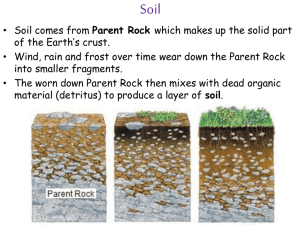

ARMY TM 5-852-4 AIR FORCE AFM 88-19, Chap. 4

advertisement