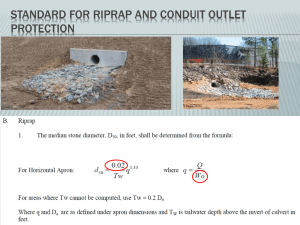

Matrix (Partially Grouted) Riprap Lab Flume Study April 2015

advertisement