Breakout A Design Space Implementation of ICH Q8, Q9, Q10

advertisement

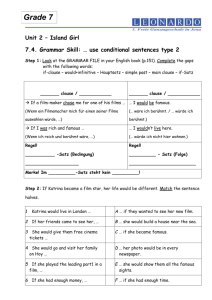

Implementation of ICH Q8, Q9, Q10 Breakout A Design Space International Conference on Harmonisation of Technical Requirements for Registration of Pharmaceuticals for Human Use ICH Quality Implementation Working Group - Integrated Implementation Training Workshop Breakout A: Design Space Disclaimer The information within this presentation is based on the ICH Q-IWG members expertise and experience, and represents the views of the ICH Q-IWG members for the purposes of a training workshop. © ICH, Washington D.C., October 2010 © ICH, October 2010, Breakout A: Design Space slide 2 1 ICH Quality Implementation Working Group - Integrated Implementation Training Workshop Breakout A: Design Space Introduction • Structure of this session - Discussion of key messages on Design Space - Examples from the Case Study - Wrap up - - Feedback on barriers to implementation - Feedback on issues where further clarification is required Breakout report © ICH, Washington D.C., October 2010 slide 3 ICH Quality Implementation Working Group - Integrated Implementation Training Workshop Breakout A: Design Space Introduction • There are no regulatory requirements to have a Design Space • Quality Risk Management approaches need to be considered to ensure the robustness of the Design Space • Design space can illustrate understanding of parameter interactions and provides manufacturing flexibility - Proven acceptable range alone is not a design space • Design space can include critical and non-critical parameters • Design space should be verified and opperational at full scale - No requirement to develop a design space at the full manufacturing scale Many options exist for how (and where) to present a design space © ICH, Washington D.C., October 2010 © ICH, October 2010, Breakout A: Design Space slide 4 2 ICH Quality Implementation Working Group - Integrated Implementation Training Workshop Breakout A: Design Space Training Objectives • Design Space development - Steps in Development of Design Space - Prior knowledge - QRM - DOE & modeling - Process Parameter and Quality Attribute as factors in Design Space development • Implementation of Design Space • Presentation of Design Space in regulatory submission © ICH, Washington D.C., October 2010 slide 5 ICH Quality Implementation Working Group - Integrated Implementation Training Workshop Breakout A: Design Space Steps in Development of Design Space • Consider QTPP in establishing the Design Space • Initial determination of CQAs • Assess prior knowledge to understand variables and their impact - Scientific principles & historical experience • Perform initial risk assessment of manufacturing process • • • relative to CQAs to identify the high risk manufacturing steps (->CPPs) Conduct Design of Experiments (DoE) Evaluate experimental data Conduct additional experiments/analyses as needed © ICH, Washington D.C., October 2010 © ICH, October 2010, Breakout A: Design Space slide 6 3 ICH Quality Implementation Working Group - Integrated Implementation Training Workshop Breakout A: Design Space QbD Story per Unit Operation QTPP & CQAs Quality Risk Management Process Variables Design of Experiments Design Space Control Strategy Batch Release Illustrative Examples of Unit Operations: API Crystallization Blending Compression Real Time Release testing (Assay, CU, Dissolution) © ICH, Washington D.C., October 2010 slide 7 ICH Quality Implementation Working Group - Integrated Implementation Training Workshop Breakout A: Design Space DS development - Prior knowledge • Key messages - Prior knowledge may include : - internal knowledge from development and - manufacturing - External knowledge: scientific and technical publications (including literature and peer-reviewed publications) Citation in filing: regulatory filings, internal company report or notebook, literature reference No citation necessary if well known and accepted by scientific community © ICH, Washington D.C., October 2010 © ICH, October 2010, Breakout A: Design Space slide 8 4 ICH Quality Implementation Working Group - Integrated Implementation Training Workshop Breakout A: Design Space DS development - Prior knowledge • What might be applicable sources of Prior Knowledge ? • Identify other type of prior knowledge that can be used in DS development Example from Case Study : Crystallization of the drug substance - Particle size control needed during crystallization Prior knowledge/1st principles shows that other unit operations (Coupling reaction, aqueous workup, filtration and drying) have low risk of affecting purity or PSD. > Knowledge from prior filings > Knowledge from lab / piloting data, including data from other compounds using similar “platform” technologies > First principles knowledge from texts/papers/other respected sources slide 9 © ICH, Washington D.C., October 2010 ICH Quality Implementation Working Group - Integrated Implementation Training Workshop Breakout A: Design Space DS development - QRM • Risk assessment is based on prior knowledge and relevant experience for the product and manufacturing process - Gaps in knowledge could be addressed by further - experimentation Assignments of risk level must be appropriately justified • Risk assessments/control will iterate as relevant new information becomes available - Final iteration shows control of risks to an acceptable level © ICH, Washington D.C., October 2010 © ICH, October 2010, Breakout A: Design Space slide 10 5 ICH Quality Implementation Working Group - Integrated Implementation Training Workshop Breakout A: Design Space DS development - QRM • Training questions - If the risk acceptance criteria (conclusions) are different than scientific theory/prior knowledge would indicate, then is further explanation provided to justify unexpected conclusions? - If there are gaps in the information then what would the plan be to make adjustments to further reduce risk? slide 11 © ICH, Washington D.C., October 2010 Case Study ICH Quality Implementation Working Group - Integrated Implementation Training Workshop Example Breakout A: Design Space Illustration from the Case Study - Risk Assessment for PSD Control Unit Operation Parameter IM PA C PR T OB De . tec t What is the Impact that ------------- will have on purity? 1) minimal 5) moderate 9) significant What is the Probability that variations in ------------ will occur? 1) unlikely 5) moderately likely 9) highly likely What is our Ability to Detect a meaningful variation in --------------- at a meaningful control point? 1) certain 5) moderate 9) unlikely Comments RPN Crystallization Crystallization Feed Temperature Water content of Feed 1 5 1 1 5 5 5 25 To be investigated in DOE 405 9 5 9 Crystallization Addition Time (Feed Rate) Crystallization Seed wt percentage 9 5 5 1 1 1 Crystallization Antisolvent percentage Crystallization Temperature Crystallization Agitation (tip speed) Crystallization Seed particle size distribution Crystallization Feed Concentration 9 5 9 9 5 5 9 1 1 1 1 1 Change in addition time is easy to detect, but rated high since there is no possible corrective action 225 1 Yield loss to crystallization already low (< 5%), so reasonable variations in antisolvent percentage (+/10%) will not affect the percent of batch crystallized, and will not affect PSD 405 Change in crystallization temperature is easily detected, but rated high since no possible corrective action (such as, if seed has been dissolved) 225 Prior knowledge indicates that final PSD highly sensitive to Agitation, thus requiring further study. 9 Seed PSD controlled by release assay performed after pin milling. 1 Same logic as for antisolvent percentage slide 12 © ICH, Washington D.C., October 2010 working documents like this would likely not be included in the submission Detailed © ICH, October 2010, Breakout A: Design Space 6 ICH Quality Implementation Working Group - Integrated Implementation Training Workshop Breakout A: Design Space DS development – DOE & Modeling • Target the desired quality attribute range from QTPP • Determination of edge of failure is not required • Modeling is not required to develop a Design Space • Models need to be verified, updated and maintained © ICH, Washington D.C., October 2010 slide 13 ICH Quality Implementation Working Group - Integrated Implementation Training Workshop Breakout A: Design Space DS development – DOE & Modeling - Does the DOE results, as presented in the case study, provide sufficient information to define a design space? - Describe which parameters are addressed by univariate vs. multivariate DOEs and how these are factored into the design space - Model implementation: Describe how variability due to the process operations and/or analytical method is considered in use of the model - Describe the process for maintenance & updating of the model © ICH, Washington D.C., October 2010 © ICH, October 2010, Breakout A: Design Space slide 14 7 ICH Quality Implementation Working Group - Integrated Implementation Training Workshop Breakout A: Design Space DS development – Process parameter & quality attributes - Design space presentation in the submission could - include critical and non-critical parameters - Critical parameter ranges/model are considered a regulatory commitment and non-critical parameter ranges support the review of the filing - Critical parameter changes within design space are handled by the Quality System and changes outside the design space need appropriate regulatory notification Non-critical parameters would be managed by Quality System © ICH, Washington D.C., October 2010 slide 15 ICH Quality Implementation Working Group - Integrated Implementation Training Workshop Breakout A: Design Space DS development – Process parameter & quality attributes • Illustration & training questions - Has the model for PSD Control (next slide) been - demonstrated to be scale and equipment independent? Is a mathematical model always needed to have a design space? How to evaluate the impact of changing non-critical process parameters when included in the design space ? - Technical evaluation of a change of non-critical is the same scientific principle as for critical © ICH, Washington D.C., October 2010 © ICH, October 2010, Breakout A: Design Space slide 16 8 ICH Quality Implementation Working Group - Integrated Implementation Training Workshop Breakout A: Design Space Illustration from case study : QTPP and CQAs QTPP Dosage form and strength Immediate release tablet containing 30 mg of active ingredient. Specifications to assure safety and efficacy during shelf-life Assay, Uniformity of Dosage Unit (content uniformity) and dissolution. Description and hardness Robust tablet able to withstand transport and handling. Appearance Film-coated tablet with a suitable size to aid patient acceptability and compliance. Total tablet weight containing 30 mg of active ingredient is 100 mg with a diameter of 6 mm. Drug Product CQAs •Assay •Content Uniformity CQAs derived using Prior Knowledge (e.g. previous experience of developing tablets) •Dissolution CQAs may be ranked using quality risk assessment. •Tablet Mechanical Strength slide 17 © ICH, Washington D.C., October 2010 ICH Quality Implementation Working Group - Integrated Implementation Training Workshop Breakout A: Design Space API Crystallization: Design Space & Control Strategy 20 to 30ºC Particle Size Crystallization Temperature Particle Size Crystallization Feed Time Particle Size Crystallization Agitation Particle Size Crystallization Seed Wt% 1 to 2 wt% Hydrolysis Degradate Distillation / Crystallization Water Content < 1 wt% Control between 23 and 27ºC 5 to 15 hours Control via flow rate settings Quality system should ensure 1.1 to 2.5 m/s changes in agitator size result in change to speed setting © ICH, Washington D.C., October 2010 © ICH, October 2010, Breakout A: Design Space Controlled through weigh scales and overcheck Control via in process assay (e.g. < 0.5%) slide 18 9 ICH Quality Implementation Working Group - Integrated Implementation Training Workshop Breakout A: Design Space Implementation of Design Space • What PQS element need to be considered ? • How DS is captured in batch documentation and batch release ? • How DS knowledge used in managing changes in the manufacturing process? • What information would be transmitted to the manufacturing site? © ICH, Washington D.C., October 2010 slide 19 ICH Quality Implementation Working Group - Integrated Implementation Training Workshop Breakout A: Design Space Presentation of Design Space in regulatory submission • Design Space need to be clearly presented and justified in regulatory submission - Design Space need to be described in sufficient details in regulatory filing - Description could include critical and non critical parameters to assure complete understanding - Designation of criticality need to be justified in regulatory submission based on QRM and/or experimental results © ICH, Washington D.C., October 2010 © ICH, October 2010, Breakout A: Design Space slide 20 10 ICH Quality Implementation Working Group - Integrated Implementation Training Workshop Breakout A: Design Space Presentation of design space in regulatory submission • What is needed in the manufacturing process description in the filing to demonstrate the implementation of the Design Space? • What is the appropriate level of detail to present DOE and it’s conclusions in regulatory submissions ? slide 21 © ICH, Washington D.C., October 2010 ICH Quality Implementation Working Group - Integrated Implementation Training Workshop Breakout A: Design Space Illustration from the case study : Options for Depicting a Design Space • In the idealized example at left, the Seed wt% Pressure • oval represents the full design space. It would need to be represented by an equation. Alternatively, the design space can be represented as the green rectangle by using ranges - Temperature a portion of the design space is not utilized, but the benefit is in the simplicity of the representation Large square shows the ranges tested in the DOE Red area shows points of failure Green area shows points of success. © ICH, Washington D.C., October 2010 © ICH, October 2010, Breakout A: Design Space slide 22 11 ICH Quality Implementation Working Group - Integrated Implementation Training Workshop Breakout A: Design Space Acknowledgement This presentation has been developed by members of the ICH Quality Implementation Working Group (Q-IWG) • • • • • • • • • • • • Jean-Louis Robert (rapporteur) Diana Amador-Toro • Robert G. Baum • Nicholas Cappuccino • David Cockburn • Georges France • Richard L. Friedman • Nigel Hamilton • Hirotada Nagai • Yukio Hiyama • Fusashi Ishikawa • Takao Kiyohara • Urs Kopp Akira Kusai Yoshihiro Matsuda Motoaki Mitsuki Elaine Morefield Jacques Morénas Masatoshi Morisue Markus-Peter Müller Tamiji Nakanishi Moheb Nasr Kazuhiro Okochi • • • • • • • • • • • Anthony Ridgway Rachael Roehrig Stephan Rönninger Swroop Sahota Hideki Sasaki Tetsuhito Takarada Shigeki Tamura Krishnan Tirunellai Mats Welin Jean M. Wyvratt A J van Zyl © ICH, Washington D.C., October 2010 slide 23 Implementation of ICH Q8, Q9, Q10 Breakout: A Design Space Discussions Moheb Nasr Georges France International Conference on Harmonisation of Technical Requirements for Registration of Pharmaceuticals for Human Use © ICH, October 2010, Breakout A: Design Space 12 ICH Quality Implementation Working Group - Integrated Implementation Training Workshop Breakout A: Design Space Acknowledgement Facilitators • Regulator: - Krishnan Tirunellai Sharmista Chatterjee Eric Duffy Erin McCaffrey • Industry: - John Lepore Tim Watson Kevin Seibert John Berridge © ICH, Washington D.C., October 2010 slide 25 ICH Quality Implementation Working Group - Integrated Implementation Training Workshop Breakout A: Design Space Disclaimer • This represents a high level summary of workshop discussion without judgement or endorsement © ICH, Washington Washington,D.C., D.C.,October October2010 2010 © ICH, October 2010, Breakout A: Design Space slide 26 13 ICH Quality Implementation Working Group - Integrated Implementation Training Workshop Breakout A: Design Space Are we clear with the key messages? Mainly YES • Different level of understanding of the key messages and the main concepts, resulting in questioning of interpretation - For example: what is the definition of knowledge space • Lack of clarity about Change Management of non-critical parameters when included in the Design Space • Lack of clarity about Change Management of non-critical parameters when not included in the Design Space • Regulatory expectation of process description: inclusion or not of non-critical parameters © ICH, Washington D.C., October 2010 slide 27 ICH Quality Implementation Working Group - Integrated Implementation Training Workshop Breakout A: Design Space Are there practical concerns on implementation? (e.g. on harmonisation among regions needed, by region/local issue) • Design Space and scale up - Verification at full scale - Expectation of Design Space verification - Use of SUPAC 10x approach to scale up Design Space - Can we use Design Space development to replace SUPAC recommendations - Define which parameters are scale independent © ICH, Washington D.C., October 2010 © ICH, October 2010, Breakout A: Design Space slide 28 14 ICH Quality Implementation Working Group - Integrated Implementation Training Workshop Breakout A: Design Space Are there practical concerns on implementation? (e.g. on harmonisation among regions needed, by region/local issue) • Need a new approach for process validation for QbD type product with a Design Space - What is the value of conducting traditional validation studies with a single point within Design Space? - Is it an acceptable approach to conduct PQ Batches at different points within design space? - Continuous Process verification to replace traditional 3 batches process validation? © ICH, Washington D.C., October 2010 slide 29 ICH Quality Implementation Working Group - Integrated Implementation Training Workshop Breakout A: Design Space Are there practical concerns on implementation? (e.g. on harmonisation among regions needed, by region/local issue) • Linkage between QTTP to CQA to Design Space - Clinical relevance of Design Space - Potential tightening of specification based on batch history - Consider the impact of changes to Design Space on clinical safety and efficacy - Utility of in vivo data to link Design Space to QTPP • Should we consider all CQAs when developing a Design Space? © ICH, Washington D.C., October 2010 © ICH, October 2010, Breakout A: Design Space slide 30 15 ICH Quality Implementation Working Group - Integrated Implementation Training Workshop Breakout A: Design Space Are there practical concerns on implementation? (e.g. on harmonisation among regions needed, by region/local issue) • Implementation of Design Space in commercial manufacturing facilities - PQS issues, batch record, … Plan for knowledge retention • Tech transfer of Design Space - From development to manufacturing plant From site to site Outsourcing • Prior knowledge - Documentation and presentation of the prior knowledge in the regulatory submission How to utilize prior knowledge from other product development? © ICH, Washington D.C., October 2010 slide 31 ICH Quality Implementation Working Group - Integrated Implementation Training Workshop Breakout A: Design Space Are there practical concerns on implementation? (e.g. on harmonisation among regions needed, by region/local issue) • Verification, updating and maintenance of models - Consider developing an ICH guidance/Q&A on best practices for modelling Regulatory implications of model update • How to facilitate the Life Cycle management of a QbD type application, including a Design Space - Introduction and/or updating of Design Space after initial approval Development of a Design Space for legacy products © ICH, Washington D.C., October 2010 © ICH, October 2010, Breakout A: Design Space slide 32 16 ICH Quality Implementation Working Group - Integrated Implementation Training Workshop Breakout A: Design Space Are there practical concerns on implementation? (e.g. on harmonisation among regions needed, by region/local issue) • Concern about regulatory expectation/harmonization in the review of Design Space in different region inside and outside ICH? - Lack of global harmonization (outside ICH region) could reverse progress with the implementation of Q8,9 & 10 Impact of different change management regulatory processes over the life cycle of the product • Level of detail and location in regulatory submission - Consider revising CTD to adapt QbD type information (Design Space, Control Strategy, Quality Risk Management, etc.) • There is a training need for regulators and industry © ICH, Washington D.C., October 2010 slide 33 ICH Quality Implementation Working Group - Integrated Implementation Training Workshop Breakout A: Design Space Are there practical concerns on implementation? (e.g. on harmonisation among regions needed, by region/local issue) • Lack of clarity of regulatory commitment versus information intended for assessment purpose • Need for appropriate scientific dialogue between industry and regulators (inspectors & assessors) before, during & after assessment • Concern about the cost and the impact on time to market • Relationship between incoming raw material attributes (API, Excipients,…) and Design Space? © ICH, Washington D.C., October 2010 © ICH, October 2010, Breakout A: Design Space slide 34 17 ICH Quality Implementation Working Group - Integrated Implementation Training Workshop Breakout A: Design Space Where is more clarification required for practical harmonised implementation? • There is a need for more discussion on determination and the use of criticality in development of Design Space, Control Strategy and regulatory processes - There is a need for criticality justification regardless of inclusion into Design Space? - Should we consider an additional medium risk Process Parameter? - Should we reduce the emphasis of “Criticality”? © ICH, Washington D.C., October 2010 slide 35 ICH Quality Implementation Working Group - Integrated Implementation Training Workshop Breakout A: Design Space Where is more clarification required for practical harmonised implementation? • There is a need for more practical examples of Design Space development and presentation (e.g. complex Design Space and Models) - Is there a need for determination of uncertainty and robustness of Design Space? • The level of GMP relevance during DS development - For example: Need for clarity about analytical methods used in the development of Design Space (GMP validated versus Development methods)? © ICH, Washington D.C., October 2010 © ICH, October 2010, Breakout A: Design Space slide 36 18