MAINTENANCE OF MECHANICAL AND ELECTRICAL EQUIPMENT AT COMMAND, CONTROL

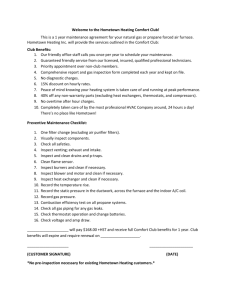

advertisement