William H. Frandsen, Intermounta n F re Sc ences Laboratory Forest Sefv

advertisement

William H. Frandsen,Intermounta

n F re Sc encesLaboratoryForestSefvce U S Departrnenl

of Agr cu ture

lvlssoula.N4onlana.

59807

Burning Rate of Smoldering Peat'

Abstract

S|nl)dl'ringgnr|nd1les1LeaddorLlrl!l)out:.|lL

\;th p.ek t(.nrp.rrrtufe!

g t u r d j h . h r s I ) ,)r , , r l i r

Canadianspllaglullpealn|l)ss!s|l.P|l's.n1uti\.]|ue]'ThetlnetobuIna|no\!atl)Li|to|

1erentorganicbulLdel'iliesa|r]n|ois|ul.rnlljnl)rguni(.ontentS.0rgaDic

]].om90fL80kgDr.'\Ioistureanrliiorglljlcon1.n|s$l.r..erpressedasnasi|atiosre]atilettr

lhc|ungco1.nlstoinedrInolclerllgtonrbustnll'\'ll)isl!f.r!ljos.

rate is irlependent oI rhe orgaric hull rlo,sitr. { !,rir,.rsalburninF rate. the unit area bunr ratc lt BRl. r rs obtuin(l br normaliz

i n g t h e b u r n i n g r a t e t o t h e ! f t ' a , ) l t h , l ) , , n , i , i 1 .s.i , r l a ( c . I t i s e x p r e s s e da s f o l l o r ; :

LBR = 0.2i

0.097 R.v -

o.olllllRr-Dl g rn']h'.

irhereD = R, if l,

Introduction

Srnoldcring.although not as risualh dranralic as

flarningcombustion.is an inlportantcomponentof

iblest lires. TL is cornnon in the duff ol the

coniierousi;rest thaLis deriveclfrorn thc accumulation of dctlitus. The dull inclrrdesthe fefmerrtation and hrrmrrs laver-sor thc O. and 0., soil

holizons that lie betleen the surface littel and

'lhe

the mineral soil (Bradv 198,1).

rate of

snloldering- mass loss orer tinre-rnd its dcpeD'

dence on olp(anicbulL clensitv.moisturc. and inorganic conterlt of the duli is the topit, of Lhis

rnanLls(,fipL.

Srnolderingis a lirrm of fife sl]read thal gencrallv octurs irr hrcl afravs thrt alc rnole tightll packed

than those that -quslainflarning. { lransilionfr_om

flaming to srnoltleringi-. erpected *hen frrel particles are Lhin or rerv small in diarnctcr and occup! morc than appro\inlateh lO Percentof Lhe

lolume. Rolhefmel(1972),.hols c dccreasing

rriiction intcnsitr. the rate ol he:rt release of

spleading lire per unit efea of the fcrreslfloor. that

e\trapolillcs lo vcr' lo\\, values r{hen the pacling

ratio ol lfacli(rnal \olumr occupicd b_r lirel np

plorcircs l0 percent.Fole-qtclLrlLthich Ias packing ratios gfealef lhan l0 pclcent. erihibits.mh

smolcJcling.lfhile litter. rrith pacldng ratios less

than 10 percent. e-.,hibits

onlv llarning.(A folm of

smolderingdoes oc lr-in larllc fuels independent

'll&rd

1t16

on Ph.D. di-.sertition {rf,lrilte.l t. tlr. t.n;\fbit',;

Uo,r

\orthr,r:st -Qcicnce.Vol. 65. \o. ,1. 1991

<

1.0. dtl

1l :

1.0 il R,>

l.l).

of packing cluling thc glowing phase in large fuel

pilc buming, but is not addle-qseclhere.i

Thc glountl fire. as the smolcleringfire is

named b! fife (r)nlfol spcciiilists.presentsno thrcat

. , , s . r - " . i t , . r np e r i r rt e r n r ,- ' l i t - r ' a l e , ,- 1p r e a r lH

sisl f.rr davs or $erks and latcr can initiate a Ilaming surfacc ilrc if it is fanned into llarnes bv a

chance gust of riind (Wein l9811. This potential

has blanded the gnrunrl firc m thc 'hold-over lire."

,Smolclering

duil temperaturesin e\.ess of 300oC

hare been obser,;edfcrr-upto 12 hour-sunder a

mired olerstorv ol rrester-nlarL:h lLurch occidenldllJ Nutt.l and lodgcpolcpine (Pinuscontotla\ar.

kttifolict Engelm.l (Hartford anri Frandscn, in

pl e-rs).

'Ihc

duif plesents an eflertire harrier to the

t r J n - l - . , , Il . r t t , ,t l r eI n i ' - " . r s1 u i l, l r r r i r rp3r - - a g "

of a surface fire. Hor,'eler. ii the duif is ignited.

the resullant srnoldcring lire is likelv to he brought

into tlirect contactrrith ihe rnineralsoil raisingits

lemperaLureaborc 300"C for severalhours.Flora

and fauna of the duff are con-rlLrnedalong with

r{)olsand see{ls.Organic matcrial in the upper p()rtion oi the mineralsoilis oxidizecl.and roots.seeds.

i r n J- o o " g c n i - r nr-r e , e - - a r tr i , " r . , r , l i n t sI t t i , I .

are killed and pc,ssiblvconsurned. Srnoldcring dufi

ran aiso contribute more than ;0 peraenLof the

air pollutants produced iiom a iire (-sancllierg

-t98ll). II. on the other hand. thc moistule and inorgrnic contcnt of the dulI exceedsthe lirrritsfor

r ! r r l r r r - t, , n t l - ,n r l , , , l i l i - l i l . l ' t " r f l n a i r , u n burrred and nol acL as d sour-ccof hcat (l'randsen

I9B7). l,nder these conditions the smoldeling

e o n b u - l i n n 2 , , n . i . I ' r ' e u r r t r , ll r o m , u m i n g i n t o

dircct contacLwith the mineral -"oil.Ho$,ever.the

moisture limit may be overcorne.A florr of heaL

frorr an abLrnclance

ol surlace lirels {slash)bnrning at thc sur-facc can {lrv Lhe fuel ancl bring it

within the combustion limits.

rrnge of organic bulk densitiesvaried 1iom 90 to

180 kg rn 3. This correspondslo lhc range that

is norrnallr' irund in duII (['oodarcl and Nlartin

are related to

-[980: Harrington l986l. ResLrlt-q

slnolderingin the abscncc of rtincl anrl slope.

-Smolcierirrg

can Le initiatedin the duff after a

lire spre:rdsthrough thc forcst littcl ii the duff is

capablcof sustainedsrnoldering(Frandsenl98i).

Larger litter iirels that sustdn burning. such as

tt'igs and concs. are igniLecland acl as cerltelsto

propagate the firc clorn into thc rluff. Orrce Lhefir'e

;s established. it plopapiates holizontallv rnd r.crticallv until it reachestrrnditionsthat \Lill noi suslain slnoldering.

The rnoistureand inorganic conlenLs\rere eric.r--.

p r , - - , d . r . m r - - r u l i ' Fr - h l i r ' I n l l r e , r ' e . r n m

The rnoistLrre

ratio. R,n. ran:icclfrorn 0 to 0.8 at

0.2 interrals and inorgarricraL;o.Rr. liom near'0

(nalrrralpeat inorganic ratio) to l rl intcrvals of

1 All conrbinatiorrsuere sampled e\cept those that

were outsidcthc snrolderirrglirnit giren bl Frandsen (19tt7) (Figule I). as

Ru + (R14,)< ] t

lf heat from the srnoJdoingcornbusL;onwa\e

is noLsufficientto olercolne the heat of vaporizatiorr requirecl b1'moist ftrcl. snroliering rrust cease.

FurLhermole. inolganic materials within thc fuel

rnalrix can absorb heat bul not o\idize to produce

rnore heat. fhus. thc arnounl of hcal produced peruniL rolurne is reduced. Both rnoi-.tureand in.rrganic content should Ieducc thc cflcctilcness ol

thc alailable heat b propagate the smoldering fire.

Srnoldering is erpected to procccclrdth the greatest

rate rlhen these inhibitinpl variables havc thcir

minirnum valucs,

The lactors that mav alTcctthc ratc of burning

ar.cthc lnoistureand inorganiccontent ol the dufl

ancl its organic buik den-ritl. Both the moistulc and

the inorganic contcnt hindcr the smoldering processand thefeioreare lierred as slowingdo$n thc

mav

rate of blu-ning. lno-casingthe bulk densit-,-slowdoln the supplv ofoxrgcn lo lhe cornbustion

interface and also slor{ the late of bul-ning.

Honcvcr'. Ohlcmiller-eL

al. \1979) found with flerible poh urethane-"that "the smolder processis Ilexible enough to adapt to rr $iclc r[ngc of oxvgen

low leveLs.'

supph lerels. inclLrdingextraordin:rrilv

t h e l ; l J o r . i . rfpr o , c J ur , u , r l l ; r ,- J l r \ t r F r i r n F ntli '

' n F a - u r et l p i l c f c r d " r r . . " i t l r , r n r - - ' u r . , r n r l t i u n

ratc of srroldering peat on ihe abo|e I;lctols.

(1)

a

t

t

t

a

t

a

a

t

-

t

t

I

F

IJJ

g 0.4

a

I

a

t

a

t

t

^ q ^

(J

-

--t

tl.,

D

I

F

L

o

=

a

a

t

t

o

_

a

t

I

I

o t {

,-',1

tt,). a

a

Methods

Canadian sphagnunrpeal rnoss\\as seleded as a

repfesentatire fuel ioI eramining the Irte of

sirnulatedfield

smoldcringin the lalioratorl Lrncler

conditions. lt has similar palticle sizes and bulk

" n d p a r l i c l e d e r r - i t i e -r - , 1 r r h .i - . r n i n p " r t r n t

ground coref in the tet boreal forestthat supports

smoldering combu-ition (Vein l9B3). and is a

uniform fuei that is cornmcrci:rllvarailable. The

0.o

INORGANIC

RATIO

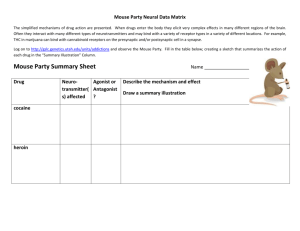

Figure l

Samphrg design. Each circle designates a sunplnrg

cornbiDation of moisrue and inorganic ratios {or each

o , p . r , i . . o r r , r r . r ..oFr" l '

nl.rrti.r "'p

h-ated three tnnes. Ferr obserations irere attempted

berond the erpected smolde ng limit (Br.

B . r n i r g R r t - , , i S m , i ' l . " i n gP - a t

lo7

Peat r,as moistened or clried to leach the

sclectedmoislure ratios.Inorganic mateial in the

lbrm of 22tr0ncsh (56 4 partide sizc) powdered

silica $as added to moist pcat to obtain inorganic

r r t i o s h i g h e rt h . r r rt h - i n h " r e n t i n o r S a n i i, r , r l . n l

ofpeat. -Silicalas uscd to ensure that thcrc lould

be thc lcast arnollnt of chcmical interaction betrreen the addcd inorganir' material dnd the combustion process.Tt is speculatedthat natural in

organic rniltcrialocculring in pcat rnav react in a

mannerto alter lhe combustionprocess.llorc dctail on sarnple prcparation can be founcl in l'rands e n( 1 9 8 9 ) .

The cxperimental sample rr.ascontained tilhin

a noncombLlsliblcinsulated box with an open top.

The box tas placed in a sealcclglass c,vlincler.The

cvlinder }as scaled except for an inlct and exit to

allrl for a florr of air. The flol las held constant

at 3.5 g min-r (rrear3.5 | min 1). an arnountthat

t'as determinrd to be suificient to maintain

- m " l , l , r i n g r ' i t h n u t, , r r c , n { t u ' \ l l t i . n . . r - ' \ p ' r i enced in the field. The sample volurnc lithin the

in-rrlrtedcomr,rr.tiunI,u',s.r.5 cm r i on in rrr,'.sect;onand,1 cm deep. The walLst'ere 2.5 crn

thjck. The insulatingmatcrial r,;asceramir.board

t'ith therrnal properlie-r similar Lo peat (lrandsen

l9fl7). Conscquentl:-. the heal transierred to the

wails wa-s not greally dilTerent iiom the hcat

transferrcdlithin the peat. This allolcd the burning peat to approximate part oI an expanded

\ olume. Thcle r{as no e:tcessivchcat loss or cooling at the u'allsof the container.as eridenccd bv

th-.rlrslnn

' o l r r r r L u n r Fl J, r J t J J j r r ' . n tt o t h . r , . J l - .

The upper cxposedsuriice of the pcdt n'as if(,

nited bv ftrur rol,".sof lesistance coils heated to a

red glorv. The gioling area approximated thc area

of the pcat slrrlace and was held t'ithin 5 nrn of

l h e . r r r f . r , . l , , r 2 m i n u t e - .P r i , , r- r l , e r i m n n t n t i o n

i n d i ,J l , d l h J l 2 m i n L r t . \-\ a - - u f l l ,i p n tl n i e n i t cI ' c a l

at all comhinationsup to the highestmoisturcand

inorganic ratios. lhe arnount of organic material

consumedunder enhancedburning during the ignition periocl is srnall cornpared to thc total mas-r

consumed.(ionseqLrerrtlv.

thcre is little error in thc

total burn time ofthe samplc that ranged iiom B0

to 25i rninutes.

The ignitel coil,<rlere liltcd ar\,avliom the pedt

sur{acewithin l5 sccondsof s$,itchingofi thc igniter'. The dur-ation of srnoldering rras taken from

th(] time the igniter !,,ass$itched off until -qmoldering stopped as evidenced bv the abscnceof carbon monoride in thc air llot'ing fiom the cvlinder

168

Frandsen

containing the smoldering peat. Carlron monoxide

las considered absent ll.hen the volurnerrrc con. e r , r r r r i L r $n r . l e - - r h a n ( r . 0 0 0 5 \ \ .

Results

Datr lere obtained lrom J72 sample ohsen'ations.

This inclucles aclditions Lo the original design for

cornparison sarnpJingsand losscsdue to those conclitionsthat rrould not sustaincombustion.

'l

he average srnoldcring burn rate lvas

calculatetJ by dividing the organic rnass (sample

rnass inorganic rnass)bv the duration olsmoldering. lhe organic mass l,as cquivalent to the total

mass lost because al1of thc organic mass was consurned during smoldeling.

'lhere

is a general trcnd torrard lorler burn

ratcs lrith iDcreasinginorganic ratios above 1.0 fcrr

e a ,h r n o i - t u r 'r-: r t i or l i g r r e 2 r . B . r r nr a t , r e r i . r l i o n l ithin replictrtionsof the organic bulk densitl' rvere

as greatol-lileaterthan !arialions bctweetrorganic

brrlk densities.Hcnce. there is no dependenceon

the organic bulk densit,v.Because of this independence.one mav viern-each combinationof the

rnoisture and inorganic ratios as replicated by as

much as 12 times if all burns l.ere successful.

Tt'o commerciai rarietics of peat Iere used.

The ruiginal choice was used for all p ot expenmcnl- dnl iritirl oh-elrrti"n- Jr m(illJrc r.rtios

of 0 and 0.2. S'hen additional peat wa,<necded.

no more ol lhaLrarictv was alailable. A rcplacemcnt \ras used at rnoisturcratios of 0.4 through

0.8. Thc search lbr the replacemcnt included those

peatsharing similar bulk phvsical pr-opeticsand

thc lotest inorganic contcnt apptoaching that oi

the original pcat. Con4)arisonsof the burn rates

sho$,edthe l\\o pcats to be equi,,alentat 0 moisture

ratio. but the burn rate ofthe originalpcat tlas 20

percent grealer at thc lar€iel rnoisture ratios (0.,1

to 0.8). ObsenaLions$'ith the replacementpeat

rere adjustcd up\rard bl- 20 perccnt so that they

could be rrsedto complementthe oliginal obserlations (Frandser I989).

Noting thal lhc burn rates al inorganic ratios

n e J r f t a r ' l r t I - h o r ' L i t t l ed i l h r F r , . J t m o i - t u r e

ratios 0 throrrgh0.4 (Figure 2). *e can linearize

the burn rate bv cornbining thc burn rates at I *'ith

those neal zero and gir'ing the combined inorgani<:

ratio a dummv valuc of 0 and reducing all the

highcr inorganic ratios bv l. (This is not the case

for mo;sturc ratios 0.6 ancl 0.8 but the data at

moislure ratio 0.6 account for onlv 14 percent of

the data and onlv 2 percent at 0.8 moistureratio.)

Moisture

Rotio

I

_c

tr

T

c)

Y

t

M

tr

T

v

1

^v -- \rJ\. \ J r l

ot -- lr' \

C

t :O.2

o:0.4

o :0.8

. u

A

T

T

A

I

o

1

T

l.

A

v

c

t:l

rn

z

0

J

lnnrrtnnin

!igrre

5

Prr{in

2. tsunr rut. dr:pc,!l, n(r'on lhc i,n)rgoni,i ratb at moisture ratios of0 to tl.il. Note the decline ofthe burn rate irith increasirg niorga . ratn hegh.iig ar 1 Eror bars rilaL. t,) th{,sknda

d { ' v i d r i o n .n : 6 t o

1 2 o b s e r l a t i o n s .S i n c e o b s e r y a

tions hare no error hars elcepl for moisture ratio 0.,1 at inorgaDic rrtjos o10.09 ard 1 {hcre Lhr: rrror is lcss than th.

s r m b o l s i z e .{ l g h ' = 2 . i 8 a l 0 ' k g s ' r

Thc modi{icd data hale the appearance of being linear in both the inorganic and rnorsturerallos.

A lineal mociel derelopecl b_r appl_-ving

a lcast

squar-esfit to Lhe modified data is shol,n bclor'.

It also cmbraccs thc shift in the inorganic axis

disursscd abovc.

B R : 7 . 5 8 - 2 . 7 2 R r / 0 . 9 1 8 ( R J- D l s h '

(l s h' = 2.78 r 10-' kg -"-r) \2)

lhere BR : bLLlnrale

andD: R' ifRr < ].0

D:

1 . 0i f R I > 1 . 0

The burn r-ttc \.clsus moistlrre ratio is shor'n

in I'igure 3. along tith the linearized rnodel- The

percentage error (predicted- ar'Lual)/acLual.

is

.Lrlsrr ur-r th- r.rns, ol inurtrril rrlio- Jt n

rnoistureratio oi 0 in Figurc 4. Estirnatcsof the

burn rate frorn the linear noclcl indicatc that 91,

89. and 90 percent of the prcdictcd lalues lie

rvithin t 10 percent of the actual valuc for'

rroisture r-atiosof 0, 0.2, and 0.i[. Err-ors ale

greater at moisturc ratios o{ 0.6 and 0.8. Onlr

about 70 percent ol the predicted values !,,ere

within + l0 percent ol the actual valLres.The lower

predictive capabiJitv is not surprising considering

thc dcputurc of these data from the form of the

data at the lol'er-moislureratiosin Figlre 2. Furthennore. these data. as mentioned above. accounl

for onh 14 and 2 pcrccnt of all the obserrations.

Discussion

\lany people think in terms of the linear spread

latc of smoldering t'hen reference is made to burn

fale. rather than to the milssloss burn rate presented

here. S'e gain insight inb the -(preadrate ;f1r'econvert thc burn ratc to a unit area burn rate by normalizing thc burn late to the area of the burning

srrrlaceof thc smolderingl avc. Thc resultingunit

area burn fate rclales to lhc smoldedn€t$ave and

is independent of the combustion bc,^.

'fhe

cross-sectionalarea. A. of the burning

volume of the combusL;onbor (Figurc 5) approximates the burning surface a-qit mores dolvn*ard.

Thc lincar sprcad rate can be obtained by equating

the mass loss burn ratc, Am/At. to the product ol

the organic bulk dcnsit_-v.p,. and the volume

Burning Rate of Smoldering Peat

169

I n o r g o n i cR o t i o

o:0.04 -0.09

v =3

o:4

a :1

n:2

I

_c

a)

t

c

lf

0.0

0.2

0.4

0.6

0.8

1.0

Moisture Rqtio

Figurc 3- l.in($ least squaFs lit to olscnatioD-r. Enor burs rclare ro the stardarrl rlcriation. | = 6 Lo l2 observations. Silglr

ohserrlri,nrshalenoerrorLars.\ot.singlelinear{lrro;n.reanicrariosfron0.0,1tol itIh'=2.78rl0'k8s'l

25

20

M o i s t u r eR o t i o - O

t 3

t-

L!

c

o

10

5

0

o

0_ - 1 0

- t 3

-24

0.0

1.0

2.O

J.0

I n o r g o n i cR c t i o

figure-1. lnors

t 70

i,r rnalietiDg rhe lrrn

Frandsen

ral,. \

4.0

5.0

rndD=&iIRr<1.0

I ) = 1 . 0i i R , > 1 . 0

-t.

I BR rangesflorn alroLrt0.15 to 0.i30 g crn-']h

L.singa cornmonr oluc for thc olganic bulk dcnsitv. 0.1 g r,nr-r in Eq. (1). rre arrire at a range of

1.:) kr ll.0 .nr hrthat is in the right c,r'derc,1

rnagnitudefor smoldering i\\ ein 1983).

Figure 5. TLe bunnig roLLunerithin tlie cornbustioD bor sho\r

rrg the burning surface. ,\. as it nores rtorrnnarrl

a r l i s t r n r r ' . J r . s ' r r 1 , i n g r ) , , ta \ o l u t r t r 'r l f r I n t . l l

c.m-eumptiorlrate. Alv/At. as s\rept out b! thc

btrrning sLrliacein Figrrre 5.

lm/41

:

Q,AA!/-\I

g h-'

{3)

Transposing.1\'c halc lhc lincar ratc ol spr-ead

(4)

-\rilt : (lArn/lt)/{)iq.

or h 1

rrirele Arn/At is the burn latc. Blt

antl (\n/At)/-A. is the ulit nca blun latc . LBR

Although Lhe bor tas riesigneclltrr a cro-.sscr,tionalar-eaof 25 t mr. the adual areaincreased

slightll iiorn dete oraiicrr o1 the rr'alls lith cach

burn. l'hree bores rrcrc uscd during thc cxpcriment to enslrr-cthat thc alcr rlicl not dcparl grcalll lrom thc designcd lrr-caof 25 cmr. Thc arcl

renged frdn 26 to 30 cnl'. lhe meclian.28 crn'.

rras used to lppro\imatc thc ar-caof thc bulning

surlace. Relinements in cstinuting thc arca ar-cpl-cclLrdcLlbl unceftainlies irr the shape of Lhe srrr'face.The LrrriL

area burn rate is a uni\ersal l)ararneter Lhatrelatesonl! to the hurning surlaceoi the

srrolderingrrarc arrclis e\l)ressedrs lhe lnassl(rss

r a l e p e f u n i L a r e a o f L h eb L r r n i n gs u r ' { r c e .

LBR : BR/28

R e p l a c i n gB R r r i t h e q u a t i o n( 2 )

t t s R = 0 . 2 i - 0 . 0 9 ?l t . , - 0 . 0 3 3 t t-, l l l

gcm

n

ll

( 1g c m ' h ' = 2 . 7 8 r1 0 ' h g mz s ' )

lhele [-BR = unit areaburn rate

Note that in llq. 1.1)thc burn r-utc is rclatcd

directll to thc lincar splcad lalc through thc

If the densiLr

organicbulk riensiLri.{ is r.orrstant).

is halvecl. the linear spread rate rnust be doublecl

to maintairl thc sanrc nrass loss ratc. This is

feasonable$hen rorr consider thal a combuslion

Jront must pas-sthrough a le-rsdense luel alrav

fastef lhan through a nloLe dense arr:rv to consume

nas-r at the -ranlelate. lt should be clear that the

line:rr spread rate rnlv be thought of as r'olumetic

burn ralc as the burning surfir'e srleelrsoLrtvolunle. but it cannot be thought of in the snrne sense

as the mass burn ratc.

I'lobable errol arralvsiswasernplovedto examine Lhe rariabilitv of the independent rariables

(Flandsen t9B9). Tladitional -statistical

methods are

not appJicable $hen the sample is prepared to

varachicvcprcsclcclcrilalues of thc irrdepenclent

iablesas designedin FigLrre-t. Basedon this analr . i - . t h r m o . t r u ' r . r l i uh . r .. r n , n u r l l r . r il . u E r ,J l , f

than 3.2 percent.Lheerror in the organicbulk densih i,cno gfeaLerlhan 3.5 percent.and the inorganic

ratio has an error no grealer than 2.6 percent.

Afpro)iimatelJ 90 percent oi the predictions

frorn the lincar modcl alc rrithin t 10 pclcent oi

Ihc acttralralLrcat moisLureraLiosof 0. 0.2. and

0.4. \ealll all elrors grertel than il0 percent

are rt the highrr inorganic r-tlios. Thc prcdictivc

" . r l ' . r l , i l i, tl 'r ' , t , t. , , . r r r' ' n , l , t l , r r r ,' i l J l I n u i - l J .

r a t i o so f 0 . 6 a n d 0 . 8 . T h e l ) f e p o n d e f a n coef d a t a

afe at the lo\ref inorganic ratios.at and belou l.

This is a rellection ol lirnitecl sust:rined smolder'ing and uncertaintics lhcn appr-oachingthe coml , . r - t ,i r rl i r r ' . rt F | r r r , l - - r lrq H l ' . r l I n ' ,- l , r r cf i r l ' at and rbor e 0.,1. lt is likelv that rrhltever order

liness there mav lr in the relatiolship lrreaks dotn

as that boundlu'r is rpploachcd.

Thc rcsultsof thi,.stutJl clcfincthc clepcndcncc

of Lherate ol burningon lhe nmistureand inorganic

content oi smoldeling cluli'lil<e materiaLand -shou'

a lack ol dcpcnricnccon thc organil bulk dcnsitv.

\ - i r r ' 1-, r r , ' l - l , r 1 , - . l i ,' '- t l r ,- ' , r . n r at,- r ' . t : i- - ,

that infelences can be made about the rate oi

'fhese

snlolcleing.

results contlibute to a better

urlclerstrrrlcling

ofthe combustionof srnolderingdufi.

BulningRate of Smolcleling

Peat

171

Acknowledgements

The author tishcs to thank Plof. Donald F. Potts

ofthc SchoolofForestn, at the Lnivelsit,vofl\{ontana lbr his encouragementLo pursuc this line o1

iDvestigation.

LiteratureCited

Bfrd\. \. C. 19111T

. h e \ e r L u e a r d I r f t r l r i { s , ) l , r o i l .g r h e d . .

Thc \lacnillan Conpam. \er Iorl. ;50 r).

l r u J s t n . \ 1 . H . ! 9 i J ; . T h e n l u e n c e o f m o i s t L u ca n u d n { i r l l

s o j l o r t h . r o r r b r s t n , n l i n i t s o l s m o l d e r n i gf o r e s t d u f t

Car. J. For. Iles. l;:15,10-1511.

F r a n d s e n . t r . H . 1 9 8 9 . - r r $ l d . r i , , s ( 1 , , 1 1l i:m i l s . h e r t e r o l r e d .

and burn rate. \Iissoula-l\lontrnr. t,nirersitr of \Ion

tana. Ph.D. liissertatidi. 1'16 I)HarrnrSon. \{. tll. 1986. C,r!r)dris,)n ol lorcn lloor deprh to

loadlng Lelationshiq,s nonr *r.rrl

pon,l.rroso pine

s t a n d s .R e s e a r c hN o t e R \ ' l . 1 6 3 . F o r t a o l l i n s - C 0 : L . S .

D.rrn m f nr of r\sriculnn e. Forest SeN ice. H o.[\ N ou nLdiii!(,,, st ud Rrng. Iirperiment Station.5 p.

Hatford. Il. {.. urrl \\r. H. Irra.dsen. In press. Cround

lernt)eratLre liistori{\ l;otri 1;r.: An ilhtstration.I'lissor a.

\lT: l-.S. liefartrnent,)J Asri(! lu(. forest Serrice.

Liternrurruin

R(is.u.(ih Stuion. 1t1 p. Editorial draft.

ohlemiller. T. J.. J. Bellc,,. ur

r''. Rogers. 1979. -{ model

of smoldering ronrbustion applled to flexible

polrurethare loads. Q,mb. Flame. 36:197 215.

I t-2

l-randsen

Rothermel, R. (. 1972. .{ mlthenarr al n,odcl lbr predicting

poper INT t15.

lire spread in i,itdtand fir*. R|silrh

Ogden. LT: U.S. Depatmert ol {sri(! tur. Forest i\er

rice. Intelnountain Forest ard Rangc lirpcriment Sta

S a n d b e r g .D a r n l \ . l 9 8 i l . R . s { ! r c h l e a d s r o l e ! ! s m o L e r r o n

tresdibed lir.s. ln: PrrlrdnHs. 1983 \othNest Fire

Council {rnua1\leeLnrg 1983 \oonber

2l 22i Olvn-

pia.tr'A. 2i 1,.

trein.R. tr. 1981.Chrr!.r.filrics

andsuppre-.;ion

of fires

ii orsanic rerhiii h A,,strali!. Alsr..l. fof. ,1,1:162 169.

Sein. R. X. 1983. tjrc brhN\ior and rological effectsni

orsanic rerrain. 1a -qCOI'E 1B: 1hc Role o{ Fire in

\,,frhol Cncunpolar Ecollsten*. R. \Itin. and D.

A . \ ' l n ( j l ( j { n -( a l s . J o h n \ t i l e r & S o n s . \ e r \ o r [ . p .

8t 95.

\! oodard. P.. ard R. E. Nllrrin. I q80. Duffweight and depth

in a high eloation Pirir

J. For. Res. l0:?-9.

rontorra Dougl. forest. Can-