Document 12112515

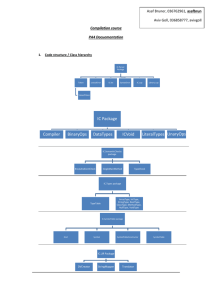

advertisement