In this mini-review we use the term ‘continuous flow synthesis’ to mean a synthetic process where chemical reactions are run using a continuously flowing stream. This definition is thus irrespective of the reactor type used and the scale involved. N. G. Anderson, Practical process research & development, Academic Press, San Diego, Calif. ; London, 2000. J.-i. Yoshida, A. Nagaki and T. Yamada, Chem. Eur. J. 2008, 14, 7450. H. Usutani, Y. Tomida, A. Nagaki, H. Okamoto, T. Nokami and J.-i. Yoshida, J. Am. Chem. Soc., 2007, 129, 3046. In flow chemisty, residence time (tR) is the time that a reaction solution spends inside a reactor and is a consequence of the flow rate. R. B. Andrew, L. P. Sarah, C. K. Daniel, J. B. Steven and D. T. McQuade, Angew. Chem., Int. Ed., 2009, 48, 8547. For a discussion see: S. Y. F. Wong-Hawkes, J. C. Matteo, B. H. Warrington and J. D. White in New Avenues to Efficient Chemical Synthesis, 2007, Springer Berlin, Heidelberg, pp. 39–55. A. Herath, R. Dahl and N. D. P. Cosford, Org. Lett., 2009, 12, 412. Website: http://www.syrris.com/ H. R. Sahoo, J. G. Kralj, K. F. Jensen, Angew. Chem., Int. Ed. 2007, 46, 5704. For an alternative flow approach to carbamates using solidsupported reagents see: M. Baumann, I.R. Baxendale, S.V. Ley, N. Nikbin and C.D. Smith, Org. Biomol. Chem., 2008, 6, 1587 and M. Baumann, I.R. Baxendale, S.V. Ley, N. Nikbin, C.D. Smith and J.P. Tierney, Org. Biomol. Chem., 2008, 6, 1577. For a very recent example of continuous separations see: T. Tricotet and D. F. O’Shea, Chem. Eur. J., DOI: 10.1002/chem.200903284. J. G. Kralj, H. R. Sahoo and K. F. Jensen, Lab Chip, 2007, 7, 256. R. L. Hartman, J. R. Naber, S. L. Buchwald and K. F. Jensen, Angew. Chem., Int. Ed., 2010, 122, 911. R. L. Hartman and K. F. Jensen, Lab Chip, 2009, 9, 2495. For a recently reported method for performing an in-line solvent switch as part of a multi-step flow sequence see: M. D. Hopkin, I. R. Baxendale and S. V. Ley, Chem. Commun., 2010, 46, 2450. This journal is © The Royal Society of Chemistry [year] 5 10 15 20 25 30 35 19 For a comprehensive compendium see: S. V. Ley, I. R. Baxendale, R. N. Bream, P. S. Jackson, A. G. Leach, D. A. Longbottom, M. Nesi, J. S. Scott, R. I. Storer and S. J. Taylor, J. Chem. Soc., Perkin Trans. 1, 2000, 3815. For other perspectives see: D. C. Sherrington, J. Polym. Sci., Part A: Polym. Chem., 39, 2001, 2364 and P. Hodge, Chem. Soc. Rev., 26, 1997, 487. 20 (a) S. Ley et al., PCT Int. Appl., W09958475, 1999; (b) I. R. Baxendale and S. V. Ley in New Avenues to Efficient Chemical Synthesis, 2007, Springer Berlin, Heidelberg, pp. 151–185.; (c) P. Hodge, Curr. Opin. Chem. Biol., 2003, 7, 362. For further discussions see references 5(e) and 19. 21 P. Kundig, Science, 314, 430. 22 For the most recent review of the group’s work see reference 5(g). 23 I. R. Baxendale, J. Deeley, C. M. Griffiths-Jones, S. V. Ley, S. Saaby and G. K. Tranmer, Chem. Commun., 2006, 2566. 24 Website: http://www.thalesnano.com/products/h-cube 25 R. Noyori, Nature Chem., 1, 5. 26 C. Wiles, P. Watts and S. J. Haswell, Lab Chip, 2007, 7, 322. It is noteworthy that even ‘traditional’ synthesis laboratories have begun to embrace multi-step flow chemistry, see: A. W. Pilling, J. Boehmer and D. J. Dixon, Angew. Chem., Int. Ed., 2007, 46, 5428. 27 I. R. Baxendale, S. V. Ley, A. C. Mansfield and C. D. Smith, Angew. Chem., Int. Ed., 2009, 48, 4017. 28 Website: http://www.vapourtec.co.uk/ 29 For a discussion of this work see: P. S. Seeberger, Nature Chem., 1, 258. 30 S. France, D. Bernstein, A. Weatherwax and T. Lectka, Org. Lett., 2005, 7, 3009. For a review of the Lectka groups work in this area see: A. M. Hafez, A. E. Taggi and T. Lectka, Chem. Eur. J., 2002, 8, 4114. 31 T. P. Petersen, A. Ritzen and T. Ulven, Org. Lett., 2009, 11, 5134. 32 I. R. Baxendale, C. M. Griffiths-Jones, S. V. Ley and G. K. Tranmer, Synlett, 2006, 3, 427. 33 I. R. Baxendale, S. V. Ley, C. D. Smith and G. K. Tranmer, Chem. Commun., 2006, 4835. 34 D. M. Roberge, B. Zimmermann, F. Rainone, M. Gottsponer, M. Eyholzer and N. Kockmann, Org. Process Res. Dev., 2008, 12, 905. This journal is © The Royal Society of Chemistry [year] Journal Name, [year], [vol], 00–00 | 5