The efficiency and eco-efficiency of manufacturing Please share

advertisement

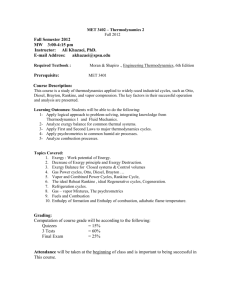

The efficiency and eco-efficiency of manufacturing The MIT Faculty has made this article openly available. Please share how this access benefits you. Your story matters. Citation Gutowski, Timothy G. "The efficiency and eco-efficiency of manufacturing." International Journal of Nanomanufacturing 6 (2010): 38 - 45. As Published http://dx.doi.org/10.1504/IJNM.2010.034770 Publisher Inderscience Version Author's final manuscript Accessed Thu May 26 06:22:45 EDT 2016 Citable Link http://hdl.handle.net/1721.1/60894 Terms of Use Attribution-Noncommercial-Share Alike 3.0 Unported Detailed Terms http://creativecommons.org/licenses/by-nc-sa/3.0/ Int. J. Nanomanufacturing, Vol. X, No. Y, xxxx 1 The efficiency and eco-efficiency of manufacturing Timothy G. Gutowski Massachusetts Institute of Technology, 77 Massachusetts Avenue, Cambridge, MA 02139-4307, USA E-mail: Gutowski@mit.edu Abstract: In this paper, we review the efficiency of both manufacturing processes and systems over recent decades and compare nano-materials technologies in this context. To a first approximation, nano-materials processes appear to be about as efficient as semi-conductor processes. That is, their second law efficiencies are of the order 10–5, while conventional processes are of order 10–2. However, many of these processes are early in their development and some opportunities do exist for improvement. At the same time, many aspects of these processes (the need for high purity materials, low yields, and operating conditions far from equilibrium) may make these materials vulnerable to high energy prices. Keywords: thermodynamic efficiency; manufacturing processes; exergy; degree of perfection; rebound. Reference to this paper should be made as follows: Gutowski, T.G. (xxxx) ‘The efficiency and eco-efficiency of manufacturing’, Int. J. Nanomanufacturing, Vol. X, No. Y, pp.000-000. Biographical notes: Timothy G. Gutowski is a Professor of Mechanical Engineering at the Massachusetts Institute of Technology. 1 Introduction In this paper, we review the efficiency and eco-efficiency of manufacturing processes and systems, and present data which locates nano-materials and manufacturing processes for nano-materials in this larger context. The paper has two parts. In the first part, we review the thermodynamic definitions of process efficiency based on the first and second laws. Second law efficiencies, including the so-called ‘degree of perfection’, are calculated for several different manufacturing processes ranging to nano-scale materials and devices. In the second part of this paper, we present the idea of eco-efficiency, which is generally the ratio of product output divided by some measure of environmental impact. For example, manufacturing processes can be described in terms of energy consumed per unit of material processed. Eco-efficiency would be the reciprocal of this term. Eco-efficiency data is presented for manufacturing processes as well as industrial sectors. Again, the performance of nano-manufacturing will be located relative to other more traditional methods of manufacturing. Copyright © 200x Inderscience Enterprises Ltd. 2 2 T.G. Gutowski Thermodynamic efficiency of materials conversion processes Efficiency, ‘η’, is usually formed as a ratio of the useful output to the inputs. The number is dimensionless and can range from 0, (totally inefficient process) to 1, (a perfect process). Applying this definition to a heat engine for example, one could form the dimensionless ratio of the work out, Wout, divided by the heat input, Qin. η= W out Q in (1) This is the conventional first law efficiency for a heat engine. While this type of measure is commonly reported in the literature, it fails on one important dimension. It is easy to show that no heat engine can ever obtain an efficiency of one. This shortcoming can be corrected by applying a second law analysis to a heat engine, which states that the useful work output cannot exceed the heat input times the so-called Carnot factor (1 – TL / TH) where the temperatures correspond to the low and high temperature reservoirs. This is also a dimensionless ratio and can in fact range from zero to one, with one representing a perfect, so-called reversible heat engine. η II = W out T Q H (1 − L ) TH (2) In this calculation, we used the result that the maximum work output is the function of the heat input from the high temperature reservoir QH times the Carnot factor. If the low temperature heat is exhausted at the environmental reference temperature say T0, the denominator in equation (2) gives the exergy content of the input heat. Exergy is a thermodynamic variable that gives the work potential of a system with respect to a reference environment. Exergy accounting includes the work potential of heat and work interactions, as well as the work potential of the physical and chemical states of the materials. It is particularly useful when analysing material transformation processes, such as those that take place in manufacturing. Exergy can be defined as the difference in a free energy type term in reference to an identified reference environment (denoted by the subscript ‘o’) as given below. B = ( H − To S ) − ( H o − To S o ) (3) Here, H is enthalpy, S is entropy and B is exergy (see Gyftopoulos and Beretta, 2005; de Swaan Arons et al., 2004; Szargut et al., 1988). In terms of material transformation processes such as used in manufacturing, it can be shown that the minimum work input required to effect the transformation is just the difference between the exergy output minus the exergy input (Branham et al., 2008). From this formulation, we can estimate the efficiency of a transformation process by taking the ratio of the exergy of the useful output and divide by the exergy of the combined inputs. This ratio is called the ‘degree of perfection’ and is denoted as ηp (Szargut et al., 1988). The efficiency and eco-efficiency of manufacturing ηp = 3 B out B in (4) When one considers the manufacturing processes in which the materials enter and exit at the environmental temperature and pressure, the exergy of the output is essentially the exergy of the processed materials. The exergy of the inputs for most of the processes considered here includes electricity and materials. Hence, the degree of perfection can be calculated from a list of input and output materials and energy interactions for any materials transformation process. We have calculated these values for a number of conventional processes (i.e. sand casting and injection molding), semi conductor processes (i.e. plasma enhanced chemical vapour deposition, sputtering and the wet thermal oxidation process) and nano-materials processes (primarily variations on the chemical vapour deposition process), see Table 1. Table 1 ηp for various manufacturing processes ηp Processes Injecting moulding, Induction melting of iron 0.7 – 0.9 Semi-conductor processes 10–4 – 10–7 Nano-materials 10–3 – 10–7 To construct this table, electricity was counted as pure exergy (losses at the utility were not counted) and the material exergy values and reference system developed by Szargut et al. (1988) was employed. As one can see, the conventional processes have relatively high values of ηp due to a high transit exergy (exergy embodied in the material throughput). The semi conductor processes have very low values due to several effects; relatively low output exergies, low material utilisation, the use of high exergy auxiliary materials (mostly for cleaning which are destroyed as part of the abatement process), and operation at relatively high temperatures and low pressures. The nano-materials processes can be in the same range as semi-conductor processes or slightly higher due to a number of possible effects including: higher output material exergies, higher yields, and more modest temperature and pressure requirements. For example, Nanda et al. (2003) review results for the surface energies of nano-particles. In some manufacturing processes, the object is to remove material (milling, turning, etching, etc.), in which case the output is in fact a hole or an area of missing material in the incoming solid raw materials. In this case, rather than using the degree of perfection, one might prefer an alternative definition for a second law efficiency, such as the ratio of the minimum work required to perform the specified operation divided by the exergy of the inputs. This is given in the equation below (see Branham et al., 2008). η II = W min B in (5) 4 3 T.G. Gutowski The eco-efficiency of manufacturing Eco-efficiency is defined as the ratio of a useful output divided by some measure of environmental impact or resource use. Hence, it is most commonly not a dimensionless ratio. An example of eco-efficiency would be the ratio of say one kilogram of aluminium divided by the energy required to produce one kilogram of aluminium. This is, in fact, the reciprocal of the energy intensity of aluminium, which is in the range of 100 – 200 MJ/kg. Hence, eco-efficiency is often the reciprocal of some intensity metric. By convention, the energy referred to here is the cumulative equivalent fossil fuel energy in terms of lower heating values. This cumulative energy value would include all of the steps required to make the particular product under consideration. For example, if the product is a kilogram of aluminium, then all of the energy required to make this aluminium, including mining, milling and smelting would be accounted for. Clearly, these values are dependent on a number of factors including typical ore grades and technologies employed. As a result, energy intensities or eco-efficiencies depend heavily on the boundaries and details of the study employed. 4 The eco-efficiency of manufacturing process If one tracks the historical development of any particular manufacturing technology, generally one finds that the eco-efficiency improves with time. That is, the resources used per unit of production are reduced. Particular attention is focused on those resources which are the most expensive. A particularly clear illustration of this is the data on cutting times in machining over the course of the last hundred years. The data show that over the last one hundred years, the cutting time for machining has been reduced by about a factor of 100 due in large part by new developments in cutting tool materials (Kalpakjian, 1995). Because considerable energy can be consumed by auxiliary equipment as well as the cutting spindle, this also translates into a significant reduction in the energy consumed per unit of material machined. However, if one looks at the development of new manufacturing processes over the same time period, one sees a significantly different pattern. The general trend is to substitute low cost resources for high cost resources to gain some competitive advantage. Since over the last several decades energy prices have been stable and declining (omitting our most recent history) this has translated into the substitution of energy and materials for human labour. Furthermore, recent progress in manufacturing has emphasised the development of techniques to make micro and nano scale devices. The result has been a very significant increase in the energy used per unit of material processed. In a recent publication, we have reviewed 20 different manufacturing processes ranging from conventional processes (i.e. machining, grinding, injection moulding, sand casting, die casting), advanced machining processes (abrasive water jet, wire and drill electrical discharge machining), rapid prototyping (laser direct metal deposition), semi conductor additive processes (chemical vapour deposition, plasma enhanced chemical vapour deposition, thermal oxidation and sputtering), semi conductor subtractive processes (dry etching of oxide and nitride films) and nano-materials production processes (single walled carbon nano tubes, carbon nano tubes and carbon nano fibres) and have found that the energy intensity of these processes has increased by almost eight orders of The efficiency and eco-efficiency of manufacturing 5 magnitude over the last several decades. The results are summarised in Table 2 (Gutowski et al., 2009). Table 2 The energy intensity of manufacturing processes Process Approximate energy intensity (J/kg of material processes) Conventional 1 – 20 × 106 Advanced machining 2 × 108 – 2 × 1012 Rapid prototyping 1010 Semi conductor additive 109 – 5 × 1013 Semi conductor subtractive 2 × 1010 Nano-materials 109 – 1012 5 The eco-efficiency of industrial sectors The concept of eco-efficiency or impact/resource intensity is applicable over any size scale of activity. We have investigated the historical eco-efficiency of ten different production and consumption sectors in terms of energy resources used. A summary of the sectors, time periods, and parameters measured are given in Table 3. In general, we collected annual data on the quantity of production or consumption Q, and the resources used R. The time periods for some of these observations are very long, in the case of pig-iron starting in 1800 (Dahmus and Gutowski, 2009). Our discussion of this data can be framed using a simple mathematical identity that relates resources used R to the quantity produced or consumed Q. R = Q. R 1 = Q. Q e (6) In this expression, e is the so-called eco-efficiency measured in terms of quantity produced or consumed Q divided by the resources used R. For infinitesimal changes, one can write an expression for the incremental change in resources used in terms of the incremental change in quantity Q and eco-efficiency e. ΔR ΔQ Δe = − R Q e (7) It is quite clear that to reduce resources, eco-efficiency must outpace production or consumption. Our review of the data in these ten sectors shows that, in general for the industrial sectors, eco-efficiency increases unrelentingly throughout the history of production. However, in almost every case, the quantity produced increases faster resulting in an increase in resources used. Hence, as a general trend, based on historical observation, eco-efficiency improvement does not lead to resource conservation. In reviewing the 75 decades of data represented in Table 3, we did find several exceptions, decades of industrial activity when resources used actually decreased. In other words, eco-efficiency outpaced production or consumption. This almost always happened due to either T.G. Gutowski 6 1 government intervention such as efficiency standards 2 increased prices. The reasons for increased production or consumption can be understood by expanding equation (6) to include additional factors. R = P. D Q R . . P D Q (8) In this expression P represents population, and D dollars. Hence the first term in equation (8) accounts for increases in population and/or market size. The second term accounts for buying power or affluence. The third term represents choice on how one spends their dollars to buy a particular quantity of product Q, and the last term is, of course, the reciprocal of eco-efficiency. The relentless increase in resources used, both in production and consumption, is in large part due to our relentless growth in population and market size as well as affluence and spending power. This equation is similar to the so-called IPAT equation, which has a significant literature (Ehrlich and Holdren, 1972; Commoner, 1971; Chertow, 2000). Table 3 Production and consumption sectors studied for resource use Activity Dates Boundary Quantity Resource Pig-iron 1800–1990 World kg pig iron Joules of coke Aluminium 1900–2005 World kg aluminium Joule of electricity Nitrogen fertiliser 1915–2000 World kg Nitrogen Joule energy Electricity from coal 1920–2007 US Joule electricity kg coal Electricity from oil 1920–2007 US Joule electricity Liter of oil Electricity from natural gas 1920–2007 US Joule electricity m3 of natural gas Freight rail 1960–2006 US Revenue tonne – km Liter fuel Air travel 1960–2005 US Seat – km Liter fuel Motor vehicle 1936–2006 US Vehicle – km Liter fuel Refrigeration 1960–2002 US Hours refrigeration Joule electricity In this discussion, it is important to point out that the terms in equations (6), (7) and (8) may not be independent. That is, affluence affects population growth, quantity produced affects eco-efficiency and so forth. For this discussion, we are particularly interested in the interaction between the quantity Q and the efficiency e represented in equations (6) and (7). There are several well known effects that cause these variables to interact. For example, learning affects and economies of scale, suggest that as the scale of production Q increases, this leads to an increase in the efficiency of production. Hence large Q leads to increased eco-efficiency. On the other hand, it has also been observed that increased efficiency can result in increased demand and larger Q. This is so-called the rebound effect. In simple terms, rebound can occur because efficiency improvements can lead to price reductions. In the case where there is a significant elasticity of demand, price reductions can in turn lead to increased quantities produced and consumed. For example, we could capture the rebound effect by writing The efficiency and eco-efficiency of manufacturing ΔQ / Q ΔQ / Q Δπ / π ⋅ = ε ⋅γ = Δπ / π Δe / e Δe / e 7 (9) In this expression, ε is the so-called own price elasticity. The second term captures how price, π, is affected by changes in eco-efficiency. In general ε may vary from very low values for in-elastic goods, to numbers much larger than one for highly elastic goods (see for example, Gwartney et al., 2000, p.510, for elasticities that range from 0.1 to 4.6). The magnitude of γ depends on what fraction of the product cost is represented by the resource, how large the profit is, and to what extent the efficiency increase is converted into a price reduction. In any case 0 < ⎜ γ ⎜ < 1, and strictly speaking both ε and γ are actually negative. The effect of the rebound can be illustrated by first considering the case where there is an improvement in eco-efficiency but no change in quantity, then from equation (7) one gets a clear reduction in resource use, i.e. ∆R/R = –∆e/e. However, if there is a rebound effect and the quantity Q increases according to equation (9), then substitution into equation (7) gives ΔR Δe = ( ε ⋅γ −1) R e (10) In the remote (but not impossible) case where ε ⋅ γ = 1 , the entire savings due to improved eco-efficiency could be negated by the rebound effect. Numerous micro-economic studies show that ε ⋅ γ is finite but less than one (Greening et al., 2000; Kalakkad Jayaraman, 2008). At the macro economic level, some have put forth the argument that it is in fact our very efficiency that drives growth (Herring, 1998). While this is a very contentious debate, it is worth paying attention to it, as our future may depend upon us understanding these mechanisms. References Branham, M., Gutowski, T., Jones, A. and Sekulic, D. (2008) ‘A thermodynamic framework for analyzing and improving manufacturing processes’, IEEE International Symposium on Electronics and the Environment, 19–20 May, San Francisco, USA. Chertow, M. (2000) ‘The IPAT equation and its variants: changing views of technology and environmental impact’, Journal of Industrial Ecology, Vol. 4, No. 4, p.13–29. Commoner, B. (1971) The Closing Circle, Knopf, Inc., USA. Dahmus, J.B., and Gutowski, T. (2009) ‘Can efficiency improvements reduce resource consumption? A historical analysis of ten activities’, accepted for publication to Journal of Industrial Ecology. de Swaan Arons, J., van der Kooi, H. and Sankaranarayanan, K. (2004) Efficiency and Sustainability in the Energy and Chemical Industries, Marcel Dekker Inc., New York. Ehrlich, P.R. and Holdren, J.P. (1972) ‘Critique: one dimensional ecology’, Bulletin of the Atomic Scientists, Vol. 28, No. 5, pp.18–27. Greening, L.A., Greene, D.L. and Difiglio, C. (2000) ‘Energy efficiency and consumption – the rebound effect – a survey’, Energy Policy, Vol. 28, Nos. 6–7, pp.389–401. Gutowski, T.G., Branham, M.S., Dahmus, J.B., Jones, A.J., Thiriez, A. and Sekulic, D.. (2009) ‘A thermodynamic analysis of resources used in manufacturing processes’, Environmental Science and Technology, Vol. 43, pp.1584–1590. 8 T.G. Gutowski Gwartney, J.D., Stroup, R.L. and Sobel, R.S. (2000) Economics – Private and Public Choice, 9th ed., South-Western, Mason, Ohio. Gyftopoulos, E. and Beretta, G. (2005) Thermodynamics – Foundations and Applications, Dover, Mineola, New York. Herring, H. (1998) ‘Does energy efficiency save energy: the economists debate’, Energy and Environment Research Unit Report No. 074, July, available online at http://technology.open.ac.uk/eeru/staff/horace/hh3.htm. Kalakkad Jayaraman, S.K. (2008) ‘Computation of economic rebound effect in different sectors of the U.S. economy’, S.M. Thesis, Massachusetts Institute of Technology, Department of Mechanical Engineering. Kalpakjian, S. (1995) Manufacturing Engineering and Technology, 3rd ed., Addison-Wesley Publishing Company, Reading, Massachusetts. Nanda, K.K., Maisels, A., Kruis, F.E., Fissan, H. and Stappert, S. (2003) ‘Higher surface energy of free nanoparticles’, Physical Review Letters, The American Physical Society, Vol. 91, No. 10, pp.106102–4. Szargut, J., Morris, D.R. and F.R. Steward (1988) Energy Analysis of Thermal Chemical and Metallurgical Processes, Hemisphere Publishing Corporation and Springer-Verlag, New York.