Document 12112506

advertisement

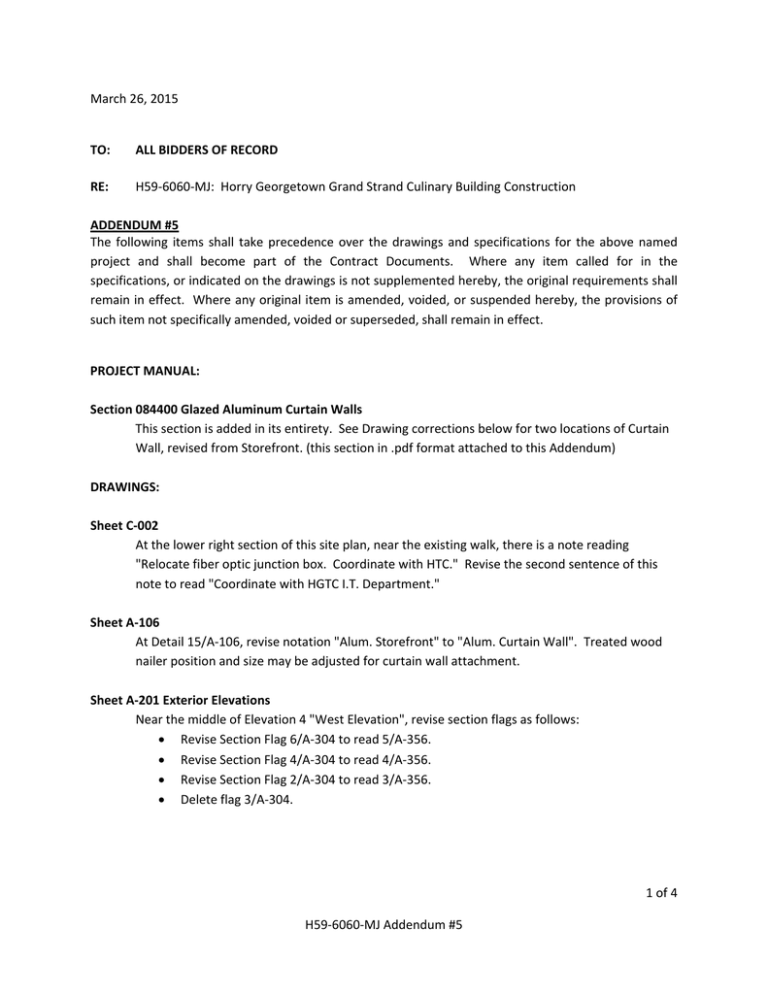

March 26, 2015 TO: ALL BIDDERS OF RECORD RE: H59‐6060‐MJ: Horry Georgetown Grand Strand Culinary Building Construction ADDENDUM #5 The following items shall take precedence over the drawings and specifications for the above named project and shall become part of the Contract Documents. Where any item called for in the specifications, or indicated on the drawings is not supplemented hereby, the original requirements shall remain in effect. Where any original item is amended, voided, or suspended hereby, the provisions of such item not specifically amended, voided or superseded, shall remain in effect. PROJECT MANUAL: Section 084400 Glazed Aluminum Curtain Walls This section is added in its entirety. See Drawing corrections below for two locations of Curtain Wall, revised from Storefront. (this section in .pdf format attached to this Addendum) DRAWINGS: Sheet C‐002 At the lower right section of this site plan, near the existing walk, there is a note reading "Relocate fiber optic junction box. Coordinate with HTC." Revise the second sentence of this note to read "Coordinate with HGTC I.T. Department." Sheet A‐106 At Detail 15/A‐106, revise notation "Alum. Storefront" to "Alum. Curtain Wall". Treated wood nailer position and size may be adjusted for curtain wall attachment. Sheet A‐201 Exterior Elevations Near the middle of Elevation 4 "West Elevation", revise section flags as follows: Revise Section Flag 6/A‐304 to read 5/A‐356. Revise Section Flag 4/A‐304 to read 4/A‐356. Revise Section Flag 2/A‐304 to read 3/A‐356. Delete flag 3/A‐304. 1 of 4 H59‐6060‐MJ Addendum #5 Sheet A‐356 Wall Sections Section 5: Revise section to show steel angle lintel at ceiling line to separate storefront into upper and lower panels. (revised drawing sheet attached in .pdf format) Sheet A‐414 Storefront Details At Detail 5/A414, revise window frame from storefront to curtain wall. Nailer position may be revised as required to fit curtain wall installation. At Detail 7/A414, revise window frame from storefront to curtain wall. Nailer position may be revised as required to fit curtain wall installation. Sheet A‐415 Storefront Details Add Detail 8/A‐415, showing steel angle support/lintel between upper and lower panels at storefront E. (revised sheet in pdf format attached to addendum) Sheet A‐456 Storefront Schedule At Elevation 5, Storefront E, at right side of elevation, upper spandrel glazing section of storefront revised to a separate storefront panel from lower section. There will be a double frame profile between upper and lower sections of storefront. Add detail flag 8/A‐415 at the double frame. (revised sheet attached to addendum in .pdf format) At Elevation 11, Revise name to read "Curtain Wall M" in lieu of "Storefront M". At Elevation 13, Revise name to read "Curtain Wall O" in lieu of "Storefront O". Note: glazing will not change for these windows. (revised sheet in pdf format attached to addendum) Sheet S2.0 Foundation Plan Revise note atop concrete slab for HVAC Chiller in Service Yard from ' T.O. SLAB = 0'‐0" REF.' to 'T.O. SLAB = ‐1'‐6" REF.' RESPONSE TO QUESTIONS: 1. Elevation D1 on page A‐423 calls out Demo Kitchen‐‐Plastic Lam. Wall Panels. Please tell us where these panels are to be located. Please advise. Elevation D‐1 is meant to show plastic laminate color selections for the angled panels that are mounted on the curved wall between the two entrance doors to the Demonstration Auditorium. Elevation B1 on A‐421 shows these panels, but in the background behind the suspended light fixtures. The panels are detailed on sheet A‐605 at details C2 and F6. 2 of 4 H59‐6060‐MJ Addendum #5 2. The “Chiller Yard” floor level appears to be shown in two different configurations: One without a base floor of concrete over the entire space, with only the chiller support slab under the chiller (see 1/A104, 2/A302, 7/A304 for example) One with a 6” concrete floor over all the space and with the 8” chiller support slab under the chiller (see 5/A202, 8/A202, 3/A359 for example) Please provide guidance as to which configuration is correct. The concrete slab for the Chiller shall be as dimensioned in plan detail 1/A104, with thickness and reinforcing noted on sheet S2.0. This is an independent slab surrounded by a gravel drainage bed. However, the elevation for the slab noted on Sheet S2.0 (0'‐0") is incorrect. The top of slab for the Chiller shall be ‐1‐6" below the interior floor slab (see correction in Drawing section above). The slab at the service courtyard, even where shown on plans extending to the fence, does not go under the fence. The entire fence sits on its own footing, not a turned down slab. 3. May a liquid applied vapor permeable air barrier be used over the concrete masonry exterior walls in lieu of the specified adhesive backed membrane? No. Bids are to be based on specified product. 4. How do you envision the spray foam being applied to the construction of walls so as to create a smooth surface, at the correct depth, ready for rigid insulation to be applied over with no voids or bulges? Install the rigid insulation first, then spray the back side of rigid insulation. 5. Is it required to obtain "Boiler and Machinery insurance" for this project? The way the item reads, it could be interpreted in two ways. Contractor is required to purchase and maintain boiler and machinery insurance. 6. The interlayer material specified for the solid polymer resin sheets is not available in the 10 ft. lengths necessary to fit into the folding panel doors at the bistro. For this bid, in lieu the metallic interlayer, supply 3/8" thick sheets with pattern equal to Lumicor Graphics pattern "Ovalesque Print". 3 of 4 H59‐6060‐MJ Addendum #5 SUBSTITUTION REQUESTS: Section 072119 ProSeal MD‐C‐200 v3 by Icynene, Inc. is Approved as an alternate material for this specification. Section 126100 Navetta (Sumettra Plus) is Approved as a supplier for this specification. Section 283111 Silent Knight (by Honeywell) is Approved as a supplier for the following devices in this specification: Fire Alarm Control Unit (Silent Knight IFP‐1000) Fire Alarm Boxes (Silent Knight Manual Fire Boxes) Smoke Detectors (Silent Knight Electric Smoke Detector) Duct Smoke Detectors (Silent Knight Duct Detector) Heat Detector (Silent Knight Heat Detector) Notification Appliance (Silent Knight System Sensor) Remote Annunciator (Silent Knight Annunciator) Addressable Interface Device (Silent Knight Monitor Module) Addressable Interface Device (Silent Knight Control Module) END OF ADDENDUM #5 4 of 4 H59‐6060‐MJ Addendum #5 MOZINGO + WALLACE LS3P HORRY GEORGETOWN - GRAND STRAND CULINARY ARTS BUILDING CONSTRUCTION Construction Specifications H59-6060-MJ 10/28/2014 SECTION 084400 - GLAZED ALUMINUM CURTAIN WALL PART 1 - GENERAL 1.1 RELATED DOCUMENTS A. 1.2 Drawings and general provisions of the Contract, including General and Supplementary Conditions and Division 01 Specification Sections, apply to this Section. SUMMARY A. Section includes glazed aluminum curtain walls. B. Related Sections: 1. 2. 1.3 Section 088000 - Glazing Section 079200 - Sealants ACTION SUBMITTALS A. Product Data: For each type of product. 1. B. LEED Submittals: 1. C. Include construction details, material descriptions, dimensions of individual components and profiles, and finishes. Product Data for Credit IEQ 4.1: For glazing sealants used inside the weatherproofing system, documentation including printed statement of VOC content. Shop Drawings: For glazed aluminum curtain walls. Include plans, elevations, sections, full-size details, and attachments to other work. 1. 2. Include details of provisions for assembly expansion and contraction and for draining moisture occurring within the assembly to the exterior. Include full-size isometric details of each vertical-to-horizontal intersection of glazed aluminum curtain walls, showing the following: a. b. c. d. e. 3. Joinery, including concealed welds. Anchorage. Expansion provisions. Glazing. Flashing and drainage. Show connection to and continuity with adjacent thermal, weather, air, and vapor barriers. GLAZED ALUMINUM CURTAIN WALLS 084400 - 1 MOZINGO + WALLACE LS3P HORRY GEORGETOWN - GRAND STRAND CULINARY ARTS BUILDING CONSTRUCTION Construction Specifications H59-6060-MJ 10/28/2014 D. Samples for Initial Selection: For units with factory-applied color finishes. E. Samples for Verification: For each type of exposed finish required, in manufacturer's standard sizes. F. Delegated-Design Submittal: For glazed aluminum curtain walls indicated to comply with performance requirements and design criteria, including analysis data signed and sealed by the qualified professional engineer responsible for their preparation. 1.4 INFORMATIONAL SUBMITTALS A. Qualification Data: For Installer. B. Energy Performance Certificates: For glazed aluminum curtain walls, accessories, and components from manufacturer. 1. Basis for Certification: NFRC-certified energy performance values for each glazed aluminum curtain wall. C. Product Test Reports: For glazed aluminum curtain walls, for tests performed by manufacturer and witnessed by a qualified testing agency. D. Sample Warranties: For special warranties. 1.5 CLOSEOUT SUBMITTALS A. 1.6 Maintenance Data: For glazed aluminum curtain walls to include in maintenance manuals. QUALITY ASSURANCE A. Installer Qualifications: An entity that employs installers and supervisors who are trained and approved by manufacturer. B. Product Options: Information on Drawings and in Specifications establishes requirements for aesthetic effects and performance characteristics of assemblies. Aesthetic effects are indicated by dimensions, arrangements, alignment, and profiles of components and assemblies as they relate to sightlines, to one another, and to adjoining construction. 1. 1.7 Do not change intended aesthetic effects, as judged solely by Architect, except with Architect's approval. If changes are proposed, submit comprehensive explanatory data to Architect for review. WARRANTY A. Special Assembly Warranty: Installer agrees to repair or replace components of glazed aluminum curtain wall that do not comply with requirements or that fail in materials or workmanship within specified warranty period. GLAZED ALUMINUM CURTAIN WALLS 084400 - 2 MOZINGO + WALLACE LS3P 1. H59-6060-MJ 10/28/2014 Failures include, but are not limited to, the following: a. b. c. d. e. 2. HORRY GEORGETOWN - GRAND STRAND CULINARY ARTS BUILDING CONSTRUCTION Construction Specifications Structural failures including, but not limited to, excessive deflection. Noise or vibration created by wind and thermal and structural movements. Deterioration of metals, metal finishes, and other materials beyond normal weathering. Water penetration through fixed glazing and framing areas. Failure of operating components. Warranty Period: 10 years from date of Substantial Completion. PART 2 - PRODUCTS 2.1 PERFORMANCE REQUIREMENTS A. General Performance: Comply with performance requirements specified, as determined by testing of glazed aluminum curtain walls representing those indicated for this Project without failure due to defective manufacture, fabrication, installation, or other defects in construction. 1. 2. Glazed aluminum curtain walls shall withstand movements of supporting structure including, but not limited to, story drift, twist, column shortening, long-term creep, and deflection from uniformly distributed and concentrated live loads. Failure also includes the following: a. b. c. d. e. B. Structural Loads: 1. 2. C. Wind Loads: As indicated on Drawings. Other Design Loads: As indicated on Drawings. Deflection of Framing Members: At design wind pressure, as follows: 1. D. Thermal stresses transferring to building structure. Glass breakage. Noise or vibration created by wind and thermal and structural movements. Loosening or weakening of fasteners, attachments, and other components. Failure of operating units. Deflection Normal to Wall Plane: Limited to edge of glass in a direction perpendicular to glass plane not exceeding 1/175 of the glass edge length for each individual glazing lite, 1/175 of clear span for spans up to 13 feet 6 inches (4.1 m) and to 1/240 of clear span plus 1/4 inch (6.35 mm) for spans greater than 13 feet 6 inches (4.1 m) or an amount that restricts edge deflection of individual glazing lites to 3/4 inch (19.1 mm), whichever is less. Structural: Test according to ASTM E 330 as follows: 1. When tested at positive and negative wind-load design pressures, assemblies do not evidence deflection exceeding specified limits. GLAZED ALUMINUM CURTAIN WALLS 084400 - 3 MOZINGO + WALLACE LS3P 2. 3. E. Fixed Framing and Glass Area: No evidence of water penetration through fixed glazing and framing areas when tested according to a minimum static-air-pressure differential of 20 percent of positive windload design pressure, but not less than 6.24 lbf/sq. ft. (300 Pa). Energy Performance: Certify and label energy performance according to NFRC as follows: 1. 2. 3. 4. Thermal Transmittance (U-factor): Fixed glazing and framing areas shall have U-factor of not more than 0.69 Btu/sq. ft. x h x deg F as determined according to NFRC 100. Solar Heat Gain Coefficient: Fixed glazing and framing areas shall have a solar heat gain coefficient of no greater than 0,35 as determined according to NFRC 200. Condensation Resistance: Fixed glazing and framing areas shall have an NFRC-certified condensation resistance rating of no less than 71 as determined according to NFRC 500. Outdoor-Indoor Transmission Class: Minimum 34. Windborne-Debris Impact Resistance: Pass missile-impact and cyclic-pressure tests when tested according to ASTM E 1886 and testing information in ASTM E 1996 for Wind Zone 3. 1. 2. I. Maximum air leakage of 0.06 cfm/sq. ft. (0.30 L/s per sq. m)at a static-air-pressure differential of 6.24 lbf/sq. ft. (300 Pa). Water Penetration under Static Pressure: Test according to ASTM E 331 as follows: 1. H. 10/28/2014 When tested at 150 percent of positive and negative wind-load design pressures, assemblies, including anchorage, do not evidence material failures, structural distress, or permanent deformation of main framing members exceeding 0.2 percent of span. Test Durations: As required by design wind velocity, but not less than 10 seconds. a. G. H59-6060-MJ Air Infiltration: Test according to ASTM E 283 for infiltration as follows: 1. F. HORRY GEORGETOWN - GRAND STRAND CULINARY ARTS BUILDING CONSTRUCTION Construction Specifications Large-Missile Test: For glazed openings located within 30 feet (9.1 m) of grade. Small-Missile Test: For glazed openings located more than 30 feet (9.1 m) above grade. Thermal Movements: Allow for thermal movements resulting from ambient and surface temperature changes: 1. 2. Temperature Change: 120 deg F (67 deg C), ambient; 180 deg F (100 deg C), material surfaces. Thermal Cycling: No buckling; stress on glass; sealant failure; excess stress on framing, anchors, and fasteners; or reduction of performance when tested according to AAMA 501.5. a. b. High Exterior Ambient-Air Temperature: That which produces an exterior metalsurface temperature of 180 deg F (82 deg C). Low Exterior Ambient-Air Temperature: 0 deg F . GLAZED ALUMINUM CURTAIN WALLS 084400 - 4 MOZINGO + WALLACE LS3P 2.2 HORRY GEORGETOWN - GRAND STRAND CULINARY ARTS BUILDING CONSTRUCTION Construction Specifications H59-6060-MJ 10/28/2014 MANUFACTURERS A. Acceptable Manufacturers: 1. Kawneer 2. YKK 3. Efco 4. US Aluminum B. Source Limitations: Obtain all components of curtain wall system, including framing and accessories, from single manufacturer. 2.3 FRAMING A. Framing Members: Manufacturer's extruded- or formed-aluminum framing members of thickness required and reinforced as required to support imposed loads. 1. 2. 3. 4. 5. B. Construction: Thermally broken, 2 1/2" face by 6" to 7 1/2" depth frame, screw spline fabrication, 1 5/16" impact resistant glazing. Glazing System: Retained mechanically with gaskets on four sides. Glazing Plane: Front. Finish: Clear anodic finish. Fabrication Method: Either factory- or field-fabricated system. Pressure Caps: Manufacturer's standard aluminum components that mechanically retain glazing. 1. Include snap-on aluminum trim that conceals fasteners. C. Brackets and Reinforcements: Manufacturer's standard high-strength aluminum with nonstaining, nonferrous shims for aligning system components. D. Materials: 1. Aluminum: Alloy and temper recommended by manufacturer for type of use and finish indicated. a. b. c. d. 2. Sheet and Plate: ASTM B 209. Extruded Bars, Rods, Profiles, and Tubes: ASTM B 221. Extruded Structural Pipe and Tubes: ASTM B 429/B 429M. Structural Profiles: ASTM B 308/B 308M. Steel Reinforcement (if required): Manufacturer's standard zinc-rich, corrosion-resistant primer complying with SSPC-PS Guide No. 12.00; applied immediately after surface preparation and pretreatment. Select surface preparation methods according to recommendations in SSPC-SP COM, and prepare surfaces according to applicable SSPC standard. a. b. c. Structural Shapes, Plates, and Bars: ASTM A 36/A 36M. Cold-Rolled Sheet and Strip: ASTM A 1008/A 1008M. Hot-Rolled Sheet and Strip: ASTM A 1011/A 1011M. GLAZED ALUMINUM CURTAIN WALLS 084400 - 5 MOZINGO + WALLACE LS3P 2.4 HORRY GEORGETOWN - GRAND STRAND CULINARY ARTS BUILDING CONSTRUCTION Construction Specifications H59-6060-MJ 10/28/2014 GLAZING A. Glazing: Comply with Section 088000 "Glazing." B. Glazing Gaskets: Manufacturer's standard sealed-corner pressure-glazing system of black, resilient elastomeric glazing gaskets, setting blocks, and shims or spacers. C. Glazing Sealants: Comply with Section 088000 "Glazing." D. Sealants used inside the weatherproofing system shall have a VOC content of 250 g/L or less. 2.5 ACCESSORIES A. Fasteners and Accessories: Manufacturer's standard corrosion-resistant, nonbleeding fasteners and accessories compatible with adjacent materials. 1. 2. B. 2.6 Use self-locking devices where fasteners are subject to loosening or turning out from thermal and structural movements, wind loads, or vibration. Reinforce members as required to receive fastener threads. Anchors: Three-way adjustable anchors with minimum adjustment of 1 inch (25.4 mm) that accommodate fabrication and installation tolerances in material and finish compatible with adjoining materials and recommended by manufacturer. 1. C. nonstaining, Concrete and Masonry Inserts: Hot-dip galvanized cast-iron, malleable-iron, or steel inserts complying with ASTM A 123/A 123M or ASTM A 153/A 153M requirements. Bituminous Paint: Cold-applied asphalt-mastic paint complying with SSPC-Paint 12 requirements except containing no asbestos, formulated for 30-mil (0.762-mm) thickness per coat. FABRICATION A. Form or extrude aluminum shapes before finishing. B. Fabricate components that, when assembled, have the following characteristics: 1. 2. 3. 4. 5. 6. C. Profiles that are sharp, straight, and free of defects or deformations. Accurately fitted joints with ends coped or mitered. Physical and thermal isolation of glazing from framing members. Accommodations for thermal and mechanical movements of glazing and framing to maintain required glazing edge clearances. Provisions for field replacement of glazing from exterior for vision glass and exterior for spandrel glazing or metal panels. Fasteners, anchors, and connection devices that are concealed from view to greatest extent possible. Fabricate components to resist water penetration using method(s) as follows: GLAZED ALUMINUM CURTAIN WALLS 084400 - 6 MOZINGO + WALLACE LS3P 1. 2. HORRY GEORGETOWN - GRAND STRAND CULINARY ARTS BUILDING CONSTRUCTION Construction Specifications H59-6060-MJ 10/28/2014 Internal guttering system or other means to drain water passing joints, condensation occurring within framing members, and moisture migrating within glazed aluminum curtain wall to exterior. Pressure-equalized system or double barrier design with primary air and vapor barrier at interior side of glazed aluminum curtain wall and secondary seal weeped and vented to exterior. D. Curtain-Wall Framing: Fabricate components for assembly using manufacturer's standard assembly method. E. After fabrication, clearly mark components to identify their locations in Project according to Shop Drawings. 2.7 ALUMINUM FINISHES A. High-Performance Organic Finish: Thee-coat fluoropolymer finish complying with AAMA 2605 and containing not less than 70 percent PVDF resin by weight in both color coat and clear topcoat. Prepare, pretreat, and apply coating to exposed metal surfaces to comply with coating and resin manufacturers' written instructions. 1. Color and Gloss: As selected by Architect from manufacturer's full range. PART 3 - EXECUTION 3.1 EXAMINATION A. Examine areas, with Installer present, for compliance with requirements for installation tolerances and other conditions affecting performance of the Work. B. Proceed with installation only after unsatisfactory conditions have been corrected. 3.2 INSTALLATION A. General: 1. 2. 3. 4. 5. 6. 7. B. Comply with manufacturer's written instructions. Do not install damaged components. Fit joints to produce hairline joints free of burrs and distortion. Rigidly secure nonmovement joints. Install anchors with separators and isolators to prevent metal corrosion and electrolytic deterioration and to prevent impeding movement of moving joints. Where welding is required, weld components in concealed locations to minimize distortion or discoloration of finish. Protect glazing surfaces from welding. Seal joints watertight unless otherwise indicated. Metal Protection: GLAZED ALUMINUM CURTAIN WALLS 084400 - 7 MOZINGO + WALLACE LS3P 1. 2. HORRY GEORGETOWN - GRAND STRAND CULINARY ARTS BUILDING CONSTRUCTION Construction Specifications H59-6060-MJ 10/28/2014 Where aluminum is in contact with dissimilar metals, protect against galvanic action by painting contact surfaces with primer, applying sealant or tape, or installing nonconductive spacers as recommended by manufacturer for this purpose. Where aluminum is in contact concrete or masonry, protect against corrosion by painting contact surfaces with bituminous paint. C. Install components to drain water passing joints, condensation occurring within framing members, and moisture migrating within glazed aluminum curtain wall to exterior. D. Install components plumb and true in alignment with established lines and grades. E. Install glazing as specified in Section 088000 "Glazing." 3.3 ERECTION TOLERANCES A. Erection Tolerances: Install glazed aluminum curtain walls to comply with the following maximum tolerances: 1. 2. 3. 3.4 Plumb: 1/8 inch in 10 feet (3.2 mm in 3 m). Level: 1/8 inch in 20 feet (3.2 mm in 6 m). Location: Limit variation from plane to 1/8 inch in 12 feet over total length. FIELD QUALITY CONTROL A. Testing Agency: Engage a qualified testing agency to perform tests and inspections. B. Test Area: Perform tests on representative areas of glazed aluminum curtain walls. C. Field Quality-Control Testing: Perform the following test on representative areas of glazed aluminum curtain walls. 1. Water-Spray Test: Before installation of interior finishes has begun, areas designated by Architect shall be tested according to AAMA 501.2 and shall not evidence water penetration. a. Perform a minimum of one test in areas as directed by Architect. D. Glazed aluminum curtain walls will be considered defective if they do not pass tests and inspections. E. Prepare test and inspection reports. END OF SECTION 084400 GLAZED ALUMINUM CURTAIN WALLS 084400 - 8 HORRYGEORGETOWN GRAND STRAND CULINARY ARTS BUILDING CONSTRUCTION E MOZINGO + WALLACE ARCHITECTS, LLC 618 CHESTNUT RD., STE. 205, M.B. , SC 29572 TEL. 843.449.8000 FAX 843.843.1113 admin@mozingowallace.com r3 C r2 r2 r2 D 1 COLUMN CENTERLINE COLUMN CENTERLINE COLUMN CENTERLINE A-356 3 A-365 3 A-365 Sim Sim 1' - 0" 1' - 0" 2' - 0" 1' - 0" 1' - 0" 2' - 0" 2' - 0" ALUM. COPING CAP ALUM. COPING CAP TURN ROOFING MEMBRANE UP PARAPET AND OVER TOP OF BLOCKING. (TYP.) PROVIDE ROOFING MEMBRANE OVER PARAPET WALL AND OVERLAP BLOCKING AND VAPOR BARRIER. (TYP.) (2) 2x10 TREATED BLOCKING TURN ROOFING MEMBRANE UP PARAPET AND OVER TOP OF BLOCKING. (TYP.) (2) 2x8 TREATED BLOCKING 1' - 5" 1' - 8" 1' - 3" TAPERED INSULATION SOLID MASONRY VENEER CAVITY WALL MORTAR NET SYSTEM (TYP.) WATER RESISTANT BARRIER 1 1/2" RIGID INSULATION MASONRY VENEER WALL TIES @ 16" EACH WAY REFER TO STRUCTURAL 2x4 TREATED BLOCKING DETAIL 9/A-413 sim. ALUM. FLASHING AND COUNTER FLASHING THRU THE WALL FLASHING. TURN FLASHING UP 8" BEHIND THE WATER RESISTANT BARRIER. WEEPS @16" O.C (MAX.) C ROOFING MEMBRANE 2" SPRAY APPLIED INSULATION ALUM. COPING CAP WATER RESISTANT BARRIER 1 1/2" RIGID INSULATION WATER RESISTANT BARRIER 3" METAL DECK AND 4 1/2" RIGID ROOFING INSULATION. (TYP.) 1 1/2" RIGID INSULATION STEEL BEAM. REFER TO STRUCTURAL DRAWINGS 8" METAL STUDS @ 16" O.C. (TYPICAL) 8" METAL STUDS @ 16" O.C. (TYPICAL) 6" METAL STUDS BRACE @ 48" O.C. (TYPICAL) STEEL BEAM REFER TO STRUCTURAL DRAWINGS (TYP.) ALUM. STOREFRONT SYSTEM WITH SPANDREL GLASS 9 A-414 5/8" GYPSUM BOARD STEEL BEAM. REFER TO STRUCTURAL DRAWINGS 3" METAL DECK AND RIGID TAPERED ROOFING INSULATION. (TYP.) 3" METAL DECK (PAINTED) AND TAPERED RIGID ROOFING INSULATION. (TYP.) STEEL PLATE. REFER TO STRUCTURAL DRAWINGS (TYP.) ALUM. RAINSCREEN SYSTEM ROOFING MEMBRANE 6' - 0" 8" STEEL CHANNEL. (PAINTED) REFER TO STRUCTURAL DRAWINGS (TYP.) ALUM. RAINSCREEN SYSTEM ALUM. FLASHING AND COUNTER FLASHING 15" C CHANNEL (PAINTED) REFER TO STRUCTURAL DRAWINGS 8" METAL STUDS @ 16"O.C. (TYP.) STEEL BEAM. (PAINTED) REFER TO STRUCTURAL DRAWINGS (TYP.) 1' - 5" 8 A-415 18' - 0" 16' - 4" 18' - 0" 11' - 4" WWW.LS3P.COM 9' - 0" 1 1/2" RIGID INSULATION ROOFING MEMBRANE UP UNDER RAINSCREEN PANEL 6' - 2" 3' - 8" 3" METAL DECK AND 4 1/2" RIGID ROOFING INSULATION. (TYP.) TAPERED INSULATION ALUM. RAINSCREEN SOFFIT SYSTEM STEEL COLUMN. (PAINTED) REFER TO STRUCTURAL DRAWINGS (TYP.) 6 A-415 12' - 1 1/8" B ALUM. STOREFRONT SYSTEM 2' - 0" ALUM. STOREFRONT SYSTEM BEYOND PAINTED STEEL COLUMN MEMBERS OF THE AMERICAN INSTITUTE OF ARCHITECTS COPYRIGHT 2013 ALL RIGHTS RESERVED PRINTED OR ELECTRONIC DRAWINGS AND DOCUMENTATION MAY NOT BE REPRODUCED IN ANY FORM WITHOUT WRITTEN PERMISSION FROM MOZINGO + WALLACE ARCHITECTS, LLC AND LS3P ASSOCIATES LTD. ALUM. RAINSCREEN SOFFIT SYSTEM 1' - 3" 12' - 0 7/8" 12' - 0" PAINTED STEEL COLUMN 1' - 3" ALUM. STOREFRONT SYSTEM REVISIONS: No. DECORATIVE PANEL BISTRO 140 Revision 1 #5 ADDENDUM Date Date 1 3/26/15 BISTRO DECK BISTRO DECK BISTRO 140 PLASTIC LAMINATE OVER 3/4" PLYWOOD. EXTERIOR EXTERIOR BISTRO 140 1/2" REVEL 3 5/8" METAL STUDS @ 16" O.C.. (TYP.) CAVITY WALL MORTAR NET SYSTEM (TYP.) STAINLESS STEEL FLASHING. RUN FLASHING UP 8" METAL STUD WALL. LAP CMU 2". 8 A-414 4" CONCRETE SLAB. (TYP.) THRU THE WALL FLASHING. TURN FLASHING UP 6" BEHIND THE VAPOR BARRIER. PROVIDE WEEPS @ 16" O.C. (MAX.) ALUM. STOREFRONT SYSTEM WITH ALUM. SILL 4" CONCRETE SLAB. (TYP.) 2' - 11 1/2" ALUM. STOREFRONT SYSTEM WITH SPANDREL GLASS 5/8" GYPSUM BOARD 4" CONCRETE SLAB. (TYP.) ALUM. STOREFRONT SYSTEM WITH ALUM. SILL 4" CONCRETE SLAB. (TYP.) CONCRETE SLAB. LIGHT BROOM FINISH. SLOPE existing grade -2' - 6" existing grade -2' - 6" 1 WALL SECTION 6c BISTRO DECK 3/4" = 1'-0" 3 WALL SECTION 6c BISTRO DECK PATIO WALL 3/4" = 1'-0" WALL SECTION 6b BANQUETTE WALL @ BISTRO 4 3/4" = 1'-0" OCTOBER 28, 2014 DRAWN BY: JLD CHECKED BY: SDMJ 2' - 0" 2' - 0" A WALL SECTION 6d PATIO WALL @ BISTRO DECK 2 3/4" = 1'-0" DATE: Entry Level 0" FINISHED GRADE AT PLANTER 2' - 0" OSE PROJECT #: H59-6060-MJ DETAIL 9/A-413 DETAIL 9/A-413 Entry Level 0" 3/25/2015 9:00:27 AM C:\Documents and Settings\Administrator\Desktop\HGTC Culinary - 111914 - exterior central model.rvt BISTRO DECK Description 9' - 0" 9' - 0" 1 COOKING SUITE 141 FAX 843.722.4789 TAPERED INSULATION 9' - 0" WATER RESISTANT BARRIER 5' - 11 1/8" MASONRY VENEER TEL. 843.577.4444 8" METAL STUDS @ 16" O.C. (TYPICAL) DETAIL 13/A-364 ALUM. RAINSCREEN SYSTEM 3' - 0" ALUM. FLASHING AND COUNTERFLASHING 205 1/2 KING ST. CHARLESTON SC 29401 TOP OF CMU WALL 18' - 0" ROOFING MEMBRANE ALUM. RAINSCREEN SYSTEM ROOFING MEMBRANE LS3P ASSOCIATES LTD. (2) 2x8 TREATED BLOCKING CONT. TREATED WOOD CANT STRIP TOP OF CMU WALL 18' - 0" 1' - 0" ALUM. COPING CAP WALL SECTION 6a GLAZED REVEAL @ BANQUETTE 5 3/4" = 1'-0" WALL SECTIONS Bistro Canopy A-356 SOLUTIONS THROUGH LISTENING SERVICE BY DESIGN 1 2 3 4 5 6 CONSTRUCTION DOCUMENTS 6" METAL STUDS @ 16" O.C. (TYPICAL) 5/8" GYP.BD. 4" METAL STUDS @ 16" O.C. (TYPICAL) SEALANT AND BACKER ROD SEALANT AND BACKER ROD SEALANT AND BACKER ROD 5/8" GYPSUM BOARD (TYPICAL) LIQUID APPLIED WINDOW FLASHING ALUM. SLIDING DOOR SYSTEM STEEL COLUMN. REFER TO STRUCTURAL DRAWINGS SEALANT AND BACKER ROD TREATED WOOD BLOCKING BREAKMETAL OVER LIQUID APPLIED WINDOW FLASHING. RETURN OVER BOTH EXTERIOR FACES. TREATED WOOD BLOCKING SEALANT AND BACKER ROD 4" SPRAY APPLIED INSULATION EDGE CLOSER & SEALANT WATER RESISTANT BARRIER EDGE CLOSER & SEALANT EDGE CLOSER & SEALANT 1 1/2" RIGID INSULATION TREATED WOOD BLOCKING WATER RESISTANT BARRIER HORRYGEORGETOWN GRAND STRAND CULINARY ARTS BUILDING CONSTRUCTION VERTICAL PANEL RAIL SYSTEM 7/8" HAT CHANNELS @ 16" O.C. ALUM. RAINSCREEN SYSTEM SEALANT AND BACKER ROD 5/8" GYP. BD. WATER RESISTANT BARRIER 4" SPRAY APPLIED INSULATION HARD COAT DRAINABLE STUCCO SYSTEM TREATED WOOD BLOCKING 1/2" EXTERIOR GYPSUM SHEATHING LIQUID APPLIED WINDOW FLASHING SEALANT AND BACKER ROD ALUM. RAINSCREEN SYSTEM 1/2" EXTERIOR GYPSUM SHEATHING DRAINABLE STUCCO SYSTEM VERTICAL PANEL RAIL SYSTEM BREAKMETAL OVER LIQUID APPLIED WINDOW FLASHING. RETURN OVER BOTH EXTERIOR FACES. BREAKMETAL OVER LIQUID APPLIED WINDOW FLASHING. RETURN OVER BOTH EXTERIOR FACES. 1 1/2" RIGID INSULATION ALUM. RAINSCREEN SYSTEM SEALANT AND BACKER ROD VERTICAL PANEL RAIL SYSTEM 6" METAL STUDS @ 16" O.C. (TYPICAL) WATER RESISTANT BARRIER 7/8" HAT CHANNELS @ 16" O.C. (TYPICAL) ALUM. SLIDING DOOR SYSTEM LIQUID APPLIED WINDOW FLASHING 1 1/2" RIGID INSULATION 8" CMU ALUM. SLIDING DOOR SYSTEM LIQUID APPLIED WINDOW FLASHING E TREATED WOOD BLOCKING EDGE CLOSER & SEALANT ALUM. STOREFRONT SYSTEM BREAKMETAL OVER LIQUID APPLIED WINDOW FLASHING. RETURN OVER BOTH EXTERIOR FACES. SEALANT AND BACKER ROD SEALANT AND BACKER ROD ALUM. STOREFRONT SYSTEM LIQUID APPLIED WINDOW FLASHING WATER RESISTANT BARRIER JAMB DETAIL @ ENTRY - STUCCO TO GYPSUM BOARD 2 3" = 1'-0" JAMB DETAIL @ ENTRY - METAL PANEL TO METAL PANEL 3 3" = 1'-0" JAMB DETAIL @ ENTRY - STUCCO TO STUCCO 4 3" = 1'-0" 5 HEAD DETAIL @ BISTRO - SIDE STOREFRONT 6 3" = 1'-0" JAMB DETAIL @ CONFERENCE ROOM 3" = 1'-0" MOZINGO + WALLACE ARCHITECTS, LLC 3"X7"x4"x 3/16" BENT PLATE AT EACH STUD. WELD 4"X8"X5/16" ANGLE TO BENT PLATE. (9) #12 SCREWS AT EACH STUD. (TYP.) ALUM. STOREFRONT SYSTEM 9 618 CHESTNUT RD., STE. 205, M.B. , SC 29572 ALUM. STOREFRONT SYSTEM 3"X7"x4"x 3/16" BENT PLATE AT EACH STUD. WELD 4"X8"X5/16" ANGLE TO BENT PLATE. BREAKMETAL OVER LIQUID APPLIED WINDOW FLASHING. RETURN OVER BOTH EXTERIOR FACES. (9) #12 SCREWS AT EACH STUD. (TYP.) A-415 BITUMINOUS PAINT AT FRAME SIDE OF ANGLE EDGE CLOSER & SEALANT 7/8" HAT CHANNELS @ 16" O.C. 5/8" GYP. BD. D SEALANT AND BACKER ROD TEL. 843.449.8000 FAX 843.843.1113 admin@mozingowallace.com ALUM. RAINSCREEN SYSTEM 8" METAL STUDS @ 16" O.C. (TYPICAL) 4"x8"x5/16" STEEL ANGLE (PAINTED) 1 SEALANT AND BACKER ROD LS3P ASSOCIATES LTD. ALUM. STOREFRONT SYSTEM WATER RESISTANT BARRIER 205 1/2 KING ST. CHARLESTON SC 29401 LIQUID APPLIED WINDOW FLASHING TEL. 843.577.4444 FAX 843.722.4789 WWW.LS3P.COM STOREFRONT HEAD/SILL DETAIL @ BISTRO - STOREFRONT OVER STOREFRONT 8 3" = 1'-0" STOREFRONT JAMB DETAIL @ BISTRO BENT PLATE SUPPORT DETAIL 9 3" = 1'-0" C 2" PIPES FOR LARGER PENETRATIONS USE LIQUID FLASHING TOOLED AT LEAST 2" ONTO THE FACE AND 2" OUT ALONG ALL SIDES OF THE PENETRATION FASTENERS APPLY SUFFICIENT DOW 758 TYPE SEALANT TO COMPLETELY SEAL FASTENER PENETRATIONS MEMBERS OF THE AMERICAN INSTITUTE OF ARCHITECTS CUT WEATHER MEMBRANE PIECES FOR HEAD, JAMBS AND SILL OF OPENING SO THAT EACH PIECE EXTENDS 9" PAST EDGE OF OPENING, AND WILL FOLD INWARD TO COVER WIDTH OF WALL. KEEP BACKING ON LOWER 6" OF SILL PIECE TO GO OVER WALL MEMBRANE. 3. INSTALL JAMB FLASHING, ADHERING ENTIRE FLASHING TO THE LEFT AND RIGHT OF THE JAMB BY REMOVING BACKING, STARTING AT THETOP AND SLOWLY PULLING DOWN, SMOOTHING MEMBRANE AS BACKING IS REMOVED. SLIT MEMBRANE AT CORNERS AND FOLD FLAPS INTO OPENING. INSTALL MEMBRANE AT SILL FIRST, LEAVING 6" OF BACKING ALONG BOTTOM EDGE OF MEMBRANE FOR SHINGLING OVER WALL MEMBRANE. B NOTE: WALL SHOWN IN DETAIL IS MASONRY. MEMBRANE WRAP SEQUENCE IS SAME FOR ALL SUBSTRATES. COMPLEX PENETRATIONS APPLY LIQUID FLASHING TO COMPLEX PENETRATIONS (I.E. STRUCTURAL ELEMENT) TOOLED EVENLY AT LEAST 2" ONTO THE FACE AND AT LEASE 2" OUT ALONG ALL SIDES OF THE PENETRATION. PROVIDE BACKING WHERE NEEDED OR OVER 1/4" GAP. 2" REVISIONS: No. GASKETED FASTENERS GASKETED FASTENERS TYPICALLY REQUIRE NO ADDITIONAL SEALING 1 Description Revision 1 #5 ADDENDUM Date Date 1 3/26/15 2" CONDUIT / SMALL PIPE APPLY AND LIGHTLY TOOL DOW 758 TYPE SEALANT AROUND SMALLER PENETRATIONS UP TO 1" DIAMETER OSE PROJECT #: H59-6060-MJ DATE: OCTOBER 28, 2014 DRAWN BY: Author CHECKED BY: Checker WINDOW WRAP DETAILS A 4. INSTALL HEAD MEMBRANE ONLY AFTER BOTH JAMBS ARE FULLY ADHERED. AS BEFORE, SLIT MEMBRANE AT CORNERS AND FOLD INTO OPENING. 3/25/2015 8:58:38 AM C:\Documents and Settings\Administrator\Desktop\HGTC Culinary - 111914 - exterior central model.rvt 2. SLIT MEMBRANE AT CORNERS TO ALLOW IT TO FOLD INTO THE OPENING. 2" 1. ENSURE THAT ALL SURFACES TO BE COVERED ARE CLEAN AND FREE OF DUST. COPYRIGHT 2013 ALL RIGHTS RESERVED PRINTED OR ELECTRONIC DRAWINGS AND DOCUMENTATION MAY NOT BE REPRODUCED IN ANY FORM WITHOUT WRITTEN PERMISSION FROM MOZINGO + WALLACE ARCHITECTS, LLC AND LS3P ASSOCIATES LTD. 5. USING CAULKING GUN, APPLY LIQUID FLASHING IN ZIGZAG PATTERN ON THE WALL FACE SURROUNDING THE OPENING. IMMEDIATELY SPREAD THE APPLIED MATERIAL WITH A PUTTY KNIFE, CREATING A MINIMUM 1" WIDE BORDER AROUND THE ROUGH OPENING. 1 6. APPLY ADDITIONAL LIQUID FLASHING IN ZIGZAG PATTERN AT ALL INNER SURFACES OF THE OPENING. 7. ALLOW LIQUID FLASHING TO SET UP UNTIL DRY TO THE TOUCH, THEN INSPECT FOR VOIDS AND APPLY ADDITIONAL FLASHING AS NEEDED TO ACHIEVE COMPLETE COVERAGE. 7 WATER RESISTANT BARRIER PENETRATION DETAILS A-415 SCALE : NTS IMMEDIATELY SPREAD FLASHING WITH PUTTY KNIFE UNTIL ALL SURFACES ARE COMPLETELY COVERED AND SUBSTRATE BELOW IS NO LONGER VISIBLE (APPROXIMATELY 12 TO 15 WET MILS, VERIFY WITH MANUFACTURER). SOLUTIONS THROUGH LISTENING WINDOW WRAP DETAIL 3/8" = 1'-0" SERVICE BY DESIGN 1 2 3 4 5 6 CONSTRUCTION DOCUMENTS 15 EQUAL LITES IN RADIUS PATTERN (SEE FLOOR PLAN) 18 DEGREE TURN BETWEEN PANELS 1 STOREFRONT A 1/4" = 1'-0" 1' - 11 5/8" 3' - 11 1/8" 1' - 11 3/4" 4' - 0" 4' - 0" 4' - 0" 4' - 0" 4' - 0" 4' - 0" 15' - 11 1/2" 14' - 0 3/4" 1' - 10" 5' - 2 1/4" 1' - 11" 5' - 1 1/2" 2' - 0" 5' - 2 1/4" 1' - 11" 5' - 1 1/2" 1' - 10 3/4" 5' - 4 3/8" 4 414 CORNER MULLION JOINS WITH STOREFRONT F 16 WINDOWS AT ADMIN AREA STOREFRONT AA 1/4" = 1'-0" WINDOW AT ADMIN TLT. 2 Storefront B 1/4" = 1'-0" 3 SEGMENTED GLAZING AT CONFERENCE ROOM 6 415 8 415 X102 3 413 3' - 1" 1' - 7" 9 413 SPANDREL GLAZING 17' - 11" 3' - 3 1/2" X101 9 415 8' - 8" 14' - 0 3/4" 11' - 11 1/2" 3' - 3 1/2" 3 414 3 413 9 413 2' - 10 1/8" 16' - 0 3/4" 8' - 8" 7' - 4 1/2" 8 EQUAL LITES HATCHING INDICATES SPANDREL GLAZING 11' - 11 1/2" 12 413 12' - 0" 12' - 0" 9 413 4' - 0" 3' - 6 1/2" 5 413 8 EQUAL LITES 5 413 4' - 0" 1' - 10" 1 413 HORRYGEORGETOWN GRAND STRAND CULINARY ARTS BUILDING CONSTRUCTION CORNER MULLION 35' - 9" 2' - 5" HATCHING INDICATES SPANDREL GLAZING 1 413 6 413 8' - 11 1/2" E 3' - 10" 2 413 4' - 1 3/8" 11' - 11 3/4" 21' - 5 1/8" STOREFRONT C 1/4" = 1'-0" 4 STOREFRONT D 1/4" = 1'-0" LEFT SIDE ENTRY WITH AUTOMATIC SLIDING DOOR 9 413 5 LEFT SIDE ENTRY (INTERIOR) WITH AUTOMATIC SLIDING DOOR MOZINGO + WALLACE ARCHITECTS, LLC SPANDREL GLAZING 618 CHESTNUT RD., STE. 205, M.B. , SC 29572 TEL. 843.449.8000 FAX 843.843.1113 admin@mozingowallace.com STOREFRONT E 1/4" = 1'-0" BISTRO WINDOW WALL D 14' - 1 1/2" 6' - 0 5/8" 6' - 0 5/8" 3' - 5" LS3P ASSOCIATES LTD. 1' - 11 5/8" 3' - 11 1/8" 1' - 11 1/2" 205 1/2 KING ST. CHARLESTON SC 29401 2 413 5' - 10 3/4" TEL. 843.577.4444 2' - 11 7/8" 2' - 11 7/8" 3' - 0" 3' - 2 3/8" 2' - 11 7/8" 3' - 3 1/8" 14' - 1 1/2" 3' - 0 1/2" 6 13 413 STOREFRONT F 1/4" = 1'-0" 7 PATIO WALL AT BISTRO 3' - 3 1/2" 8' - 8" 11' - 11 1/2" 10' - 5 1/2" 7' - 5 1/2" 13 413 8 KITCHEN BAY WINDOWS 4 414 PUSH BARS AT INSIDE OF EMERGENCY PANELS ONLY 8' - 8" 1' - 5" STOREFRONT G 1/4" = 1'-0" 3 414 3 413 PUSH BARS AT INSIDE OF EMERGENCY PANEL ONLY 1' - 5" 8 414 8 413 1' - 7 1/4" 3' - 1 1/2" 8 413 10' - 5" 7' - 3" CORNER MULLION JOINS W/ STOREFRONT E X103 8' - 10" X104 1' - 6 3/4" HATCHING INDICATES SPANDREL GLAZING 11' - 11 1/2" 4 413 3' - 3 1/2" 4 413 3' - 1 1/2" C 5' - 11 1/2" 5' - 4" 5' - 4" 9 414 2' - 1 1/2" 26' - 4 1/4" 6' - 0 1/2" STOREFRONT H 1/4" = 1'-0" 9 STOREFRONT K 1/4" = 1'-0" 10 STOREFRONT L 1/4" = 1'-0" 6 414 11 RIGHT SIDE ENTRY CORRIDOR BAY WINDOW 2' - 7 1/2" 2' - 11 7/8" WWW.LS3P.COM 3' - 8 1/2" 2' - 11 7/8" 4' - 1 5/8" 27' - 10" 3' - 5 1/2" FAX 843.722.4789 5' - 10 3/4" 6 413 8' - 2 3/4" 11' - 11 3/4" 2' - 0 1/4" RIGHT SIDE ENTRY (INTERIOR) WITH AUTOMATIC DOOR CURTAINWALL M 1/4" = 1'-0" MEMBERS OF THE AMERICAN INSTITUTE OF ARCHITECTS DEMONSTRATION KITCHEN ENTRY COPYRIGHT 2013 ALL RIGHTS RESERVED PRINTED OR ELECTRONIC DRAWINGS AND DOCUMENTATION MAY NOT BE REPRODUCED IN ANY FORM WITHOUT WRITTEN PERMISSION FROM MOZINGO + WALLACE ARCHITECTS, LLC AND LS3P ASSOCIATES LTD. 2' - 2 3/8" 7 414 REVISIONS: 5' - 10 1/4" No. 3' - 1" A 12 VERIFY AUTO. DOOR REQUIREMENTS VERIFY AUTO. DOOR REQUIREMENTS 4' - 11 5/8" 5' - 0 5/8" 2' - 6 1/4" 5' - 0 5/8" 4' - 11 5/8" VERIFY AUTO. DOOR REQUIREMENTS 2' - 6 1/4" 5' - 0 5/8" 4' - 11 5/8" 11' - 11 1/2" 3' - 5 1/2" 1 414 3' - 5 1/2" 10' - 0 1/4" OSE PROJECT #: H59-6060-MJ 2 414 13 DEMONSTRATION AUDITORIUM SEGMENTED WINDOW DATE: OCTOBER 28, 2014 DRAWN BY: GCW CHECKED BY: SDM Storefront schedule 2 414 STOREFRONT N 1/4" = 1'-0" 3/26/15 Date 1 8' - 6" 6' - 1" 8' - 2 1/4" 6' - 0" 15 106 11' - 11 1/2" 3' - 9" 5' - 10 1/2" 11' - 11 1/2" 16 106 10' - 0 1/4" 10' - 0 1/4" 8' - 6" 5 414 VERIFY AUTO. DOOR REQUIREMENTS 4' - 11 5/8" 5' - 0 5/8" 2' - 7 1/2" 26' - 4 1/4" 13 304 Addendum Revision 1 #5 Date 22' - 6 3/4" 22' - 6 3/4" 10' - 0 1/4" 2' - 10 1/2" 3' - 0 3/4" Description 1 5' - 11 1/4" 10 EQUAL PANELS IN RADIUS (SEE FLOOR PLAN) 7 DEGREE ANGLE BETWEEN PANELS 3/25/2015 8:40:49 AM C:\Documents and Settings\Administrator\Desktop\HGTC Culinary - 111914 - exterior central model.rvt B CURTAINWALL O 1/4" = 1'-0" 14 DEMONSTRATION KITCHEN ENTRY STOREFRONT P 1/4" = 1'-0" 15 STOREFRONT Q 1/4" = 1'-0" A-456 FRONT ENTRY (INTERIOR) WITH TWO SINGLE PANEL AUTOMATIC SLIDING DOORS FRONT ENTRY WITH TWO DOUBLE PANEL AUTOMATIC SLIDING DOORS SOLUTIONS THROUGH LISTENING SERVICE BY DESIGN 1 2 3 4 5 6 CONSTRUCTION DOCUMENTS